Enerdis Enerium 100 User manual

MS1 – 735

2

FOR

ENERIUM

2

Ed04

U

ENERIUM

100/110/200/210/300/310

P

OWER

232 / 332 / 333

Power

Monitor

U

SER MANUAL

100/110/200/210/300/310

OWER

M

ONITORS

232 / 332 / 333

U

SER MANUAL

–

ENERIUM

100/200/300

MS

1

-

7352 ENERIUM100/200/300_ Ed0

4

User

Manual

Page

2

/

86

TABLE OF CONTENTS

1

SAFETY ..................................................................3

1.1

P

REAMBLE

........................................................... 3

1.2

I

NITIAL PRECAUTIONS

............................................. 3

1.3

C

LEANING INSTRUCTIONS

........................................ 3

2

WARRANTY, RESPONSIBILITY AND INTELLECTUAL

PROPERTY .....................................................................4

2.1

W

ARRANTY

.......................................................... 4

2.2

I

NTELLECTUAL PROPERTY RIGHTS

.............................. 4

2.3

M

AINTENANCE

..................................................... 4

2.4

E

QUIPMENT END

-

OF

-

LIFE

........................................ 4

3

OVERVIEW ............................................................5

3.1

P

ACKING

............................................................. 5

3.2

O

PTIONAL ACCESSORIES AND DOCUMENTATION

.......... 5

3.3

O

VERVIEW

...........................................................

3.4

M

ODEL COMPARISON

............................................ 7

3.5

T

ERMINOLOGY

..................................................... 8

4

MECHANICAL CONSTRUCTION ..............................9

4.1

P

REAMBLE

........................................................... 9

4.2

V

ERSION WITH DISPLAY

(M

ODELS

100/200/300) ..... 9

4.3

V

ERSION WITHOUT DISPLAY

(M

ODELS

110/210/310)

11

5

FRONT VIEW ........................................................ 12

5.1

D

ISPLAY SCREEN

.................................................. 12

5.2

O

PTICAL INTERFACE

............................................. 14

6

REAR VIEW .......................................................... 16

.1

M

EASUREMENT INPUTS

........................................ 1

.2

A

UXILIARY SOURCE

.............................................. 20

.3

O

PTIONAL CARDS

................................................ 21

.4

C

ARD OPTION

-

2

ANALOG OUTPUTS

....................... 22

.5

C

ARD OPTION

-

2

ANALOG INPUTS

.......................... 23

.

C

ARD OPTION

-

2

DIGITAL OUTPUTS

........................ 24

.7

C

ARD OPTION

-

2

DIGITAL INPUTS

........................... 25

.8

RS485

COMMUNICATION

.................................... 2

.9

E

THERNET COMMUNICATION

................................. 28

7

MAIN SCREEN AND MAIN MENUS ....................... 3

7.1

M

AIN SCREEN

..................................................... 30

7.2

E

LECTRICAL QUANTITIES AND UNITS

........................ 31

7.3

M

ENUS AND SUB

-

MENUS

..................................... 32

8

MEASUREMENTS SCREEN .................................... 33

8.1

T

HE SCREENS

...................................................... 33

8.2

D

ISPLAY RULES

................................................... 3

9

ENERGIES SCREEN ............................................... 38

9.1

T

HE SCREENS

...................................................... 38

9.2

E

NERGY DISPLAY RULES

........................................ 39

1

SERVICES SCREEN ............................................ 4

10.1

T

HE SCREENS

...................................................... 40

11

ALARMS SCREEN .............................................. 42

11.1

T

HE SCREENS

...................................................... 42

12

CUSTOM SCREENS ........................................... 44

13

CONFIGURATION SCREEN ................................ 45

13.1

E

LECTRICAL NETWORK

.......................................... 4

13.2

RS485

COMMUNICATION

.................................... 48

13.3

R

EMOTE

E

THERNET COMMUNICATION

.................... 50

13.4

D

ISPLAY

............................................................ 51

13.5

P

ASSWORD

....................................................... 52

13.

D

EFAULT PARAMETERS

........................................ 53

13.7

P

ARAMETERS NOT MODIFIABLE BY THE KEYBOARD

..... 53

14

HARMONICS SCREEN ...................................... 54

14.1

T

HE SCREENS

..................................................... 54

15

PHASOR DIAGRAMS SCREEN ........................... 55

15.1

T

HE SCREENS

..................................................... 55

16

POWER QUALITY SCREEN ............................... 58

1 .1

T

HE SCREENS

..................................................... 58

17

WAVEFORMS MANAGEMENT ......................... 64

18

LOAD CURVES ................................................. 65

19

TREND CURVES ............................................... 66

2

LOCAL AND REMOTE COMMUNICATION......... 67

20.1

E.S

ET AND

E.V

IEW APPLICATIONS

.......................... 7

20.2

S

PECIFIC APPLICATION

......................................... 7

21

CHARACTERISTICS ........................................... 69

21.1

M

EASUREMENTS

................................................ 9

21.2

L

OAD CURVES

.................................................... 70

21.3

A

LARMS

........................................................... 70

21.4

A

NALOG OUTPUTS

.............................................. 70

21.5

T

REND CURVES

................................................... 71

21.

I

NHERENT ERRORS

.............................................. 71

21.7

E

NVIRONMENTAL CONSTRAINTS

............................ 73

21.8

S

AVING INFORMATION

......................................... 74

22

FORMULAE AND CALCULATION METHODS ..... 75

22.1

C

ONVENTION

..................................................... 75

22.2

P

HASE VOLTAGES

................................................ 75

22.3

L

INE VOLTAGES

.................................................. 75

22.4

C

URRENT

.......................................................... 75

22.5

R

EAL POWER

..................................................... 7

22.

P

OWER ROTATION DIRECTION

............................... 7

22.7

R

EACTIVE POWER

............................................... 7

22.8

A

PPARENT POWER

.............................................. 7

22.9

P

OWER FACTOR

................................................. 77

22.10

C

OS

(

Φ

) ........................................................ 77

22.11

P

EAK FACTOR

................................................. 77

22.12

T

AN

(

Φ

) ........................................................ 78

22.13

F

REQUENCY

................................................... 78

22.14

H

ARMONICS

.................................................. 78

22.15

T

OTAL HARMONIC DISTORTION

.......................... 78

22.1

E

NERGY AND ENERGY METERING

........................ 79

22.17

U

NBALANCE

.................................................. 79

22.18

P

HASE ORDER

................................................ 80

22.19

H

OUR METER

................................................. 80

22.20

A

VERAGE MEASUREMENTS

............................... 80

22.21

C

ALCULATION OF MINIMA

................................ 82

22.22

Q

UANTITY MINIMA

......................................... 82

22.23

M

INIMA OF AVERAGE QUANTITIES

..................... 83

22.24

C

ALCULATION OF MAXIMA

................................ 83

22.25

Q

UANTITY MAXIMA

......................................... 83

22.2

M

AXIMA OF AVERAGE QUANTITIES

..................... 84

22.27

A

NALOG INPUTS

............................................. 85

U

SER MANUAL

–

ENERIUM

100/200/300

MS

1

-

7352 ENERIUM100/200/300_ Ed0

4

User

Manual

Page

3

/

86

1 S

AFETY

1.1 Preamble

Read the following recommendations before installing and using the device.

