EMPERO EMP.HA.01 User manual

1

DOUGH ROLLER

CONTENTS

A GENERAL INFORMATION Page 2

A1 PRODUCT DESCRIPTION Page 3

A2 TECHNICAL INFORMATION Page 3

A3 TRANSPORTATION Page 4

A4 UNPACKING Page 4

B INSTALLATION Page 4

C SAFETY INSTRUCTIONS Page 5

D OPERATION Page 6

E CLEANING & MAINTENANCE Page 7

F TROUBLESHOOTING Page 8

G SPARE PART LIST- EXPLODING DRAWINGS Page 9

H ELECTRIC CIRCUIT SCHEMA Page 17

2

DOUGH ROLLER

A GENERAL INFORMATION

Before installing the appliance, read operation and maintenance instructions

carefully.Wrong installation and part changing may damage the product or may cause

injury on people.These are not in our company’s responsibility to damage the

appliance intentionally,negligence,detriments because of disobeying instructions and

regulations,wrong connections.Unauthorized intervention to appliance invalidates the

warranty.

1. This instruction manual should be kept in a safe place for future reference.

2. Installation should be made in accordance with ordinances and security rules of

that country by a qualified service personnel.

3. This appliance has to be used by trained person.

4. Please turn off the appliance immediately in the event of malfunction or failure.The

appliance should be repaired only by authorized service personnel.Please demand

original spare part.

3

DOUGH ROLLER

A1 PRODUCT DESCRIPTION

*Professional Dough Roller ,that provides high efficiency has been designed to be used in

industrial kitchens.

Product Code

Dimensions (mm)

Weight (kg)

Packaging

Dimensions (mm)

EMP.HA.01

530x550x650

41

550x500x800

EMP.HA.02

430x550x650

37

560x520x770

EMP.HA.01.Y

530x550x650

41

600x550x770

EMP.HA.02.Y

430x550x650

37

560x600x770

EMP.HA.03

910x575x535

63

950x630x550

A2 TECHNICAL INFORMATION

Product

Code

Roller

Dimensions

(mm)

Operating

Frequency

(Hz)

Power

(Kw)

Operating

Voltage

(V)

Cable

(mm²)

Fuse

(A)

EMP.HA.01

400

50

0,25

220

3x1,5

16

EMP.HA.02

300

50

0,25

220

3x1,5

16

EMP.HA.01.Y

400

50

0,25

220

3x1,5

16

EMP.HA.02.Y

300

50

0,25

220

3x1,5

16

EMP.HA.03

550

50

0,75

220-240

3x1,5

16

4

DOUGH ROLLER

A3 TRANSPORTATION

*This appliance can be moved by hand from area to area.Do not crash and drop the appliance

while transporting.

A4 UNPACKING

*Please unpack the package according to the security codes and ordinances of current

country and get rid from the pack.Parts which contacts with food are produced by stainless

steel.All plastic parts are marked by material’s symbol.

*Please check that all the parts of appliance had come completely and if they are damaged or

not during the shipping.

B INSTALLATION

*Please place the product to the straight and sturdy ground,please take necessary steps

against possibility of overturn.

*Technician who will serve for installation and service for the appliance must be professional

on this subject and must have installation and service licenses by the company.

*Connection to Electric Power Supply must be done by authorized person.

*Please be sure that the voltage connected to appliance must be equal with the voltage which

is on appliance’s label.

This appliance must be connected to an earthed outlet in accordance with safety rules

and standards.

*Appliance’s earthing must be connected to earthing line on panel which is nearest to electric

installation.

*Connection to the main fuse and leak current fuse must be done in accordance with the

current regulations.

!

5

DOUGH ROLLER

C SAFETY INSTRUCTIONS

*Do not use the appliance in insufficient lighted place.

*Do not touch the moving attachments while the appliance operates.

*Do not install the appliance in the presence of flammable or explosive materials.

*Do not operate the appliance when the machine is empty.

*Do not load so less or more than appliance’s capacity.

*Do not attempt to use the appliance without suitable protective equipments.

*Because of any reason if there is a fire or flame flare where the appliance is

used,turn off all gas valves and electric contactor switch quickly and use fire

extinguisher .Never use water to extinguish the fire.

*All the damages because of not having earthing connection will not be on

warranty.

*Do not put your hands between rollers while the appliance is going on dough rolling

process.

!

!

!

!

!

!

!

