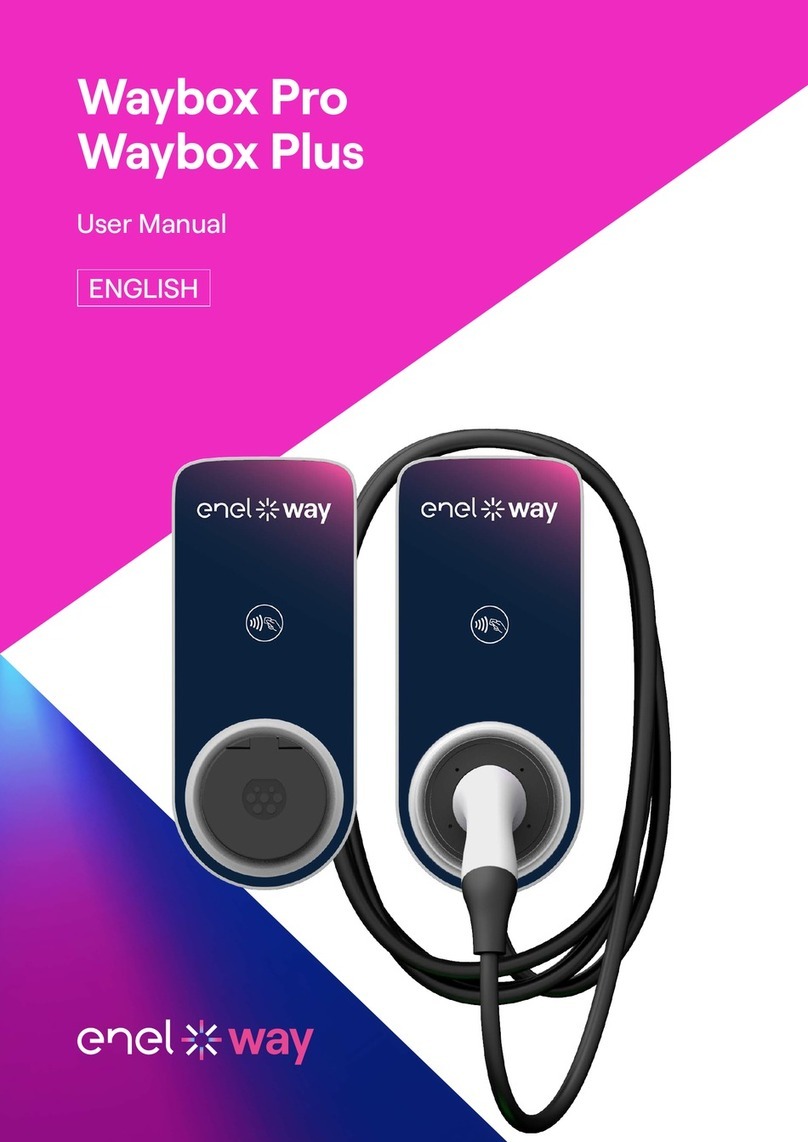

Enel X JuicePump Guide

175 kW DC

RT

www.enelx.com

Phone: +1-844-584-2329

User Unit Installation Manual

TRI125-175-S (USA)

www.enelx.com

Phone: +1-844-584-2329

TRI125.INS.036.3

Important safety instructions................................................................................................1

Packaging, handling, & receipt...............................................................................................4

Servicing distance............................................................................................6

Cable range......................................................................................................6

Baseplate dimensions............................................................................................................7

Installation requirements & equipment.................................................................................8

Unpacking..............................................................................................................................9

Installation............................................................................................................................10

Wiring and commissioning...................................................................................................12

Ethernet port access............................................................................................................14

Closing checklist...................................................................................................................16

Contents

1www.enelx.com

Phone: +1-844-584-2329

TRI125.INS.036.3

Important safety instructions

This manual contains important

instructions for the JuicePump electric

vehicle fast charger.

Read the installation and operating

instructions before installing and

commissioning the equipment.

These instructions must be followed

during installation, operation, and

maintenance of the unit.

CAUTION

The JuicePump fast charger user unit

must be installed and serviced only by

To achieve EMC compliance, the chassis

of the JuicePump user unit must be

bonded to Earth locally at the charger.

Grounding instructions

This unit must be connected to a

grounded, metal, permanent wiring

system. An equipment-grounding conduc-

tor must be run with circuit

conductors and connected to

equipment-grounding terminal or lead on

the electric vehicle charger.

Connections to the battery charger shall

comply with all local codes and

ordinances.

Observe all pertinent national,

regional, and local safety laws and

regulations when installing and

commissioning the JuicePump fast

charger.

Identifying symbols

CRITICAL

CAUTION

RISK OF ELECTRIC SHOCK

Equipment Grounding

Conductor Symbol

ø Phase Symbol

Alternating Current Supply

Symbol

Wiring

Power and Protective Earth (PE) Conduc-

section), V90 class, rated to operate at

90°C.

The manufacturer recommends the use of

copper cables. Refer to the TRI125.

INS.016 JuicePump RT 175-S Piping and

Cabling-

tions.

Take care to observe local regulations

same conduit, including the ethernet

link if used. In general, all conductors

occupying the same conduit shall have

an insulation rating equal to at least the

conductor within the conduit.