You have just purchased an ENERIUM 100, 110, 200, 210, 300 or 310 power monitor. Thank you for

choosing it.

Make sure the device is intact and undamaged as soon as you receive it. In the event of any problems,

please contact the after-sales department for any repairs or replacements.

To get best use from your device please read this manual carefully and apply its storage, installation

and operating instructions with care.

The device described in this manual is intended to be used by trained staff only.

Any maintenance operations must be carried out by qualified and authorised personnel only.

For correct and safe use and for all maintenance operations it is essential that staff follow standard

safety procedures.

This device is intended to be used in Category III, pollution degree 2 installation conditions in

accordance with IEC 61010-1.

Before installation, check that the supply voltage matches that of the ENERIUM device.

1.2 Initial precautions

1.2.1 Safety precautions

Before installing this electrical device and any associated peripherals, check that the power is

disconnected and isolated in accordance with current safety norms.

1.2.2 Precautions against parasitics

Although the ENERIUM is protected from electrical and electromagnetically induced interference, keep

away from the immediate vicinity of equipment generating significant electrical noise (high-power

switches, busbars, etc.) The quality of data communication on the data bus depends heavily on taking

such precautions.

1.2.3 Precautions in the event of breakdowns

When safe operation is no longer possible, the instrument must be switched off and isolated. This

applies when:

•The device is visibly damaged during operation (whether the device still operates or not),

•The device does not work after prolonged storage in poor conditions,

•The device no longer works following severe damage during transport.

1.3 Cleaning instructions

When the monitor is disconnected from the mains, clean the outer surface using only a dry cloth. Do not

use abrasives or solvents. Prevent the connector terminals getting wet.

U

SER MANUAL

–

ENERIUM

100/200/300

MS

1

-

7352 ENERIUM100/200/300_ Ed0

4

User

Manual

Page

4

/

86

2 W

ARRANTY

,

R

ESPONSIBILITY AND

I

NTELLECTUAL

P

ROPERTY

2.1 Warranty

Unless expressly stipulated, the warranty runs for twelve months after the date of supply of the monitor

(extract from our General Conditions of Sale, available on request).

2.2 Intellectual property rights

This manual is the property of ENERDIS and is protected by copyright. It may not be distributed,

reproduced, or translated, in whole or in part, in any manner and in any form whatsoever.

ENERIUM is a registered ENERDIS trademark.

2.3 Maintenance

As no electrical or electronic part is end user-replaceable, the monitor must be returned to the

Manumesure after-sales service centre.

2.4 Equipment end-of-life

This product falls within the scope of the Directive 2012/19/CE on waste electrical and electronic

equipment (WEEE).

Contact the company ENERDIS for information regarding the dismantling and end of life equipment.

U

SER MANUAL

–

ENERIUM

100/200/300

MS

1

-

7352 ENERIUM100/200/300_ Ed0

4

User

Manual

Page

5

/

86

3 O

VERVIEW

3.1 Packing

Each delivered product should contain, at least, the following parts:

Designation No. Off

ENERIUM 100,110, 200, 210, 300 or 310 power monitor 1

CD-ROM containing:

This manual in pdf format

E.Set configuration software (with a 30-day trial version of E.View/E.View+)

The USB driver for the optical head accessory

1

Simplified operating instructions (A4 format) 1

ENERIUM 100, 200 or 300 table brackets 4

ENERIUM 110, 210 or 310 DIN rail brackets 2

Alternative parts depending on the option chosen:

Designation No. Off

Removable connectors for optional cards 0 to 4

3.2 Optional accessories and documentation

Designation Comment Code

USB optical head To enable local communication P01330401

E.View software Display software (Tabular) P01330401

E.View+ software Display software (Graphical) P01330401

E.Online software Multi-energy application software P01335075

Mapping and control words manual Manual MS0-7423

Load curves operating manual Manual MS0-7389

Recording curves operating manual Manual MS0-7390

User manual power quality measurements

Manual MS1-7530

DIN rail and cabinet base fixing kit Allows fitting on DIN rails and to the cabinet base P01330401

E.Set / E.View / E.view+

manual User manual MS0-7376

Firmware update Instruction manual MS0-7419

MS

1

-

7352 ENERIUM100/200/300_ Ed0

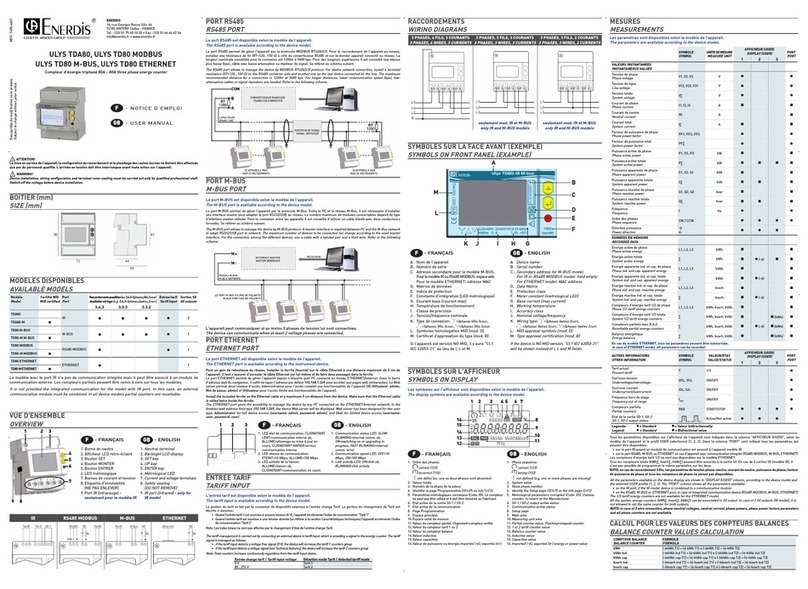

3.3 Overview

ENERIUM 100, 110, 200, 210, 300 and 310 power monitors are 144 x 144 format monitors, conforming

to DIN 43700, for electrical networks of all types, for all measurement, display and

applications on low and medium voltage networks.

ENERIUM 100, 110, 200, 210, 300 and 310 conform to the NF EN 61557

standard.

ENERIUM 100 and 110 conform

ENERIUM 200 and 210 conform

ENERIUM 300 and 310 conform

ENERIUM power monitors process more than 50 network quantities (U, V, I, P, Q, S, PF, tan

reactive and apparent energy, THD, etc.).

The infor

mation collected is available on the front panel of the monitor in 5 languages, via a backlit LCD

display, as

well as via an RS485 digital output using ModBus/RTU or ASCII, or Ethernet using

Modbus/TCP.

One or more optional outputs generate an alarm signal

It can be programmed locally or remotely, enabling the monitor to be integrated into an installation

rapidly.

The power monitor is available in six different models: ENERIUM 100, 110, 200, 210, 300 and310.

Models 110, 210 and 310 have no display; equivalent models with a display are the 100, 200 and 300.

(1) Source : http://www.gimelec.fr

U

SER MANUAL

–

ENERIUM

7352 ENERIUM100/200/300_ Ed0

4

User

Manual

ENERIUM 100, 110, 200, 210, 300 and 310 power monitors are 144 x 144 format monitors, conforming

to DIN 43700, for electrical networks of all types, for all measurement, display and

applications on low and medium voltage networks.

