4Product-specific information

8

Product-specific information

•The measuring instrument being dropped or any other comparable

mechanical stress may cause breakage of the pipe pieces in the refrigerant

hoses. The valve positioners may also suffer damage, causing further

damage inside the measuring instrument that is not necessarily visible

externally. Therefore, always replace the refrigerant hoses with new ones

after the measuring instrument is dropped or after any comparable

mechanical stress. For your own safety, you should return the measuring

instrument to the Testo Customer Service for technical inspection.

•Electrostatic charging may destroy the instrument. Integrate all the

components (system, manifold's valve block, refrigerant bottle, etc.) into the

potential bonding (earthing). Please see the safety instructions for the

system and the refrigerant used.

•Refrigerant gases can harm the environment. Please note the applicable

environmental regulations.

•Use with A2L refrigerants

Testo measuring instruments (as of July 2020) can be used in compliance

with the prescribed laws, standards, directives and safety regulations for

refrigeration systems and refrigerants as well as regulations of the

manufacturers of refrigerants of safety group A2L as per ISO 817.

Regional standardization and interpretation must always be observed.

For example, DIN EN 378-Part 1-4 applies to the scope of the EN

standards.

During maintenance work, the employer must ensure that a hazardous

explosive atmosphere is prevented (see also: TRBS1112, TRBS2152

VDMA 24020-3).

A hazardous and potentially explosive atmosphere must be anticipated

during maintenance and repair work on refrigeration systems with

flammable refrigerants (e.g. those of category A2L and A3).

Maintenance, repairs, removal of refrigerants and commissioning of

systems may only be carried out by qualified personnel.

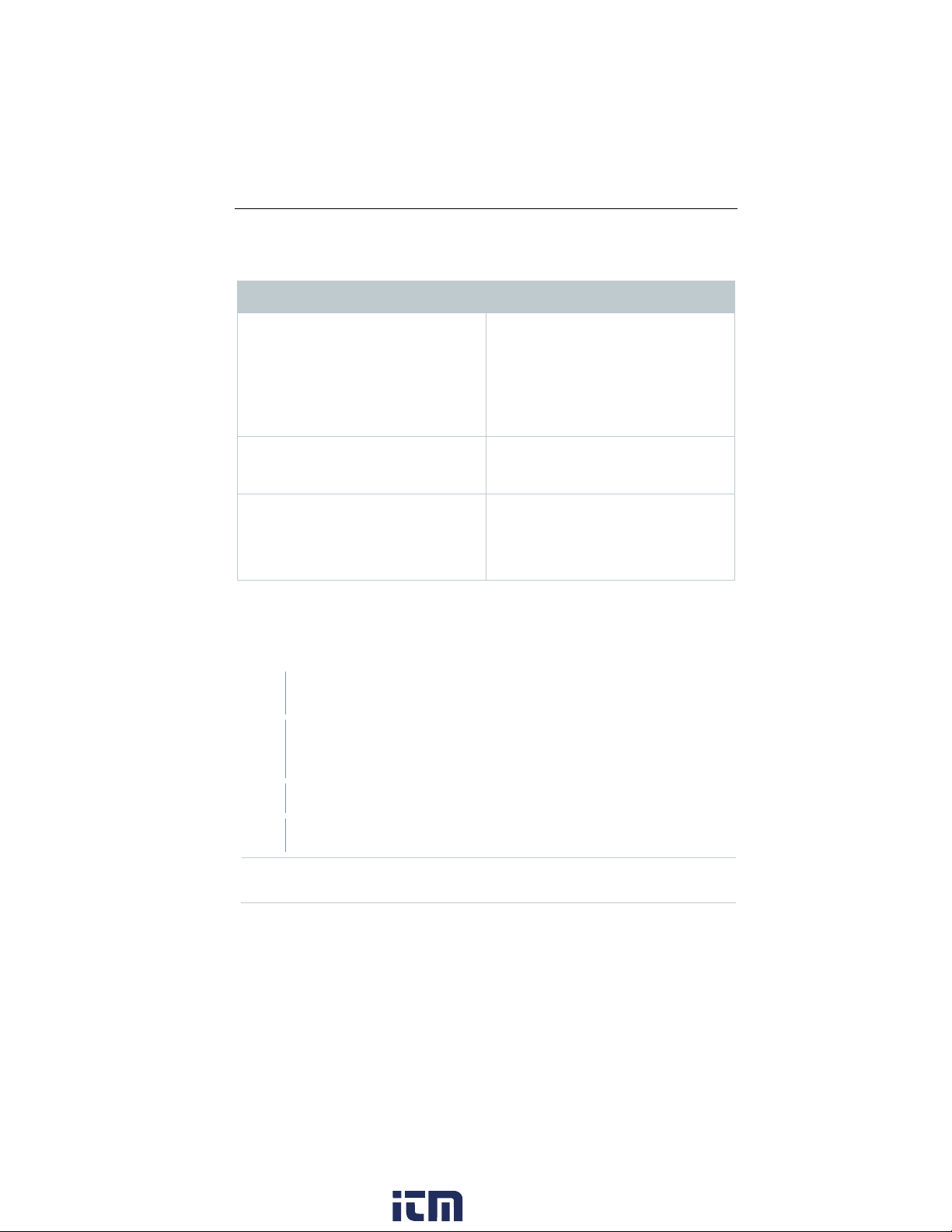

Use

testo 550s and testo 557s are digital manifolds for maintenance and service

work refrigeration systems, heat pumps, and other air conditioning systems.

They may only be used by qualified authorized personnel.

The functions of the instruments testo 550s and testo 557s mean they can

replace mechanical manifolds, thermometers and pressure/temperature charts.

Pressures and temperatures can be applied, adapted, tested and monitored.

The instruments testo 550s and testo 557s are compatible with most non-

corrosive refrigerants, water and glycol. The instruments testo 550s and testo

557s are not compatible with refrigerants containing ammonia.

The products must not be used in potentially explosive atmospheres!

www. .com information@itm.com1.800.561.8187