Emerson Fisher A11 User manual

Other Emerson Control Unit manuals

Emerson

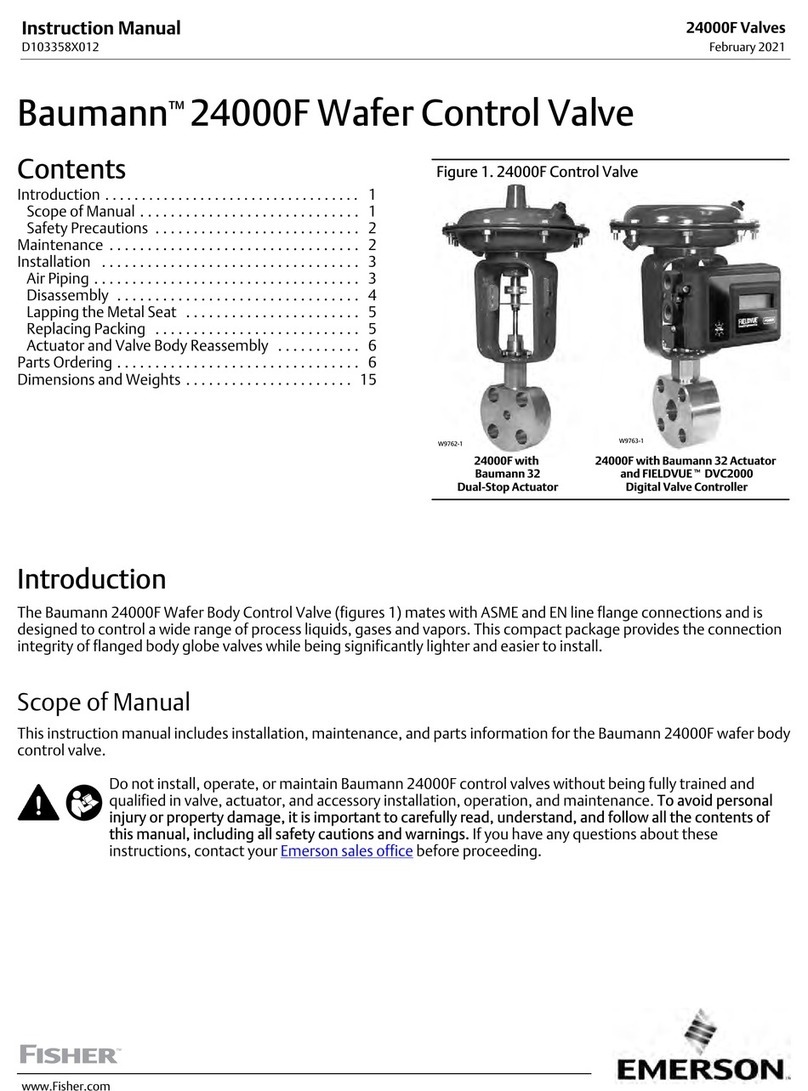

Emerson Fisher Baumann 24000F User manual

Emerson

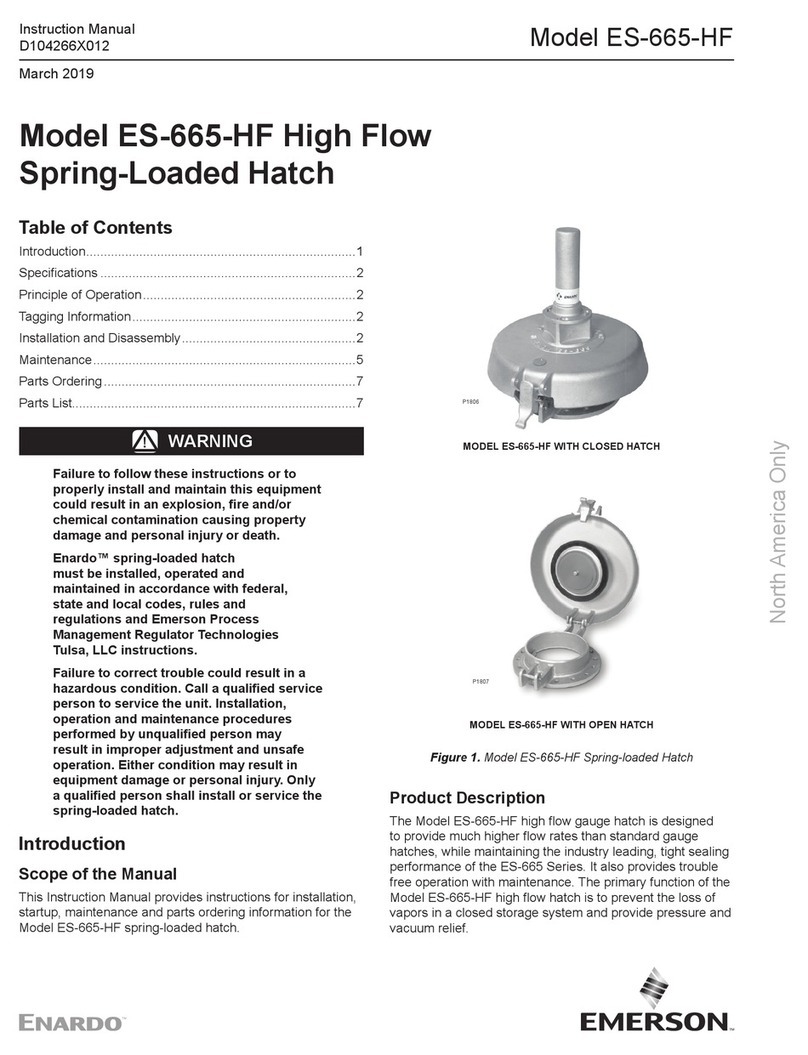

Emerson Enardo ES-665-HF User manual

Emerson

Emerson SM-I/O 24V Protected User manual

Emerson

Emerson PACSystems IC695ACC302 User manual

Emerson

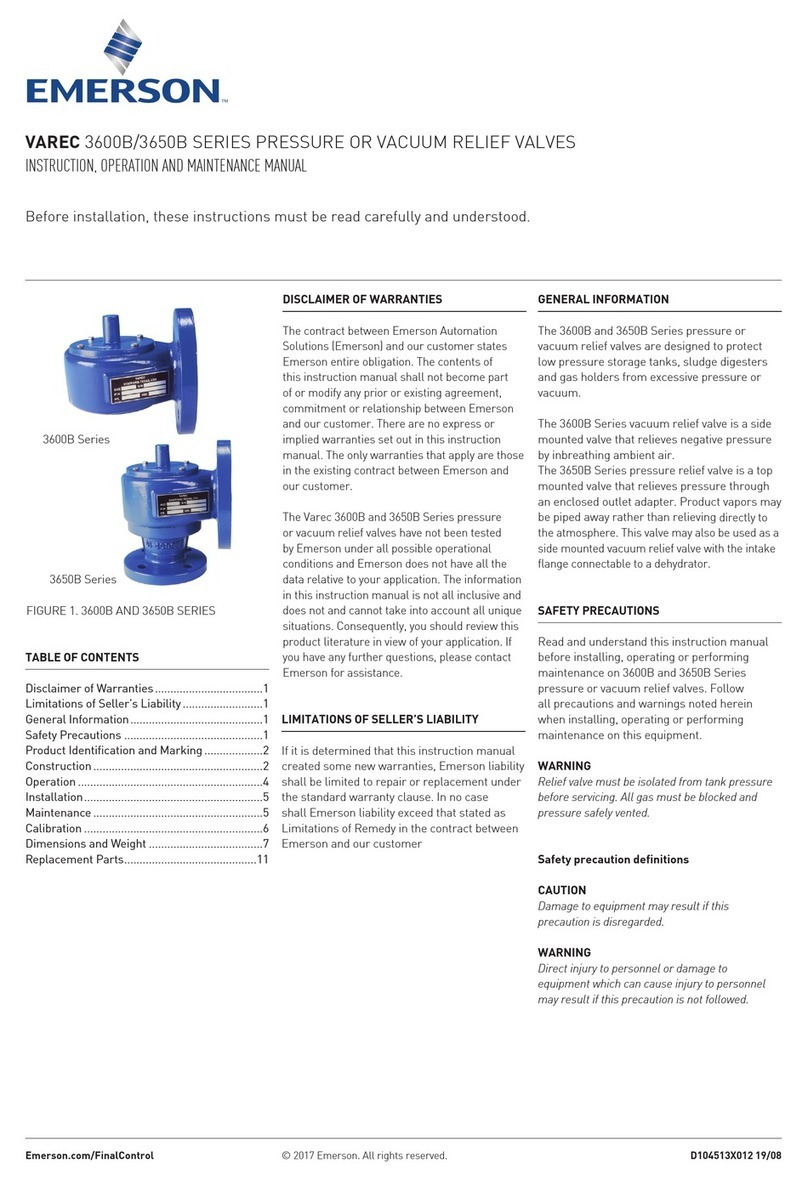