ENERIUM 100, 110, 200, 210, 300 and 310 conform to the NF EN 61557

ENERIUM 100 and 110 conform

to

the (1) (IM2) 232 measurement index.

ENERIUM 200 and 210 conform

to

the (1) (IM2) 332 measurement index.

ENERIUM 300 and 310 conform

to

the (1) (IM2) 333 measurement index.

ENERIUM power monitors process more than 50 network quantities (U, V, I, P, Q, S, PF, tan

reactive and apparent energy, THD, etc.).

mation collected is available on the front panel of the monitor in 5 languages, via a backlit LCD

well as via an RS485 digital output using ModBus/RTU or ASCII, or Ethernet using

One or more optional outputs generate an alarm signal

, send pulse counts or manage analog outputs.

It can be programmed locally or remotely, enabling the monitor to be integrated into an installation

The power monitor is available in six different models: ENERIUM 100, 110, 200, 210, 300 and310.

Models 110, 210 and 310 have no display; equivalent models with a display are the 100, 200 and 300.

The ENERIUM 300 monitor

ENERIUM

100/200/300

Page

6

/

86

ENERIUM 100, 110, 200, 210, 300 and 310 power monitors are 144 x 144 format monitors, conforming

to DIN 43700, for electrical networks of all types, for all measurement, display and

supervisory

-12 power measurement

the (1) (IM2) 232 measurement index.

the (1) (IM2) 332 measurement index.

the (1) (IM2) 333 measurement index.

ENERIUM power monitors process more than 50 network quantities (U, V, I, P, Q, S, PF, tanφ, real,

mation collected is available on the front panel of the monitor in 5 languages, via a backlit LCD

well as via an RS485 digital output using ModBus/RTU or ASCII, or Ethernet using

, send pulse counts or manage analog outputs.

It can be programmed locally or remotely, enabling the monitor to be integrated into an installation

The power monitor is available in six different models: ENERIUM 100, 110, 200, 210, 300 and310.

Models 110, 210 and 310 have no display; equivalent models with a display are the 100, 200 and 300.

U

SER MANUAL

–

ENERIUM

100/200/300

MS

1

-

7352 ENERIUM100/200/300_ Ed0

4

User

Manual

Page

7

/

86

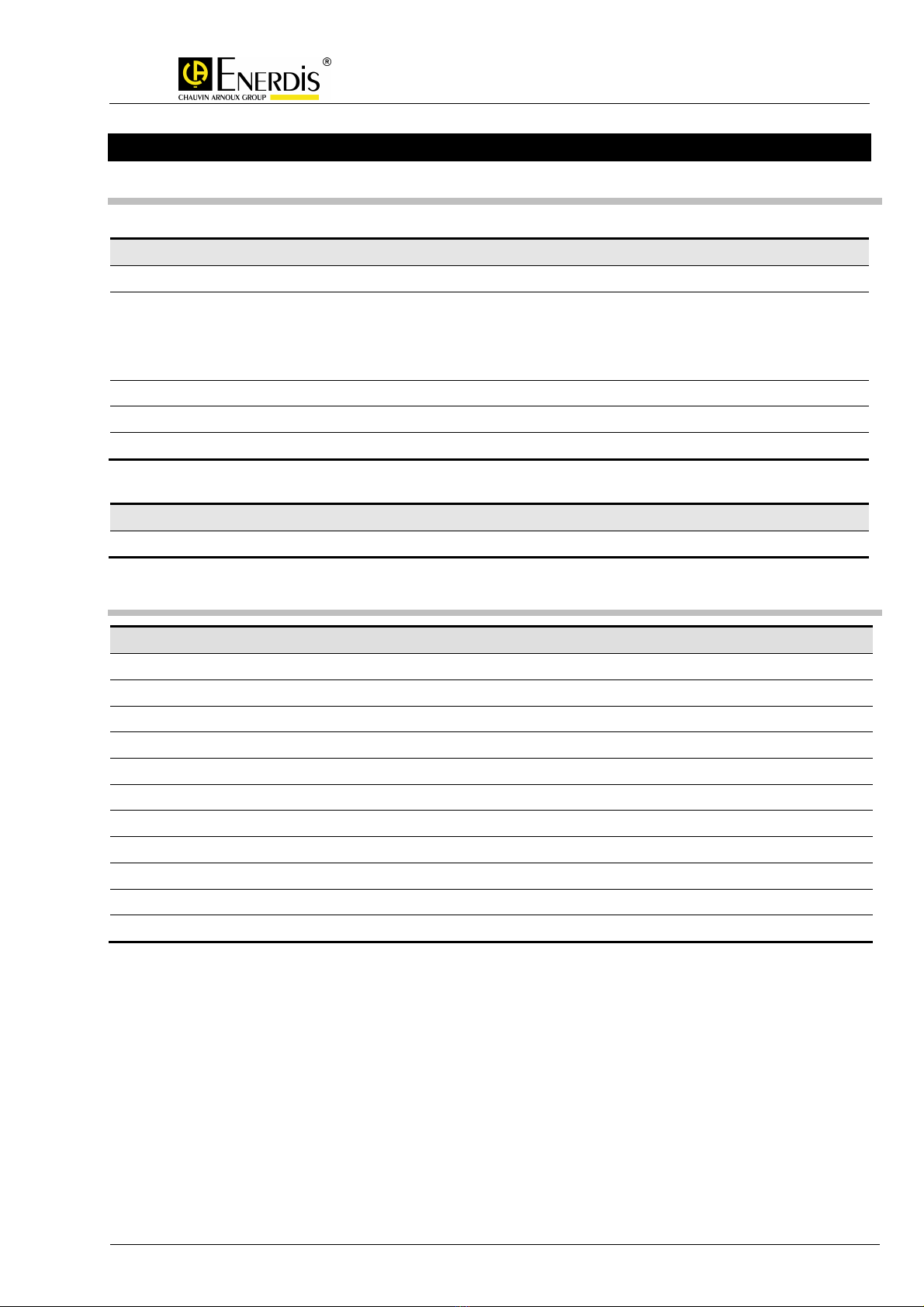

3.4 Model comparison

The table below shows the main characteristics of the 100, 110, 200, 210, 300 and 310 models.

Enerium

100

Enerium

110

Enerium

200

Enerium

210

Enerium

300

Enerium

310

Measurements

Calculation and measurement of the

neutral current

3- or 4-wire capability

Tan ϕ

Harmonics up to order 25 25 50 50 50 50

400 Hz network - - - - - -

EN 50160 - - - -

Waveforms (64 samples per cycle) - - - -

Display

Custom screens

-

-

-

Power Quality - - - -

I/O cards

Optional card

(1)

4 4 4 4 4 4

Alarms

Basic 16 16 16 16 16 16

Global 8 8 8 8 8 8

Event journal records 1024 1024 1024 1024 1024 1024

Curves

Load curve - -

8

quantities

chosen

from 10

possible

ones

(2)

8

quantities

chosen

from 10

possible

ones

(2)

8

quantities

chosen

from 10

possible

ones

(2)

8

quantities

chosen

from 10

possible

ones

(2)

Recording curve

Communication

Optical (front panel)

-

-

-

Optical (rear panel)

Ethernet (Modbus / TCP)

(3)

RS485 (Modbus RTU or ASCII)

(3)

IP address parameters at the front

-

-

-

Graphs

Phasor

-

-

-

Harmonics - -

-

-

Fixing

LCD display

-

-

-

DIN Rail

Panel

- - -

Inside cabinet With fixing

kit

4)

With fixing

kit

4)

With fixing

kit

4)

U

SER MANUAL

–

ENERIUM

100/200/300

MS

1

-

7352 ENERIUM100/200/300_ Ed0

4

User

Manual

Page

8

/

86

Enerium

100

Enerium

110

Enerium

200

Enerium

210

Enerium

300

Enerium

310

LED counter

-

-

-

(1) The card options are type 2 analog outputs, 2 analog inputs, 2 digital outputs and 2 digital inputs.

