4

Rosemount Manifolds August 2016

EmersonProcess.com/Rosemount

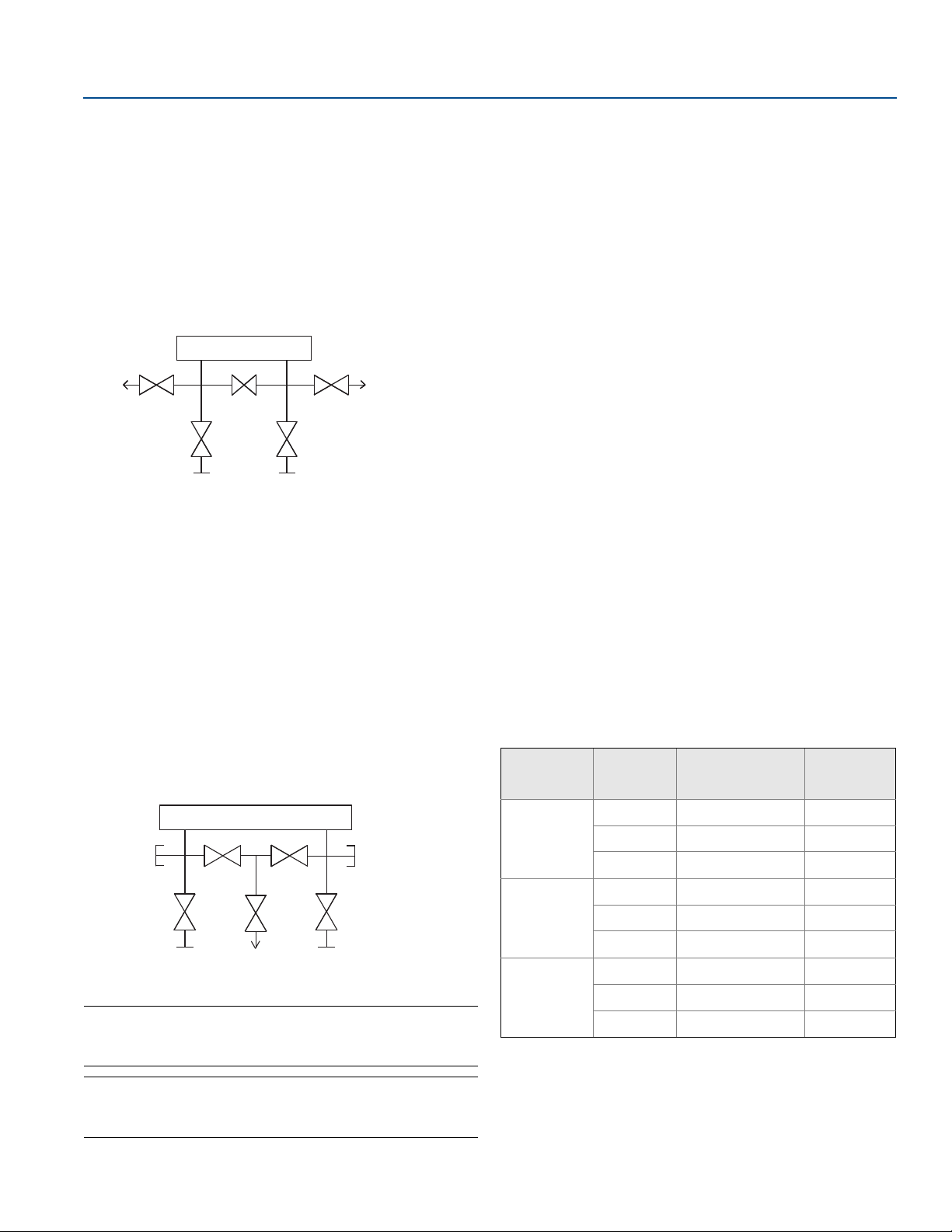

Five-valve

The 5-valve configuration is available on Rosemount 305 and 304

Manifolds for use with differential pressure and multivariable

transmitters. Two isolate valves provide instrument isolation and

one equalize valve is positioned between the high and low process

connections. In addition, two drain/vent valves allow for controlled

venting, 100 percent capture of vented or drained process, and

simplified in-process calibration capability.

Rosemount 305 Manifolds and 304 (Wafer)

Five-valve natural gas

The 5-valve natural gas configuration is available on the

Rosemount 305 and 304 Manifolds for use with differential

pressure and multivariable transmitters. Two isolate valves provide

instrument isolation and a single drain/vent valve allows for

controlled venting, 100 percent capture of vented or drained

process, and simplified in-process calibration capability. In

addition, two equalize valves provide extra protection from

leaking to ensure DP signal integrity.

