BODY SIZE DIAPHRAGM

MATERIAL

MAXIMUM OPERATING

INLET PRESSURE(4)

MAXIMUM OPERATING

DIFFERENTIAL PRESSURE(3)(4)

MAXIMUM EMERGENCY INLET

AND DIFFERENTIAL PRESSURE MAIN SPRING COLOR

DN NPS bar psig bar psig bar d psid

25 1

17E68 Nitrile (NBR) 20.7 300 20.7 300 20.7 300 Black and Yellow

17E97 Nitrile (NBR) 20.7 300 20.7 300 20.7 300 Black and Yellow

41.4 600 41.4 600 41.4 600 Black and White(2)

17E88

Fluorocarbon (FKM)

20.7 300 20.7 300 20.7 300 Black and Yellow

41.4 600 34 500 41.4 600 Black and White(2)

50 2

17E68 Nitrile (NBR) 20.7 300 20.7 300 20.7 300 Green and White

17E97 Nitrile (NBR) 20.7 300 20.7 300 20.7 300 Green and White

41.4 600 41.4 600 41.4 600 Purple(2)

17E88

Fluorocarbon (FKM)

20.7 300 20.7 300 20.7 300 Green and White

41.4 600 34 500 41.4 600 Purple(2)

80 3

17E68 Nitrile (NBR) 20.7 300 20.7 300 20.7 300 Light Blue and White

17E97 Nitrile (NBR) 20.7 300 20.7 300 20.7 300 Light Blue and White

41.4 600 41.4 600 41.4 600 Black(2)

17E88

Fluorocarbon (FKM)

20.7 300 20.7 300 20.7 300 Light Blue and White

41.4 600 34 500 41.4 600 Black(2)

100 4

17E68 Nitrile (NBR) 20.7 300 20.7 300 20.7 300 Green and White

17E97 Nitrile (NBR) 20.7 300 20.7 300 20.7 300 Green and White

41.4 600 41.4 600 41.4 600 Red(2)

17E88

Fluorocarbon (FKM)

20.7 300 20.7 300 20.7 300 Green and White

41.4 600 34 500 41.4 600 Red(2)

1. See Table 1 for main valve structural design ratings and Table 2 for pilot ratings.

2. The black and white, purple, black and red springs are only recommended for applications where the maximum inlet pressure can exceed 20.7 bar / 300 psig.

3. Maximum differential pressures may be lower for applications where cavitation may be present.

4. These are recommendations that provide the best regulator performance for a typical application. Please contact your local Sales Ofce for further information if a deviation from the

standard recommendations are required.

Table 5. Main Valve Maximum Pressure Ratings, Diaphragm Selection Information and Main Spring Selection(1)

