Endress+Hauser

Liquistation CSF48

Table of contents

1 Safety instructions . . . . . . . . . . 4

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Installation, commissioning and operation . 4

1.3 Operational safety . . . . . . . . . . . . . . . . . . . 4

1.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Notes on safety conventions and icons . . . . 5

2 Identification . . . . . . . . . . . . . . 6

2.1 Device designation . . . . . . . . . . . . . . . . . . . 6

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . 6

2.3 Certificates and approvals . . . . . . . . . . . . . . 7

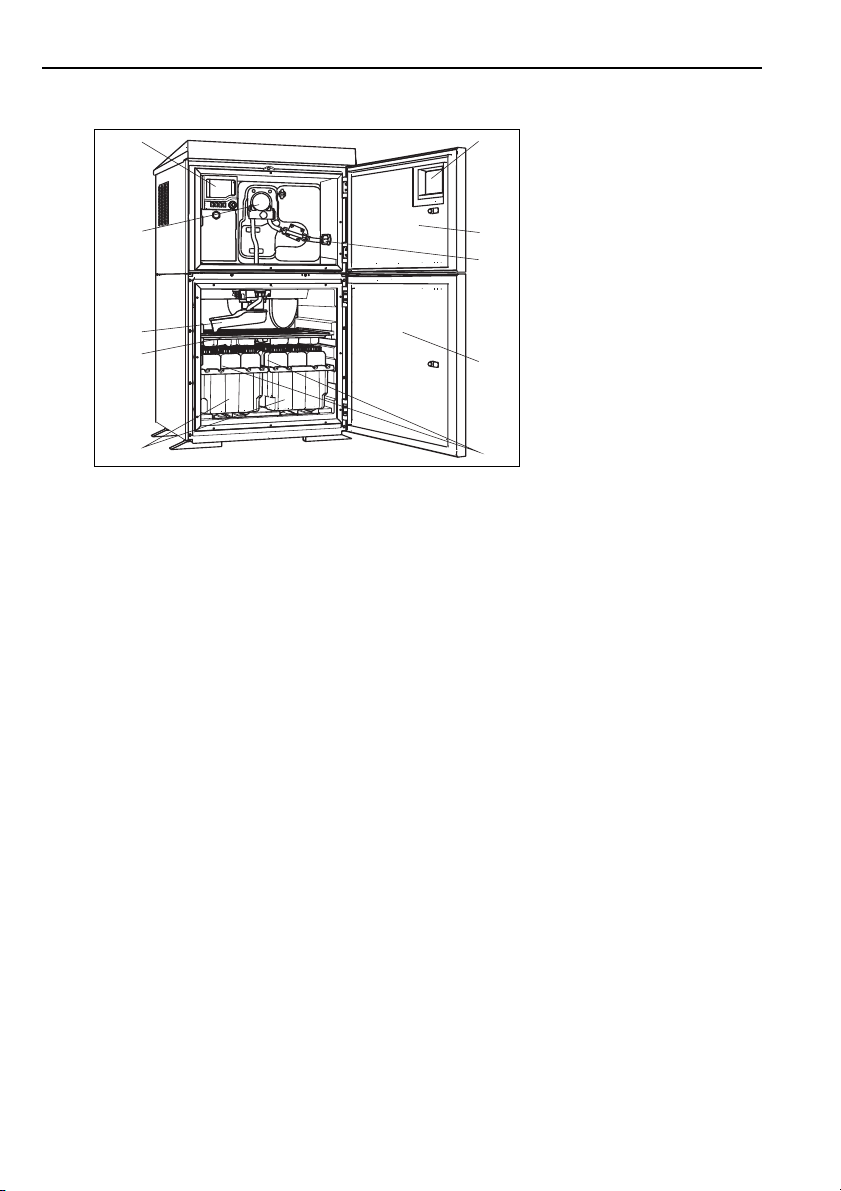

3 Device description . . . . . . . . . . 7

4 Installation . . . . . . . . . . . . . . . . 8

4.1 Incoming acceptance, transport, storage . . . 8

4.2 Installation conditions . . . . . . . . . . . . . . . . 9

4.3 Erecting the sampler . . . . . . . . . . . . . . . . 13

4.4 Sampling with a flow assembly . . . . . . . . . 16

4.5 Post-installation check . . . . . . . . . . . . . . . 17

5 Wiring . . . . . . . . . . . . . . . . . . 18

5.1 Quick wiring guide . . . . . . . . . . . . . . . . . 18

5.2 Terminal assignment for input/output signals

22

5.3 Optional sensor inputs, current outputs and

relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.4 Sampler controller . . . . . . . . . . . . . . . . . . 28