6

DOUGH ROLLER

D OPERATION

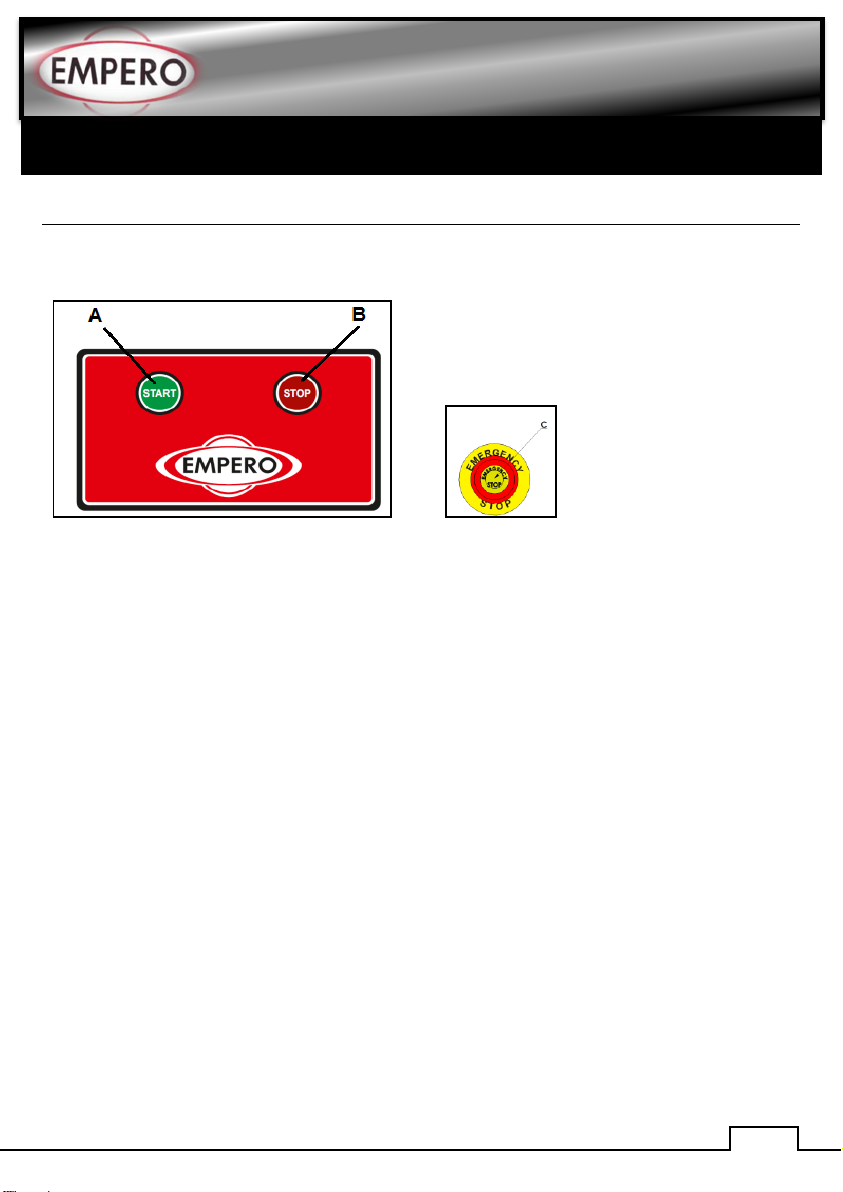

*Control Panel;

A: START Button

B: STOP Button

C: Urgent Stop Button

*Operating;

•Before operating,clean the rollers and body with a wet cloth and dry.

•For adjusting the thickness of dough,pull the latches near the roller slowly to unsettle the

pin.In this way when you turn the latch up; the dough will be thin,,when you turn the latch

down;the dough will be thick.

•After adjusting the thickness provide the latch pin to pass into circular places.

•For operating the appliance be sure that URGENT STOP BUTTON must be unpressed

and press the START BUTTON.

•In order to prevent the dough pieces to stick on the rollers,be sure that the rollers are

floured.

•Keep upper roller at least 2 stage thicker than lower roller in order to prevent the dough to

wrap up the roller and to provide dough balls pass through roller.

•In order to obtain pitta dough,provide the dough balls pass through upper roller,if you

reach desired thickness provide it pass through lower roller.

•In order to obtain the pizza dough ; dough balls that pass through upper roller must be

turned to opposite way that it comes and it should be enlarged by passing through upper

roller and then it should be passed through lower roller.

•Turn off the appliance by pressing STOP button after dough rolling process.

7

DOUGH ROLLER

E CLEANING &MAINTENANCE

➢CLEANING AND MAINTENANCE AFTER EVERY USE

•Always turn off the appliance and disconnect from the power supply before cleaning.

•Clean outer surface of appliance and rollers with wet cloth and dry after every use.

•Do not clean the rollers with blade or cutting tool.Otherwise circular forms of rollers

may be disrupted.

•Do not use abrasive cleaning chemicals as these can leave harmful residues.

•Do not clean the appliance by spraying water directly,otherwise electric motor may

get damaged.

