ENDA ETC4420 User manual

ETC4420-E-02-R

1/4

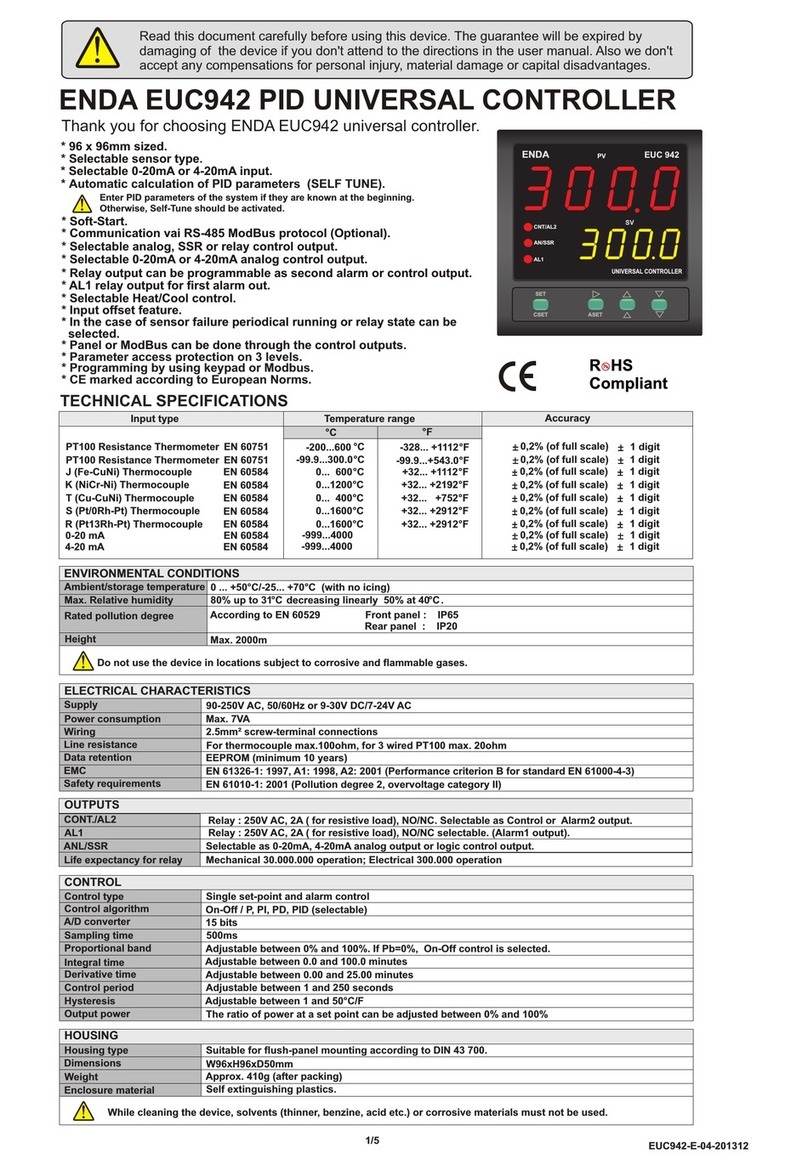

ENDA ETC4420 PID TEMPERATURE CONTROLLER

Read this document carefully before using this device. The guarantee will be expired by

damaging of the device if you don't attend to the directions in the user manual. Also we don't

accept any compensations for personal injury, material damage or capital disadvantages.

Thank you for choosing ENDA ETC4420 temperature controller.

* 48 x 48mm sized.

* Selectable sensor type.

* Soft-Start.

* Automatic calculation of PID parameters (SELF TUNE).

* Selectable Heat/Cool control.

* Communication vai RS-485 ModBus protocol (Optional).

* Relay output can be programmable as second alarm or control output.

* AL1 relay output for first alarm out.

* Input offset feature.

* In the case of sensor failure relay state can be

selected. periodical running or

* Parameter access protection on 3 levels.

* Programming by using keypad or Modbus.

* CE marked according to European Norms.

* Selectable SSR or relay control output.

