Emerson Fisher 8532 User manual

Other Emerson Control Unit manuals

Emerson

Emerson Enardo ES-800 Series User manual

Emerson

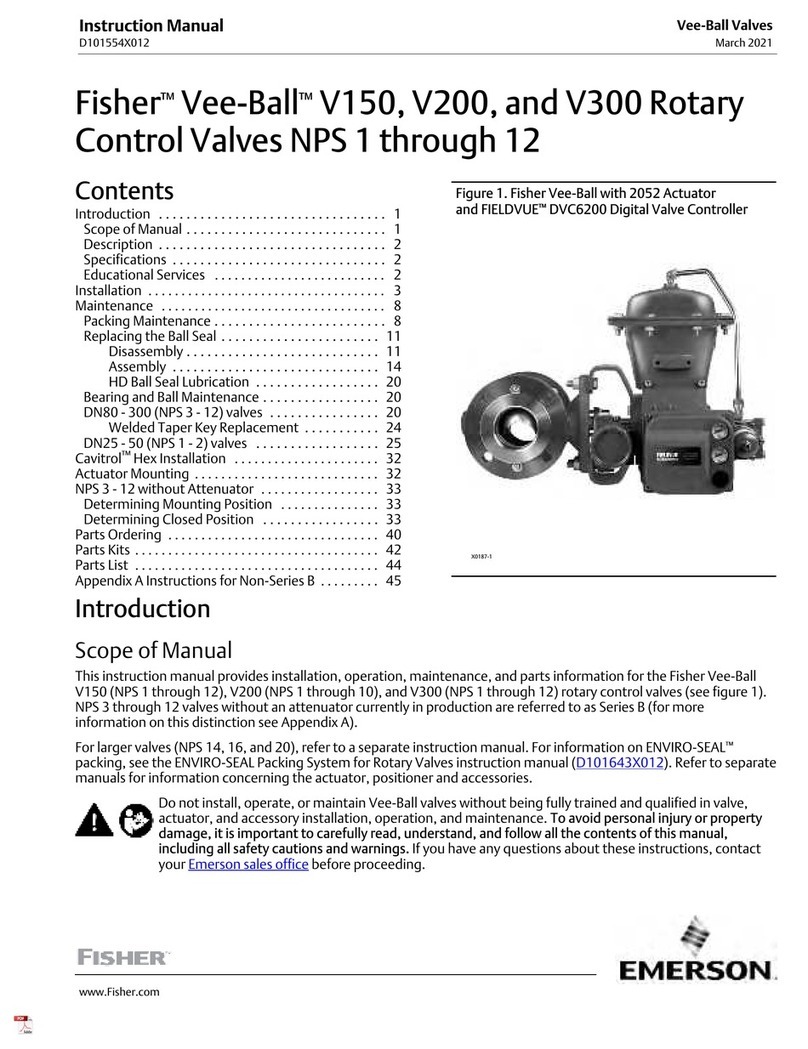

Emerson Fisher V260 User manual

Emerson

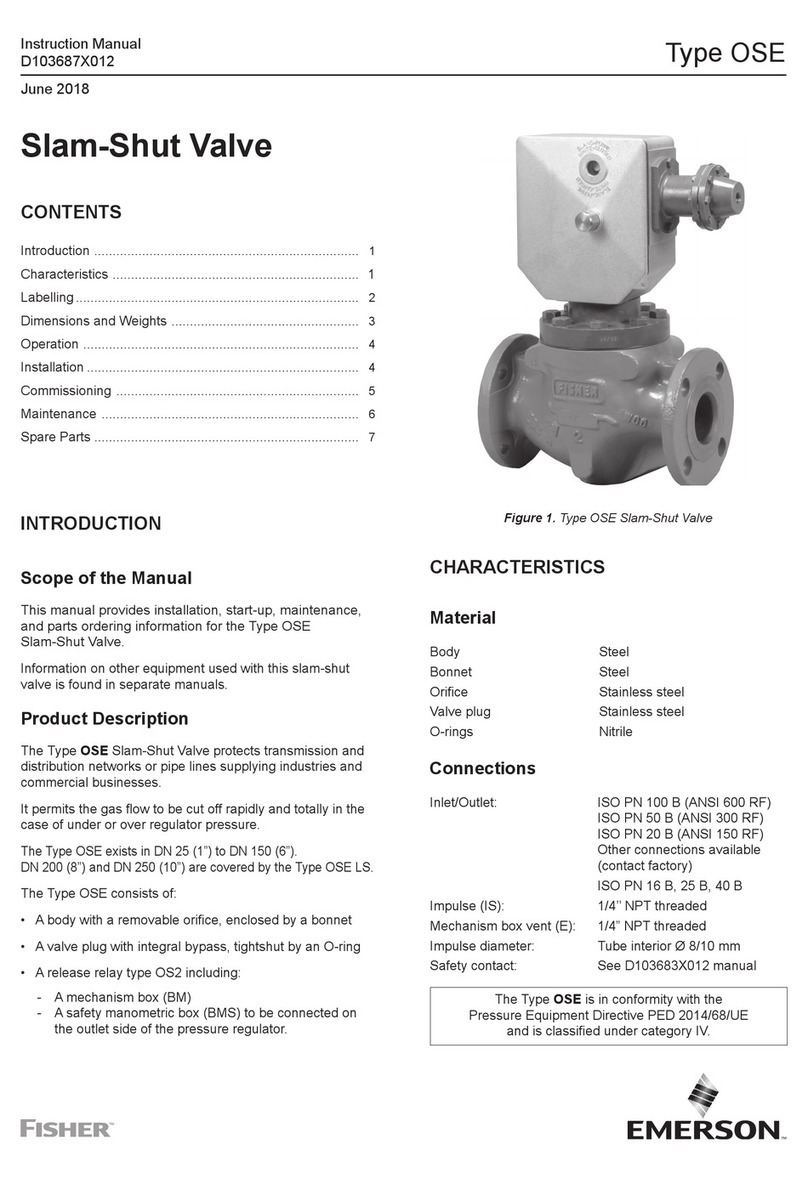

Emerson Fisher OSE User manual

Emerson

Emerson Fisher Baumann 87000 User manual

Emerson

Emerson Fisher VS100 Series User manual

Emerson

Emerson FASANI User manual

Emerson

Emerson Dixell XEV20D User manual

Emerson

