6350 Series

D100178XENG

Installation Guide

English – May 2002

www.FISHERregulators.com

Introduction

This installation guide provides instructions for installation,

startup, and adjustment. To receive a copy of the instruction

manual, contact your local Fisher Sales

Office or Sales Representative or view a copy at

www.FISHERregulators.com. For further information refer to:

Type 1098-EGR Instruction Manual, form 5084, D100339X012

Type 627F Instruction Manual, form 5282, D101545X012

(for Type 6351F only)

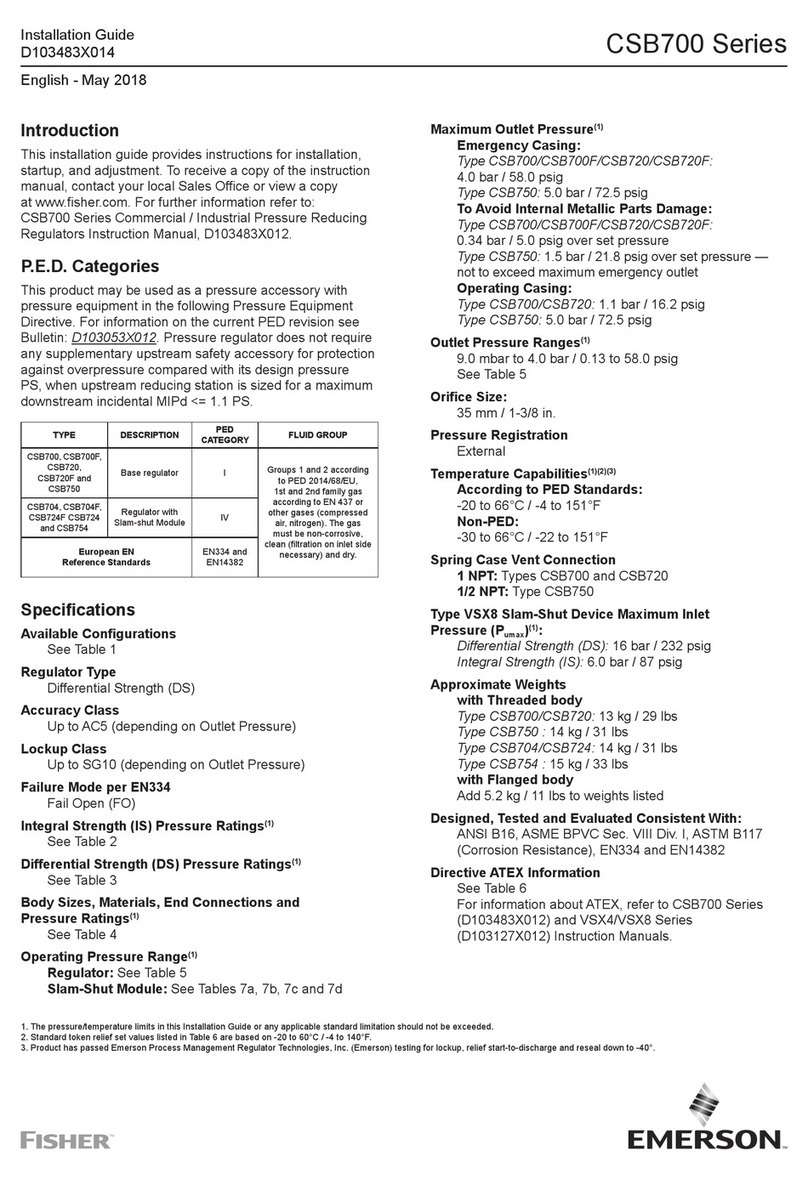

P.E.D. Categories

This product may be used as a safety accessory with

pressure equipment in the following Pressure Equipment

Directive 97/23/EC categories. It may also be used out-

side of the Pressure Equipment Directive using sound

engineering practice (SEP) per table below.

EZISTCUDORPSEIROGETACEPYTDIULF

)hcni-4/1(6NDPES1

Specifications

Available Configurations

6351: Set pressures – 0,21 to 6,9 bar (3 to 100

psig). This pilot has an unbalanced valve plug

design and fixed restriction.