Enter PID parameters of the system if they are known at the beginning.

Otherwise, Self-Tune should be activated.

J (Fe-CuNi) Thermocouple

K (NiCr-Ni) Thermocouple

T (Cu-CuNi) Thermocouple

S (Pt/0Rh-Pt) Thermocouple

R (Pt13Rh-Pt) Thermocouple

EN 60584

EN 60584

EN 60584

EN 60584

EN 60584

0... 600

0...1200

0... 400

0...1600

0...1600

°C

°C

°C

°C

°C

+32... +1112

+32... +2192

+32... +752

+32... +2912

+32... +2912

°F

°F

°F

°F

°F

Pt 100 Resistance Thermometer

Pt 100 Resistance Thermometer

EN 60751

EN 60751

-200...600

-99.9...300.0

°C

°C

0,2% ( )of full scale

0,2% ( )of full scale

1 digit

1 digit

0,2% ( )of full scale 1 digit

0,2% ( )of full scale 1 digit

0,2% ( )of full scale 1 digit

0,2% ( )of full scale 1 digit

0,2% ( )of full scale 1 digit

-328... +1112

-99.9...+543.0

°F

°F

°C °F

OUTPUTS

Selectable as Control or Alarm2 output.Relay : 250V AC, 2A ( for resistive load), NO/NC.

Selectable logic control output. (Max 12V 20mA(

(Alarm1 output).Relay : 250V AC, 2A ( for resistive load), NO/NC selectable.

AL1

SSR out

Mechanical 30.000.000 operation; Electrical 300.000 operation

Life expectancy for relay

CONT./AL2

TECHNICAL SPECIFICATIONS

Input type Temperature range Accuracy

ENVIRONMENTAL CONDITIONS

Height Max. 2000m

80 up to 31 decreasing linearly 50 at 40 .% %

Ambient/storage temperature

Max. Relative humidity

0 ... +50 /°C -25... +70°C (with no icing)

°C °C

Rated pollution degree According to EN 60529 Front panel : IP65

Rear panel : IP20

Do not use the device in locations subject to corrosive and flammable gases.

ELECTRICAL CHARACTERISTICS

Supply 230V AC +10 -20 , 50/60Hz or 24V AC ±10 , 50/60Hz.% % %

Power consumption Max. 5VA

2.5mm² screw-terminal connections

Wiring

Line resistance

Data retention

EMC

Safety requirements

EN 61326-1: 1997, A1: 1998, A2: 2001 (Performance criterion B for standard EN 61000-4-3)

EEPROM (minimum 10 years)

EN 61010-1: 2001 (Pollution degree 2, overvoltage category II)

For thermocouple max.100ohm, for 3 wired Pt 100 max. 20ohm

CONTROL

Control type Single set-point and alarm control

On-Off / P, PI, PD, PID (selectable)

Control algorithm

A/D converter 15 bits

Sampling time

Proportional band

Derivative time

Integral time

Control period

Hysteresis

Output power

500ms

Adjustable between 0 and 100 . If Pb=0 , On-Off control is selected.% % %

Adjustable between 0.0 and 100.0 minutes

Adjustable between 0.00 and 25.00 minutes

and 250 secondsAdjustable between 1

1 and 50Adjustable between °C/F

The ratio of power at a set point can be adjusted between 0 and 100% %

HOUSING

Housing type Suitable for flush-panel mounting according to DIN 43 700.

Dimensions W48xH48xD87mm

Weight Approx. 250g (after packing)

Self extinguishing plastics.

Enclosure material

While cleaning the device, solvents (thinner, benzine, acid etc.) or corrosive materials must not be used.

TEMPERATURE CONTROLLER

ENDA

PV

SV

CSET ASET

SET

ETC4420

CNT/AL2

AL1

SSR

A1.tp.

ýndE.

A2.tp.

ýndE.

A1.St.

Hý.

A2.St.

Hý.

A1.P.e.

oFF

A2.P.e.

oFF

A1.Hy.

2

A2.Hy.

2

ALr.o. ConF.

ýnP.

FE.cn.

C.Hi.L.

600

C.Lo.L.