SAVE THESE INSTRUCTIONS

2www.enelx.com

Phone: +1-844-584-2329

TRI125.INS.036.3

Warning

commercial garage (repair facility) or

closer than 6,096 mm / 20 feet of an

outdoor motor fuel dispensing device.

Input

190A

1ø, 240 VAC

3A

connected to a circuit provided with

appropriate over-current protection in

accordance with the National Electrical

Code, ANSI/NFPA 70.

Tightening torque

Wiring terminals

30 Nm / 22 lb-ft

Service hatch

2 Nm / 17.7 lb-in

Weather rating

NEMA Type 3R

Usage limitations

cable assemblies shall not be used

in addition to the cable assembly for

the connection of the vehicle to the

charger.

Adaptors shall not be used to

connect a vehicle connector to a

vehicle inlet.

Important safety instructions

SAVE THESE INSTRUCTIONS

3www.enelx.com

Phone: +1-844-584-2329

TRI125.INS.036.3

Important safety instructions

FCC Notice

Information to the User

(FCC Part 15.105)

Class A product:

NOTE:

This equipment has been tested and

found to comply with the limits for a

of the FCC rules. These limits are

designed to provide reasonable protection

against harmful interference when the

equipment is operated in a commercial

environment. This equipment generates,

uses, and can radiate radio frequency

energy and, if not installed and used in

accordance with the instruction manual,

may cause harmful interference to

radio communications. Operation of this

equipment in a residential area is likely to

cause harmful interference in which case

the user will be required to correct the

Modication warning

(FCC Part 15.21)

-

turer could void the user’s authority to

operate this equipment.

SAVE THESE INSTRUCTIONS

4www.enelx.com

Phone: +1-844-584-2329

TRI125.INS.036.3

Read these instructions carefully to

become familiar with the JuicePump user

unit packaging and handling procedures

prior to unpacking and installation.

In all cases, the JuicePump user unit

must be transported to the installation

site in its original packaging and only

unpacked at the installation site.

Installation, commissioning, and servicing

of the JuicePump user unit should only be

Materials

The JuicePump user unit is transported in

a reinforced cardboard crate.

Please respect the environment and

recycle/reuse the materials.

Storage

Store in the original packaging in a

Store in a dry location, protected from

the weather, i.e., in warehouse

conditions.

Storage temperature:

Handling

Only lift the JuicePump user unit pack-

forklift or pallet jack or with lifting straps

and engine hoist, forklift, or crane. Check

the weight on the delivery documents and

ensure the lifting apparatus used is

compatible.

Receipt

Check that the crate packaging is in

good condition and that the JuicePump

user unit is not damaged.

If there are any problems noted, make a

formal complaint to the carrier and notify

your supplier.

Packed crate weight

Crate size

Packaging, handling, & receipt

www.enelx.com

Phone: +1-844-584-2329

TRI125.INS.036.3

Site survey

installation site to determine the

and weight of the JuicePump user unit in

accordance with local regulations.

The JuicePump user unit is best

installed following the recommended site

Ground xing

fasteners.

Fasteners are not supplied, as the type

required depends on the foundation used

and must be chosen by the installer

accordingly.

user unit securely to the foundation

through the baseplate in accordance with

the “Baseplate dimensions” section.

Note: Keep the plastic inserts from the

bolts for use in the baseplate holes.

Conduit requirement

Ø 110 mm OD conduit.

When preparing the foundation,

ensure that conduit and wiring terminates

above ground according to the document

TRI125.INS.016 JuicePump RT 175-S Pip-

ing and Cabling.

Foundation requirements

have the appropriate density for the

weight of the JuicePump user unit.

foundation and level of the JuicePump

Communications

between the IPU and UU. If the UU and

(default).

4G network capability.

Category 6a STP Ethernet cable required

with a minimum length from the founda-

tion surface.

Fiber Optic Cable: OM3 Multi Mode 2 Core

For detailed wiring instructions, see

-

ing and Cabling

.

6www.enelx.com

Phone: +1-844-584-2329

TRI125.INS.036.3

Servicing distance

inches from the front and rear of the

JuicePump user unit is required to open

the front panel for servicing, as shown in

the image below.

