2

Plant downtimes

NOTICE

For longer system downtimes, a downtime

preservation must be carried out.

If systems are set out of operation for a shorter

or longer time, procedures (VGB - R 116)

depending on downtime duration and frequency

should be applied to preserve the system.

Limitation of liability

All specifications and notices in this instruction

manual were drawn up with consideration of

the applicable standards and regulations, the

status of technology and our longstanding

findings and experiences.

The manufacturer does not assume liability for

damages in the following cases:

• Non-adherence to this instruction manual

• Usage deviating from the intended use

• Employment of untrained personnel

• Independent reconstruction

• Technical modifications

• Usage of unauthorized spare parts

• Use of unauthorized operating media

• Improper maintenance and setting of

thevalve

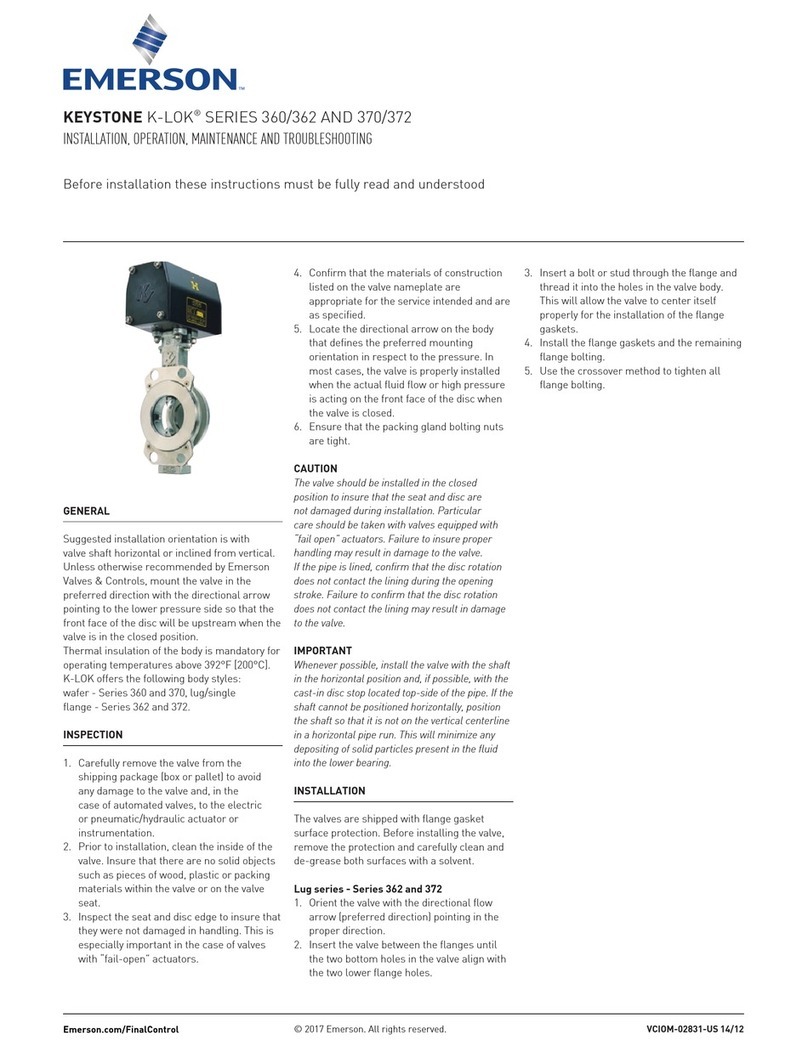

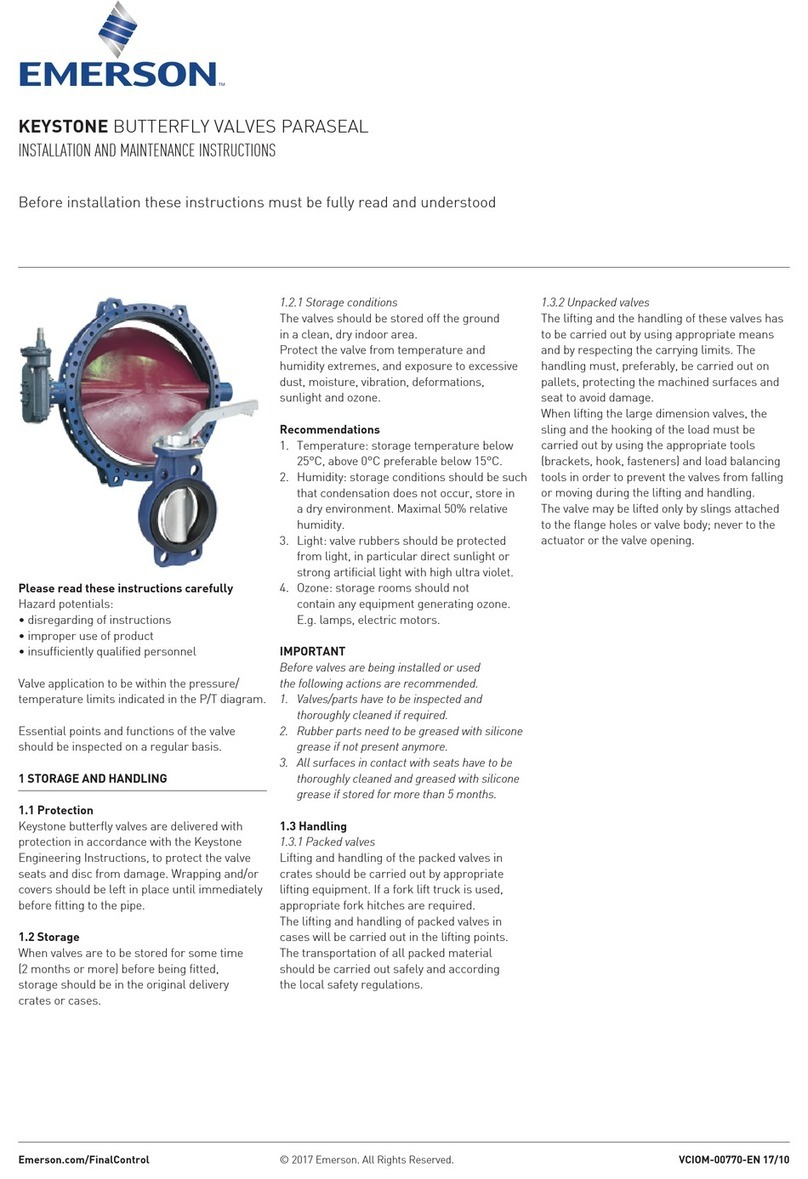

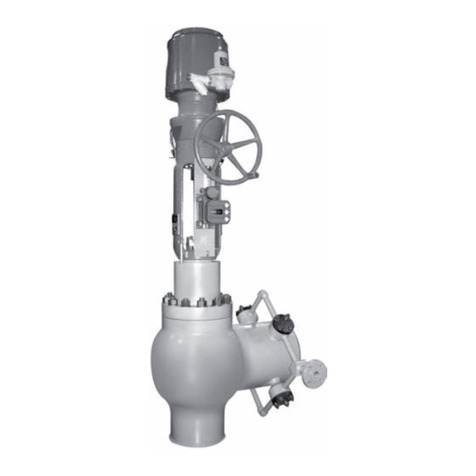

2 DESCRIPTION

Spring-loaded safety valves are direct acting

safety valves with which pressure vessels

are protected against inadmissible excess

pressure.

A cylindrical compression spring creates the

closing force on the valve disc against the

opening pressure of the medium below the

valve disc. Under normal operating conditions

the valve seat is kept tight.

By changing the spring compression the

set pressure can be changed. When the set

pressure is surpassed, the pressure of the

medium prevails and the safety valve opens.

In case of full-lift characteristic the safety valve

opens abruptly over the full lift and discharges

the whole mass flow which is necessary to

prevent further increase of the pressure.

The safety valve closes again after a defined

pressure reduction.

Please observe the planning manual for the

precise design of the safety valves.

For the application of this operating instruction

please take the exact type name (e.g. SC, SB)

from the nameplate of your valve.

Please observe the following points besides

the notes given in the text

• Danger of burning at safety valves and with

their connected lines while operating under

increased temperature.

