LOCKSHIELDS WITH FLOW METER

FLOW REGULATION AND ISOLATION DEVICE WITH SET CALIBRATION

MEMORY AND REGULATED FLOW DISPLAY SYSTEM.

SIMPLE, DIRECT CALIBRATION BY MEANS OF INDICATOR THAT

DISPLAYS THE CIRCUIT FLOW.

THE SPECIAL DESIGN ALSO MAKES IT POSSIBLE TO CLEAN THE WIN-

DOW OR REPLACE THE ENTIRE MEASUREMENT COMPONENT WITHOUT

DRAINING THE SYSTEM.

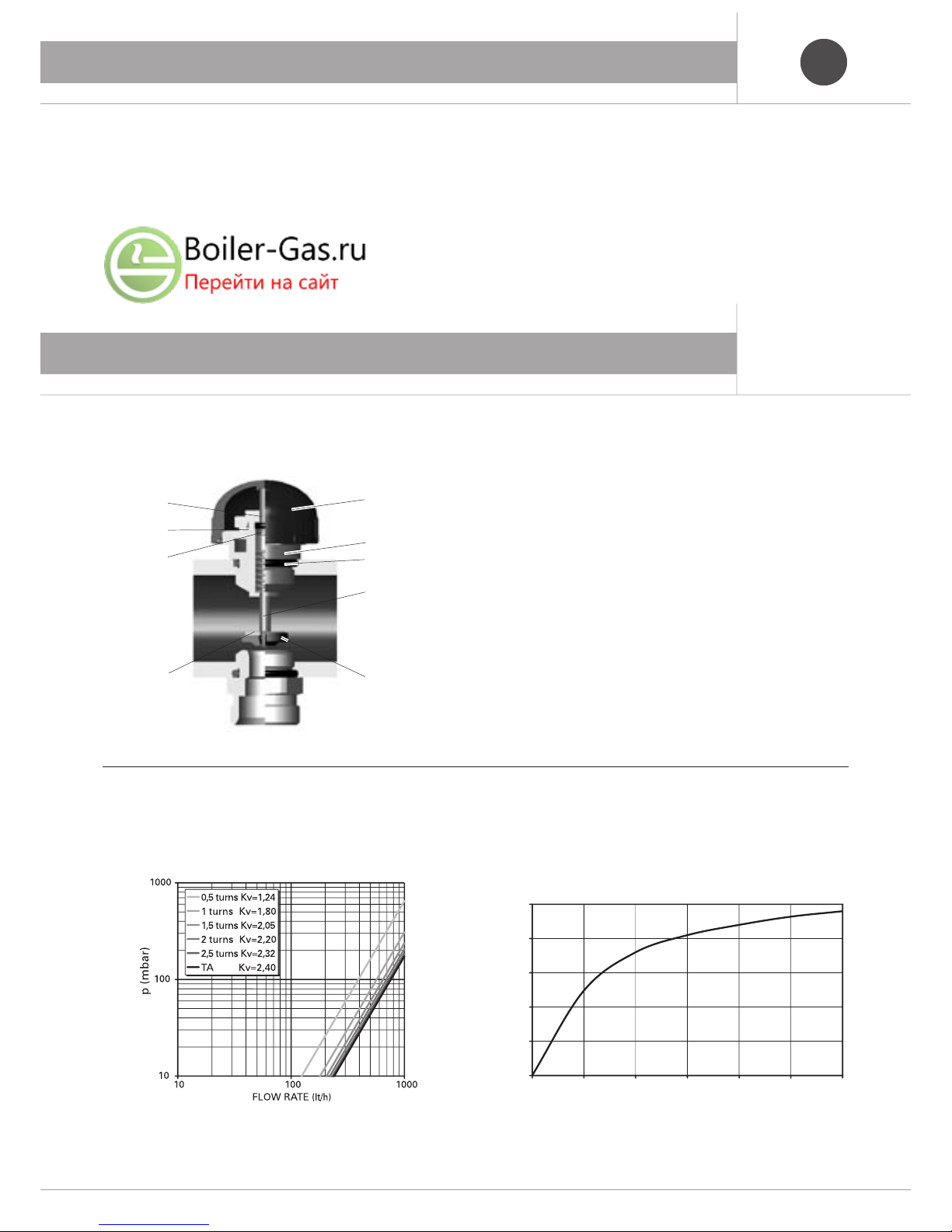

• MEASUREMENT FIELD 0-4 l/min

• INDICATION ERROR ± 10% OFF SCALE

• MAX WORKING PRESSURE 6 bar

• MAX WORKING TEMPERATURE 90 °C

• PRESSURE DROPS Kv from 0,15 (1 l/min)

to 0,55 (4 l/min)