Cable range

4300

Figure 2. Cable range

4300 mm / 169.291 inches

7www.enelx.com

Phone: +1-844-584-2329

TRI125.INS.036.3

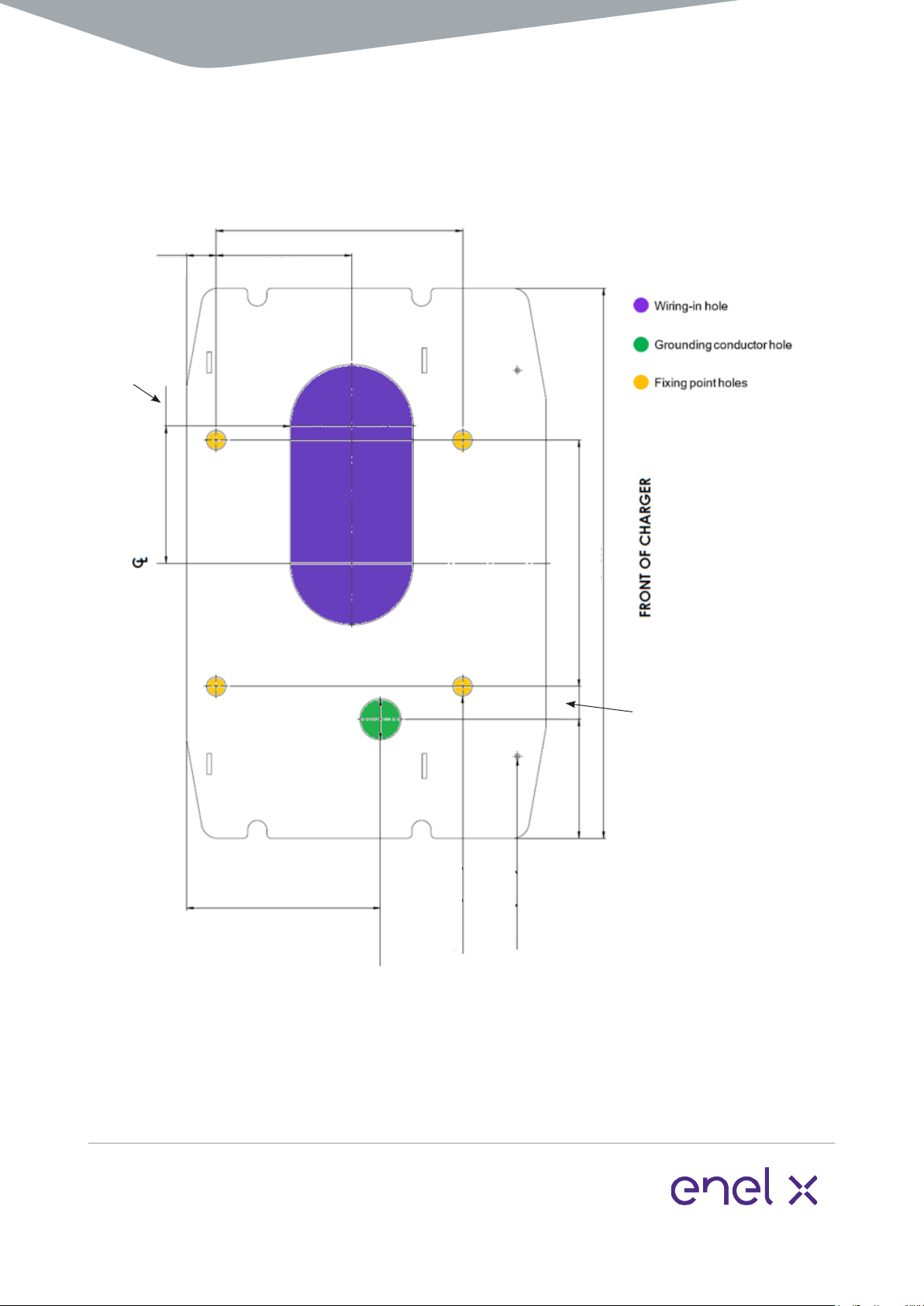

Baseplate dimensions

Note: Do not scale. All dimensions shown in millimeters (mm)/inches (in).

A mounting stencil may be supplied by the manufacturer at customer re-

quest.

300 / 11.811

36 / 1.417

236 / 9.291

670 / 26.377

300 / 11.811

8www.enelx.com

Phone: +1-844-584-2329

TRI125.INS.036.3

Installation requirements & equipment

These instructions provide a systematic

guide for installing and commissioning

the JuicePump user unit.

The JuicePump user unit must be

electrical personnel.

Observe all pertinent national, regional,

and local safety regulations when you

install and commission the JuicePump

user unit.

electronics enclosure rating, however, as

it must be opened for installation, this is

best done in dry weather or under cover

to avoid moisture and debris ingress.

The JuicePump user unit must be properly

installed, assembled, and commissioned

according to these instructions before it is

used.

Prior to installation contact your supplier

Supplied with JuicePump user

unit:

•

panels

• 4 mm Allen key to remove fasteners

on the enclosure access cover

•

•

• M10 fasteners for wiring in

•

Required equipment (not sup-

plied):

• Lifting apparatus. See the “Packag-

ing, handling, & receipt” section for

weights. Ensure lifting apparatus is

• 110 mm / 4.330 inch OD Conduit

•

for wiring installation.

•

are not supplied, as the type required

depends on the foundation used and

must be chosen by the installer

accordingly.

