[SM-P00045-A/2] -3-

UNPACKING (Chapter 3.)

Bags containing solenoid valves should be opened only when you

are ready to connect the valves to the pipes immediately afterward.

yIf bags are opened before the valves are ready to be connected to

the pipes, the entry of foreign matter from the piping ports could

cause the solenoid valves to fail or malfunction.

INSTALLATION (Chapter 4.)

If you have to use the product under conditions that are different

from the specified conditions or if you intend to use the product for

a special application, be sure to consult us about the product

specifications before using the product.

ENVIRONMENT (Section 4.1)

a) In a dusty environment, foreign matter may enter even

through the exhaust port.

yForeign matter may go into the inside of a solenoid valve by the

direction of an exhaust port, which may cause inhalation of foreign

matter near the exhaust port. Attach a silencer to the exhaust port

or have the exhaust port face downward.

b) Keep the solenoid valve system dry. Take care to avoid direct

contact with dripping water or splashes of cutting oil.

yIf the solenoid valve system is wet by a direct contact with water or

cutting oil, an electrical leak or burnt solenoid coils may result.

Protect the solenoid valve system by using a cover or by installing

it inside a paneled casing. If the cylinder rod is splashed with

cutting oil, the oil may penetrate through the cylinder into the

secondary side piping of the solenoid valve. This must be

prevented to avoid malfunctions.

c) The coils will produce heat.

yParticularly if the solenoid valve system is installed in a control

board or if the solenoid coils need to be energized for a long time,

consider providing sufficient ventilation to release the heat. The

coils can get very hot.

yThe coil temperature may be raised with the ambient temperature

and/or energization time, thus pay sufficient attention when

touching the valves.

d) Do not use the solenoid valve system in an atmosphere that

includes a corrosive gas or solvent vapors.

yDo not use the solenoid valve system in an atmosphere that

includes a corrosive gas such as the sulfur dioxide gas or in an

atmosphere that includes solvent vapors.

e) Vibration resistance and shock resistance

yDo not subject the solenoid valve system to vibrations 50m/s2or

stronger or shocks 300m/s2or stronger.

f) Avoid using the solenoid valve system in a humid environment

because the humidity is likely to cause condensation with a

change in the temperature.

g) Do not use the normal type solenoid valves for an application

that requires conformity with explosion-proof specifications.

Choose explosion-proof solenoid valves instead.

h) The packing and gaskets may deteriorate sooner than usual if

used in an atmosphere with a higher than normal density of

ozone (for example, the atmosphere near a beach or in an area

with frequent thunderstorms).

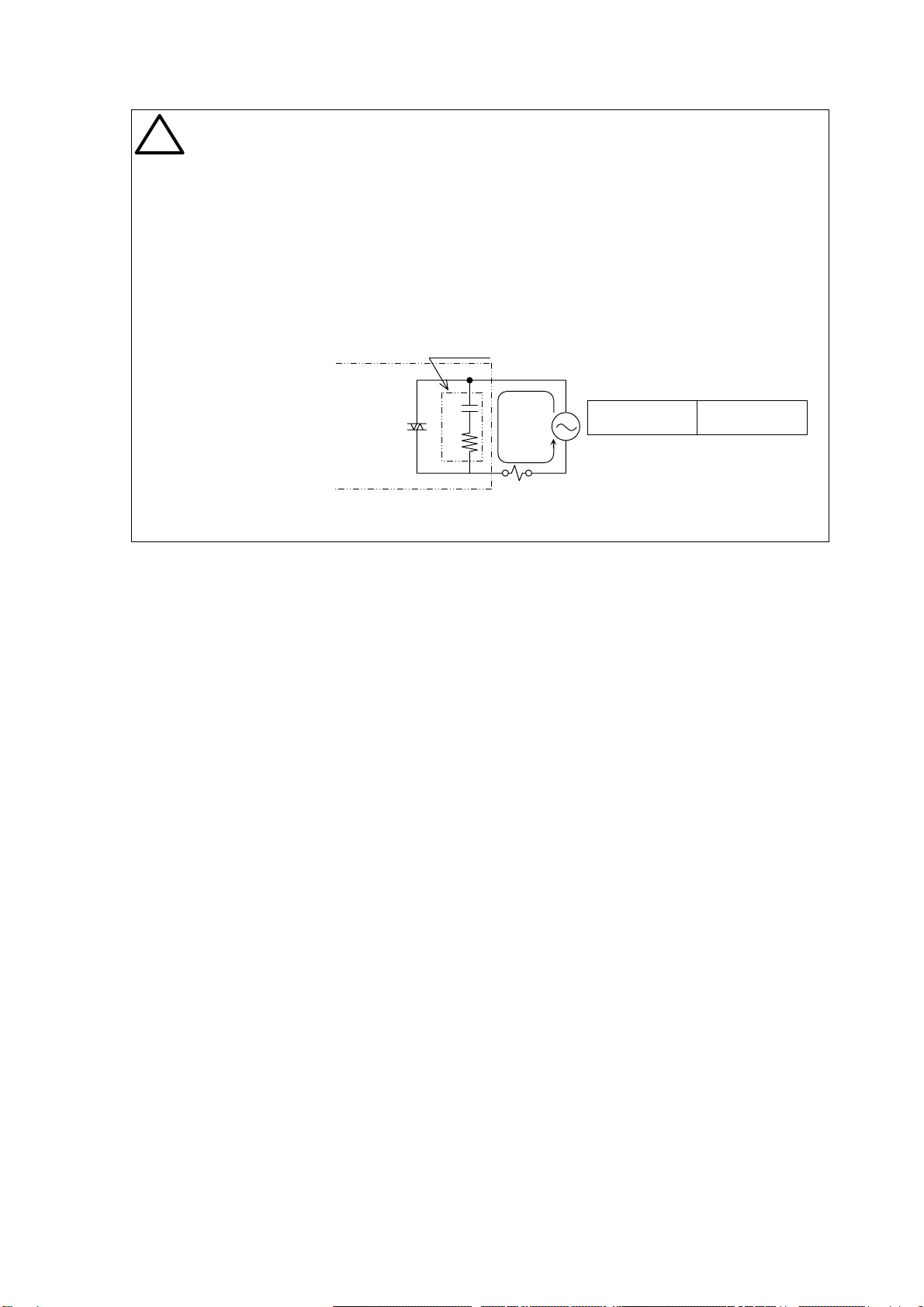

i)There is no resistance to surges caused by overvoltage from

switching and lightning transients(CE Marking :IEC61000-4-5).

Please take measures against surges on the equipment side.

!

WARNING :

!

CAUTION :

!

CAUTION :