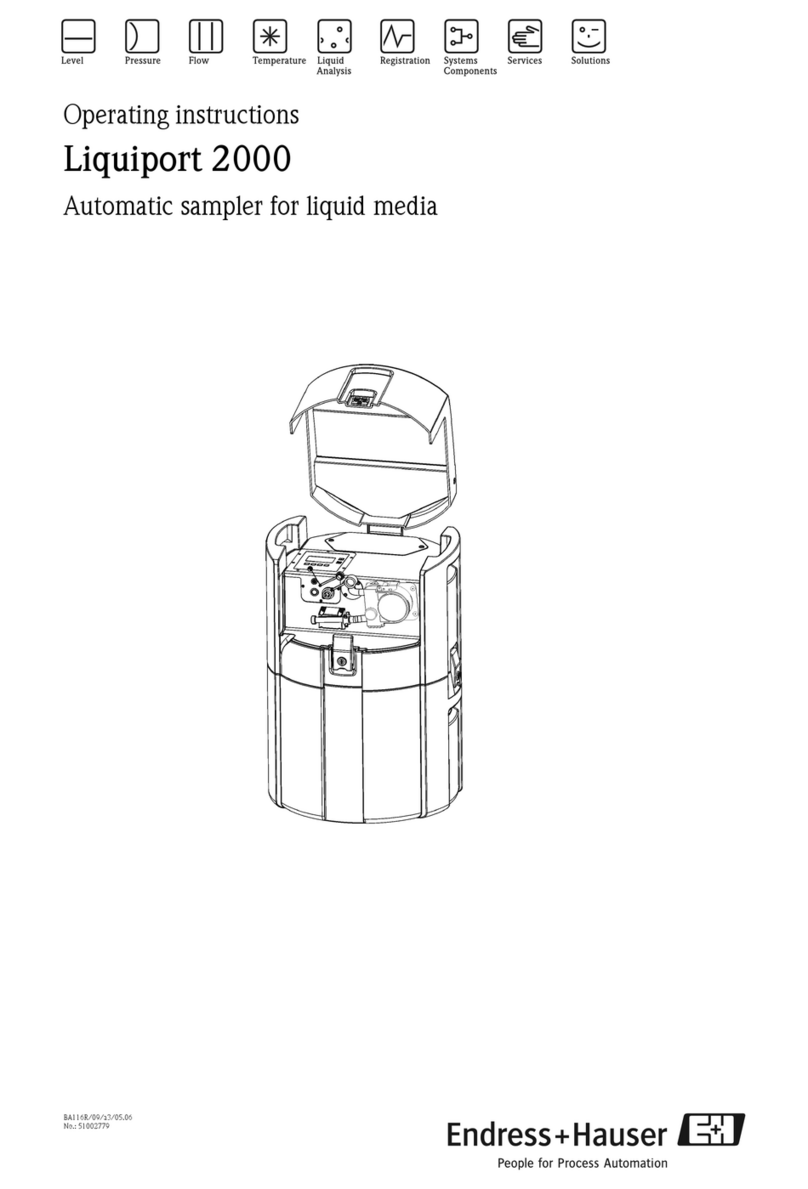

General Remove the external protection film as soon as possible as this can stick

