All Installations

The robust design of the Type EZR allows this

regulator to be installed indoors or outdoors. When

installed outdoors, the Type EZR does not require

protective housing. This regulator is designed

to withstand the elements. The powder paint

coating protects against minor impacts, abrasions

and corrosion.

When installed indoors, no remote venting is required

except on the pilot spring case. This regulator can

also be installed in a pit that is subject to ooding

by venting the pilot spring case above the maximum

possible ood level so the pilot setting can be

referenced at atmospheric pressure.

1. Only personnel qualied through training and

experience should install, operate and maintain a

regulator. Before installation, make sure that there

is no damage to or debris in the regulator. Also,

make sure that all tubing and piping are clean

and unobstructed.

Note

The Type EZR optional inlet strainer is

intended to prevent occasional large

particles from entering the main valve.

If the gas contains continuous particles,

upstream ltration is recommended.

When using an inlet strainer (key 23), do

not use the shim (key 23) and vice versa.

2. Type EZR regulator may be installed in any

orientation, as long as ow through the regulator

matches the direction of the arrow on the main

valve body. However, for easier maintenance,

install the regulator with the bonnet up.

CAUTION

When installing a Type EZR trim package

in an existing E-body, make sure ow is

up through the center of the cage and

down through the cage slots. In some

cases, correct ow path is achieved

by removing the body from the line

and turning it around. If this is done,

change the ow arrow to indicate the

correct direction. Damage may result

if ow is not in the correct direction.

After assembly, check the regulator for

shutoff and leakage to atmosphere.

Types EZR/399 restricted trim bodies

(NPS 6 x 4, 8 x 4, 8 x 6 and 12 x 6 /

DN 150 x 100, 200 x 100, 200 x 150 and

300 x 150) are different than EW valve

bodies and are not interchangeable.

Install trims only in correct restricted

trim bodies.

