Liquiport 2010 CSP44 Maintenance

Endress+Hauser 9

1.3.4 Digital sensors (for version with sensors with the Memosens protocol)

1. If an error occurs or the maintenance schedule stipulates that the sensor has to be replaced,

use a new sensor, or a sensor that has been precalibrated in the laboratory.

A sensor is calibrated in the laboratory under optimum external conditions, thereby

ensuring better quality of measurement.

2. Remove the sensor to be serviced and install the new sensor.

3. You must perform calibration if you use a sensor that is not precalibrated.

4. The sensor data are automatically accepted by the transmitter. A release code is not

required.

5. Measurement is resumed.

6. Take the used sensor back to the laboratory. In the laboratory you can get the sensor ready

for reuse while ensuring the availability of the measuring point.

– Clean the sensor. For this purpose, use the cleaning agent specified in the sensor

manual.

– Inspect the sensor for cracks or other damage.

– If no damage is found, regenerate the sensor. Where necessary, store the sensor in a

regeneration solution (--> sensor manual).

– Recalibrate the sensor for reuse.

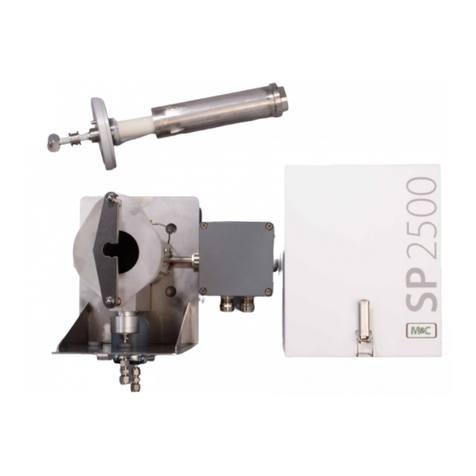

1.3.5 Assemblies (for version with sensors with the Memosens protocol)

Refer to the assembly operating manual for information on servicing and troubleshooting the

assembly. The assembly operating manual describes the procedure for mounting and

disassembling the assembly, replacing the sensors and seals, and contains information on the

material resistance properties, as well as on spare parts and accessories.

1.4 Calibration

All information on calibration is provided in BA467C "Calibration".

The position of the distribution arm is set at the factory.

The sample volume of the peristaltic pump is also calibrated at the factory.

For version with sensors with the Memosens protocol:

Users must decide whether the process conditions present require calibration during initial

commissioning.

Additional calibration is not required in many standard applications.

Sensors with Memosens protocol are calibrated at the factory.

Calibrate the sensors at sensible intervals depending on the process.