• Socket set & ratchet

• Torque wrench with 30 Nm setting

• Torque wrench with 2 Nm setting

•

9www.enelx.com

Phone: +1-844-584-2329

TRI125.INS.036.3

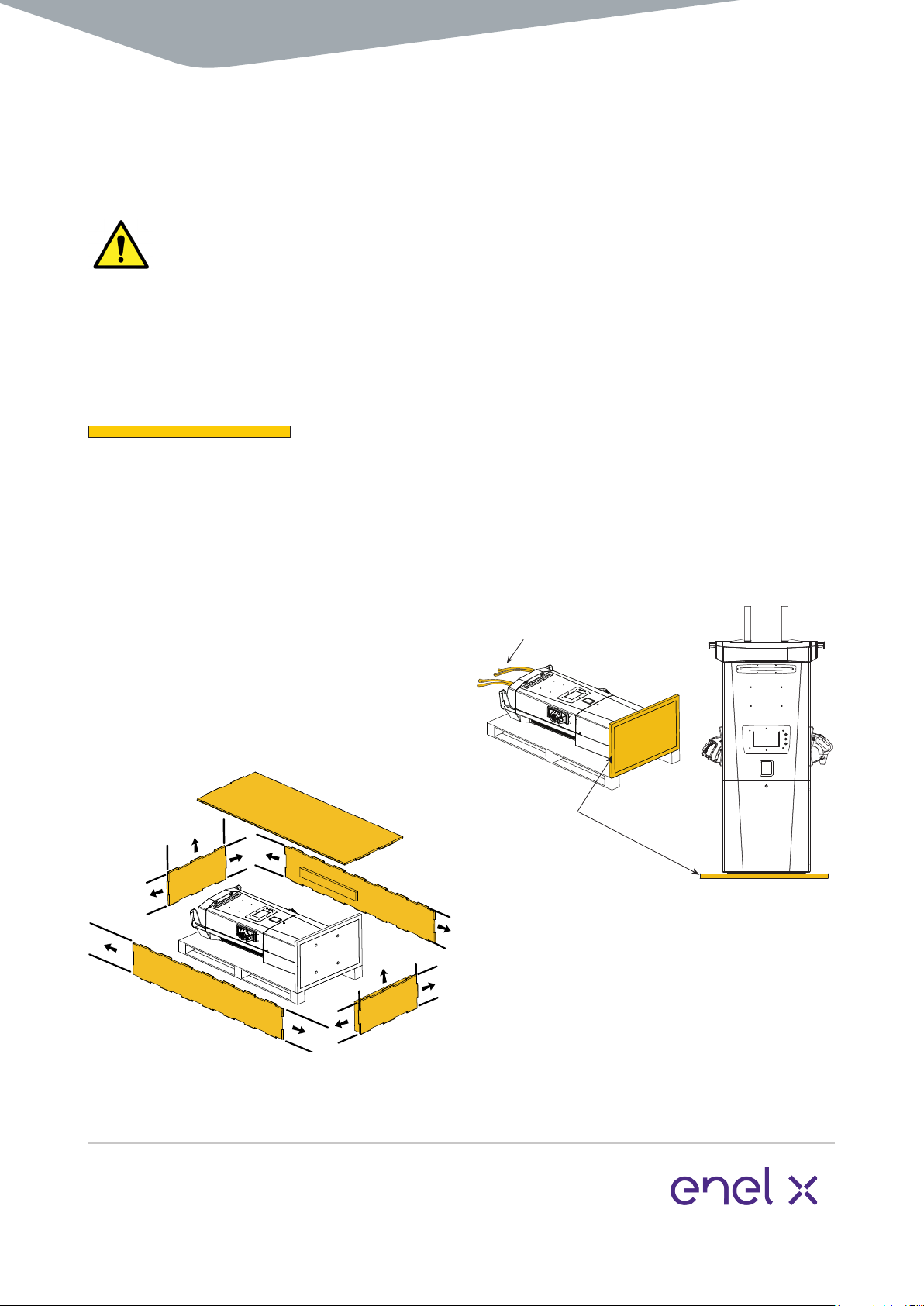

Do not work under suspended loads.

Two people may be required as the unit

may swing.

DOCUMENT KEY:

Items shown in orange are parts that

require action for that step.

1. Open crate

Move the crate as close to the

prepared installation site as possible.

Ensure there is enough room to

maneuver the lifting apparatus.

Remove/slide out all crate tubes to

disassemble the cardboard crate.

2. Lift JuicePump user unit

to vertical

Securely attach the lifting straps at the

top of JuicePump to the lifting apparatus

and gently raise to a standing position on

the shipping baseplate.

NOTE: The JuicePump user unit is

2,060 mm / 81.102 inches tall on the

shipping baseplate.

Once the unit is upright remove all wrap-

ping. Ensure the connection to the lifting

apparatus is secure at all times.