(2) P+, P-, Q1, Q2, Q3, Q4, S+, S-, E-TOR1, E-TOR2, TOR3, TOR4, TOR5, TOR6, TOR7, TOR8, ANAI1, ANAI2, ANAI3,

ANAI4, ANAI5, ANAI6, ANAI7 and ANAI8.

(3) The RS485 and Ethernet interfaces cannot both be present simultaneously.

(4) See § 4Mechanical Construction

3.5 Terminology

Measurements

Meaning

Vi, Ui Phase-Ground (Neutral) Voltage

Uij Phase-Phase Voltage

U

SER MANUAL

–

ENERIUM

100/200/300

MS

1

-

7352 ENERIUM100/200/300_ Ed0

4

User

Manual

Page

9

/

86

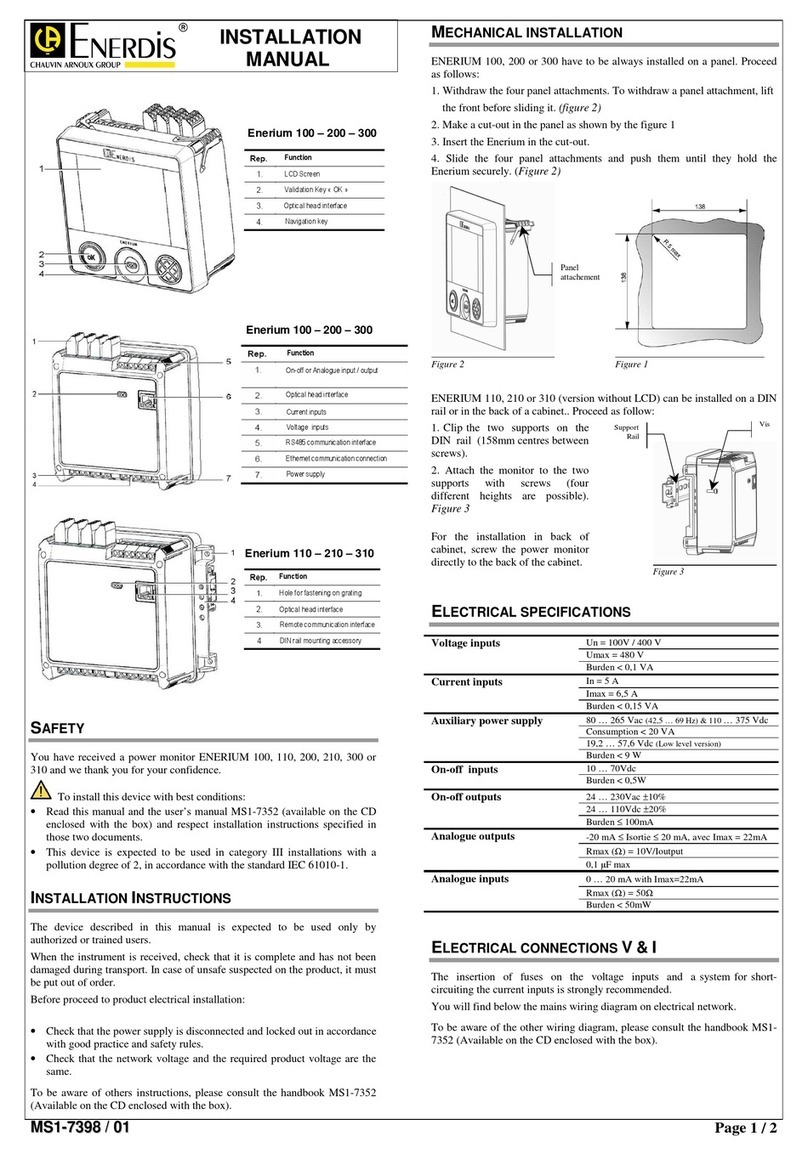

4 M

ECHANICAL

C

ONSTRUCTION

4.1 Preamble

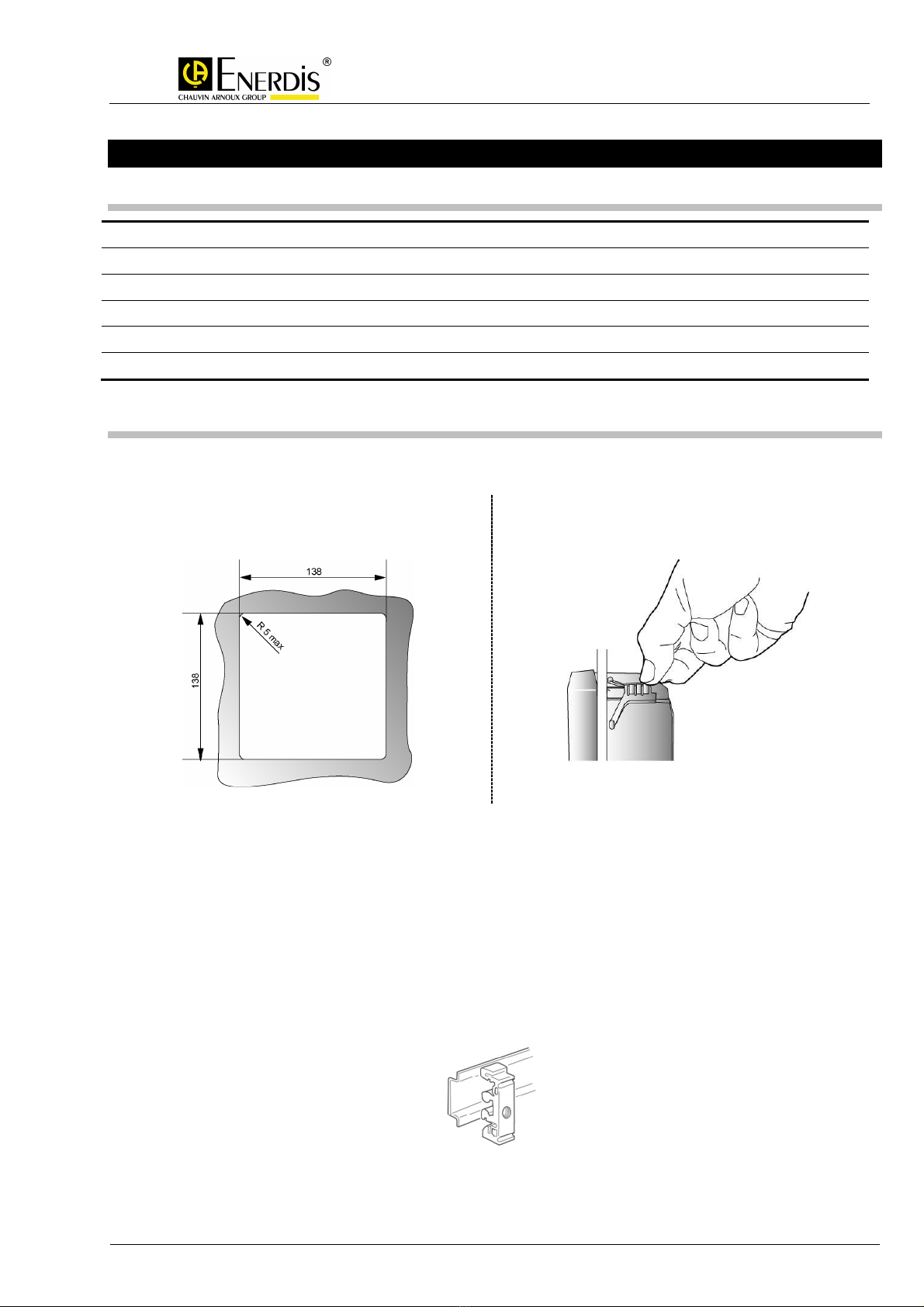

Overall dimensions (mm) See below

Weight With display: 800 g & without display: 700 g

Fixing Panel mounting, DIN Rail to DIN 43700, inside cabinet

Cutout size 138 x 138 mm

Fixing See paragraphs 4.2 and 4.3 (Optional DIN Rail and paragraph 3.2 Page 5)

Rating plate At the rear of the equipment

4.2 Version with display (Models 100/200/300)

Fixing can be by panel, DIN Rail, or inside the cabinet Proceed as follows:

For panel fixing:

•Make a cutout as shown below: •Insert the ENERIUM in the cutout from the front.

•Slide the four panel fasteners and push them until

they lock the ENERIUM into place.

Panel cutout dimensions Insert into the panel by lifting up the front and sliding it in

For DIN Rail and fixing inside the cabinet:

•DIN Rail fixing :

oInsert the ENERIUM in the cutout in the support fixture.

oFit the DIN Rail clips in the support fixture.