➢PERIODIC CLEANING AND MAINTENANCE

•Maintenance should be done by qualified person.

•Get the periodic maintenance of the appliance once in every 15 days.

•Dough Roller requires low maintenance (Motor and ball bearings are lubricated).

•Gear Boxes must be lubricated particularly once in a month with grease .

•Maintenance of appliance’s contactor should be done by compressed air according

to frequency of use.

•When there is dough residues accumulated on roller scraper,clean the rollers by

ripping off the springs .

8

DOUGH ROLLER

F TROUBLESHOOTING

THE APPLIANCE DOESN’T OPERATE

1. Check if the appliance is plugged in.

2. Check the electrical connections and

voltage.

3. Check the urgent stop button.

4. Check the start button if it works or not.

5. Check that if there is problem with

contactor.

ROLLERS STOPPED

1. If the rollers stop during the

operation,check the tension of belt.

DOUGH IS NOT ROLLED DESIRED

THICKNESS

1. Check thickness setting of rollers.

2. Check the latch pins.

•If dough rolling is not done at suitable quality

•If any function of security doesn’t work

➢Do not use the appliance.

*If these problems are still going on,contact with our authorized service.

9

DOUGH ROLLER

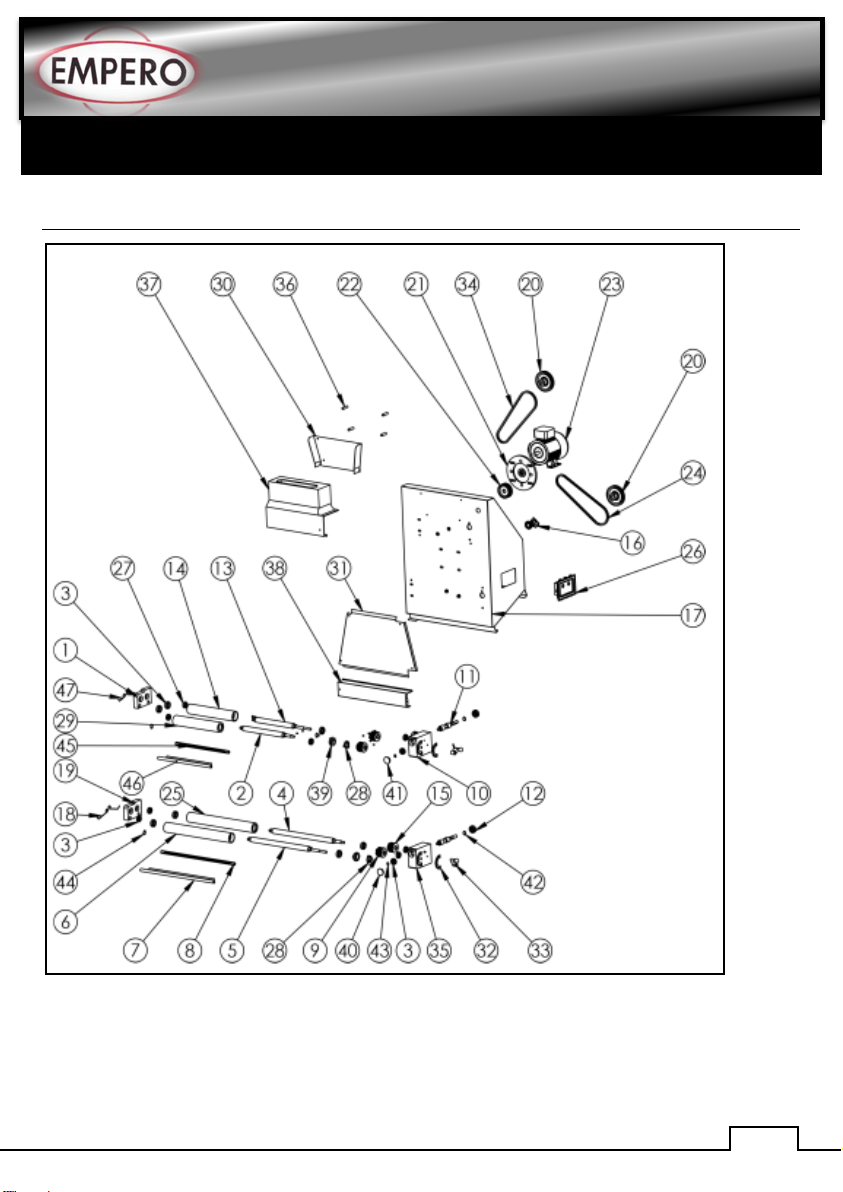

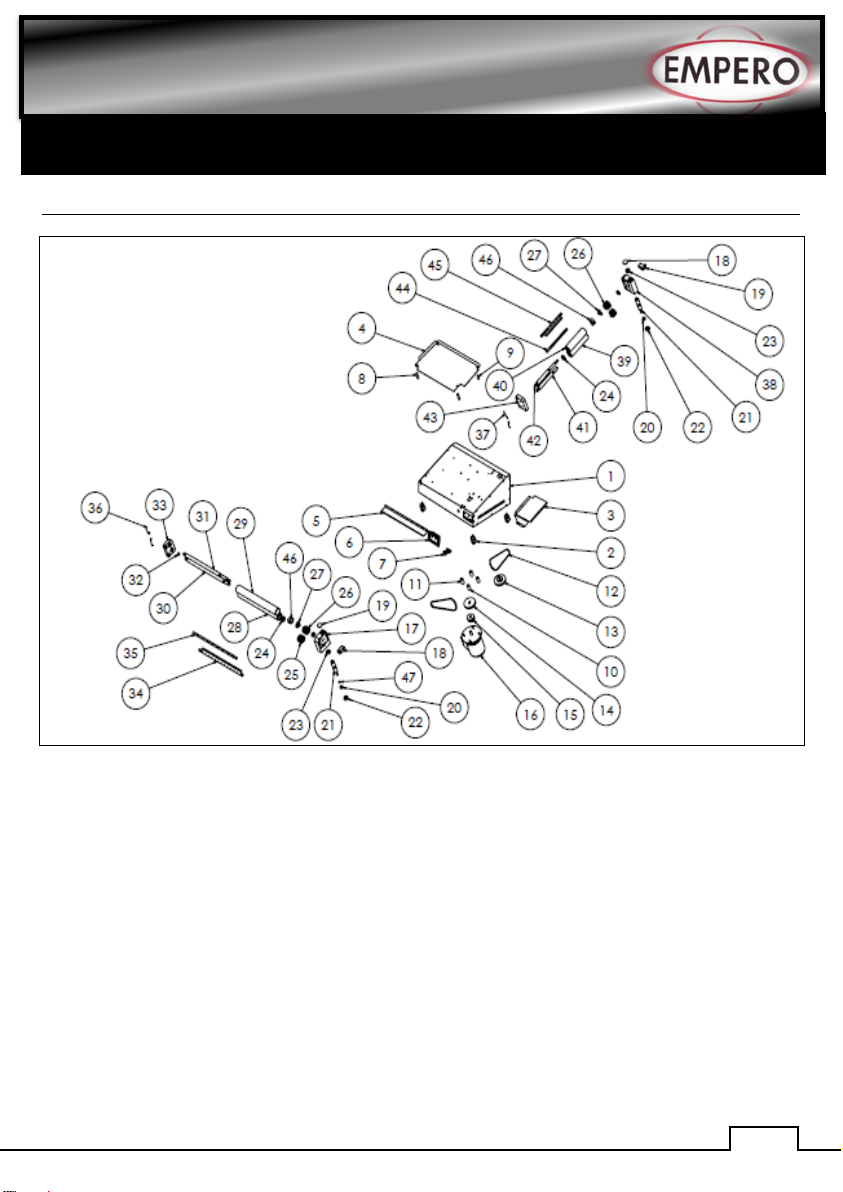

G SPARE PART LIST- EXPLODING DRAWINGS

EMP.HA.01Y-HA.02Y

10

DOUGH ROLLER

G SPARE PART LIST- EXPLODING DRAWINGS

PRODUCT CODE:EMP.HA.01.Y

NO

PRODUCT NAME

P.CODE

1

TOP GEARBOX EQUIVALENT

Y.EMP.HA.01.Y.001

2

TOP FRONT ROLLER SHAFT

Y.EMP.HA.01.Y.002

3

BALL BEARING (6200)

Y.EMP.HA.01.Y.003

4

BOTTOM BACK ROLLER SHAFT

Y.EMP.HA.01.Y.004

5

BOTTOM FRONT ROLLER SHAFT

Y.EMP.HA.01.Y.005

6

BOTTOM FRONT ROLLER

Y.EMP.HA.01.Y.006

7

BOTTOM FRONT CLEANING BLADE

Y.EMP.HA.01.Y.007

8

BOTTOM BACK CLEANING BLADE

Y.EMP.HA.01.Y.008

9

FRONT GEAR

Y.EMP.HA.01.Y.009

10

TOP GEARBOX

Y.EMP.HA.01.Y.010

11

WORM SHAFT

Y.EMP.HA.01.Y.011

12

BALL BEARING (6202)