Shipping

Baseplate

Lifting Straps

Unpacking

10 www.enelx.com

Phone: +1-844-584-2329

TRI125.INS.036.3

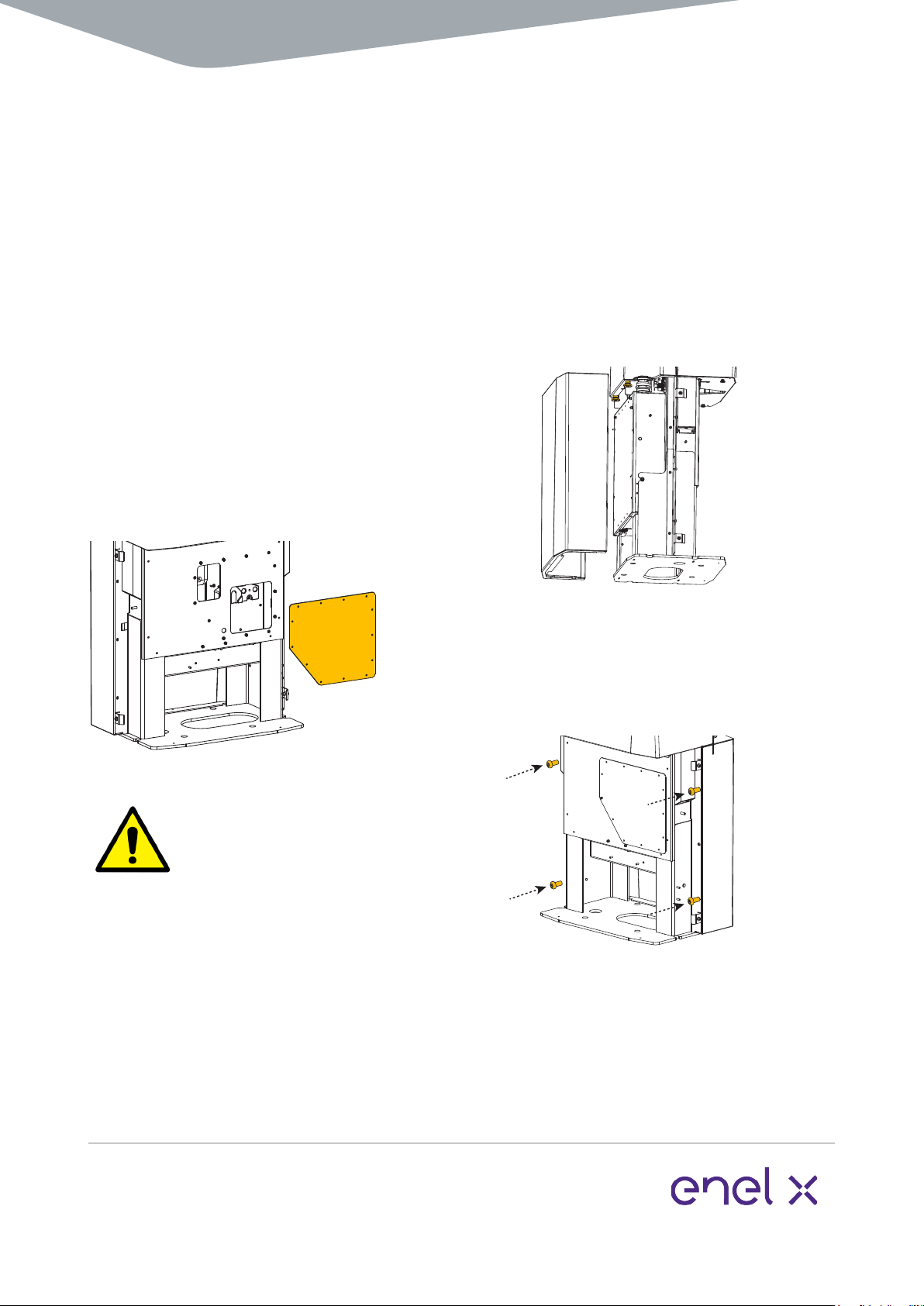

3. Remove shipping bolts

Unscrew the 4 bolts from the shipping

module not shown).

4. Secure to foundation

Lift the JuicePump user unit and place

over the prepared foundation. Feed the

conduit and wiring through the power in

points (fasteners not supplied).

Note: Use the plastic inserts in the holes

of the baseplate.