oConnect up the device.

oClip everything to the DIN Rail in the cabinet.

•Fixing inside the cabinet:

oInsert the ENERIUM in the cutout in the support fixture.

oConnect up the device.

oBolt everything into the cabinet.

Fixing clips

U

SER MANUAL

–

ENERIUM

100/200/300

MS

1

-

7352 ENERIUM100/200/300_ Ed0

4

User

Manual

Page

10

/

86

Support fixture for the DIN Rail and the inside of the cabinet

Overall dimensions in millimetres

144

144

U

SER MANUAL

–

ENERIUM

100/200/300

MS

1

-

7352 ENERIUM100/200/300_ Ed0

4

User

Manual

Page

11

/

86

4.3 Version without display (Models 110/210/310)

Fixing of these models can be by DIN Rail or inside the cabinet Proceed as follows:

•Clip the two supports (see below) on the DIN Rail

(spacing of 158 mm between bolts).

•Bolt the monitor on the two supports (for height

levels are possible).

Support for DIN Rail mounting

•To fix the monitor inside the cabinet, screw the unit

directly into the cabinet.

Overall dimensions in millimetres

U

SER MANUAL

–

ENERIUM

100/200/300

MS

1

-

7352 ENERIUM100/200/300_ Ed0

4

User

Manual

Page

12

/

86

5 F

RONT

V

IEW

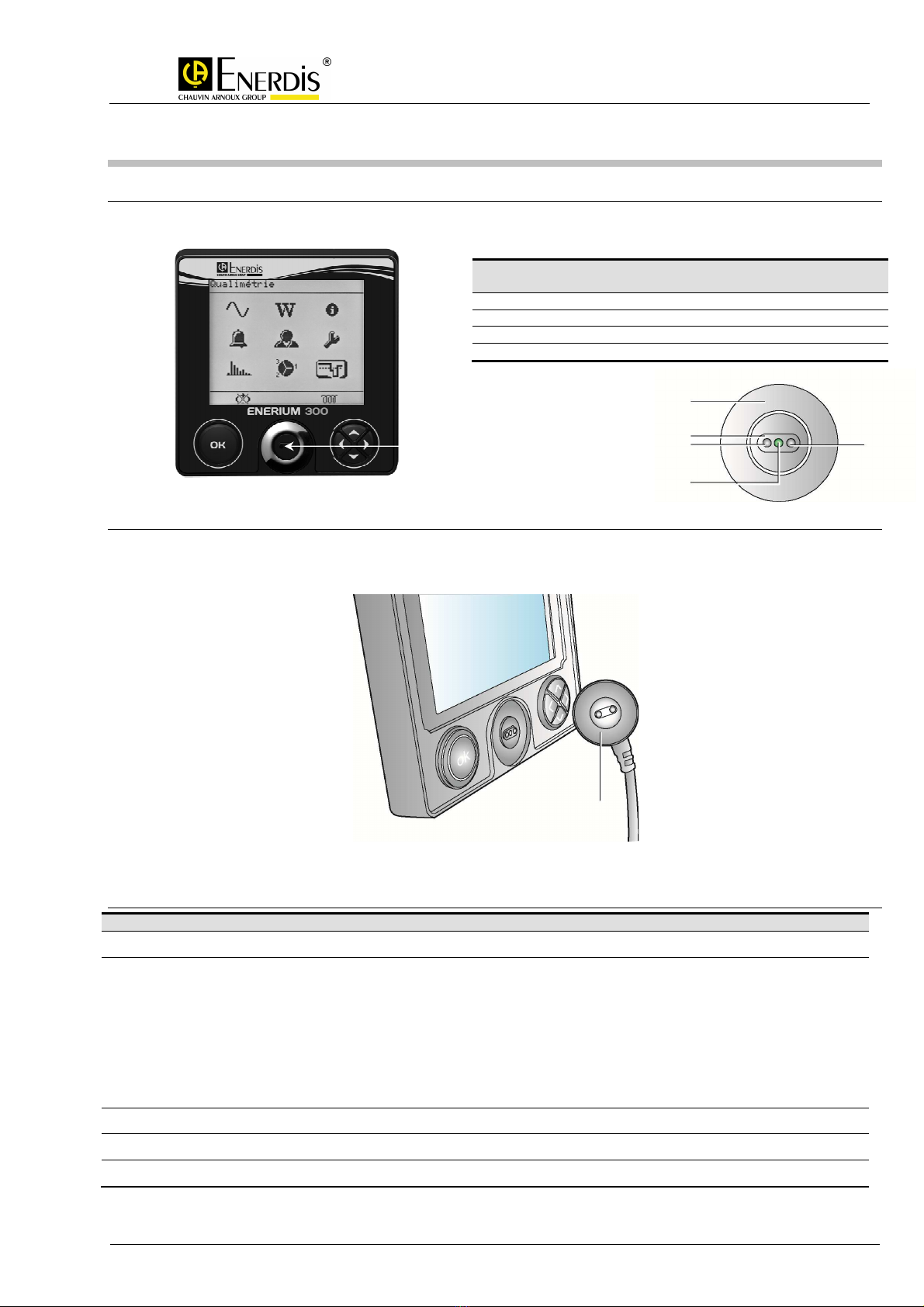

This section shows which components are accessible from the front for each model.

Front face of the ENERIUM 100, 200 or 300

5.1 Display screen

5.1.1 Introduction

The screen is a positive transmissive type LCD, has 128 lines of 160 pixels and is back-lit.

