Types P650, P163A, and P164A

3

Attach the return spring to the operating lever as shown.

The return spring must overcome the cable drag and

close the internal valve when the control is released.

Step 4: To mount the Type P163A or P164A release, rst

select a location that meets DOT, NFPA Pamphlet 58,

and/or state regulations. A 7/16-inch (11 mm) diameter

hole is required to mount the assembly.

Step 5: Run the release cable to the Type P650 latch,

making sure to secure the cable with clamps and keep a

minimum bend radius of 6-inches (152 mm) in the cable.

Step 6: Pull the release handle (Type P163A or P164A) out

about 1 foot (0,3 meter) so that inner cable will not be cut

too short.

Step 7: Attach the casing clamp to the Type P650 rear

pin as shown. Cut the Type P163A or P164A cable

and housing to the proper length to reach through the

casing clamp.

Step 8: Pull the inner wire back through the casing (push

in the release handle). Remove about 1-inch (25 mm) of

vinyl casing cover from the end of the housing. Thread

the cable through the casing clamp and t the housing

into the clamp.

Step 9: Assemble the inner cable clamp and screw

through the Type P650 latch as shown. Thread the inner

cable through the clamp and tighten the screw.

Leave only enough slack in the cable to allow the

Type P650 latch to engage the slide.

Check the following after completing the assembly:

1. The internal valve operating lever should be in the

open position when the Type P650 handle is in the

required notch.

2. The release assemblies (Type P163A or 164A) must

be capable of deactivating the Type P650 primary

control, closing the internal valve.

3. The internal valve must be completely closed with the

primary control (Type P650) in the closed position.

Maintenance

CAUTION

Do not use internal valves and cable

controls if they leak, fail to work properly

or have been damaged or have missing

parts. Prompt repairs should be made by

a properly trained serviceman. Continued

use without repair can create a hazardous

or injurious situation.

A simple preventative maintenance program for the valve

and its controls will eliminate a lot of potential problems.

Fisher recommends these steps be conducted once

a month:

1. Inspect the operating lever and cable controls to

see that they operate freely and that there is no

leakage around the retainer nut. If there is sticking

or leakage, replace the packing and bushings. Refer

to internal valve instruction manual.

2. Check for tight closure of the internal valve seat

disks regularly. Any leakage indicates a defect in

the seat caused by wear or from dirt or scale lodging

and embedding in the disks. To check for leakage,

close the valve and exhaust downstream pressure.

Close the rst valve downstream from the internal

valve, and note any pressure buildup between the

closed valve and the internal valve by means of a

pressure gauge. If leakage is indicated, both disks

should be replaced. If piping is cold allow it to warm to

ambient temperature.

3. All operating controls should be inspected, cleaned

and oiled. Rust, corrosion, and dirt can make the

controls inoperable. The controls should be checked

to see that they fully open–but not over-travel–the

internal valve operating lever and operates freely to

close the valve.

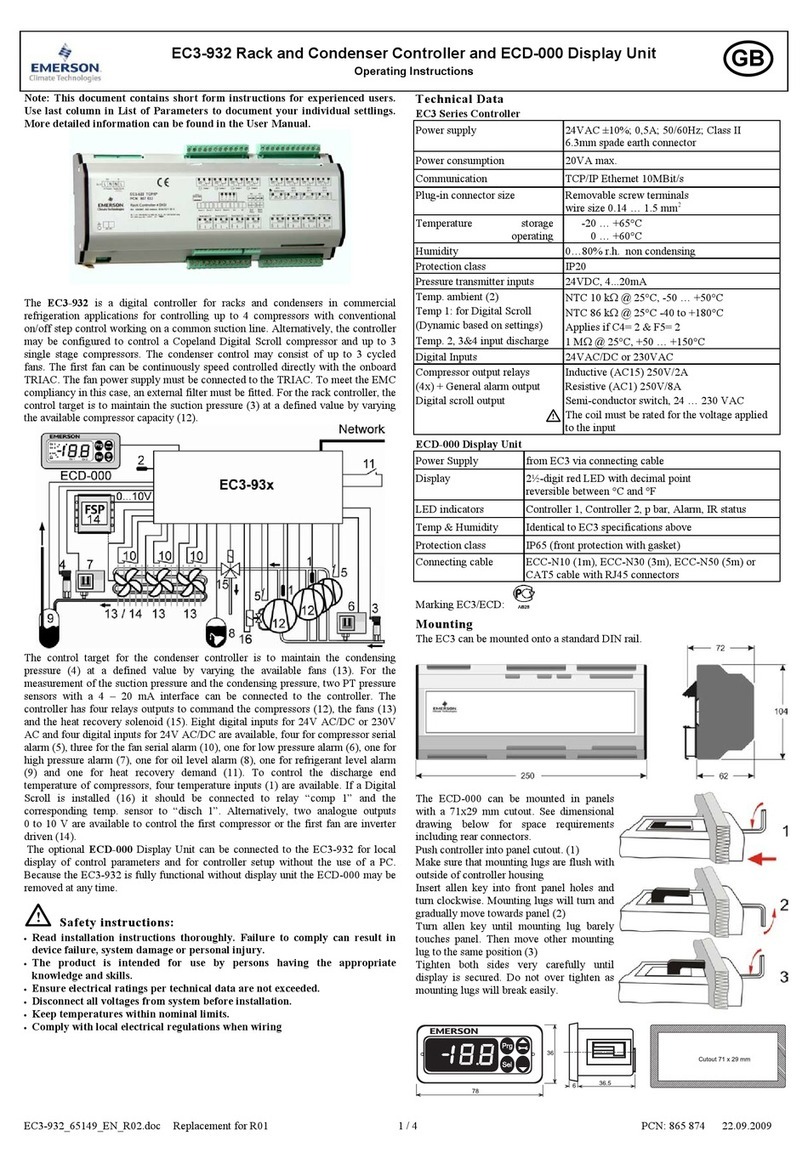

Figure 3. Type P650 Primary Cable Control Assembly

9

6

3547

8

1

PARTS NOT SHOWN: KEYS 10, 11, 12, 13, AND 14

T20350