0

oFFS.

0

A1.H.L.

600

A2.H.L.

600

A1.L.L.

0

A2.L.L.

0

ASET

ASET

Con.o.

Pb

4

C.oT.S.

Out1

S.S.T.S.

0

tý

4.0

td

1.00

Ct

20

P.SEt.

0

C.HyS.

2

C.StA.

HEAt

Pr.Er.

0

SET

CSET

SET

CSET

ASET

ASET

fL.Co.

5

S.tun.

ASET

SET

CSET

ASET

SECU.

ASET ASET

ASET

S.cod.

0

A.Con.

P.yES

A.ALr.

P.yES

A.CNF.

P.yES

A.tun.

yES

SET

CSET

ASET

SET

CSET

S.Str.

run

25

Pýd.t.

Yes

No

25

REdY.

70

TE.Hý.

25

P.SE.t.

SET

CSET

d.adr.

1

baud

off

C.HyS.

6

SET

CSET

SET

CSET

Modification Of Parameter Diagram

C.HyS.

5

C.HyS.

6

SET

CSET

SET

CSET

SET

CSET

C.HyS.

6

2/4 ETC4420-E-02-R

C.ot.S. = Type of control output

Out1 = Out1 is control output.

S.s.r = SSr control output.

Out1 = Alarm2 output.

S.S.t.S. = Soft Starttimer set point value

This parameter indicates the time to reach set point value

when the device is first energized.

Adjustable between 0 and 250 minutes.

If 0 is selected, soft start feature will be enable and the

device reaches set point value quickly.

NOTE! Setting Pb = 0, soft start feature will be disable.

Pb = Proportional band.

Adjustable between 0% and 100%

Setting Pb = 0% On-Off control is selected.

Ti = Integral time.

Adjustable between 0.0 and 100.0 minutes.

If ti = 0.0, integral effect is not used.

Setting Pb = 0 this parameter is not seen.

td = Derivative time.

Adjustable between 0.00 and 25.00 minutes.

If td = 0.00, derivation effect is not used.

Setting Pb = 0 this parameter is not seen.

Ct = Control period.

Adjustable between 1 and 250 seconds.

Setting Pb = 0 and C.ot.S.= Out1 this parameter is

not seen.

P.SEt. = The ratio of output power at the set

point.Adjustable between 0% and 100%.

If this parameter is set to 0, the output power becomes 0

at the set point. If it is adjusted to 50% output power

becomes 50% at the set point. Using this parameter the

energy requirements of the system is adjusted at the set

point. So the set point can be achieved by minimum

fluctuations and in the shortest time.Setting Pb = 0, this

parameter is not seen.

C.HYS.= Hysteresis of the control output.

Adjustable between 1 and 50 °C/F.

Setting Pb = 0 this parameter is seen.

C.StA. = Configuration of the control output.

C.StA. = HEAt means heating control.

C.StA. = cooL means cooling control.

Pr.Er. = This parameter is used to adjust the control

output during a sensor failure.

Adjustable between 0% and 100%.

If this parameter is adjusted to a value closer to the

energy requirements of the system at the set point,

process temperature is prevented to rise or drop to

dangerous levels.

A1.p.e. = State of Alarm1 output in the

case of sensor failure.

If A1.p.e.= On , the alarm output is

energized during the sensor failure.

If A1.p.e.= oFF,the alarm output is not

energized during the sensor failure.

A2.p.e. =

case of sensor failure.

If = , the alarm output is

energized during the sensor failure.

If A2.p.e.= oFF, the alarm output is not

energized during the sensor failure.

NOTE! If C.ot.S. = .out1, this

parameter is not seen.

State of Alarm2 output in the

A2.p.e. On

A1. =

output.

Adjustable between 1 and 50°C.

Hy. Hysteresis of the Alarm1

A2. =

output.

Adjustable between 1 and 50°C.

NOTE! If C.ot.S. =.out1, this

parameter is not seen.

Hy. Hysteresis of the Alarm2

A1.tP. =

Four kinds of functions can be selected.

indE. = Independent

dE. = Deviation

bAnd = Band

bAn.i. = Band with inhibition

Function of Alarm1 output.