6351F: Set pressures – 0,34 to 6,9 bar (5 to 100

psig). This pilot has an unbalanced valve plug

design and standard gain restriction. This pilot is

used with the Type 627F main valve.

6352: Set pressures – 5 mbar to 0,69 bar (2-

inches w.c. to 10 psig). This pilot has a balanced

valve plug design and a standard gain restriction.(1)

6353: Set pressures – 0,21 to 6,9 bar (3 to 100

psig). This pilot has a balanced valve plug design

and a standard gain restriction.(1)

6354L: Set pressures – 5,9 to 13,8 bar (85 to 200

psig). This pilot has a balanced valve plug design

and a standard gain restriction.(1)

6354M: Set pressures – 12,1 to 15,2 bar (175 to

220 psig). This pilot has a balanced valve plug

design and a standard gain restriction.(1)

6354H: Set pressures – 13,8 to 20,7 bar (200 to

300 psig). This pilot has a balanced valve plug

design and a standard gain restriction.(1)

Maximum Inlet Pressure(2)

41 bar (600 psig)

Maximum Outlet Pressure(2)

6351, 6351F: 10,3 bar (150 psig)

6352: 3,4 bar (50 psig)

6353: bar (150 psig)

6354L, 6354M, 6354H: 24,8 bar (360 psig)

Outlet Pressure Ranges

See table 1

Proof Test Pressure

All Pressure Retaining Components have been

proof tested per Directive 97/23/EC - Annex 1,

Section 7.4

Temperature Capabilities

Nitrile/Neoprene:

-40 to 82°C (-40 to 180°F)

Fluoroelastomer:

-18 to 149°C (0 to 300°F) hot

water limited to 82°C (180°F)

Installation

Only qualified personnel should install or service

a regulator. Regulators should be installed, oper-

ated, and maintained in accordance with interna-

tional and applicable codes and regulations, and

Fisher instructions.

If the regulator vents fluid or a leak develops in

the system, it indicates that service is required.

Failure to take the regulator out of service imme-

diately may create a hazardous condition.

Personal injury, equipment damage, or leakage

due to escaping fluid or bursting of pressure-con-

taining parts may result if this regulator is over-

pressured or is installed where service condi-

tions could exceed the limits given in the Specifi-

cations section, or where conditions exceed any

ratings of the adjacent piping or piping connec-

tions.

To avoid such injury or damage, provide pressure-

relieving or pressure-limiting devices (as required

by the appropriate code, regulation, or standard)

to prevent service conditions from exceeding lim-

its.

Additionally, physical damage to the regulator

could result in personal injury and property dam-

age due to escaping fluid. To avoid such injury

and damage, install the regulator in a safe loca-

tion.

1. Optional low gain restriction for liquid service and/or broader proportional bands or

high gain restriciton for narrower proportional bands (such as low-differential boiler

fuel service).

2. The pressure/temperature limits in this installation guide and any applicable

standard or code limitation should not be exceeded.

EPYTTOLIPEGNARERUSSERP)LORTNOC(TELTUO

1536

rab4,1ot12,0

rab4,2ot43,0

rab9,6ot4,2

)gisp02ot3(

)gisp53ot5(

)gisp001ot53(

F1536 rab4,2ot43,0

rab9,6ot4,2

)gisp53ot5(

)gisp001ot53(

2536 rabm041ot5

rab96,0ot41,0

)gisp2ot.c.wsehcni-2(

)gisp01ot2(

3536 rab8,2ot12,0

rab9,6ot4,2

)gisp04ot3(

)gisp001ot53(

L4536

)1(

M4536

)2(

H4536

rab8,31ot9,5

rab2,51ot1,21

rab7,02ot8,31

)gisp002ot58(

)gisp022ot571(

)gisp003ot002(

.retimilmgarhpaidtuohtiW.1

.retimilmgarhpaidhtiW.2

Table 1. Outlet Pressure Ranges