Y.EMP.HA.01.Y.012

13

TOP BACK ROLLER SHAFT

Y.EMP.HA.01.Y.013

14

TOP BACK ROLLER

Y.EMP.HA.01.Y.014

15

BACK GEAR

Y.EMP.HA.01.Y.015

16

URGENT STOP

Y.EMP.HA.01.Y.016

17

BASE FRAME

Y.EMP.HA.01.Y.017

18

BOTTOM SPRING

Y.EMP.HA.01.Y.018

19

BOTTOM GEARBOX EQUIVALENT

Y.EMP.HA.01.Y.019

20

GEARBOX PULLEY

Y.EMP.HA.01.Y.020

21

MOTOR FLANGE

Y.EMP.HA.01.Y.021

22

MOTOR PULLEY

Y.EMP.HA.01.Y.022

23

MOTOR

Y.EMP.HA.01.Y.023

24

BELT (8*675)

Y.EMP.HA.01.Y.024

25

BOTTOM BACK ROLLER

Y.EMP.HA.01.Y.025

26

PANEL

Y.EMP.HA.01.Y.026

27

BALL BEARING (6003)

Y.EMP.HA.01.Y.027

28

PRONG FLAKE (PLASTIC)

Y.EMP.HA.01.Y.028

29

TOP FRONT ROLLER

Y.EMP.HA.01.Y.029

30

TOP SLIDING SHEETMETAL

Y.EMP.HA.01.Y.030

31

BOTTOM SLIDING SHEETMETAL

Y.EMP.HA.01.Y.031

32

ADJUSTMENT SHEETMETAL

Y.EMP.HA.01.Y.032

33

ADJUSTMENT PIN

Y.EMP.HA.01.Y.033

34

PRONG FLAKE

Y.EMP.HA.01.Y.034

35

BELT (8*725)

Y.EMP.HA.01.Y.035

36

BOTTOM GEARBOX

Y.EMP.HA.01.Y.036

37

DOUGH ROUTING SHEETMETAL

Y.EMP.HA.01.Y.037

38

PLASTIC PIN

Y.EMP.HA.01.Y.038

39

TOP HANDLE SAFETY

Y.EMP.HA.01.Y.039

40

BOTTOM HANDLE SAFETY

Y.EMP.HA.01.Y.040

41

STOPPER (BOTTOM)

Y.EMP.HA.01.Y.041

42

STOPPER (TOP)

Y.EMP.HA.01.Y.042

43

SEGMAN 471-10

Y.EMP.HA.01.Y.043

44

SEGMAN 471-15

Y.EMP.HA.01.Y.044

45

SEGMAN 471-17

Y.EMP.HA.01.Y.045

46

TOP SPRING

Y.EMP.HA.01.Y.046

47

TOP BACK CLEANING BLADE

Y.EMP.HA.01.Y.047

48

TOP FRONT CLEANING BLADE

Y.EMP.HA.01.Y.048

11

DOUGH ROLLER

G SPARE PART LIST- EXPLODING DRAWINGS

PRODUCT CODE:EMP.HA.02.Y

NO

PRODUCT NAME

P.CODE

1

TOP GEARBOX EQUIVALENT

Y.EMP.HA.02.Y.001

2

TOP FRONT ROLLER SHAFT

Y.EMP.HA.02.Y.002

3

BALL BEARING (6200)

Y.EMP.HA.02.Y.003

4

BOTTOM BACK ROLLER SHAFT

Y.EMP.HA.02.Y.004

5

BOTTOM FRONT ROLLER SHAFT

Y.EMP.HA.02.Y.005

6

BOTTOM FRONT ROLLER

Y.EMP.HA.02.Y.006

7

BOTTOM FRONT CLEANING BLADE

Y.EMP.HA.02.Y.007

8

BOTTOM BACK CLEANING BLADE

Y.EMP.HA.02.Y.008

9

FRONT GEAR

Y.EMP.HA.02.Y.009

10

TOP GEARBOX

Y.EMP.HA.02.Y.010

11

WORM SHAFT

Y.EMP.HA.02.Y.011

12

BALL BEARING (6202)

Y.EMP.HA.02.Y.012

13

TOP BACK ROLLER SHAFT

Y.EMP.HA.02.Y.013

14

TOP BACK ROLLER

Y.EMP.HA.02.Y.014

15

BACK GEAR

Y.EMP.HA.02.Y.015

16

URGENT STOP

Y.EMP.HA.02.Y.016

17

BASE FRAME

Y.EMP.HA.02.Y.017

18

BOTTOM SPRING

Y.EMP.HA.02.Y.018

19

BOTTOM GEARBOX EQUIVALENT

Y.EMP.HA.02.Y.019

20

GEARBOX PULLEY

Y.EMP.HA.02.Y.020

21

MOTOR FLANGE

Y.EMP.HA.02.Y.021

22

MOTOR PULLEY

Y.EMP.HA.02.Y.022

23

MOTOR

Y.EMP.HA.02.Y.023

24

BELT (8*675)