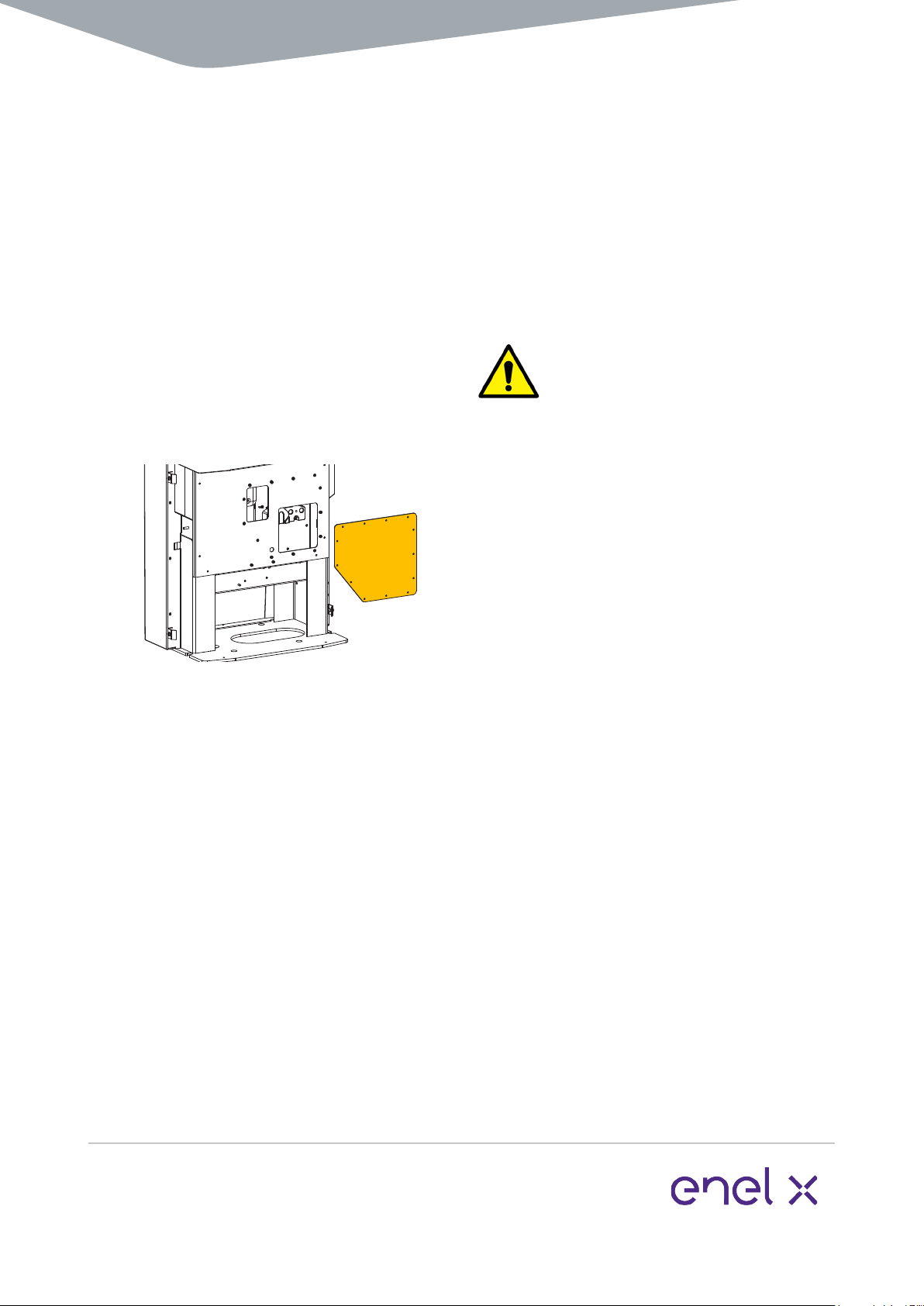

1. Remove lower front panel

4 security screws (2 per side) from the

front panel, then remove them. Pull the

front panel forward to remove and safely

store all parts.

2. Remove rear lower panel

Follow this step to increase visibility and

access to the mounting holes. If visibility

Use the 4 mm Allen key to unscrew the 4

screws that attach the rear panel to the

enclosure and slide out to remove.