Emerson VAREC 3600B Series Operation and maintenance manual

Emerson

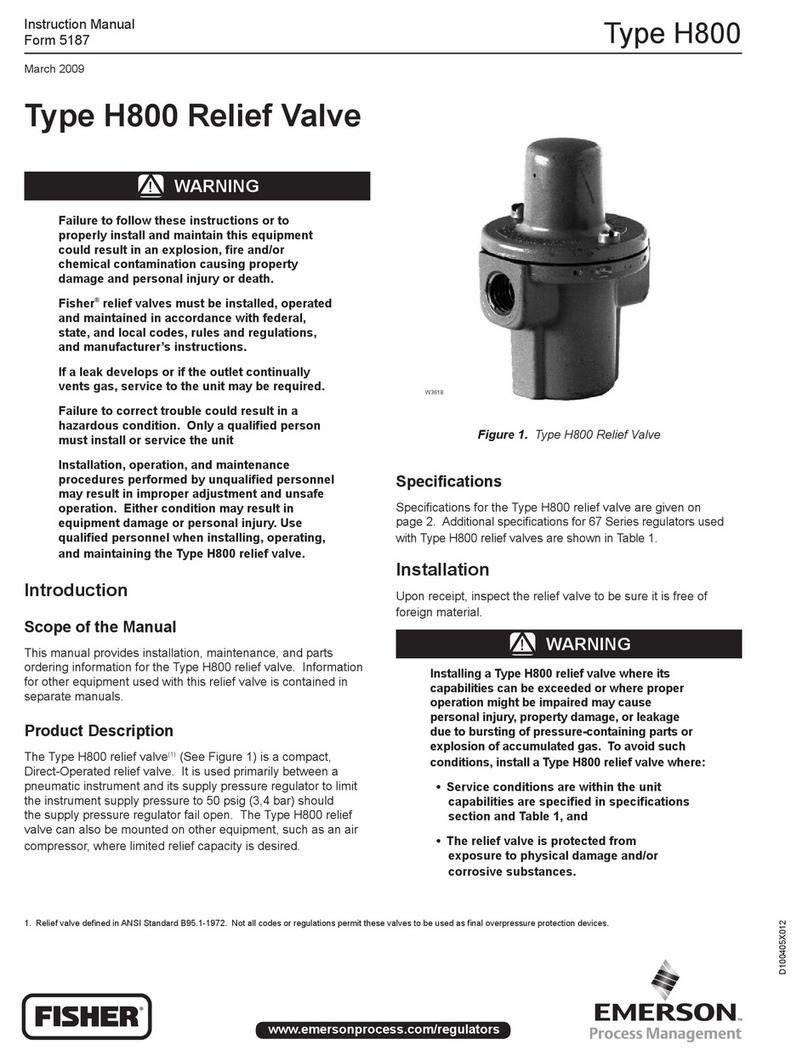

Emerson Fisher Type H800 User manual

Emerson

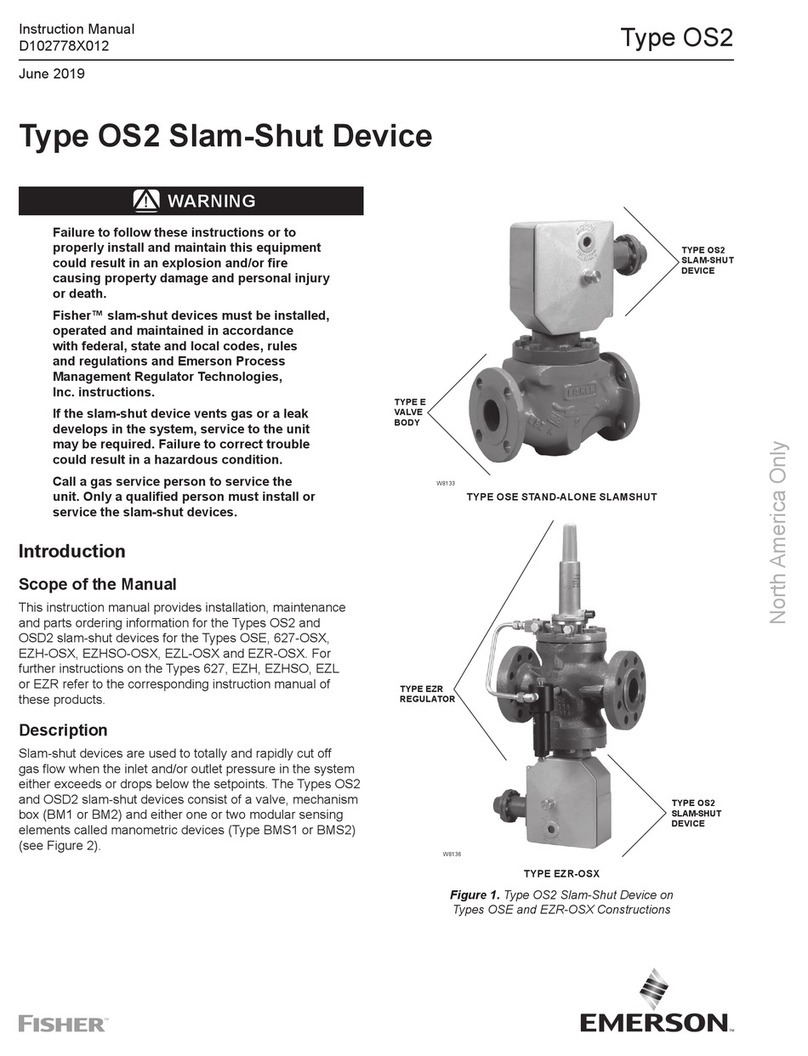

Emerson Fisher OS2 User manual

Emerson

Emerson Fisher HP User manual

Emerson

Emerson YARWAY 60Y Series User manual

Emerson

Emerson Alco Controls TCLE User manual

Emerson

Emerson Fisher ACE95 Series User manual

Emerson

