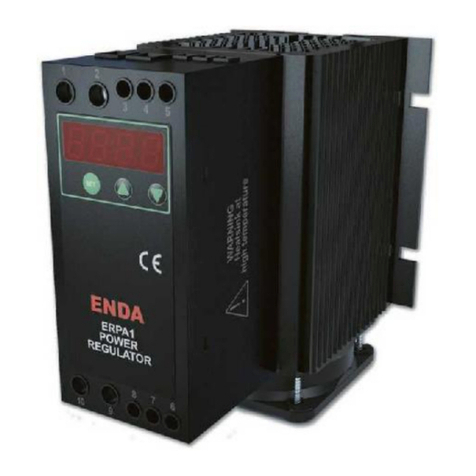

ENDA ELC-186RT

ENDA PLC PROGRAMMABLE LOGIC CONTROLOR

USER'S MANUAL

1) To avoid damaging he sys em, do no connec /disconnec he device when power

is on.

2) Make wiring according o user manual o avoid damaging he sys em.

3) Do no ouch live wires.

4) Make sure he ground connec ion is wired.

5) CE Market according to European Norms.

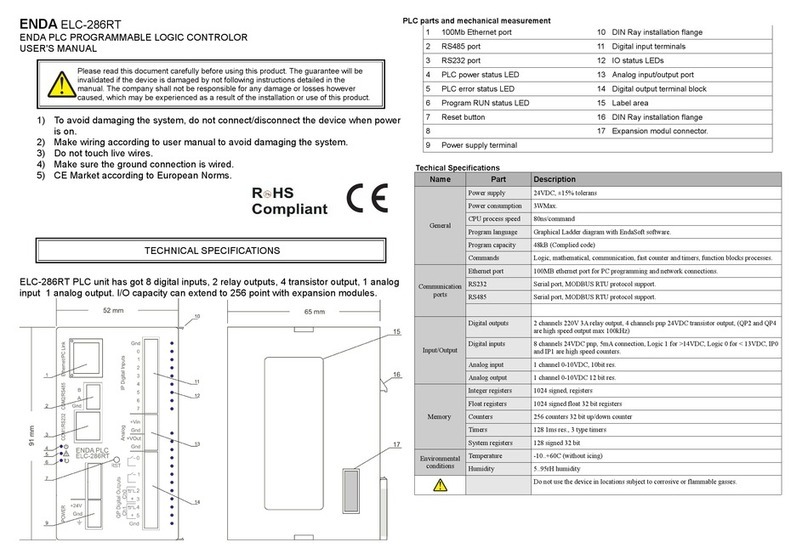

ELC-186RT PLC uni has go suppor 8 digi al inpu , 2 relay ou pu , 4 Transis or ou pu .

I/O capaci y can ex end o 256 poin wi h expansion modules.