Y.EMP.HA.02.Y.024

25

BOTTOM BACK ROLLER

Y.EMP.HA.02.Y.025

26

PANEL

Y.EMP.HA.02.Y.026

27

BALL BEARING (6003)

Y.EMP.HA.02.Y.027

28

PRONG FLAKE (PLASTIC)

Y.EMP.HA.02.Y.028

29

TOP FRONT ROLLER

Y.EMP.HA.02.Y.029

30

TOP SLIDING SHEETMETAL

Y.EMP.HA.02.Y.030

31

BOTTOM SLIDING SHEETMETAL

Y.EMP.HA.02.Y.031

32

ADJUSTMENT SHEETMETAL

Y.EMP.HA.02.Y.032

33

ADJUSTMENT PIN

Y.EMP.HA.02.Y.033

34

PRONG FLAKE

Y.EMP.HA.02.Y.034

35

BELT (8*725)

Y.EMP.HA.02.Y.035

36

BOTTOM GEARBOX

Y.EMP.HA.02.Y.036

37

DOUGH ROUTING SHEETMETAL

Y.EMP.HA.02.Y.037

38

PLASTIC PIN

Y.EMP.HA.02.Y.038

39

TOP HANDLE SAFETY

Y.EMP.HA.02.Y.039

40

BOTTOM HANDLE SAFETY

Y.EMP.HA.02.Y.040

41

STOPPER (BOTTOM)

Y.EMP.HA.02.Y.041

42

STOPPER (TOP)

Y.EMP.HA.02.Y.042

43

SEGMAN 471-10

Y.EMP.HA.02.Y.043

44

SEGMAN 471-15

Y.EMP.HA.02.Y.044

45

SEGMAN 471-17

Y.EMP.HA.02.Y.045

46

TOP SPRING

Y.EMP.HA.02.Y.046

47

TOP BACK CLEANING BLADE

Y.EMP.HA.02.Y.047

48

TOP FRONT CLEANING BLADE

Y.EMP.HA.02.Y.048

12

DOUGH ROLLER

G SPARE PART LIST- EXPLODING DRAWINGS

EMP.HA.01-HA.02

13

DOUGH ROLLER

G SPARE PART LIST- EXPLODING DRAWINGS

PRODUCT CODE:EMP.HA.01

NO

PRODUCT NAME

P.CODE

1

TOP GEAR BOX EQUIVALENT

Y.EMP.HA.01.001

2

TOP FRONT ROLLER SHAFT

Y.EMP.HA.01.002

3

BALL BEARING (6200)

Y.EMP.HA.01.003

4

BOTTOM BACK ROLLER SHAFT

Y.EMP.HA.01.004

5

BOTTOM FRONT ROLLER SHAFT

Y.EMP.HA.01.005

6

BOTTOM FRONT ROLLER

Y.EMP.HA.01.006

7

BOTTOM FRONT CLEANING BLADE

Y.EMP.HA.01.007

8

BOTTOM BACK CLEANING BLADE

Y.EMP.HA.01.008

9

FRONT GEAR

Y.EMP.HA.01.009

10

TOP GEAR BOX

Y.EMP.HA.01.010

11

WORM SHAFT

Y.EMP.HA.01.011

12

BALL BEARING (6202)

Y.EMP.HA.01.012

13

TOP BACK ROLLER SHAFT

Y.EMP.HA.01.013

14

TOP BACK ROLLER

Y.EMP.HA.01.014

15

BACK GEAR

Y.EMP.HA.01.015

16

URGENT STOP

Y.EMP.HA.01.016

17

BASE FRAME

Y.EMP.HA.01.017

18

BOTTOM SPRING

Y.EMP.HA.01.018

19

BOTTOM GEAR BOX EQUIVALENT

Y.EMP.HA.01.019

20

GEAR BOX EQUIVALENT

Y.EMP.HA.01.020

21

MOTOR FLANGE

Y.EMP.HA.01.021

22

MOTOR PULLEY

Y.EMP.HA.01.022

23

MOTOR

Y.EMP.HA.01.023

24

BELT (8*675)

Y.EMP.HA.01.024

25

BOTTOM BACK ROLLER

Y.EMP.HA.01.025

26

PANEL

Y.EMP.HA.01.026

27

BALL BEARING (6003)

Y.EMP.HA.01.027

28

PRONG FLAKE

Y.EMP.HA.01.028

29

TOP FRONT ROLLER

Y.EMP.HA.01.029

30

TOP SLIDING SHEET METAL

Y.EMP.HA.01.030

31

BOTTOM SLIDING SHEET METAL

Y.EMP.HA.01.031

32

ADJUSTMENT SHEET METAL

Y.EMP.HA.01.032

33

ADJUSTMENT PIN

Y.EMP.HA.01.033

34

BELT (8*725)