• Disassembly of the safety valve only in case of

pressureless plant or after cooling down.

• Protection against risks caused by

evaporation also in case of pressureless

system; for information please contact the

safety inspector concerned.

• After assembly check all sealing points in

regard of tightness.

• In case of adjustment make changes at

pressure screw and adjusting ring only with

sunstantially reduced pressure to avoid

unintended response.

• Carry ear protection during adjustment,

ifnecessary.

• Danger of burning by discharge of small

amounts of possibly hot medium in case

of safety valves with open spring bonnet

(typeSO).

• Danger of injury while discharging in case of

disconnected discharge line.

• Extreme vibrations can lead to inadmissible

increase of operating pressure with the

possibly destruction of the safety valve or to

the destruction of the balanced bellows with

unintentional escape of medium.

• In case the valve is provided with a steam

jacket or a steam flushing device, the

corresponding design must be considered

while connecting.

• Temporary or permanent connection of

devices not authorized by us

The actual scope of delivery may deviate from

the explanations and figures described here

regarding special versions, the utilization

of additional order options or due to newest

technical modifications.

The obligations, General Business Terms and

Conditions and the delivery conditions of the

manufacturer agreed upon in the delivery

contract are applicable, along with the legal

regulations valid at the time of contract

conclusion.

Use within areas exposed to danger of

explosion:

The safety valves underwent a hazard analysis

according to code 94/9/EC with the following

result:

• The safety valves do not have a potential

ignition source. ATEX 94/9/EC is not

applicable to these valves.

• The valves safety may be used in the EX area

• Electrical / pneumatically accessories have to

undergo a separate assessment of conformity

according to ATEX.

• The surface temperature does not depend

from the valve itself but from the operational

conditions. Observe while installing.

SEMPELL SERIES S, TYPES SO, SC, SB, SOH FULL-LIFT SAFETY VALVES

OPERATING INSTRUCTIONS