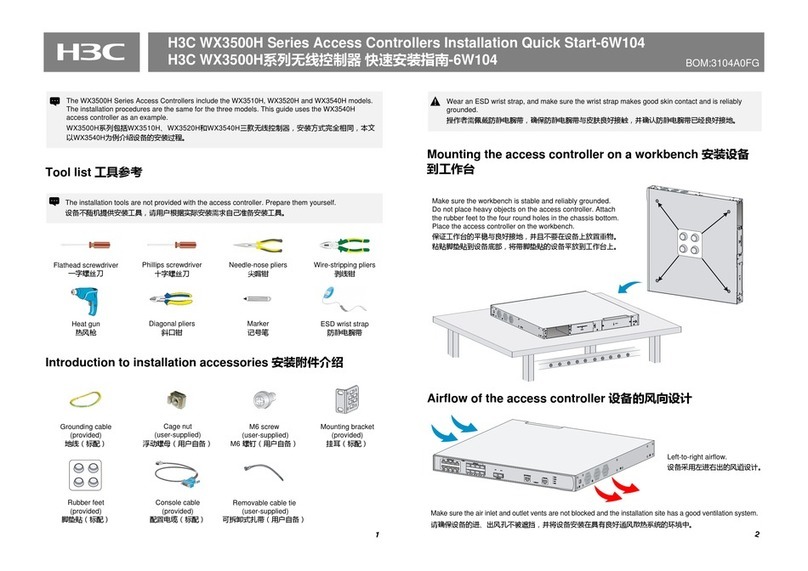

PLC parts and description

1 100Mb E herne por 10 Digi al inpu erminal

2 RS485 serial por 11 IO s a us LEDs

3 RS232 serial por 12 Digi al ou pu erminals

4 PLC power s a us LED 13 Label area

5 PLC error s a us LED 14 DIN Ray ins alla ion flange

6 Program RUN s a us LED 15 Expansion modul BUS connec or.

7 Rese bu on 16

8 Power supply erminal 17

9 DIN Ray ins alla ion flange

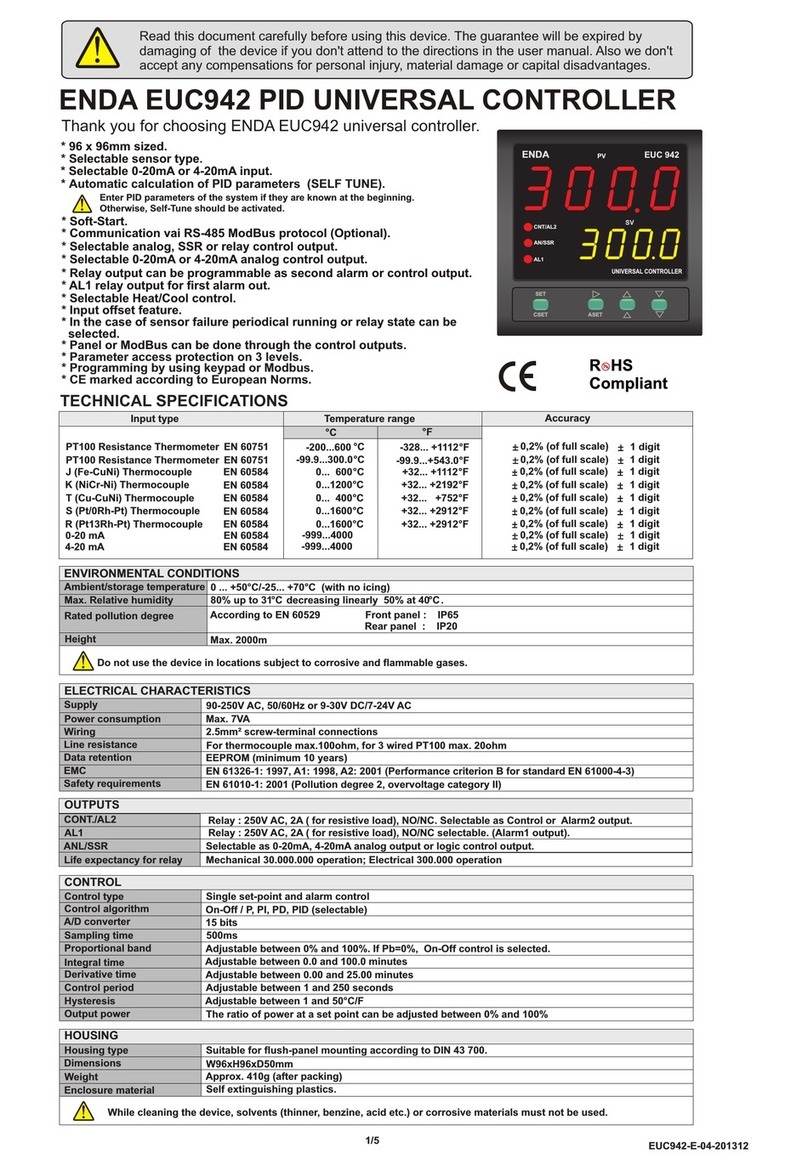

Technical Specification

Name Part Description

General

Power supply 24V C, ±15% tolerans

Power

consumption

3WMax.

CPU process speed 80ns/command

Program language Graphical Ladder diagram with EndaSoft software.

Program capasity 48kB (Complied code)

Commands Logic, mathematical, communication, fast counter and timers, function blocks processed.

Communication

ports

Ethernet port 100MB ethernet port for PC programming and network connections. Connection through

the and programmable feature.

RS232 Serial port, MO BUS RTU protocol support

RS485 Serial port, MO BUS RTU protocol support

Input/Output igital outputs 2 channels 220V 3A relay output, 4 channels pnp 24V C transistor output, (QP2 and QP4

are high speed output max 100kHz)

igital inputs 8 channels 24V C pnp, 5mA connection, Logic 1 for >14V C, Logic 0 for < 13V C

Memory

Integer registers 1024 signed registers

Float registers 1024 signed float 32 registers

Counters 256 counters 32 bit up/down cunter

Timers 128 timer with 1ms resolution, 4 type timers

System registers 128 signed registers for accessing system properties

Environmental

conditions

Temperature -10..+60C (without icing)

Humidity 5..95rH nem

o not use the device in locations subject to corrosive or flammable gasses.