Installation

11 www.enelx.com

Phone: +1-844-584-2329

TRI125.INS.036.3

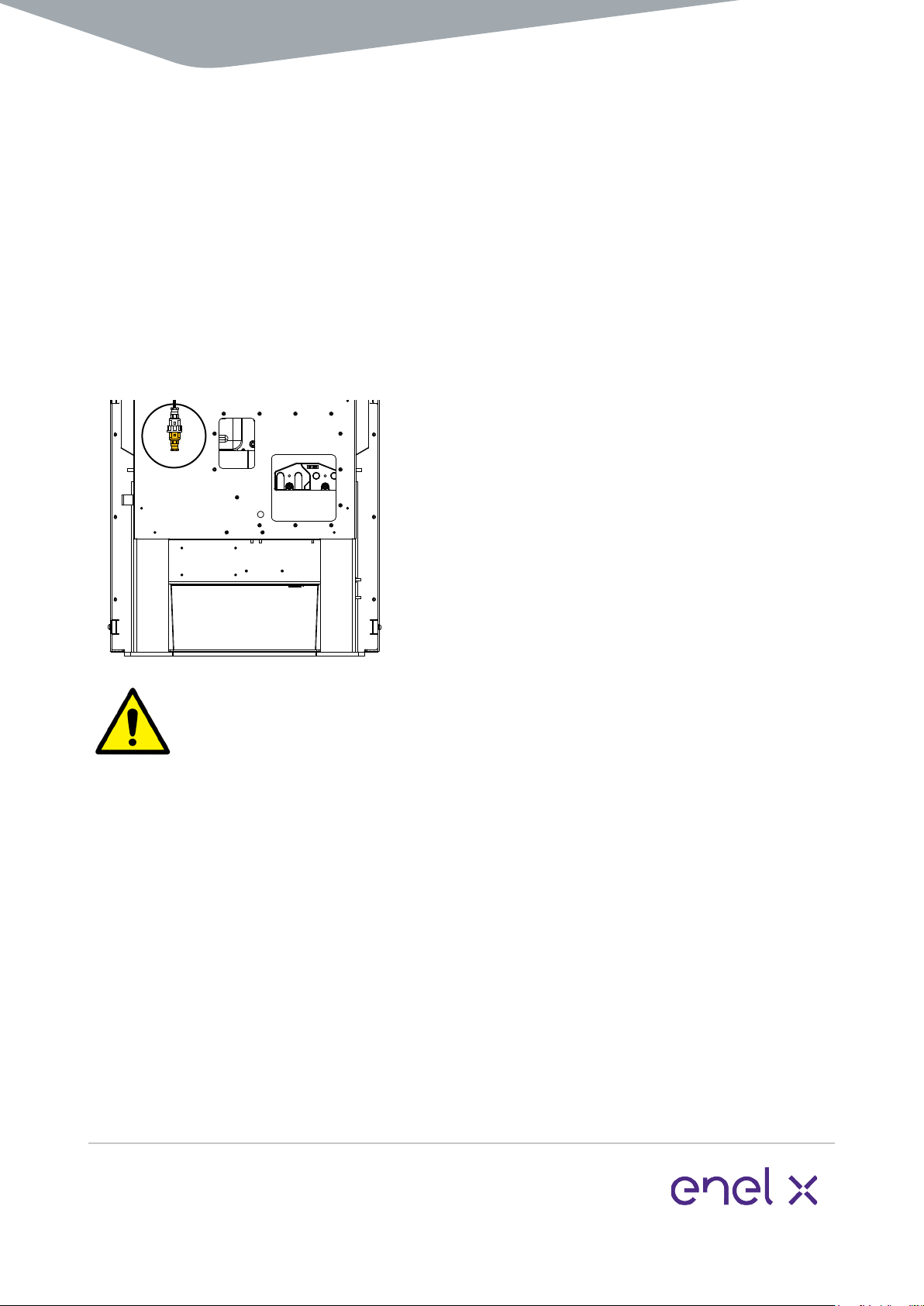

8. Remove M10 fasteners

fasteners. Remove the fasteners ready for

wiring in.

\

CAUTION

correctly into the cable gland.

Ensure the cable is sitting correctly in the

gland and tighten to ensure no water or

debris can enter. If in doubt, use an

appropriate outdoor-rated sealant.

When the cable gland has been tightened,

pull on the cable to ensure it doesn’t slip.

Remove the enclosure access cover

screws with the 4 mm allen key to pre-

pare the JuicePump for wiring installation.

The enclosure access cover has an

attached gasket. Ensure this is carefully

stored to avoid damage or accumulation

of debris.

6. Remove tape and attach

cable glands

7. Prepare wiring

Fit the individual power cabling into

each M32 cable gland, ensuring there is

enough length to add the M10 lugs (not

supplied) and attach to the busbars. Fit

each wire with an M10 lug.

Installation

12 www.enelx.com

Phone: +1-844-584-2329

TRI125.INS.036.3

Wiring & commissioning

Note: Refer to the TRI125.INS.018

JuicePump RT 175-S Site Installation

Manual for a table of all torques used

during installation.

M8 grounding stud (M8 lug not

supplied) on the inside channel.

CAUTION

Wiring and commissioning of the charger

personnel only.

The wiring diagram is also available on

the inside of the Service Hatch.

1. DC conductors

Attach the M10 lugs onto the negative

and positive busbar positions as shown.

Ensure that the lugs and connection

points are clean and free of dirt before

you make the connections.

CRITICAL

Clean the surface areas of the

mating surfaces with an abrasive pad and

use jointing compound between the

mating surfaces.

You must use a torque wrench to tighten

you must apply a torque mark to the

stud and nut.

CRITICAL

Tightening Torque:

30 Nm / 22 lb-ft

13 www.enelx.com

Phone: +1-844-584-2329

TRI125.INS.036.3

Wiring & commissioning

Note:

connections, refer to the wiring diagram

sticker on the inside of the Service Hatch.

2. Single phase power

terminals are located on the underside of

the top-left section of the wiring access

hatch. Refer to the wiring diagram on the

inside of the Service Hatch, or wire into

the terminal blocks as follows:

12

Terminal blocks

3 4

1: Line

2: Neutral

4: Earth reference

Strip and crimp the single-phase wires

before terminating to the appropriate

terminals. Once installed, perform a

pull-test to ensure that the terminations

are secure.

CRITICAL

If the single-phase wiring is run in a

three-core cable (2C+E), do not

terminate the third core (earth) to the

common grounding terminal (green and

yellow). This wire must be terminated to

terminal block 4.

If not installed correctly, it will prevent

the IMI from adequately monitoring the

site earth.