“NG” option includes wide handle pattern and soft seats for ease

of use as well as a larger bore to reduce plugging

Rosemount 305 Manifolds and 304 (Traditional)

Note

Vent ports receive plastic caps to protect threaded

connections unless otherwise noted.

Note

Plugged connections receive 1/4-in. NPT plugs unless

otherwise noted.

Ordering information

Rosemount Manifolds can be ordered as a stand-alone product or

as an integrated assembly attached to a transmitter.

Stand-alone manifold

1. Reference the “Selection guide” on page 2 for assistance on

choosing the type of manifold.

2. Specify a completed model number by referencing the

applicable ordering table for the selected manifold type:

Rosemount 305 Integral Manifold, see page 5.

Rosemount 306 In-line Manifold, see page 7.

Rosemount 304 Conventional Manifold, see page 9.

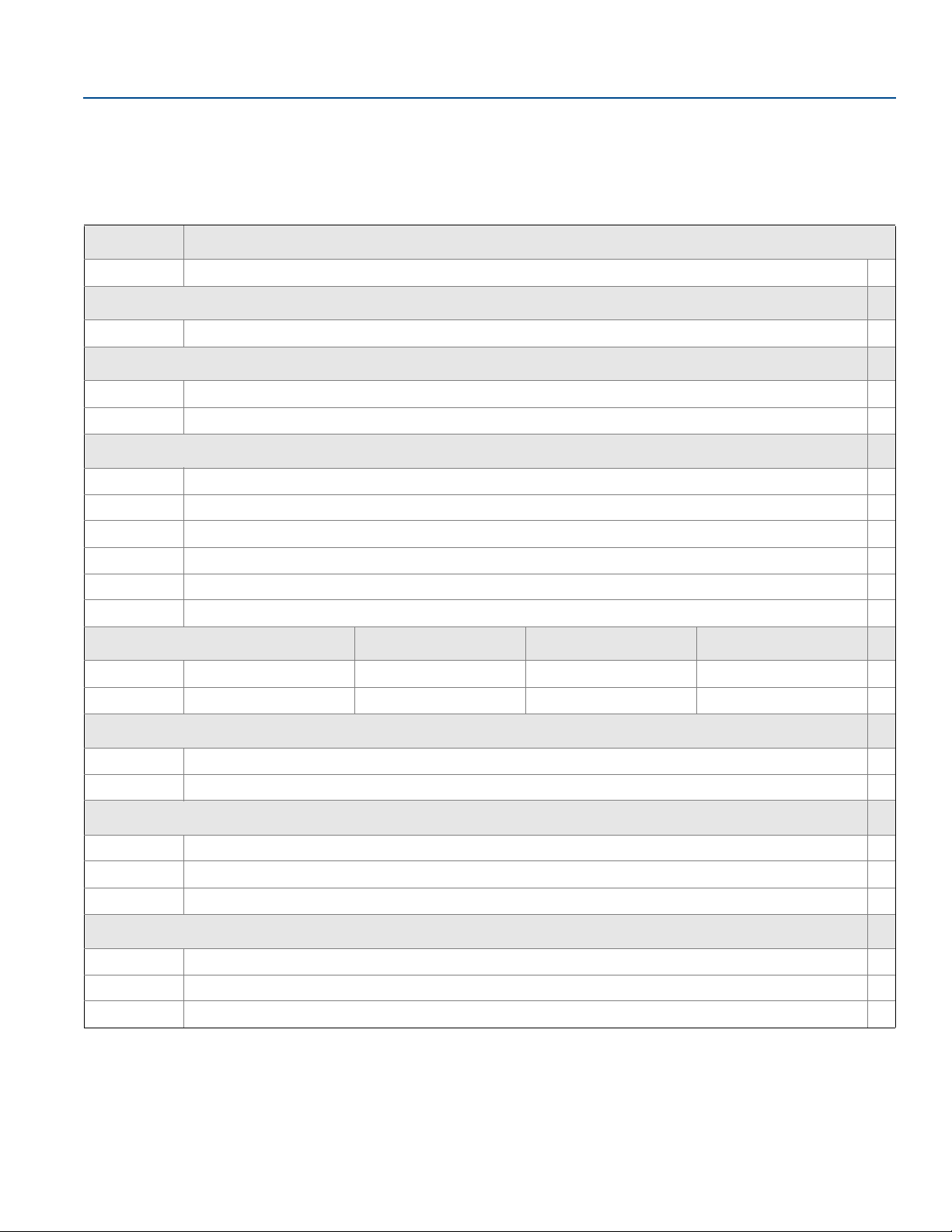

Transmitter/manifold assembly

1. Specify a completed Rosemount transmitter model number

by referencing the applicable product data sheet.