Emerson Fisher Vonk CHV User manual

Emerson

Emerson CROSBY STYLE HC ISOFLEX Guide

Emerson

Emerson Fisher 63EG-98HM User manual

Emerson

Emerson Fisher N201 Series User manual

Emerson

Emerson White-Rodgers 36C01 User manual

Emerson

Emerson EIM 2000 Series User manual

Emerson

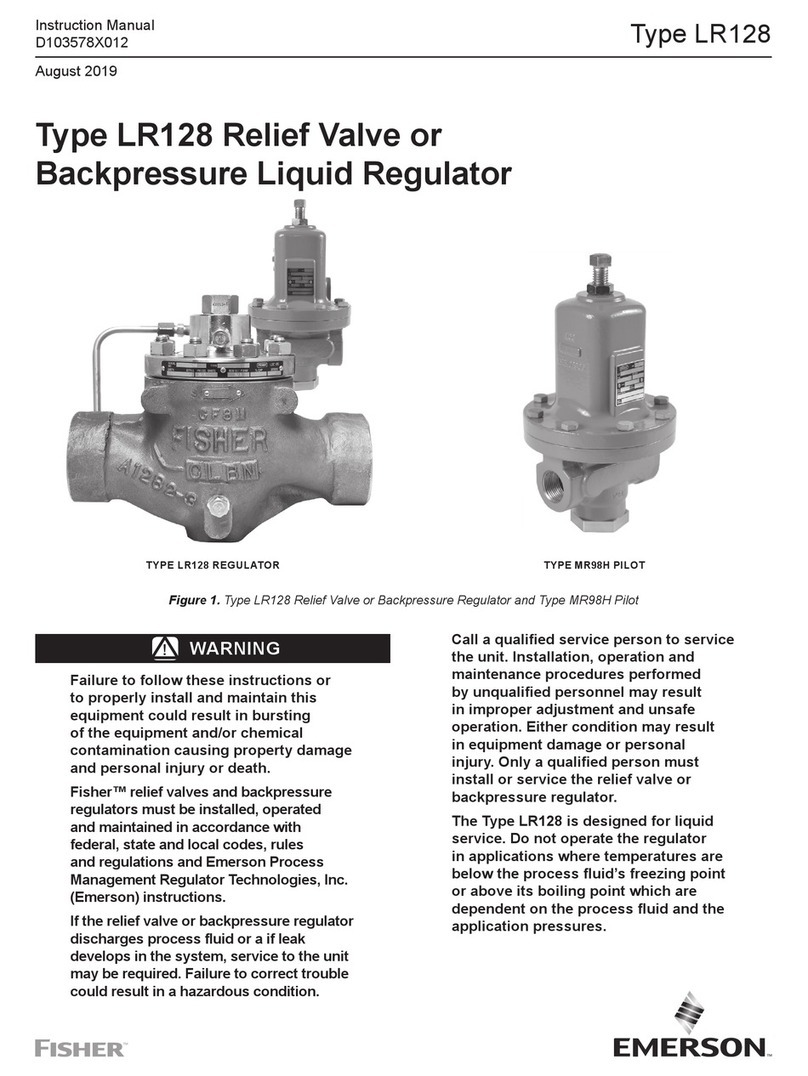

Emerson FISHER LR128 Series User manual

Emerson

Emerson BVE Series User manual

Emerson

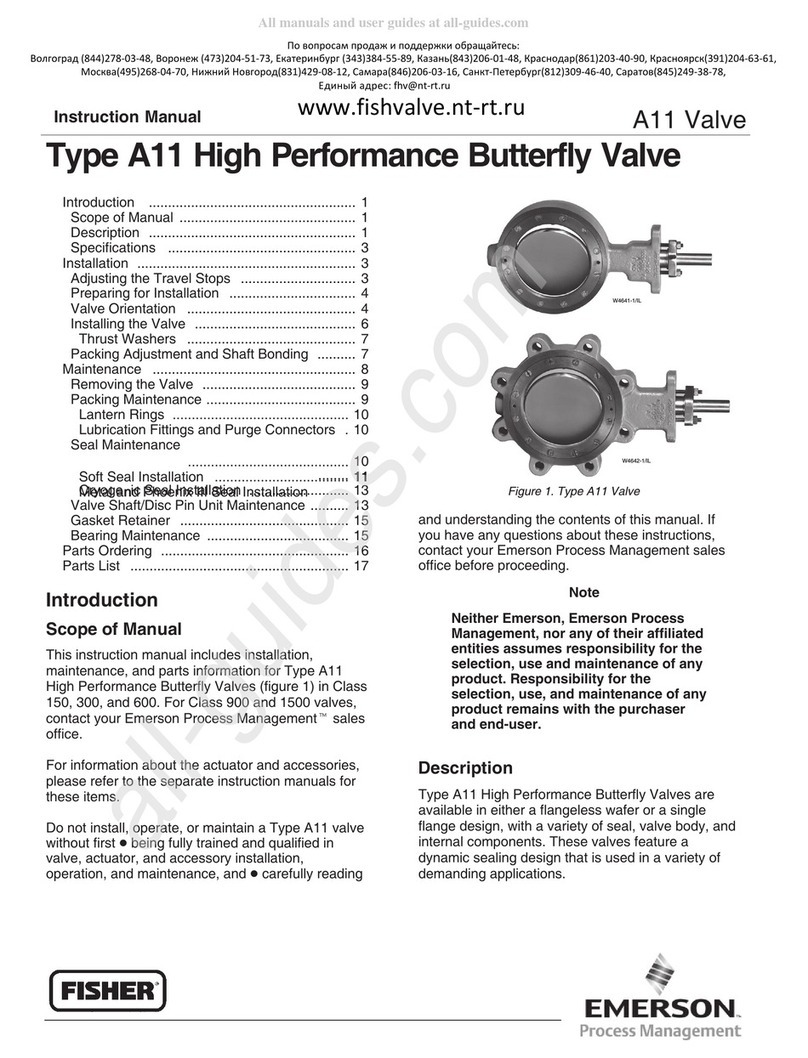

Emerson Fisher A11 User manual

Emerson