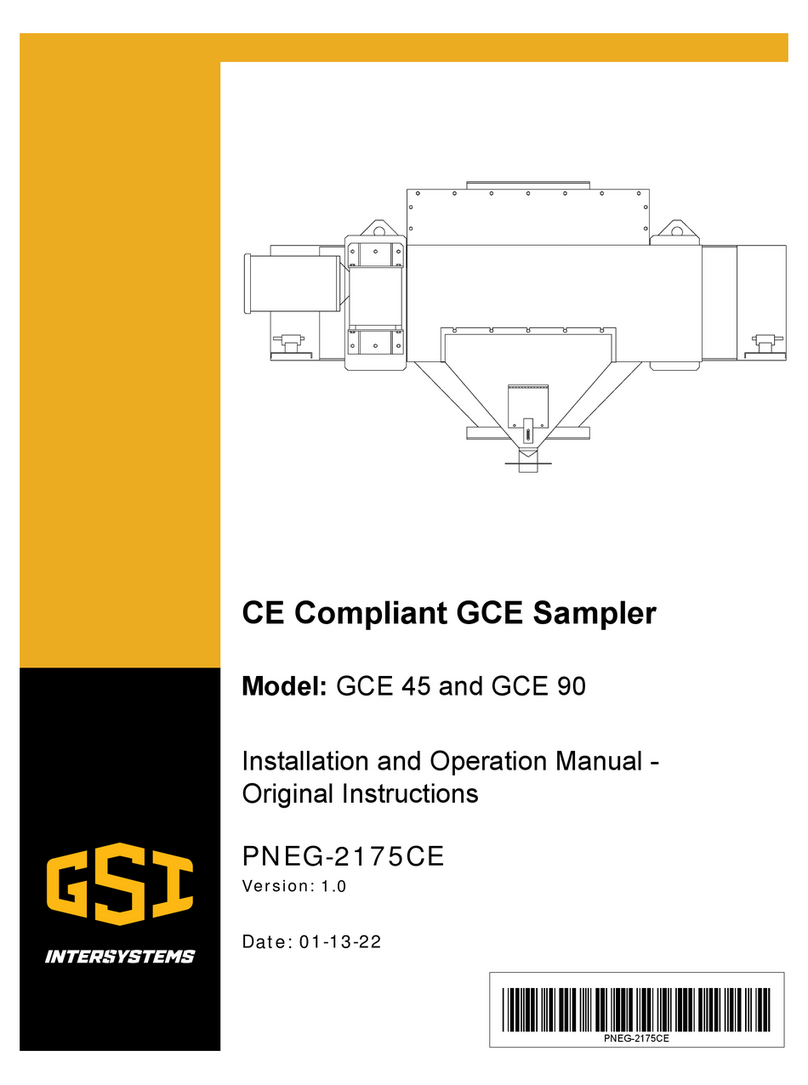

due to sun rays.The water sampler must be installed so that it stands higher

than the sampling point. It can be installed outside and mounted on a

concrete foundation or solid level ground. The unit can be levelled by using

the four levelling screws fitted in the bottom of the sampler. All components

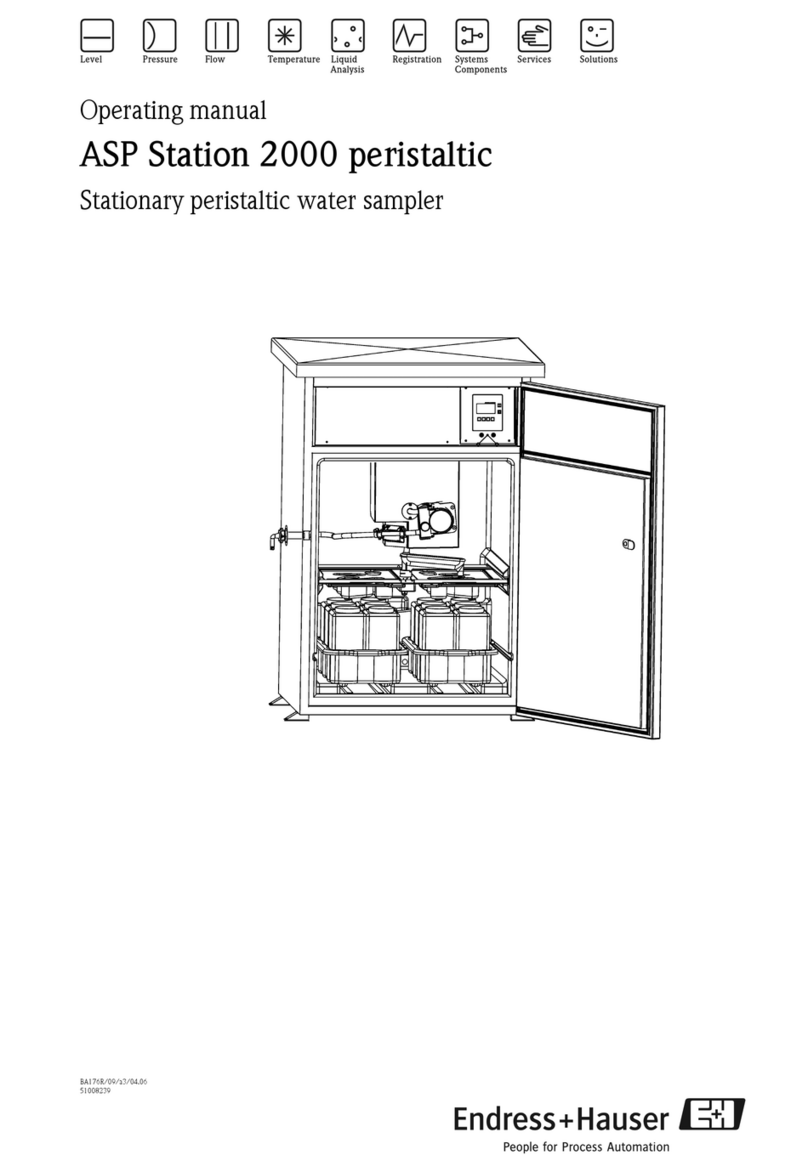

are mounted in a lockable, thermostatically controlled stainless steel cabinet.

The cabinet must be installed in an area where an additional heating effect

from external sources (eg. radiators, etc.) is avoided. In order to ventilate the

built in refrigeration system the sampler, when mounting next to a wall, must

be fitted with the 50mm long spacers supplied in the accessory pack.

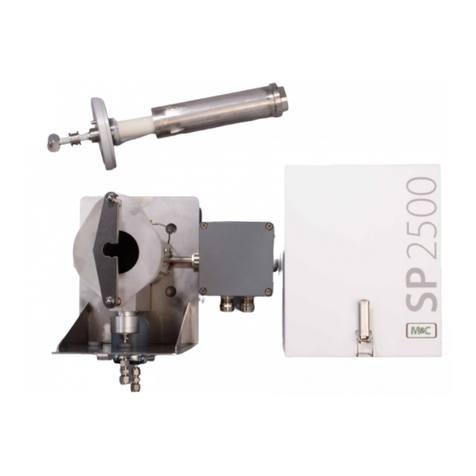

Do not install the sampler close to large magnetic fields (eg. motors,

transformers, large contactors, etc). Do not install the sampler in areas

where it can be subject to high mechanical vibration. Avoid shocks when

transporting the sampler.

Hose connection / installation The suction hose must be installed so that it always rises from the sampling

point to the hose connection on the sampler !

Syphons must be avoided between the sampling point and sampler !

Wrong Right

The sampler must not be connected to a pressurised system !

For sample lift less than 2 m we recommend using a 15 mm suction hose.

Both 13 mm and 15 mm connections are delivered.

The minimum conductivity of the sample liquid must not be less than 30

microsiemens !

●The 13 mm internal ∅hose must be of a spirally reinforced type.

●The hose can be connected to the connector on the top left hand side of

the cabinet.

●Maximum height difference: 6m from sampling point to sampler.

●Maximum hose length: 30m

Mechnanical installation asp-station d 2

6