The backlight is activated by pressing one of the two buttons and switches off if no key press is

detected for 3 minutes

The contrast and brightness are adjustable via local or remote communication.

The main menu appears as follows:

Main menu

This screen enables:

•numerous measured and electrical quantities to be displayed

•Parameters to be displayed and changed

For the ENERIUM 100, the , and icons are not available.

For the ENERIUM 200, the icon is not available.

For the ENERIUM 300, all icons are available.

No.

Function

1 LCD screen

2 “OK” confirmation key

3 Front optical interface

4 Navigation keys

U

SER MANUAL

–

ENERIUM

100/200/300

MS

1

-

7352 ENERIUM100/200/300_ Ed0

4

User

Manual

Page

13

/

86

5.1.2 The upper part

The upper part shows the name of the screen being displayed.

Display of the input phase-neutral voltages

5.1.3 The central part

The central part gives an indication of the value of quantities displayed together with the corresponding

units.

The central part displays the measurements

5.1.4 The lower part

The lower part shows the states of the various icons

Icons on the lower part of the screen

Icon

Meaning

Flashing symbol, indicating that at least one global alarm is active

Fixed symbol, indicating a phase sequence error for voltage inputs

Flashing symbol, indicating that communication is in progress via the local or remote interfaces

Fixed symbol, indicating that automatic screen scrolling mode is active

Fixed symbol, indicating that the network is capacitive

Fixed symbol, indicating that the network is inductive

Fixed symbol, indicating that the network is a generator (not shown in receiver mode)

Quantities

Values

Units

MS

1

-

7352 ENERIUM100/200/300_ Ed0

5.2 Optical interface

5.2.1 Introduction

The optical interface consists of the following

5.2.2 Description

The optical interface allows parameters to be set, the downloading of measurements stored locally on

the ENERIUM to be sent to a PC, and the firmware to be updated, via the optical cable (accessory sold

separately, paragraph

3.2

5.2.3 Characteristics

Item

Protocol

Transmission format

Digital I/O

Indicator

Connector

U

SER MANUAL

–

ENERIUM

7352 ENERIUM100/200/300_ Ed0

4

User

Manual

The optical interface consists of the following

parts:

The optical interface allows parameters to be set, the downloading of measurements stored locally on

the ENERIUM to be sent to a PC, and the firmware to be updated, via the optical cable (accessory sold

3.2

Page 5).

Optical cable

Characteristics

ModBus in RTU mode

38400 baud fixed speed

1 start bit

8 data bits

No parity

1 stop bit

0 ms turnaround time

Responds to all slave addresses from 1 to 247

Optical (infrared) ensures bidirectional optical

transmission

Integral green metrology LED (pulse counting)

Optical connection with no electrical contact, paragraph

No.

Function

1 Metal washer

2 Locating device

3

Infrared communication transmitter and receiver

4

Green metrology LED and visual indicator

Optical

interface

Optical head

ENERIUM

100/200/300

Page

14

/

86

The optical interface allows parameters to be set, the downloading of measurements stored locally on

the ENERIUM to be sent to a PC, and the firmware to be updated, via the optical cable (accessory sold

transmission

Optical connection with no electrical contact, paragraph

3.2 on Page 5

Infrared communication transmitter and receiver

Green metrology LED and visual indicator

1

3

2

4

3

MS

1

-

7352 ENERIUM100/200/300_ Ed0

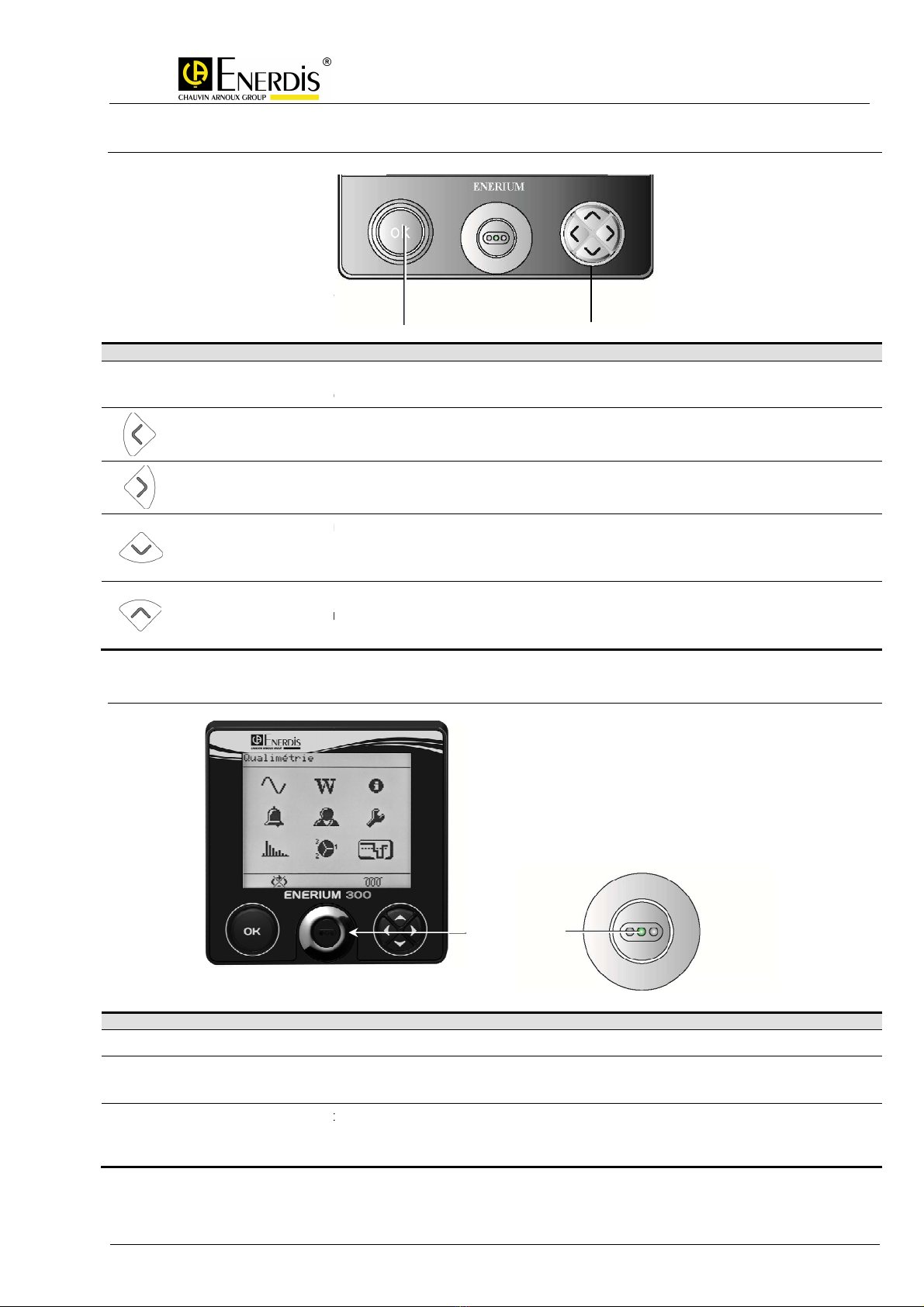

5.2.4 Keys

Key

Function

OK

Confirm selected choice

Entry to/Exit from edit mode

Move cursor left.