Y.EMP.HA.01.034

35

BOTTOM GEAR BOX

Y.EMP.HA.01.035

36

PLASTIC PIN

Y.EMP.HA.01.036

37

TOP HANDLE SAFETY

Y.EMP.HA.01.037

38

BOTTOM HANDLE SAFETY

Y.EMP.HA.01.038

39

PRONG FLAKE (PLASTIC)

Y.EMP.HA.01.039

40

STOPPER (BOTTOM)

Y.EMP.HA.01.040

41

STOPPER (TOP)

Y.EMP.HA.01.041

42

SEGMAN 471-15

Y.EMP.HA.01.042

43

SEGMAN 471-10

Y.EMP.HA.01.043

44

SEGMAN 471-17

Y.EMP.HA.01.044

45

TOP BACK CLEANING BALDE

Y.EMP.HA.01.045

46

TOP FRONT CLEANING BLADE

Y.EMP.HA.01.046

47

TOP SPRING

Y.EMP.HA.01.047

14

DOUGH ROLLER

G SPARE PART LIST- EXPLODING DRAWINGS

PRODUCT CODE:EMP.HA.02

NO

PRODUCT NAME

P.CODE

1

TOP GEAR BOX EQUIVALENT

Y.EMP.HA.02.001

2

TOP FRONT ROLLER SHAFT

Y.EMP.HA.02.002

3

BALL BEARING (6200)

Y.EMP.HA.02.003

4

BOTTOM BACK ROLLER SHAFT

Y.EMP.HA.02.004

5

BOTTOM FRONT ROLLER SHAFT

Y.EMP.HA.02.005

6

BOTTOM FRONT ROLLER

Y.EMP.HA.02.006

7

BOTTOM FRONT CLEANING BLADE

Y.EMP.HA.02.007

8

BOTTOM BACK CLEANING BLADE

Y.EMP.HA.02.008

9

FRONT GEAR

Y.EMP.HA.02.009

10

TOP GEAR BOX

Y.EMP.HA.02.010

11

WORM SHAFT

Y.EMP.HA.02.011

12

BALL BEARING (6202)

Y.EMP.HA.02.012

13

TOP BACK ROLLER SHAFT

Y.EMP.HA.02.013

14

TOP BACK ROLLER

Y.EMP.HA.02.014

15

BACK GEAR

Y.EMP.HA.02.015

16

URGENT STOP

Y.EMP.HA.02.016

17

BASE FRAME

Y.EMP.HA.02.017

18

BOTTOM SPRING

Y.EMP.HA.02.018

19

BOTTOM GEAR BOX EQUIVALENT

Y.EMP.HA.02.019

20

GEAR BOX EQUIVALENT

Y.EMP.HA.02.020

21

MOTOR FLANGE

Y.EMP.HA.02.021

22

MOTOR PULLEY

Y.EMP.HA.02.022

23

MOTOR

Y.EMP.HA.02.023

24

BELT (8*675)

Y.EMP.HA.02.024

25

BOTTOM BACK ROLLER

Y.EMP.HA.02.025

26

PANEL

Y.EMP.HA.02.026

27

BALL BEARING (6003)

Y.EMP.HA.02.027

28

PRONG FLAKE

Y.EMP.HA.02.028

29

TOP FRONT ROLLER

Y.EMP.HA.02.029

30

TOP SLIDING SHEET METAL

Y.EMP.HA.02.030

31

BOTTOM SLIDING SHEET METAL

Y.EMP.HA.02.031

32

ADJUSTMENT SHEET METAL

Y.EMP.HA.02.032

33

ADJUSTMENT PIN

Y.EMP.HA.02.033

34

BELT (8*725)

Y.EMP.HA.02.034

35

BOTTOM GEAR BOX

Y.EMP.HA.02.035

36

PLASTIC PIN

Y.EMP.HA.02.036

37

TOP HANDLE SAFETY

Y.EMP.HA.02.037

38

BOTTOM HANDLE SAFETY

Y.EMP.HA.02.038

39

PRONG FLAKE (PLASTIC)

Y.EMP.HA.02.039

40

STOPPER (BOTTOM)

Y.EMP.HA.02.040

41

STOPPER (TOP)