A2.tP. =

Four kinds of functions can be selected.

indE. = Independent

dE. = Deviation

bAnd = Band

bAn.i. = Band with inhibition

NOTE! If C.ot.S. = .out1, this

parameter is not seen.

Function of Alarm2 output.

A1.St. =

If independent or deviation alarm is

selected, this parameter can be Lo. and

Hi. For Lo. alarm output is energized

below the alarm set point. For Hi. alarm

output is energized above the alarm set

point. If band alarm is selected, this

parameter can be bIHI or boHI. bIHI

means alarm is activated inside the

band.boHI means alarm is activated

outside the band.

The state of Alarm1.

A2.St. =

If independent or deviation alarm is

selected, this parameter can be Lo.

and Hi. For Lo. alarm output is

energized below the alarm set point. For

Hi. alarm output is energized above the

alarm set point. If band alarm is selected,

this parameter can be bIHI or boHI.

bIHI means alarm is activated inside

the band. boHI means alarm is

activated outside the band.

NOTE! If C.ot.S. = .out1, this

parameter is not seen.

The state of Alarm2.

inP. = Type of input and scale.

Pt = Pt 100 -200 to +600°C

Pt.0 = Pt 100 -99.9to +300.0°C

FE.cn. = J (Iron vs. Copper-Nickel) 0 to +600°C

nc.nA. = K (Nickel-Cr.vs. Nickel-Alum.) 0 to +1200°C

c.cn. = T (Copper vs. Copper-Nickel) 0 to +400°C

P10.r. = S (Platinum-10%Rhodium vs. Pt.) 0 to +1600°C

P13.r. = R (Platinum-13%Rhodium vs. Pt.) 0 to +1600°C

Note : If the selected input type is changed, the value of C.Hi.L, C.Lo.L ,

A.Hi.L., A.Lo.L. parameters changes automatically.

C.Hi.L. =

If InP. or UnIt. parameters are changed, the maximum value of the C.Hi.L.

parameter changes to the maximum scale value of the selected input. The

minimum value is the value of C.Lo.L. parameter.

Set point upper limit.

C.LoL. =

If InP. or UnIt. parameters are changed, the minimum value of the C.Lo.L.

parameter changes to the minimum scale value of the selected input.The

maximum value is the value of C.Hi.L. parameter.

Set point lower limit.

oFFS. =

Offset value is added to the measurement value.

Adjusted between -99 and +99°C.The normal value is 0.

Offset value.

UnIt =

Selectable as °C or °F.

Note : If the temperature unit is changed, the value of the UPL., Lol., A.UP.L.,

A.Lo.L. Parameters changes automatically.

NOTE! IfInp parameter is selected TC or Pt100, this parameter is seen.

The temperature unit.

A1.H.L

If InP. or UnIt. parameters are changed, the maximum value of the A1.H.L.

parameter changes to the maximum scale value of the selected input type.

Minimum of A1.H.L. parameter is the value of A1.L.L. parameter.

=Alarm1 value upper limit.

A2.H.L

If InP. or UnIt. parameters are changed, the maximum value of the A2.H.L.

parameter changes to the maximum scale value of the selected input type.

Minimum of A2.H.L. parameter is the value of A2.L.L. parameter.

NOTE! If C.ot.S. = .out1, this parameter is not seen.

=Alarm2 value upper limit.

A1.L.L. =

If InP. or UnIt. parameters are changed, the minimum value of the A1.L.L.

parameter changes to the minimum scale value of the selected input type. The

maximum value is the value of A1.H.L. parameter.

Alarm1 value lower limit.

A2.L.L. =

If InP. or UnIt. parameters are changed, the minimum value of the A2.L.L.

parameter changes to the minimum scale value of the selected input type. The

maximum value is the value of A2.H.L. parameter.

Alarm2 value lower limit.

fL.Co. = Coefficient of digital filter.

Filter for display value.

Adjustable between 1 and 32. If this parameter is 1, digital filter runs most

quick. If the parameter is 31, the filter run most slow. The value of parameter

should be increased in interference.

d.adr. = Device address.