Return to preceding menu.

Move cursor right.

Menu: move cursor down

Parameter setting: decrement value

Lookup: go to next screen

Menu: move cursor up

Parameter setting: increment

Lookup: go to previous screen

5.2.5

Front status indicator

Indicator

Indication

Unlit ENERIUM

disconnected

Flashing

ENERIUM 100/200/300: Visual indication of the energy counter for the user or the optical

ENERIUM 110/210/310: No counter information available

Rapid flashing ENERIUM

faulty: Embedded software is faulty or requires an update

ENERIUM

awaiting embedded software to be loaded Communication is not possible and the screen is

faulty.

Confirmation

key

U

SER MANUAL

–

ENERIUM

7352 ENERIUM100/200/300_ Ed0

4

User

Manual

Confirm selected choice

or parameters

Entry to/Exit from edit mode

Return to preceding menu.

Menu: move cursor down

Parameter setting: decrement value

Lookup: go to next screen

Parameter setting: increment

value

Lookup: go to previous screen

Front status indicator

disconnected

ENERIUM 100/200/300: Visual indication of the energy counter for the user or the optical

ENERIUM 110/210/310: No counter information available

faulty: Embedded software is faulty or requires an update

awaiting embedded software to be loaded Communication is not possible and the screen is

Confirmation

Cursor keys

Status

indicator

ENERIUM

100/200/300

Page

15

/

86

ENERIUM 100/200/300: Visual indication of the energy counter for the user or the optical

cable.

awaiting embedded software to be loaded Communication is not possible and the screen is

Cursor keys

U

SER MANUAL

–

ENERIUM

100/200/300

MS

1

-

7352 ENERIUM100/200/300_ Ed0

4

User

Manual

Page

16

/

86

6 R

EAR

V

IEW

This section describes which components are accessible from the rear, for each model:

Rear view of the ENERIUM 100, 200 and 300

Rear view of the ENERIUM 110, 210 and 310

6.1 Measurement inputs

6.1.1 Voltage measurement inputs

6.1.1.1 Location

The voltage input terminals are labelled 9 to 13 on the rear right lower label.

6.1.1.2 Characteristics

Variables

Range

Nominal phase voltage 57.7/230 V

Nominal line voltage 100/400 V

Maximum line voltage 520V

Crest factor 2

Frequency 42.5 Hz to 69 Hz

24-hour overvoltage 800 V

Per-phase consumption 0.1 VA

Impedance 1 MΩ

No.

Function

1 Optional card connector block (digital or analog)

2 Rear optical interface

3 Current input terminals

4 Voltage input terminals

5 RS485 connector

6 Ethernet connector

7 Auxiliary source connector

Voltage inputs

U

SER MANUAL

–

ENERIUM

100/200/300

MS

1

-

7352 ENERIUM100/200/300_ Ed0

4

User

Manual

Page

17

/

86

Variables

Range

Non-removable terminals 5 screw terminals for rigid and flexible cables of between 4 and 6 mm²

Maximum torque: 0.8 Nm

6.1.2 Current measurement inputs

6.1.2.1 Location

The current input terminals are labelled 1 to 5 on the rear right lower label.

6.1.2.2 Characteristics

Variables

Range

Starting current 5 mA

Normal input current 5 A

Maximum input current 6.5 A

Crest factor 3

Frequency 42.5 Hz to 69 Hz

24-hour overcurrent 10A

Short-term overcurrent 250 A, over 1s

Per-phase consumption < 0.2 VA

Non-removable terminals 8 screw terminals for rigid and flexible cables of between 4 and 6 mm²

Maximum torque: 0.8 Nm

6.1.3 U and I protection

The use of fuses on the voltage inputs and a system for short-circuiting the input current is highly

recommended.

