1592023040 XM668D GB r1.1 2011.07.05.doc XM668D 5/14

The Adr parameter cannot be duplicated because in this case the defrost

cannot be correctly managed.

BEGIN

Press for 3 sec, the rtC or other will be showed.

The measurement unit blinks.

Find Adr

Press more than once the DOWN arrow to find the

Adr parameter, the press SET.

Modify

Adr or

Set the value of Adr parameter, then press SET to

confirm the parameter.

EXIT

Press the two keys together to exit from menu or

wait for about 10 sec.

The LSn and LAn parameter are only to show the actual settings (read only). Se the

following example of configuration:

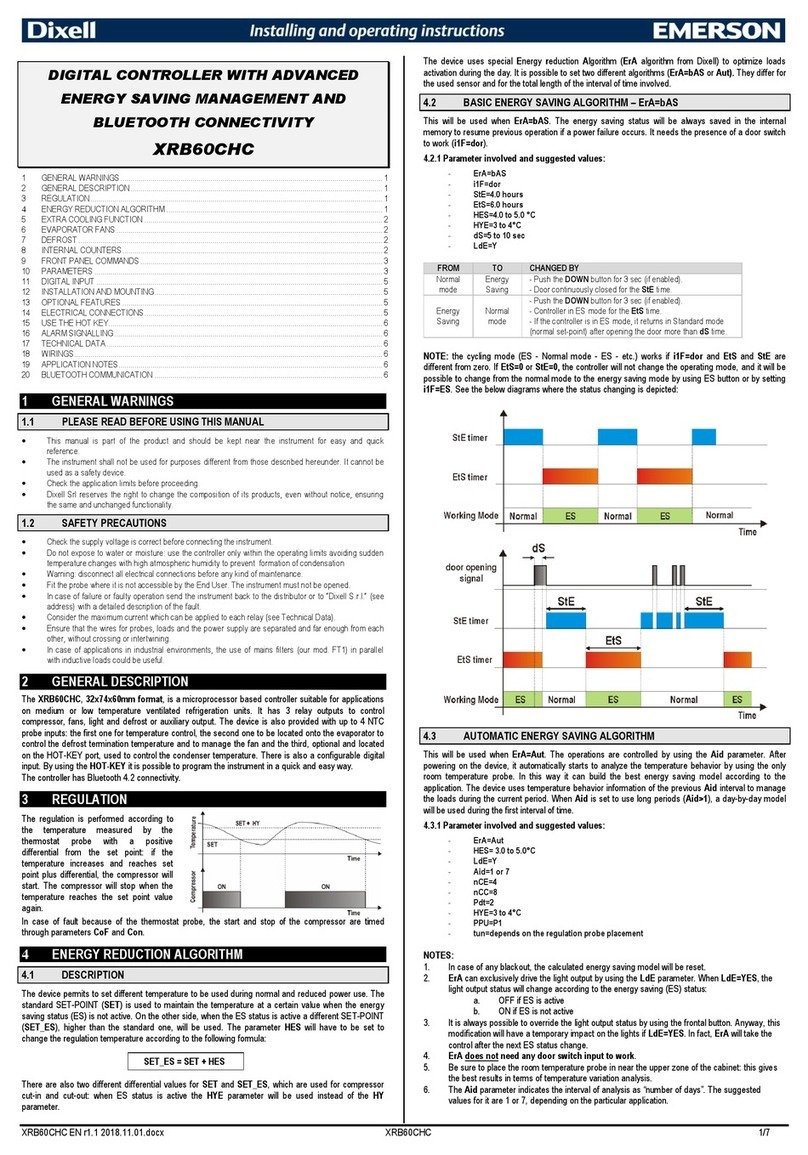

DAILY DEFROST FROM RTC: [CbP = Y] and [EdF = rtC]

idF Parameter: for safety reason force the value of idF at +1 respect to the interval

between two Ld parameters. The idF timer is reinitialized after defrost and at every

power-on.

DEFROST START: at the time selected by the parameters Ld1 to Ld6 or Sd1 to

Sd6.

DEFROST END: if the probes reach the dtE temperature or for maximum MdF time.

SAFETY and rtC or rtF ALARM: with clock alarm the device will use the parameter

idF, dtE and MdF.

WARNING: don’t set [EdF=rtC] and [CPb=n].

MULTIMASTER DEFROST: all the probes with clock

Table for example

n N + 1 N + 2

rtC (clock) rtC (clock) rtC (clock)

Y Y Y

9 hours safety 9 hours safety 9 hours safety

45 min safety 45 min safety 45 min safety

12°C safety 12°C safety 12°C safety

06:00 1° 06:00 1° 06:00 1°

14:00 2° 14:00 2° 14:00 2°

22:00 3° 22:00 3° 22:00 3°

10. DISPLAY MESSAGES

1 nod

No display: the keyboard is trying

to work with another board that is

not working or not present

Press for 3 sec UP arrow,

the SEC menu and select LOC

entry.