Y.EMP.HA.02.041

42

SEGMAN 471-15

Y.EMP.HA.02.042

43

SEGMAN 471-10

Y.EMP.HA.02.043

44

SEGMAN 471-17

Y.EMP.HA.02.044

45

TOP BACK CLEANING BALDE

Y.EMP.HA.02.045

46

TOP FRONT CLEANING BLADE

Y.EMP.HA.02.046

47

TOP SPRING

Y.EMP.HA.02.047

15

DOUGH ROLLER

G SPARE PART LIST- EXPLODING DRAWINGS

EMP.HA.03

16

DOUGH ROLLER

G SPARE PART LIST- EXPLODING DRAWINGS

PRODUCT CODE:EMP.HA.03

NO

PRODUCT NAME

P.CODE

1

BASE FRAME

Y.EMP.HA.03.001

2

WHELL

Y.EMP.HA.03.002

3

SLIDING SHEET METAL (CHECK IN)

Y.EMP.HA.03.003

4

SLIDING SHEET METAL (MEDIUM)

Y.EMP.HA.03.004

5

SLIDING SHEET METAL (EXIT)

Y.EMP.HA.03.005

6

BUTTON (START-STOP)

Y.EMP.HA.03.006

7

URGENT STOP

Y.EMP.HA.03.007

8

PLASTIC PIN (LONG)

Y.EMP.HA.03.008

9

PLASTIC PIN (SHORT)

Y.EMP.HA.03.009

10

MOTOR RING (FIXED)

Y.EMP.HA.03.010

11

MOTOR RING (ADJUSTABLE)

Y.EMP.HA.03.011

12

BELT (10X850)

Y.EMP.HA.03.012

13

PULLEY (LITTLE ROLLER)

Y.EMP.HA.03.013

14

PULLEY (LARGE ROLLER)

Y.EMP.HA.03.014

15

PULLEY (MOTOR)

Y.EMP.HA.03.015

16

MOTOR

Y.EMP.HA.03.016

17

RIGHT GEARBOX

Y.EMP.HA.03.017

18

ADJUSTMENT PIN

Y.EMP.HA.03.018

19

GEARBOX PLUG

Y.EMP.HA.03.019

20

WORM SHAFT SLEEVE

Y.EMP.HA.03.020

21

WORM SHAFT

Y.EMP.HA.03.021

22

BALL BEARING (6004)

Y.EMP.HA.03.022

23

BALL BEARING (6203)

Y.EMP.HA.03.023

24

BALL BEARING (6005)

Y.EMP.HA.03.024

25

BOTTOM GEAR

Y.EMP.HA.03.025

26

TOP GEAR

Y.EMP.HA.03.026

27

PRONG FLAKE

Y.EMP.HA.03.027

28

BOTTOM LONG ROLLER

Y.EMP.HA.03.028

29

TOP LONG ROLLER

Y.EMP.HA.03.029

30

BOTTOM LONG ROLLER SHAFT

Y.EMP.HA.03.030

31

TOP LONG ROLLER SHAFT

Y.EMP.HA.03.031

32

SEGMAN 471-25

Y.EMP.HA.03.032

33

RIGHT GEAR BOX EQUIVALENT

Y.EMP.HA.03.033

34

BOTTOM BACK LONG BLADE

Y.EMP.HA.03.034

35

BOTTOM FRONT LONG BLADE

Y.EMP.HA.03.035

36

BIG SPRING

Y.EMP.HA.03.036

37

SMALL SPRING

Y.EMP.HA.03.037

38

LEFT GEARBOX

Y.EMP.HA.03.038

39

BOTTOM SHORT ROLLER

Y.EMP.HA.03.039

40

TOP SHORT ROLLER

Y.EMP.HA.03.040

41

BOTTOM SHORT ROLLER SHAFT

Y.EMP.HA.03.041

42

TOP SHORT ROLLER SHAFT

Y.EMP.HA.03.042

43

LEFT GEAR BOX EQUIVALENT

Y.EMP.HA.03.043

44

TOP BACK SHORT BLADE

Y.EMP.HA.03.044

45

TOP FRONT SHORT BLADE

Y.EMP.HA.03.045

46

PRONG PLASTIC FLAKE

Y.EMP.HA.03.046

47

SEGMAN 471-25

Y.EMP.HA.03.047

17

DOUGH ROLLER

HELECTRIC CIRCUIT SCHEMA

M

A1

Motor

Urgent Stop

This manual suits for next models

4

Table of contents

Other EMPERO Kitchen Appliance manuals

Popular Kitchen Appliance manuals by other brands

Tomato Saber

Tomato Saber 943 Series operating instructions

Cuisinart

Cuisinart CTG-00-SSC INSTRUCTION AND RECIPE BOOKLET

Cuisinart

Cuisinart CSS-100C INSTRUCTION AND RECIPE BOOKLET

Crofton

Crofton CAST IRON 12 IN. SKILLET user manual

Unold

Unold 48955 Instructions for use

U-Line

U-Line Captain 1000 Series User guide & service manual