Current inputs

U

SER MANUAL

–

ENERIUM

100/200/300

MS

1

-

7352 ENERIUM100/200/300_ Ed0

4

User

Manual

Page

18

/

86

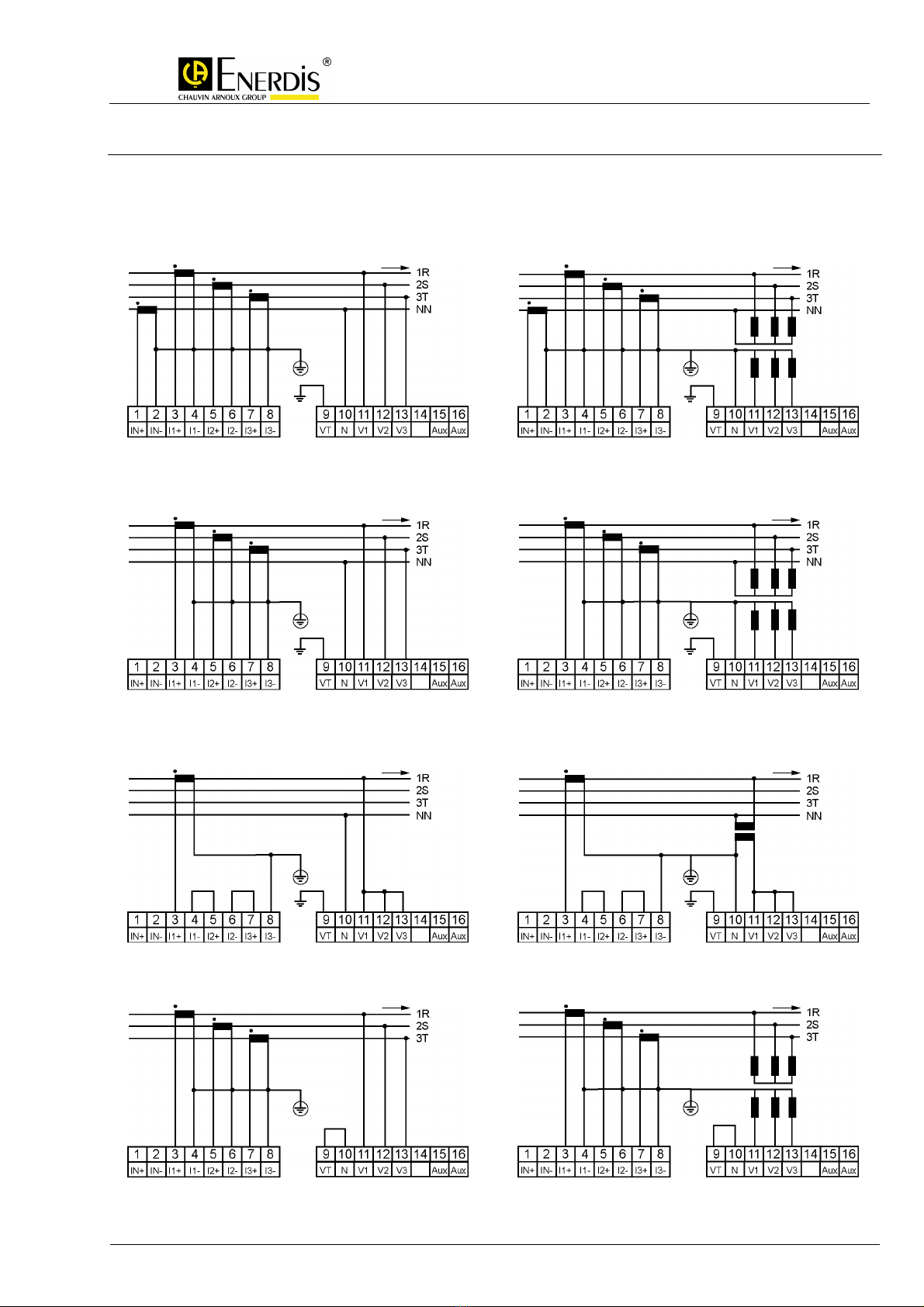

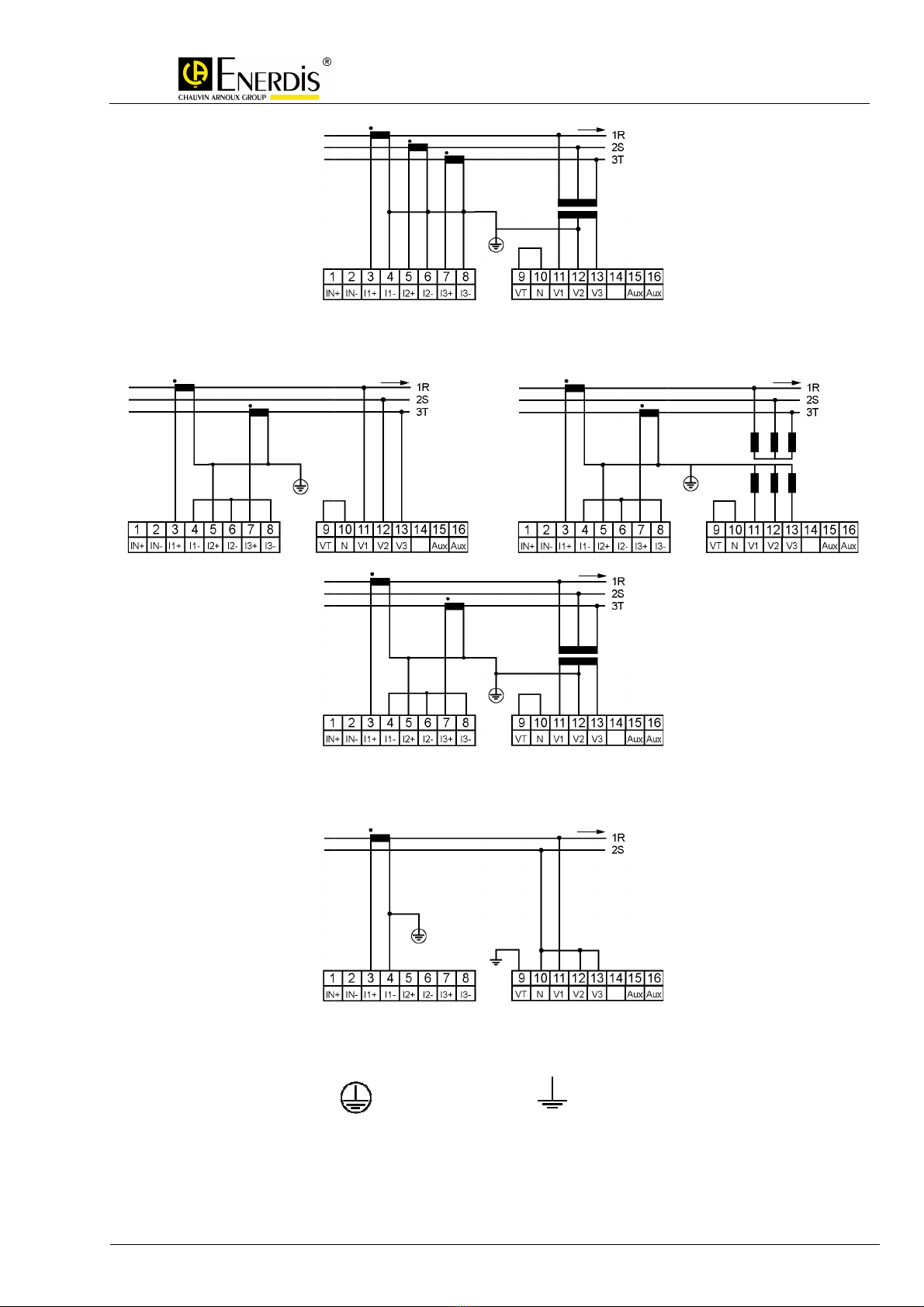

6.1.4 Recommended connection diagrams

The voltage and current inputs are connected according to the type of installation selected. The

recommended connection diagrams are as follows:

6.1.4.1 Unbalanced three-phase, 4 wire – 4 TC

Direct voltage input Voltage input 3 TP star

6.1.4.2 Balanced three phase, 4 wire – 3 TC

Direct voltage input Voltage input 3 TP star

6.1.4.3 Unbalanced three-phase, 4 wire – 1 TC

Direct voltage input Voltage input 1 TP

6.1.4.4 Unbalanced three-phase, 3 wire – 3 TC

Direct voltage input Voltage input 3 TP star

3

MS

1

-

7352 ENERIUM100/200/300_ Ed0

6.1.4.5 Unbalanced three-

phase, 3 wire

Direct voltage input

6.1.4.6 Unbalanced three-

phase, 2 wire

U

SER MANUAL

–

ENERIUM

7352 ENERIUM100/200/300_ Ed0

4

User

Manual

Voltage input 3 TP delta

phase, 3 wire

– 2 TC

Direct voltage input

Voltage input 3 TP star

Voltage input 3 TP delta

phase, 2 wire

– 1 TC

Direct voltage input

: Protective earth : Signal earth

ENERIUM

100/200/300

Page

19

/

86

Voltage input 3 TP star

U

SER MANUAL

–

ENERIUM

100/200/300

MS

1

-

7352 ENERIUM100/200/300_ Ed0

4

User

Manual

Page

20

/

86

6.2 Auxiliary source

6.2.1 Location

The auxiliary source terminals are labelled 15 to 16 on the rear right lower label.

Following a break in the auxiliary source, critical data are stored in non-volatile memory (paragraph

21.8).

6.2.2 Characteristics

Source

Characteristics

High Level supply (*) 80 Vac/dc to 265 Vac/dc

Frequency in the range 42.5 Hz to 69 Hz

Polarity-insensitive

Low Level supply (*) 19 Vdc to 58 Vdc

Consumption < 20 VA – 10 W

Non-removable terminals 2 screw terminals for rigid and flexible cables of between 4 and 8 mm²

Maximum torque: 0.8 Nm

(*) One or other. Power provided by the manufacturer

6.2.3 Connection

Ensure correct polarity if using the Low Level supply.

Connect the AC or DC power supply as paragraph 6.2.1.

A fuse or circuit breaker must be used.

Auxiliary source inputs

Other manuals for Enerium 100

1

This manual suits for next models

5

Table of contents

Other Enerdis Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Umarex

Umarex Laserliner AutoCross-Laser 2 XP operating instructions

MONARCH INSTRUMENT

MONARCH INSTRUMENT PALM STROBE x instruction manual

BTI

BTI PROFILINE Disfix 50 manual

YOKOGAWA

YOKOGAWA PZ4000 user manual

CET

CET PMC-S963-E quick start guide

Dwyer Instruments

Dwyer Instruments 460 Operating instructions and parts list