Endress+Hauser UniFit CPA 441 User manual

Other Endress+Hauser Measuring Instrument manuals

Endress+Hauser

Endress+Hauser Gammapilot FMG50 User manual

Endress+Hauser

Endress+Hauser ria45 Technical specifications

Endress+Hauser

Endress+Hauser Proline Promag 50P Manual

Endress+Hauser

Endress+Hauser Gammapilot M FMG50 Technical specifications

Endress+Hauser

Endress+Hauser Proline Promass 83 User manual

Endress+Hauser

Endress+Hauser Cerabar M PMP55 User manual

Endress+Hauser

Endress+Hauser Silopilot FMM50 User manual

Endress+Hauser

Endress+Hauser FTL64 Series Instructions for use

Endress+Hauser

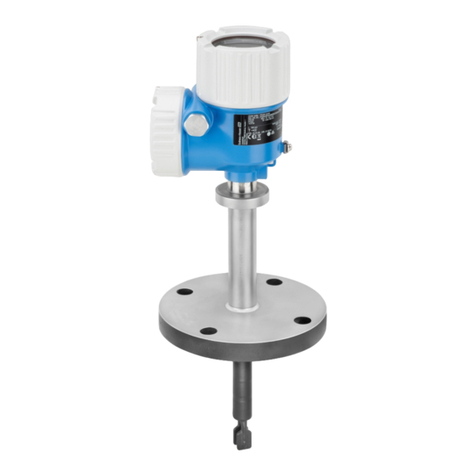

Endress+Hauser mypro CLM 431 User manual

Endress+Hauser

Endress+Hauser Proline Promag 50 User manual

Endress+Hauser

Endress+Hauser PROline promag 50 w Manual

Endress+Hauser

Endress+Hauser SS500 Firmware update

Endress+Hauser

Endress+Hauser PROFI BUS Proline Promag 53 PROFIBUS DP User manual

Endress+Hauser

Endress+Hauser Proline Promag 51 User manual

Endress+Hauser

Endress+Hauser TOC Analyzer CA79 User manual

Endress+Hauser

Endress+Hauser Proline Prosonic Flow 91W Technical specifications

Endress+Hauser

Endress+Hauser HART Proline Promag 51 User manual

Endress+Hauser

Endress+Hauser Proline t-mass I 500 Manual

Endress+Hauser

Endress+Hauser Cerabar M PMC51? Cerabar M PMP51 User manual

Endress+Hauser

Endress+Hauser Conducal CLY421 User manual