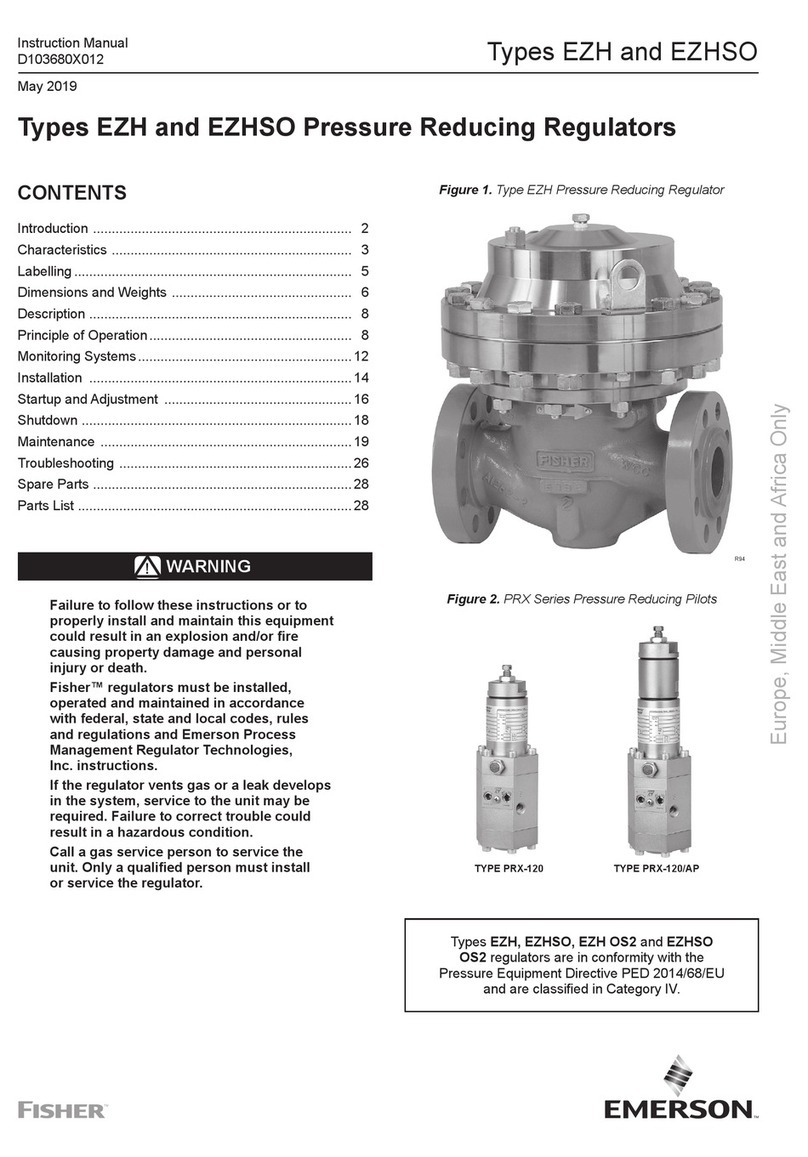

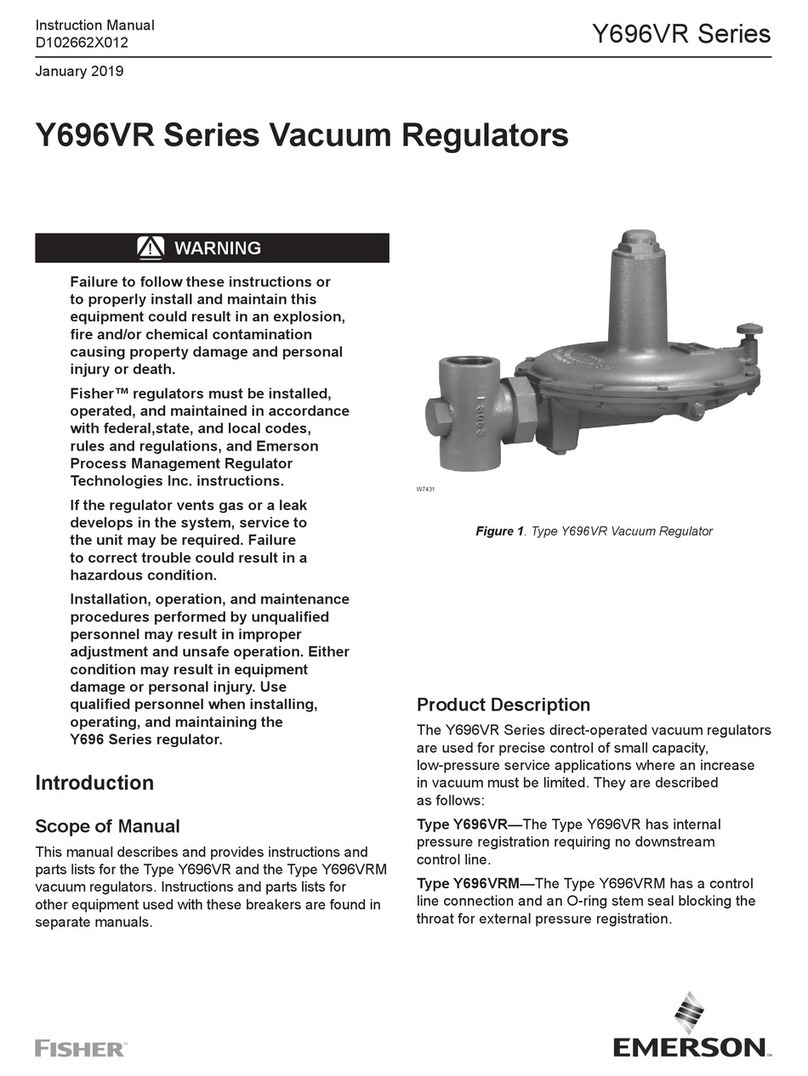

3. The standard pilot mounting position is as shown in

Figure 1. Other mounting positions are available.

4. Apply a good grade of pipe compound to the

external pipeline threads for a threaded body or

use suiTable line gaskets for a anged body. When

installing butt weld end connections, remove trim

before welding and make sure to use approved

welding practices. Use approved piping procedures

when installing the regulator.

CAUTION

A regulator may vent some gas to

the atmosphere. In hazardous or

ammable gas service, vented gas may

accumulate and cause personal injury,

death or property damage due to re

or explosion.

Vent a regulator in hazardous gas

service to a remote, safe location away

from air intakes or any hazardous

location. Protect the vent line or

stack opening against condensation

or clogging.

5. A clogged pilot spring case vent may cause the

regulator to function improperly. To prevent plugging

(and to keep the spring case from collecting moisture,

corrosive chemicals or other foreign material) point

the vent down, orient it to the lowest possible point

on the spring case or otherwise protect it. Inspect the

vent regularly to make sure it has not been plugged.

To remotely vent a spring case, remove the vent

and install obstruction-free tubing or piping into the

1/4 NPT vent tapping. Provide protection on a remote

vent by installing a screened vent cap onto the

remote end of the vent pipe. The 161AY Series pilot

has a vent restriction (key 55, Figure 20) to enhance

low ow stability. Do not remove this restriction.

!

WARNING

To avoid freeze-up because of pressure

drop and moisture in the gas, use

antifreeze practices, such as heating the

supply gas or adding a de-icing agent to

the supply gas.

7

Type EZR