Emerson Micro Motion User manual

Emerson

Emerson Heated Flame Ionization Detector Module Model NGA 2000... User manual

Emerson

Emerson Daniel 762 User manual

Emerson

Emerson Rosemount RM5800 User manual

Emerson

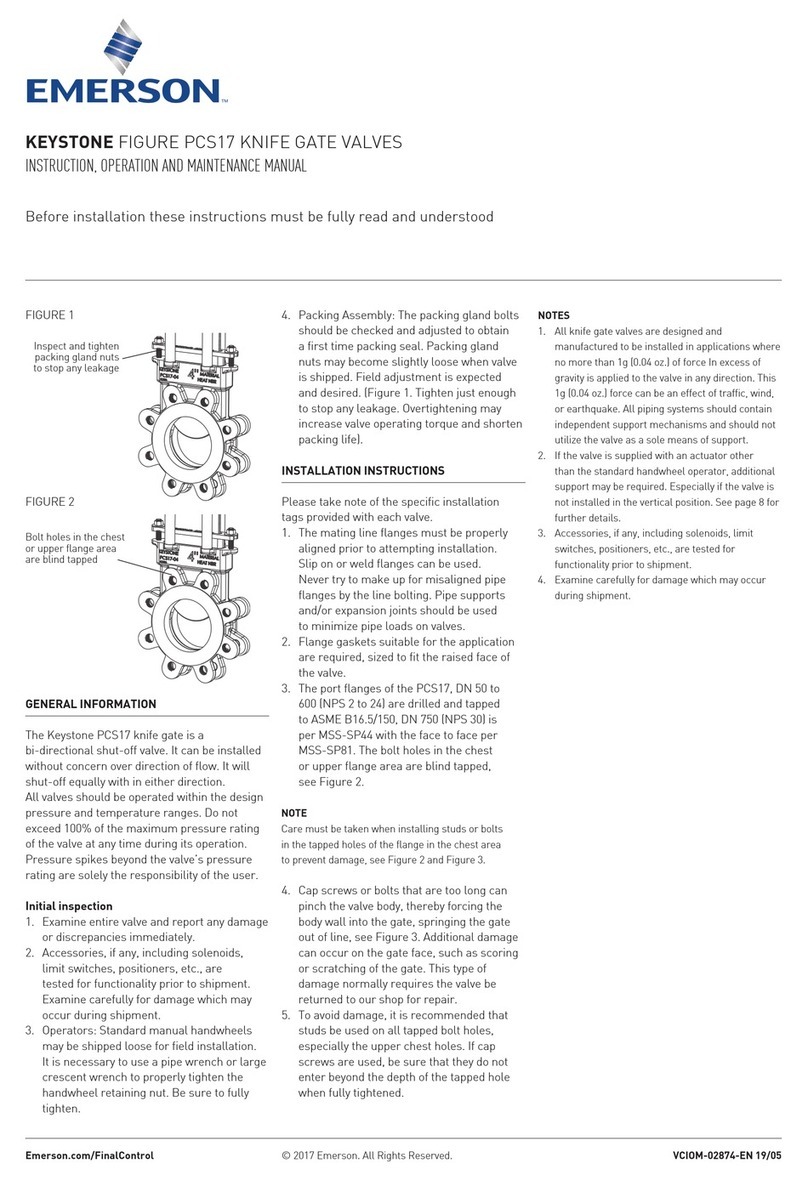

Emerson KEYSTONE FIGURE PCS17 Operation and maintenance manual

Emerson

Emerson Tartarini PRX Series User manual

Emerson

Emerson ENARDO 860 Series User manual

Emerson

Emerson Bettis Om3-SCE300 User manual

Emerson

Emerson MVME7616E Quick start guide

Popular Control Unit manuals by other brands

Festo

Festo Compact Performance CP-FB6-E Brief description

Elo TouchSystems

Elo TouchSystems DMS-SA19P-EXTME Quick installation guide

JS Automation

JS Automation MPC3034A user manual

JAUDT

JAUDT SW GII 6406 Series Translation of the original operating instructions

Spektrum

Spektrum Air Module System manual

BOC Edwards

BOC Edwards Q Series instruction manual

KHADAS

KHADAS BT Magic quick start

Etherma

Etherma eNEXHO-IL Assembly and operating instructions

PMFoundations

PMFoundations Attenuverter Assembly guide

GEA

GEA VARIVENT Operating instruction

Walther Systemtechnik

Walther Systemtechnik VMS-05 Assembly instructions

Altronix

Altronix LINQ8PD Installation and programming manual