Adjusable between 1 and 247. Difference addresses should

be selected for every device.

Baud= Modbus baud rate.

Selectable 1200, 2400, 4800 and 9600.

If baud=off,Modbus communication will be disable.

S.cod. =

It should be 666.

Security menu access code.

A.Con. = CoN.o

access level code.

nonE = Invisible

P.yES = Modification can be done.

P. no = Only visible.

Parameters of menu

A.ALr.. =ALr.o

access level code.

nonE = Invisible

P.yES = Modification can be done.

P. no = Only visible.

Parameters of menu

A.CNf. = ConF.

access level code.

nonE = Invisible

P.yES = Modification can be done.

P. No = Only visible.

Parameters of menu

A.tun. = S.tun.

access level code.

no = Invisible

yES = Self tune can be done.

Parameters of menu

Before starting sef-tune

procedure, be sure A.tun

parameter is YES

in the SECU menu.

Process

value is equal or lower

than 60%of the set

point ?

After

PID is

calculated

Press

any key

Press any

key to

deactivate

the self-tune

procedure.

While holding key, run message flashes. Then when key is pressed,

self tune mode is entered if there is no probe failure. If process value is Appropriate to

begin self tune, rEdY. message flashes. Then press any key to see Pid.t. message

and self tune procedure begins.Process value must be equal or lower than 60%of the

setpoint to begin self tune procedure. If not, tE.Hi. message flashes and device waits

to decrease appropriate temperature to begin self tune. Then rEdY. message flashes

and press any key to begin sellf tune procedure.

Before self tune procedure, A.tun. parameter must be selected yES from the SECU

menu.If self tune is achieved A.tun. parameter becomes no automatically and S.tun

menu is canceled. Before self tune procedure, temperature setpoint value should be

adjusted. When self tune procedure begins with no failure, Pid.t. message flashes

and remains during the calculation of PID parameters. When PID parameters are

calculated, P.SE.t. message flashes. Then the device heats until setpoint value

according to PID parameters and calculates the energy requirement for stable

temperature and writes P.SE.t. parameter as %and run mode enters.

If any key is pressed while Pid.t. message flashes, self tune prosedure is deactivated

before calculation of PID parameters. If any key is pressed while P.SE.t. message

flashes, then self tune prosedure is deactivated as PID parameters are calculated and

P.SE.t. parameter is done 0.

Entering from the programming mode to the run mode:

If no key is pressed within 20 seconds during programming mode, the data is stored automatically and the run mode is entered.

Alternatively, the same function occurs first pressing key and then pressing keys together.

If key is pressed while holding key, the programming mode is enabled.

When holding key, the value of parameter flashes and using

keys the requested value can be adjusted.

If key is pressed and held 0.6 seconds, the value of the selected

parameter changes rapidly. If waited enough,the value increases 100 at each step.

After 1 second following the release of the key, initial condition is returned.The

same procedure is valid for the decrement key.

Unit.

°C

3/4 ETC4420-E-02-R

TERMS

( 1 )

Mnemonic parameter code during programming

Process value during normal operation

( 2 )

Data value during programming

Set point during normal operation.

( 4 )

If only this key is pressed in normal operation, software version number is seen.

Parameter selection during programming

Decrement key during normal operation

( 3 )

Parameter selection key during programming

Increment key during normal operation and programming

( 5 )

Menu selection key during programming

Alarm set key during normal operation

( 6 )

Parameter selection key during programming

Heat set key during normal operation

MODIFICATION OF CONTROL AND ALARM SET POINTS

ALARM1 AND ALARM2 OUTPUT TYPES

A1.tP.=indE

Independent Alarm

A1.tP.= DE.

Deviation Alarm

Band Alarm

A1.tP.= bAnd

A1.tP.= BAn.i.