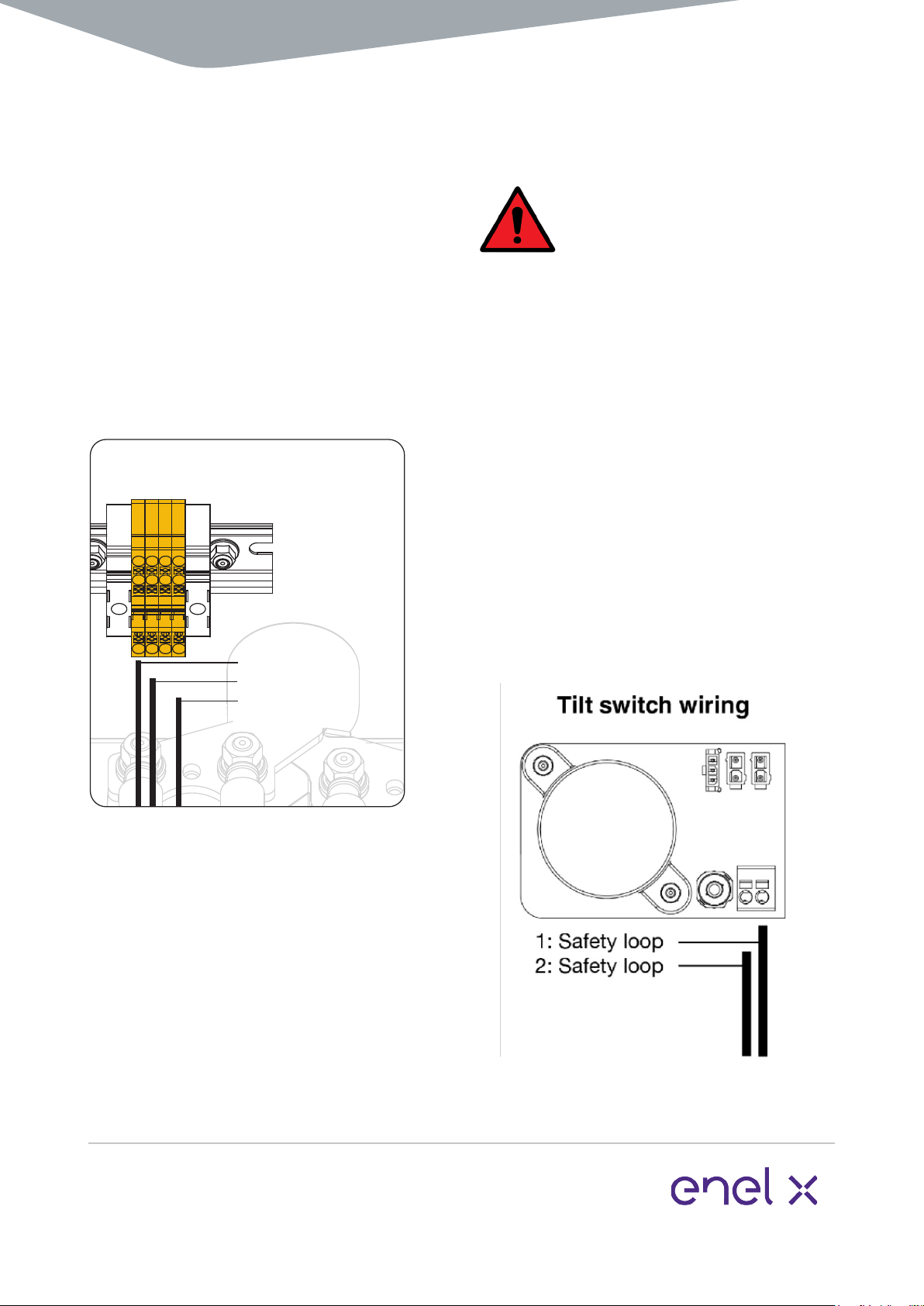

3. Safety loop

The two safety loop terminals are

located on the tilt-switch PCB, located

on the bottom-right section of the wiring

critical for these wires.

14 www.enelx.com

Phone: +1-844-584-2329

TRI125.INS.036.3

The Ethernet port is situated on the front

Twist to disengage the base cap and wire

in the Category 6a STP Ethernet cable.

CAUTION

To ensure the stability of communication

to the user unit, it is important that when

terminating the network cable, the shield

is earthed appropriately to the terminal.

Ethernet port access

www.enelx.com

Phone: +1-844-584-2329

TRI125.INS.036.3

Fiber optic access

interface module is required.

shall be mounted at the bottom of the

user unit.

into the Ethernet port of the user unit.

Ensure that the coupling ring is tight,

connected, the connection is tight.

For detailed wiring instructions, see

-

ing and Cabling

.

16 www.enelx.com

Phone: +1-844-584-2329

TRI125.INS.036.3

Follow these steps in order to ready

the unit for commissioning:

1. Remove lifting straps

Carefully remove the lifting straps from

the top slots in the plastic.

2. Attach enclosure access cover

Check to make sure the gasket has not

been damaged or soiled. Use the 4 mm

Allen key to attach the enclosure access

cover screws.

CAUTION

If using a power drill to fasten the nuts,

ensure the correct torque setting of no

greater than 2.0 Nm / 17.7 lb-inch. If

using a hand tool, fasten until resistance

is felt. Do not over-tighten.

Over-tightening may result in damage to

the screws and/or gasket, reducing the

compromise the ingress protection rating

of the enclosure.

3. Attach the rear lower panel

Lift the panel and slide it over the

both sides until it is secure under the top

screws on both sides.

Do not over-tighten.

Closing checklist

17 www.enelx.com

Phone: +1-844-584-2329

TRI125.INS.036.3

4. Plug in the parking sensor

The JuicePump user unit has a parking

sensor available for use on the front lower

panel.

Unclip the parking sensor plug from

the front metal panel and plug into the

parking sensor.

Note that the plug for the parking sensor

is located inside and under the central

edge of the front panel.

Screw the plugs together to ensure the

Raise and slide the front lower panel into

panel.

Fasten both sides with nylon washers and

tool.

Do not over-tighten.

The JuicePump is now ready for

commissioning.

Closing checklist

Other manuals for JuicePump

4

Table of contents

Other Enel X Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

Go groove

Go groove SMARTmini AUX operating manual

Air Design

Air Design SILVERADO 2014 + installation manual

Sony Ericsson

Sony Ericsson HCB-150 manual

U.S. General

U.S. General 6"OFF ROAD LIGHT 95811 Assembly and operation instructions

FormFit

FormFit HDW 9J 04 manual

MetaSystem

MetaSystem T.30 installation manual