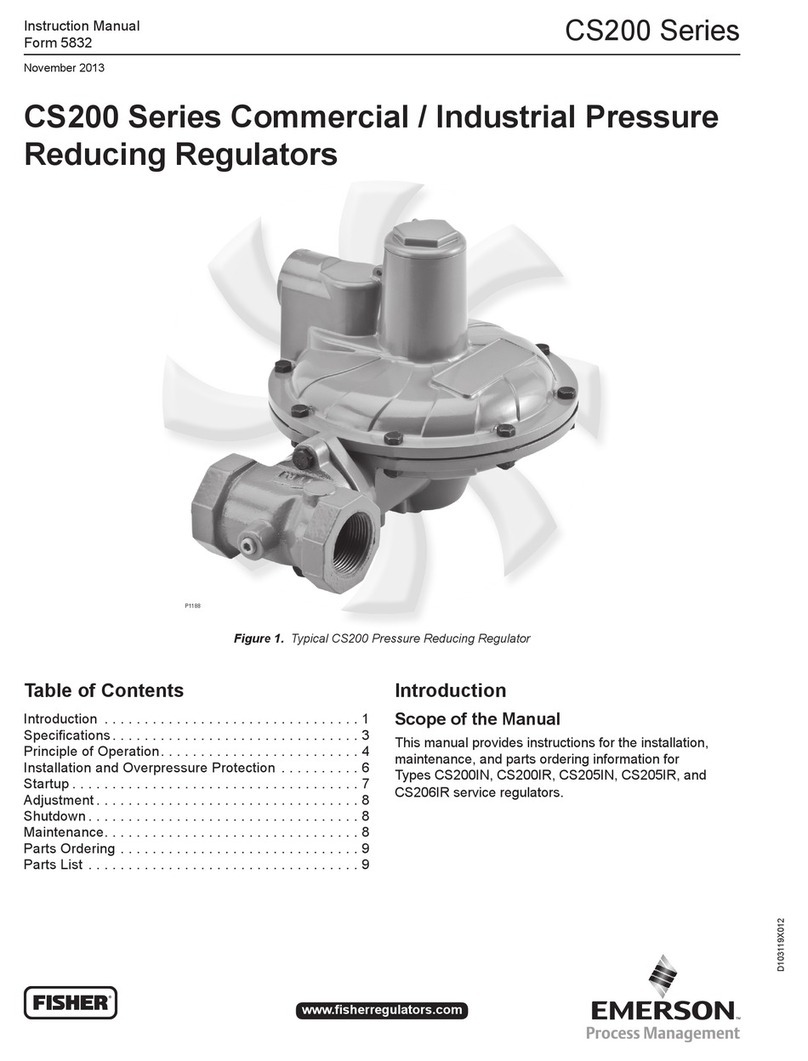

Overpressure Protection

The recommended pressure limitations are

stamped on the regulator nameplate. Some type of

overpressure protection is needed if the actual inlet

pressure exceeds the maximum operating outlet

pressure rating. Overpressure protection should

also be provided if the regulator inlet pressure

is greater than the safe working pressure of the

downstream equipment.

Regulator operation below the maximum pressure

limitations does not preclude the possibility of

damage from external sources or debris in the line.

The regulator should be inspected for damage after

any overpressure condition.

Startup

The regulator is factory set at approximately

the midpoint of the spring range or the pressure

requested, so an initial adjustment may be required

to give the desired results. With proper installation

completed and relief valves properly adjusted,

slowly open the upstream and downstream

shutoff valves.

Adjustment

To change the outlet pressure, loosen the jam nut

and turn the adjusting screw clockwise to increase

outlet pressure or counterclockwise to decrease it.

Monitor the outlet pressure with a test gauge during

the adjustment. Tighten the jam nut to maintain the

desired setting.

Taking Out of Service (Shutdown)

WARNING

To avoid personal injury resulting from

sudden release of pressure, isolate the

regulator from all pressure before

attempting disassembly.

Table 6. Main Valve Minimum Differential Pressure(1)

MAIN VALVE BODY SIZE

MAIN SPRING PART NUMBER AND COLOR DIAPHRAGM MATERIAL

MINIMUM DIFFERENTIAL, PERCENT OF CAPACITY

For 90% Capacity For 100% Capacity

DN In. bar d psid bar d psid

25 1 GE12727X022, Black and Yellow 17E68 and 17E88 2.1 30 2.1 30

17E97 2.5 35 2.5 35

19B2401X022, Black and White 17E88 and 17E97 3.0 43 3.0 43

50 2 18B2126X022, Green and White 17E68 and 17E88 1.2 18 1.3 19

17E97 1.7 24 1.7 24

18B5955X012, Red 17E88 and 17E97 2.0 29 2.1 31

80 3 19B0781X022, Light Blue and White 17E68 and 17E88 1.5 21 1.9 28

17E97 1.6 23 1.6 23

19B0782X022, Black and White 17E88 and 17E97 2.2 32 2.6 38

100 40 18B8501X022, Green and White 17E68 and 17E88 1.1 16 2.1 30

17E97 1.1 16 2.3 34

18B8502X022, Red and White 17E88 and 17E97 1.5 21 2.8 40

1. See Table 1 for Type LR125 main valve structural design ratings and Table 2 for pilot rating.