Band Alarm With Inhibition

A.StA.= Hi

A1.St.= boHi

A.StA.= Lo

A1.St.= biHi

ASV

SV SV

SV

SV+ASV

SV+ASV

SV-ASV

OFF OFF

OFF

OFF OFF

OFF

-300

300

+300

300

ON ON

ON

ON ON

ON

ON ON

OFF OFF

Beginning

of procedure

SV =Set point of CONT output ASV = Set point of AL1 output (ASV min. = 0, ASV max. = 300 )

SV = ASV =Set point of CONT output Set point of alarm output

(ASV min. =-300, ASV max. = +300)

(ASV min. = 0, ASV max. = +300)

(

ASV max = end of scale)

ASV min = beginning of scale

SV = ASV =Set point of CONT output Set point of AL1 output

Band alarm is possible Band alarm is possible

Beginning

of procedure

SV SV

SV+ASV SV+ASV

SV-ASV SV-ASV

a1.Hy. A1.Hy..

A1.Hy.

A1.Hy.

C.SEt

150

- - - -

- - - -

PFA

150

PSC

150

A1.sE.

250

C.SEt

150

A1.sE.

250

A1.sE.

249

First, press and hold key until the massage C.Set appears on the display. Then, the value is adjusted by using keys.

SET

CSET

SET

CSET

SET

CSET

SET

CSET

ASET ASET ASET

When CSET is released, it

returns to normal operation.

When ASET is released, it

returns to normal operation.

130

150

PV PV

PV PV PV PV

PV

PV

PVPV

SV SV

SV SV SV SV

C.SEt

149

PV

SV SV

SV

SV

SV

Error Messages

First, press and hold key, alarm setpoint value appears on the display. Then, the value is adjusted by using keys.

If C.ot.S different from out1. Alarm1 and Alarm2 setpoint values can be adjusted in sequence when per press key.

.

ASET

ASET

SET

CSET

ASET

NOTE: The maximum of is the value of parameter and the minimum of it is the value of parameter.

If independent alarm is selected, A1.SE. and values can be adjusted between the limits of the full scale.

If deviation alarm is selected, A1.SE. and A2.SE. values can be adjusted between - and + .

If band alarm is selected, A1.SE. and A2.SE. values can be adjusted between 0and +300.

C.SEt C.Hi.L. C.Lo.L.

A2.SE.

300 300

Temperature value is

higher than the scale Temperature value is

lower than the scale

Temperature sensor

is broken or over temperature Pt 100 or a sensor

line is short circuited

150 150

(

ASV max. = +30.0)

If ,inP = Pt..0 ASV min. = -30.0,

(If ,inP = Pt..0 ASV min. = 0.0, ASV max. = +30.0)

( 2 ) SV display

Character heights

( 3 ),( 4 ),( 5 ),( 6 ) Keypad

( 7 ) State indicator

( 1 ) PV display

PV 7 mmdisplay :

SV display :7 mm

4 digits 7 segment yellow LED

4 digits 7 segment red LED

Micro switch

3 red LEDs for Control, Alarm1 and SSR outputs

TEMPERATURE CONTROLLER

ENDA

PV

SV

CSET ASET

SET

ETC4420

CNT/AL2

AL1

SSR

( 7 )

SÝSEL MÜHENDÝSLÝK ELEKTRONÝK SAN. VE TÝC. A.Þ.

Yukarý Dudullu Barbaros Cd. Kutup Sok. No:20 34775 - ÜMRANÝYE/ÝSTANBUL-TÜRKÝYE

Tel : +90 216 499 46 64 Pbx. Fax : +90 216 365 74 01

url : www.enda.com.tr 4/4

ETC4420-E-02-R

Logic output of the instrument is not electrically

insulated from the internal circuits. Therefore,

when using a grounding thermocouple, do not

connect the logic output terminals to the ground.

1) Mains supply cords shall meet the requirements

of IEC 60227 or IEC 60245.

2) In accordance with the safety regulations, the

power supply switch shall bring the identification of

the relevant instrument and it should be easily

accessible by the operator.

Note

Holding screw

0.4-0.5Nm

Equipment is protected throughout

by DOUBLE INSULATION.

Note 1) While panel mounting, additional distance required for

connection cables should be considered.

2) Panel thickness should be maximum 9mm.