2. Specify a completed manifold model number by referencing

the applicable ordering table for the selected manifold type:

Rosemount 305 Integral Manifold, see page 5.

Rosemount 306 In-line Manifold, see page 7

Rosemount 304 Conventional Manifold, see page 9.

3. Verify the transmitter model number contains the correct

“Process Connection” code or “Manifold Option” code for

the desired transmitter manifold assembly (see Table 1).

Transmitter

Vent

Vent

Equalize

Process

IsolateIsolate

Transmitter

Equalize

Process

Equalize

Process

IsolateIsolate

(plugged)(plugged)

Vent

(closed)

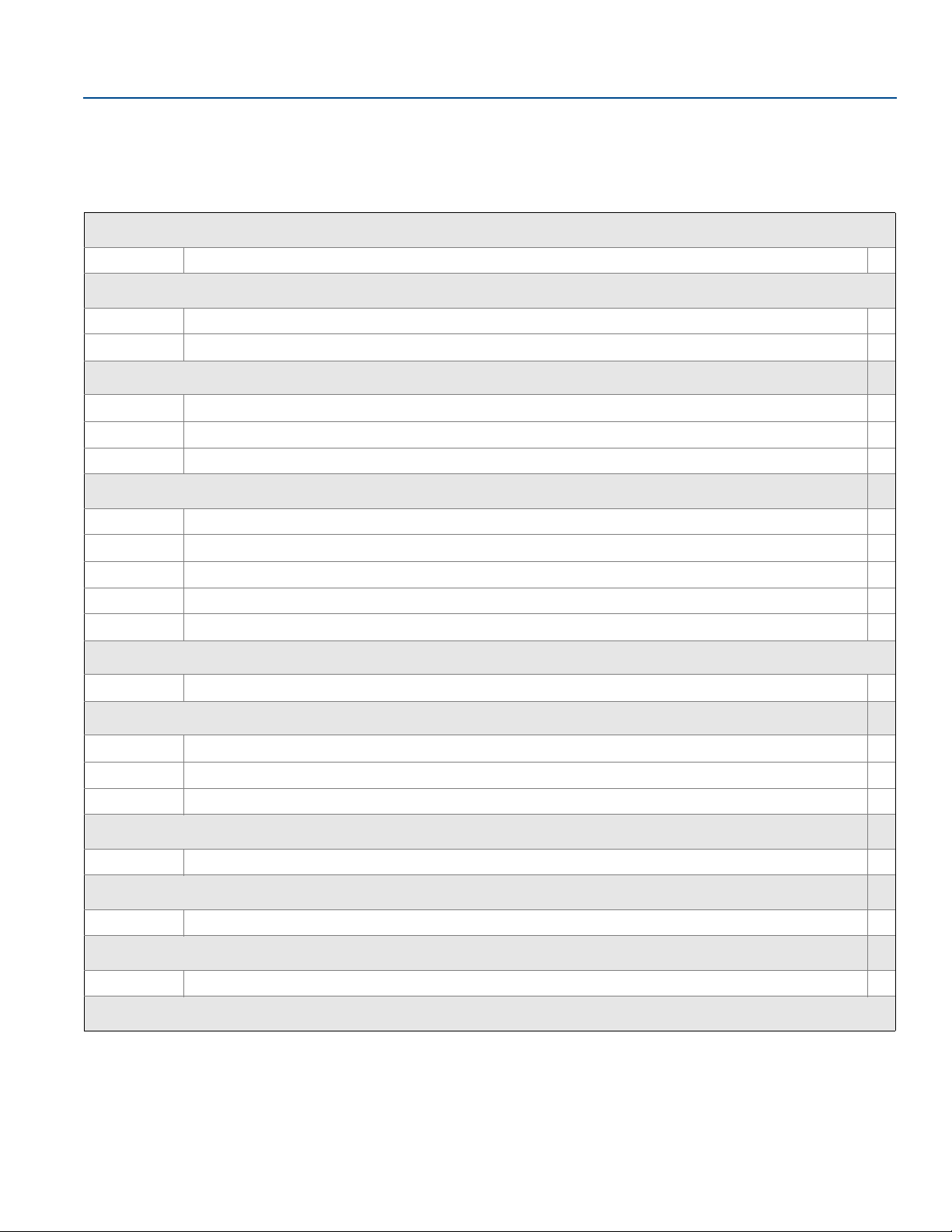

Table 1. Ordering Codes for a Transmitter/Manifold

Assembly

Transmitter Manifold Process

connection code

“Manifold”

option code

Rosemount

3051S

305 A11 N/A

306 A11 N/A

304 A12 N/A

Rosemount

3051/2051

305 N/A S5

306 N/A S5

304 N/A S6

Rosemount

2088

305 N/A N/A

306 N/A S5

304 N/A N/A