Emerson KEYSTONE OPTISEAL F16 User manual

Emerson

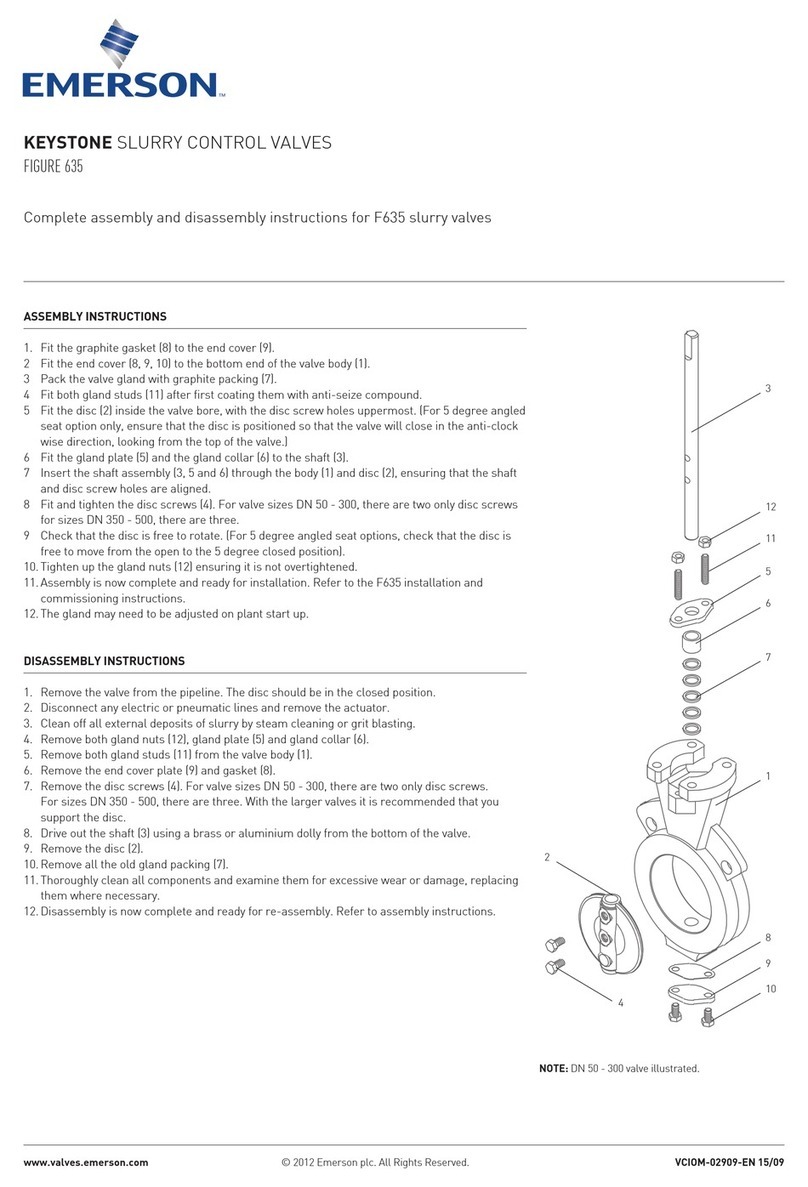

Emerson KEYSTONE F635 Installation instructions

Emerson

Emerson Fisher D4 User manual

Emerson

Emerson Micro Motion User manual

Popular Control Unit manuals by other brands

Festo

Festo Compact Performance CP-FB6-E Brief description

Elo TouchSystems

Elo TouchSystems DMS-SA19P-EXTME Quick installation guide

JS Automation

JS Automation MPC3034A user manual

JAUDT

JAUDT SW GII 6406 Series Translation of the original operating instructions

Spektrum

Spektrum Air Module System manual

BOC Edwards

BOC Edwards Q Series instruction manual

KHADAS

KHADAS BT Magic quick start

Etherma

Etherma eNEXHO-IL Assembly and operating instructions

PMFoundations

PMFoundations Attenuverter Assembly guide

GEA

GEA VARIVENT Operating instruction

Walther Systemtechnik

Walther Systemtechnik VMS-05 Assembly instructions

Altronix

Altronix LINQ8PD Installation and programming manual