Instruction Manual

D100331X012

1066 and 1066SR F & G Actuators

October 2012

9

DAlways wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

DDisconnect any actuator operating lines providing air pressure, electric power, or a control signal to the actuator. Be

sure the actuator spring compression cannot suddenly open or close the valve. Vent actuator loading pressure.

DUse process bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process

pressure on both sides of the valve. Drain the process media from both sides of the valve. Use caution when handling

hazardous process media.

DUse lockout procedures to ensure that the above measures stay in effect while you are working on the equipment.

DThe valve packing may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings.

DCheck with your process or safety engineer for any additional measures that must be taken to protect against process

media.

WARNING

This WARNING applies specifically to 1066 actuators, and to specially modified 1066SR actuators that apply pressure to the

bottom of the piston (key 3, figures 5 and 6).

To avoid personal injury from the bearing (key 4, figure 3) being forced out of the actuator with sufficient energy to cause

personal injury or property damage, carefully follow the instructions given below.

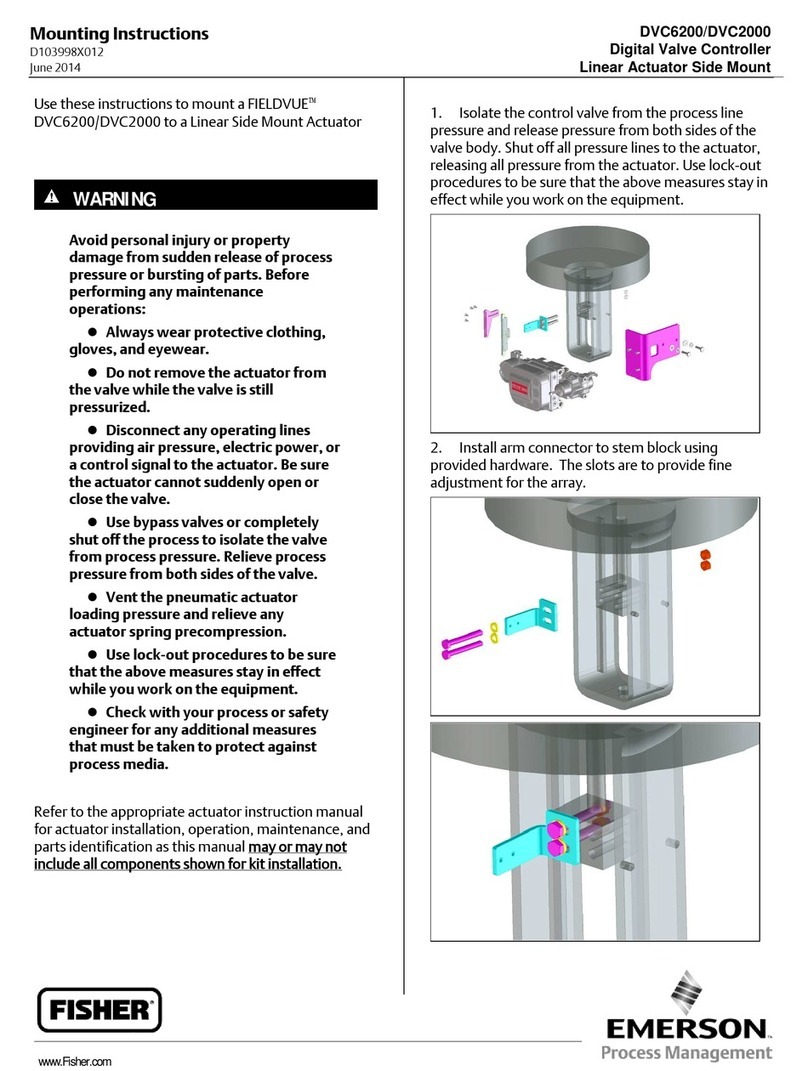

Do not apply loading pressure to a partially assembled actuator. Do not remove the mounting yoke (key 25, figure 3)

or the travel indicator scale (key 21, figure 3) from the actuator assembly when loading pressure is applied to the

bottom of the piston. The bearing (key 4) could be forced out of the actuator assembly.

Depending on the mounting position, either the mounting yoke ( key 25) or the travel indicator scale (key 21) retains

the bearing (key 4) when cylinder pressure is applied below the piston. For mounting positions A and D, the mounting

yoke (key 25) retains the bearing in place when pressure is applied below the piston. In the case of mounting positions

B and C, the indicator scale (key 21) retains the bearing in place when pressure is applied below the piston.

Disassembly

1. Isolatethecontrolvalvefromthelinepressure,releasepressure from both sides of the valve, and drain the process

media from both sides of the valve. Shut off all pressure lines to the actuator, and release the pressure. Use lockout

procedures to be sure that the above measures stay in effect while you work on the equipment.

WARNING

When removing the hex nuts (key 31), besurespringpre-compressionisnot acting on the cylinder cover (key 2). The

spring compression could result in personal injury by causing the cylinder cover to suddenly release from the actuator as

thenutsareremoved.

2. Remove the hex nuts (key 31), the flat washer (key 15), the cylinder cover (key 2), and the cylinder (key 8).

3. Inspect the O-ring (key 17) and the gasket (key 33) for nicks or flat spots that might cause leakage. Obtain all

replacement parts necessary for reassembly.

4. If replacing the O-ring (key 17) and/or gasket (key 33) is the only maintenance necessary, skip the remaining steps

in this Disassembly procedure and go to the following Assembly procedure.