2 Pon Keyboard is unlocked

3 PoF Keyboard is locked

4 rSt Alarm reset Alarm output deactivated

5 noP, nP

nA

Not present (configuration)

Not available (evaluation)

6

P2

P3

P4

P5

P6

PPF

CPF

Sensor brake down, value out of

range or sensor incorrectly

configured P1C, P2C to P6C.

PPF can be showed by slaves of

pressure that don’t receive the

value of pressure.

CPF is showed when the remote

probe 4 is not working.

P1: the cooling output works

with Con and COF,

With defrost probe on error the

defrost is performed only at

interval.

For P5, P6 and PPF: the

percentage of the valve

opening is fixed at PEO value.

7 HA

Temperature alarm from parameter

ALU on probe rAL.

8 LA

Temperature alarm from parameter

ALL on probe rAL.

9 HAd

probe defrost probe [dPa / dPb].

10

LAd

probe defrost probe [dPa / dPb].

11

HAF

probe defrost probe [FPa / FPb].

12

LAF

probe defrost probe [FPa / FPb].

13

dA

Door open alarm from input

i2F or i3F = after delay d1d, d2d

or d3d.

Cooling relay and fan follow the

odc parameter. Cooling restart

as specified on rrd parameter.

14

EA Generic alarm from digital input

i1F,i2F,i3F=EAL.

15

CA Severe alarm of regulation lock

from digital input i1F,i2F,i3F=bAL. Regulation output OFF.

16

PAL

= PAL. All the outputs are OFF.

17

LOP Minimum operating pressure

threshold from LOP parameter.

The valve output increases its

opening of dML quantity every

second.

18

MOP Maximum operating pressure

threshold from MOP parameter.

The valve output decreases its

opening of dML quantity every

second.

19

LSH Low superheating from LSH

parameter and SHd delay.

The valve will be closed; the

alarm will be showed after SHd

delay.

20

HSH

parameter and SHd delay. Only display.

21

rtC Clock settings lost.

Defrost will be performed with

IdF till restoring the settings of

RTC.

22

rtF Clock damaged. Defrost will be performed with

IdF.

EEPROM serious problem. Output OFF.

24

Err Error with upload/download

parameters. Repeat the operation.

25

End Parameters have been correctly

transferred.

10.1 ALLARM RECOVERY

Probe alarms P1, P2, P3 and P4 start some seconds after the fault in the related

probe; they automatically stop some seconds after the probe restarts normal

operation. Check connections before replacing the probe.

Temperature alarms HA, LA, HA2 and LA2 automatically stop as soon as the

temperature returns to normal values.

Alarms EA and CA (with i1F = bAL)recover as soon as the digital input is disabled.

Alarm CA (with i1F = PAL) recovers only by switching off and on the instrument.

11. USE OF THE PROGRAMMING “HOT KEY“

The XM units can UPLOAD or DOWNLOAD the parameter list from its own E2

internal memory to the HOT-KEY and vice-versa through a TTL connector. Using

HOT-KEY the Adr will not changed.

11.1 DOWNLOAD (FROM THE HOT-KEY TO THE INSTRUMENT)

1. Turn OFF the instrument by means of the ON/OFF key, insert the HOT-KEY

and then turn the unit ON.

2. Automatically the parameter list of the HOT-KEY is downloaded into the

controller memory: the doL message is blinking. After 10 seconds the

instrument will restart working with the new parameters. At the end of the data

transfer phase the instrument displays the following messages: End for right

programming. The instrument starts regularly with the new programming. Err

for failed programming. In this case turn the unit off and then on if you want to

restart the download again or remove the HOT-KEY to abort the operation.

11.2 UPLOAD (FROM THE INSTRUMENT TO THE “HOT KEY”)

1. When the XM unit is ON, insert the HOT-KEY and push è key; the uPL

message appears.

2. The UPLOAD begins; the uPL message is blinking.

3. Remove the HOT-KEY.At the end of the data transfer phase the instrument

displays the following messages:

End = right programming;

Err = failed programming. In this case push SET key if you want to restart the

programming again or remove the not programmed HOT-KEY.

12. CONTROLLING LOADS

12.1 THE COOLING OUTPUT

The regulation is performed according to the temperature measured by the

thermostat probe that can be physical probe or virtual probe obtained by a weighted

average between two probes following the formula:

value_for_room_regulation = (rPA*rPE + rPb*(100-rPE))/100

If the temperature increases and reaches set point plus differential the solenoid valve

is opened and then it is closed when the temperature reaches the set point value

again.In case of fault in the thermostat probe the opening and closing time of

solenoid valve is configured by Con and CoF parameters.

12.2 STANDARD REGULATION AND CONTINUOUS REGULATION

The regulation can be performed in three ways: the goal of the first way (standard

regulation) is reaching the best superheat via a classic temperature regulation

obtained using hysteresis. The second way permits to use the valve to realize an high

performance temperature regulation with a good factor of superheat precision. This