3) If there is no 100mm free space at back side of the device,

it would be difficult to remove it from the panel.

ENDA ETC4420 is intended for installation in control panels. Make sure that the device is used only for intended

purpose. The shielding must be grounded on the instrument side. During an installation, all of the cables that are

connected to the device must be free of energy. The device must be protected against inadmissible humidity,

vibrations, severe soiling and make sure that the operation temperature is not exceeded. All input and output lines

that are not connected to the supply network must be laid out as shielded and twisted cables. These cables should

not be close to the power cables or components. The installation and electrical connections must be carried on by

a qualified staff and must be according to the relevant locally applicable regulations.

For J-K-T-S-R type thermocouple :

Use suitable compensation cables. Don't use

jointed cables. Pay attention to the polarities of the

thermocouple cables as shown in the figure right

are connected to the .

For resistance thermometer :

When 2 wired Pt 100 is used, terminals 6 and 7 must

be short circuited.

NOTE :

Fuse should

be connected.

184-253V AC

or 99-121V AC

50/60Hz 5VA

230V or 24V AC

Supply

switch

Cable size: 1,5mm²

Fuse

F 100 mA

250V AC

Neutral

Line

SUPPLY :

SENSOR INPUT :

10

9

TC

-

+

-

+

7

8

6

7

8

Pt 100

48mm

51mm

80mm

45 mm

+0.6

45 mm

+0.6

58mm

Panel cut-out

Panel

Flush mounting

clamp

CONNECTION DIAGRAM

DIMENSIONS

TEMPERATURE CONTROLLER

ENDA

PV

SV

CSET ASET

SET

ETC 4420

CNT/AL2

AL1

AN/SSR

-

-

+

+

INDUSTRIAL ELECTRONICS

ETC4420-230VAC-RS

PID TEMPERATURE CONTROLLER

SN: XXXXXXXXX

6

3

2

1

7

4

8

5

CONT./AL2

AL1

AC 250V 2A

RESISTIVE LOAD

AC 250V 2A

RESISTIVE LOAD

230V AC +10% -20%

50/60Hz 5VA

TC Pt 100

RS-485 COM.

14

15

9

10

11

12

13

RS- 485

SSR

OUT

A

B

+

-

ENDA

-

+

INDUSTRIAL ELECTRONICS

ETC4420-24VAC

PID TEMPERATURE CONTROLLER

SN: XXXXXXXXX

6

3

2

1

7

4

8

5

CONT./AL2

AL1

AC 250V 2A

RESISTIVE LOAD

AC 250V 2A

RESISTIVE LOAD

TC Pt 100

14

15

9

10

11

12

13

+

-

ENDA

SSR

OUT

24V AC ±10%

50/60Hz 5VA

Order Code - : ETC4420-

1

1-

230VAC...230V AC

24VAC.....24V AC

Supply Voltage

2

2- Modbus Option

RS........RS-485 Modbus communication

None....Don’t support RS-485 Modbus communication

SM...........9-30V DC / 7-24V AC

SM...........9-30V DC / 7-24V AC

the panel:

- While pressing both side of

the device in direction 1, push it

in direction 2.

For removing the device from

12

1

87mm

Depth

Connection

cables

Enviroment temperature

measurement sensor

Other ENDA Controllers manuals

Popular Controllers manuals by other brands

Danfoss

Danfoss VLT MCD 200 installation instructions

Schrack

Schrack CX plus user manual

Exlar

Exlar EL120 Installation and service manual

SICK

SICK UE 440 operating instructions

Emerson

Emerson Fisherr 4660 instruction manual

SYCLOPE electronic

SYCLOPE electronic TERE'O Touch XL Installation and operating instructions

Wilo

Wilo AlarmControl 1 Installation and operating instructions

National Instruments

National Instruments SB-GPIB Getting started

LEGRAND

LEGRAND 288 12 manual

Ametek

Ametek PF1 SSR Series Instruction, Operation and Maintenance Manual

Vescent Photonics

Vescent Photonics SLICE-QT Firmware update

Carrier

Carrier 40VM Series Installation and operating instructions