Endress+Hauser iTEMP TMT31 User manual

Other Endress+Hauser Transmitter manuals

Endress+Hauser

Endress+Hauser iTEMP TMT162 User manual

Endress+Hauser

Endress+Hauser cerabar S User manual

Endress+Hauser

Endress+Hauser iTEMP TMT162 Technical specifications

Endress+Hauser

Endress+Hauser Prosonic S FMU90 Operating and installation instructions

Endress+Hauser

Endress+Hauser Liquisys CUM 252 User manual

Endress+Hauser

Endress+Hauser deltabar S PMD 25 K User manual

Endress+Hauser

Endress+Hauser Proline 500 Technical specifications

Endress+Hauser

Endress+Hauser OTMT85 User manual

Endress+Hauser

Endress+Hauser Proline 200 HART Technical specifications

Endress+Hauser

Endress+Hauser Liquisys M CLM223/253 User manual

Endress+Hauser

Endress+Hauser L20221 Technical specifications

Endress+Hauser

Endress+Hauser Heat Technical specifications

Endress+Hauser

Endress+Hauser Prosonic S FMU90 User manual

Endress+Hauser

Endress+Hauser iTEMP TMT84 Technical specifications

Endress+Hauser

Endress+Hauser Liquiline CM442R User manual

Endress+Hauser

Endress+Hauser iTEMP TMT162 User manual

Endress+Hauser

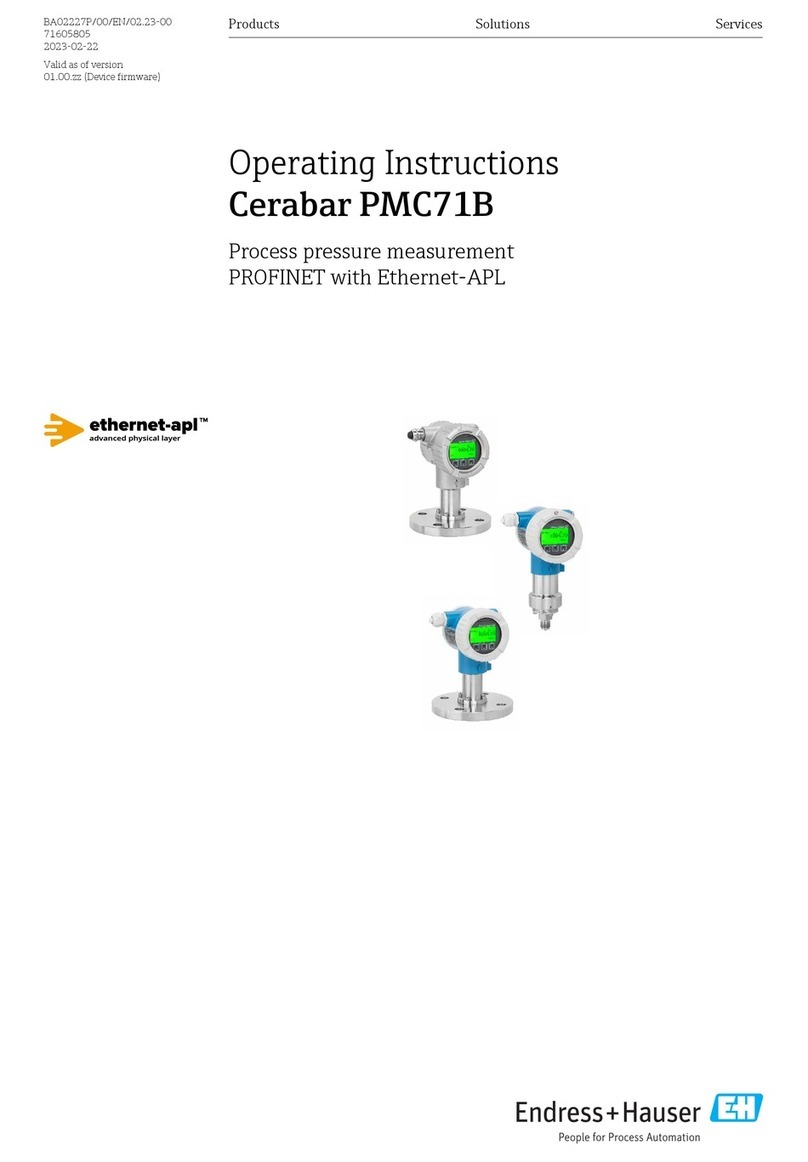

Endress+Hauser Cerabar PMC71B User manual

Endress+Hauser

Endress+Hauser tmt142 Technical specifications

Endress+Hauser

Endress+Hauser Levelflex M FMP41C User manual

Endress+Hauser

Endress+Hauser iTEMP TMT162 Manual

Popular Transmitter manuals by other brands

Dejero

Dejero EnGo 3x manual

Rosemount

Rosemount 4600 Reference manual

Speaka Professional

Speaka Professional 2342740 operating instructions

trubomat

trubomat GAB 1000 instruction manual

Teledyne Analytical Instruments

Teledyne Analytical Instruments LXT-380 instructions

Rondish

Rondish UT-11 quick start guide