5.5 Post-connection check . . . . . . . . . . . . . . . 30

6 Operation . . . . . . . . . . . . . . . . 31

6.1 Display and operating elements . . . . . . . . 31

6.2 Operation concept . . . . . . . . . . . . . . . . . . 32

6.3 Configuration options . . . . . . . . . . . . . . . . 33

7 Commissioning. . . . . . . . . . . . 34

7.1 Function check . . . . . . . . . . . . . . . . . . . . 34

7.2 Switching on the unit . . . . . . . . . . . . . . . . 34

7.3 General settings . . . . . . . . . . . . . . . . . . . . 35

8 Technical data . . . . . . . . . . . . 46

8.1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.2 Temperature inputs . . . . . . . . . . . . . . . . . 46

8.3 Binary input, passive . . . . . . . . . . . . . . . . . 46

8.4 Analog input, passive/active . . . . . . . . . . . 46

8.5 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.6 Current output, active . . . . . . . . . . . . . . . 47

8.7 Relay outputs . . . . . . . . . . . . . . . . . . . . . . 48

8.8 Power supply . . . . . . . . . . . . . . . . . . . . . . 48

8.9 Performance characteristics . . . . . . . . . . . . 49

8.10 Environment . . . . . . . . . . . . . . . . . . . . . . 51

8.11 Process . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

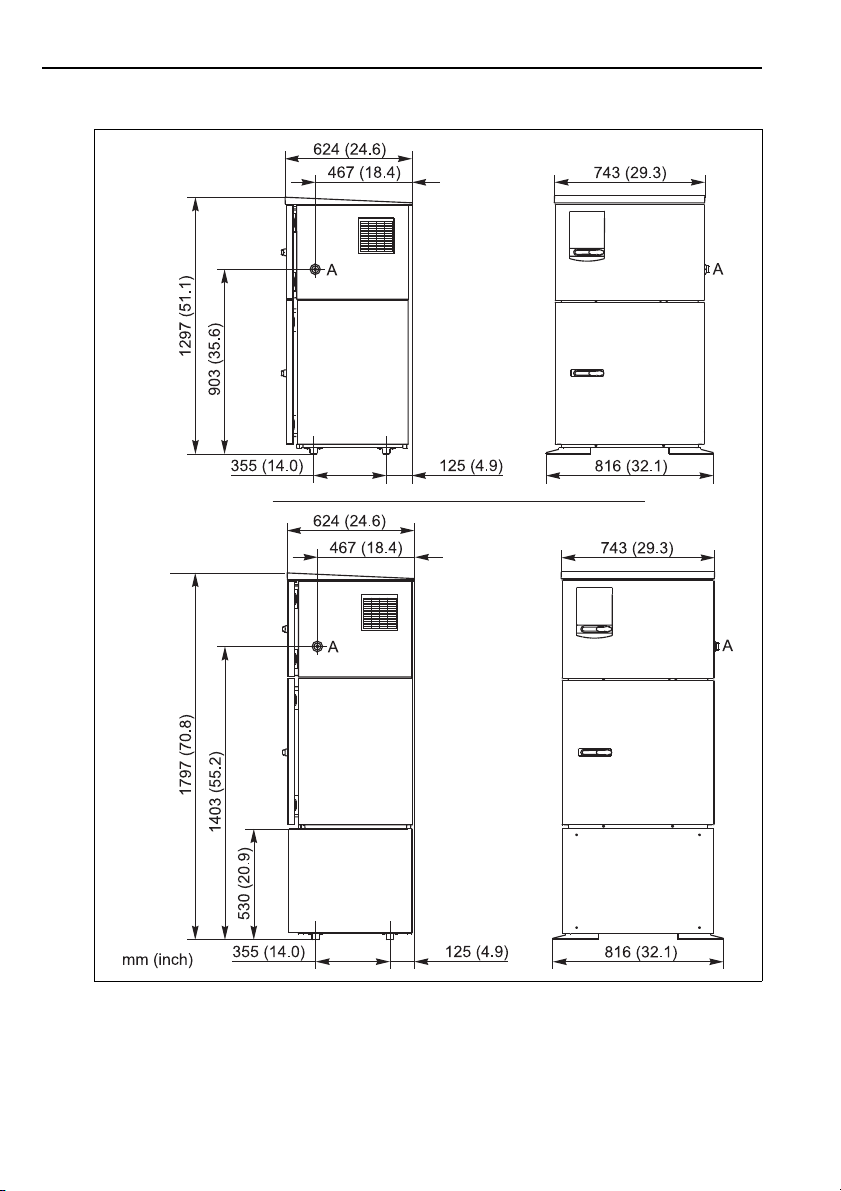

8.12 Mechanical construction . . . . . . . . . . . . . . 52

Index. . . . . . . . . . . . . . . . . . . . 54