• MAX PRESSURE DROP (OFF SCALE) Kv = 0,9

5

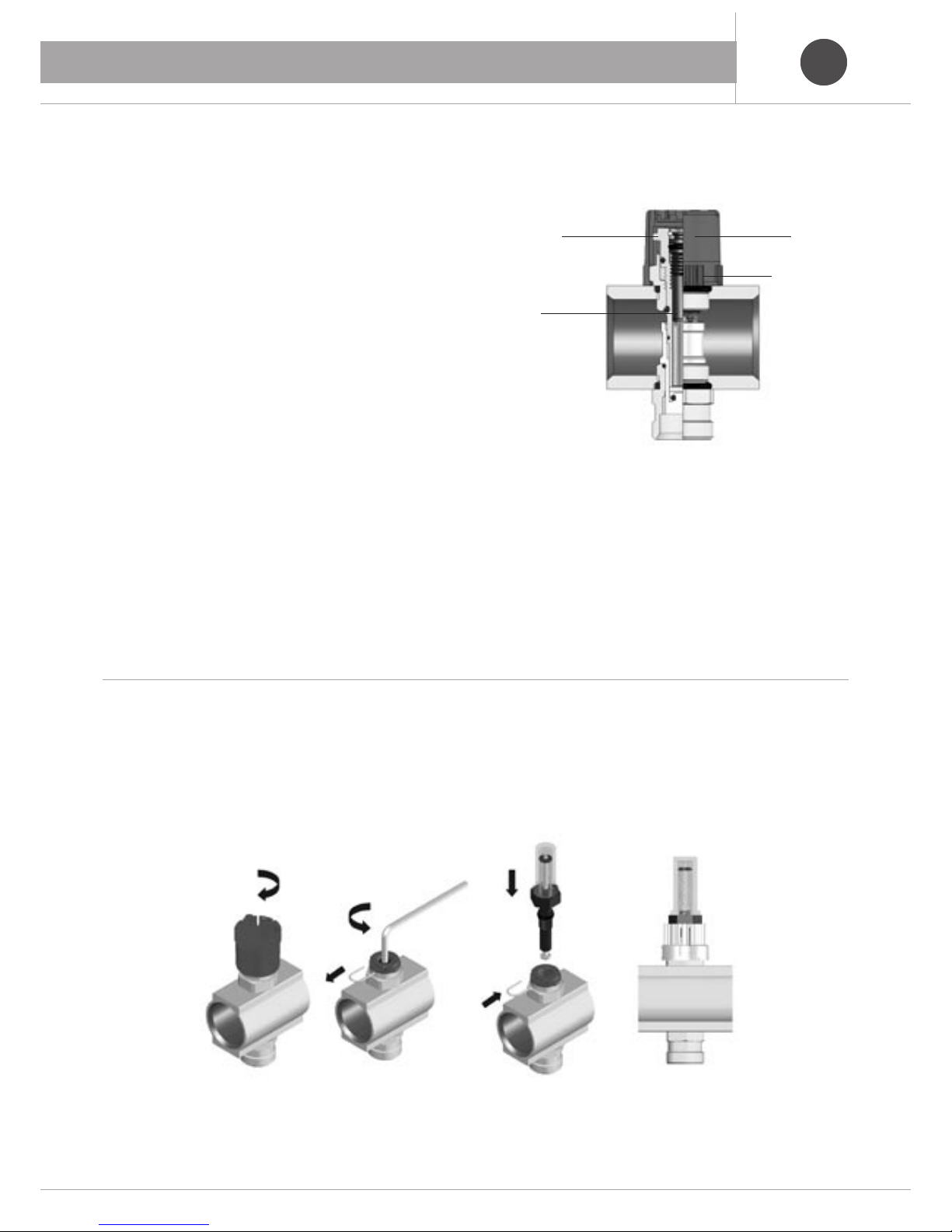

ADJUSTMENT

THE ADJUSTMENT OPERATION IS CARRIED OUT IN THE FOLLOWING WAY:

FIRST RAISE THE WHITE RING NUT. THE ISOLATING FUNCTION IS

SUPPLIED IN THE FULLY CLOSED POSITION. CARRY OUT THE FOLLOWING

ACTIVITY UNDER FLOW CONDITIONS. NOTE, IT IS NOT NECESSARY TO

USE TOOLS WHEN ADJUSTING, ONLY WHEN SERVICING.

1. TURN THE RING NUT A, ANTICLOCKWISE UNTIL THE LOCKSHIELD

ISOLATOR IS COMPLETELY OPEN.

2. LOWER THE RING NUT A, AND CALIBRATE USING THE ADJUSTER B,

UNTIL THE CORRECT FLOW IS REACHED (DIRECTLY INDICATED BY THE

LOADING CAPACITY FLOW SCALE IN THE CLEAR WINDOW).

3. RAISE THE RING NUT A, UNTIL IT CLICKS, INDICATING THAT IT IS IN

THE CORRECT POSITION.

IT IS ALSO POSSIBLE TO SEAL THE RING NUT INTO THIS POSITION USING

A LEAD SEAL AND THE HOLES IN THE VANES C TO FASTEN IT:

• DIRECTLY TO THE MANIFOLD, PREVENTING AND TAMPERING

• TO THE FLOW METER, MAKING IT POSSIBLE TO INTERCEPT THE FLOW

WITHOUT CHANGING THE SET CALIBRATION FOR MAXIMUM OPENING.

CLEANING THE WINDOW

• TURN THE RING NUT, A, CLOCKWISE, UNTIL THE LOCKSHIELD ISOLA-

TING FUNCTION IS COMPLETELY CLOSED

• REMOVE THE WINDOW BY SECURING ADJUSTER B,

AND USING HAND PRESSURE OR A 17 mm RING SPANNER, REMOVE

THE WINDOW GENTLY.

• CLEAN THE WINDOW AND SCREW IT BACK ON.

• TURN THE RING NUT, A, ANTI-CLOCKWISE, UNTIL THE LOCKSHIELD IS

COMPLETELY OPEN

1. MANIFOLD SYSTEM