10

8 Star Energy Pty Ltd | Level 35, 477 Collins Street, Melbourne VIC 3000 | https://www.energizersolar.com

8 Star Energy ESS Ltd | The Black Church, St Mary’s Place, Dublin DO7 P4AX, Ireland

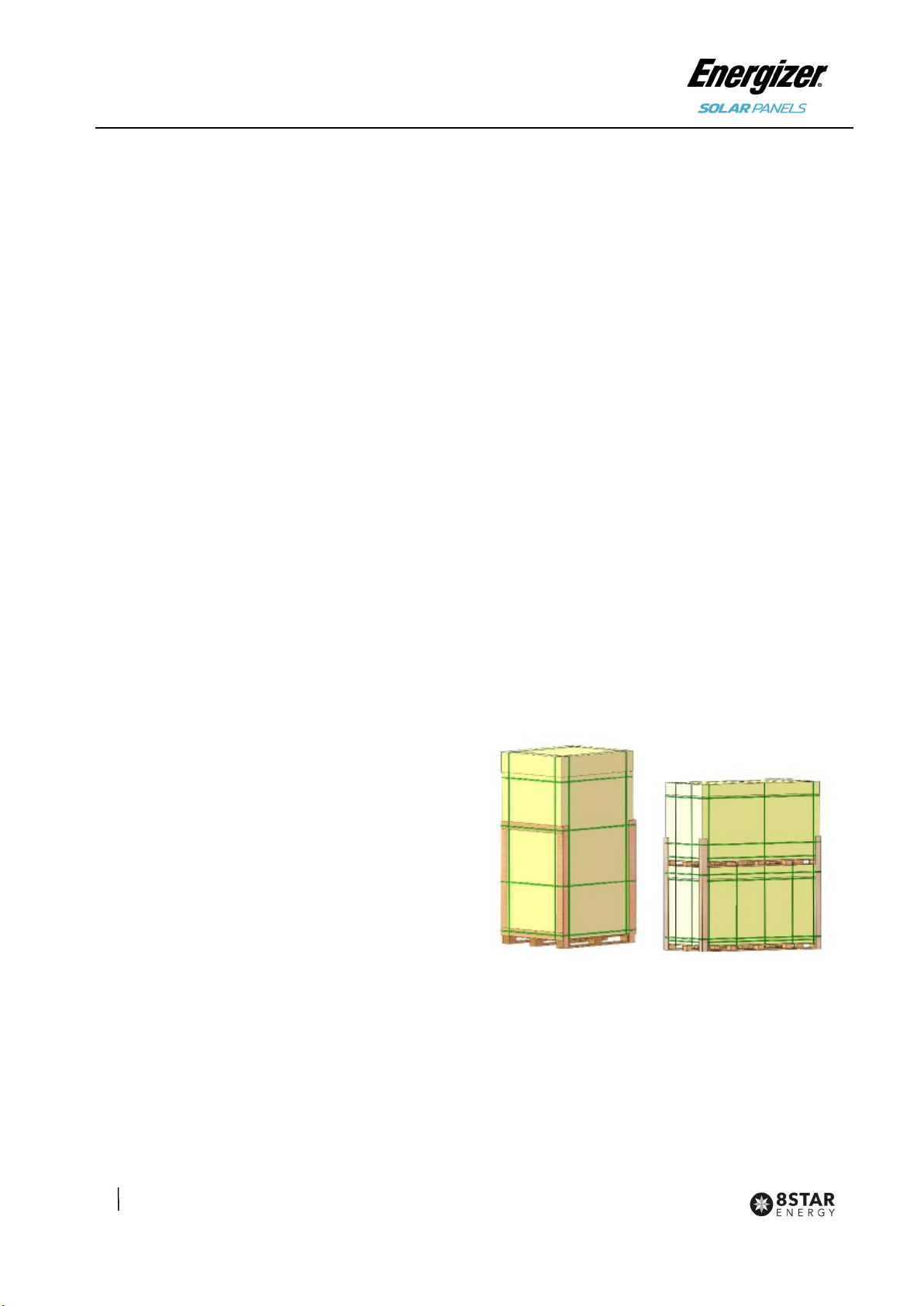

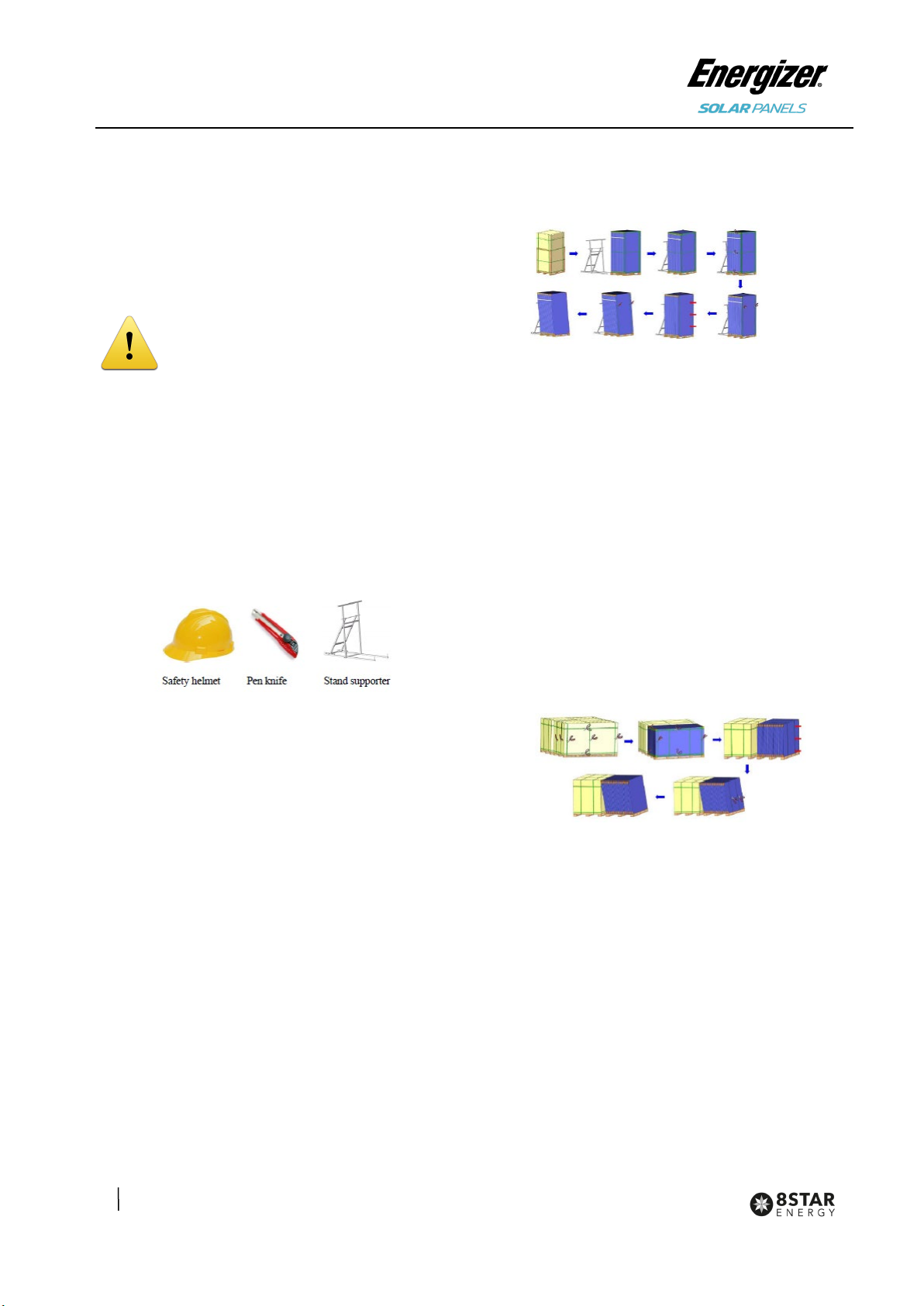

must be cardboard bedding under the photovoltaic

modules. For example, when installing photovoltaic

modules on the roof, the number of modules stacked

up on a pile should not exceed 20. For roofs with

poor load-bearing capacity, it is recommended that

the designer or installer evaluate the load-bearing

capacity of the roof and reduce the load-bearing unit

area of the roof by reducing the number of piles. At

the same time, avoid placing any installation tools or

other objects on the surface of the photovoltaic

module.

Energizer Solar PV modules adopt high and low

current bins, and the handlers need to place them

separately and mark them according to the markings

on the power list of the PV modules outer packaging

(for example, 270W-L means low current gear;

270W-H means high current gear position; the

current division method required by other customers

is similar). According to the system design

requirements, the same current gear position is

usually required in the same array during installation.

If the customer requires PV modules to be

distinguished by color, the outer packaging box shall

be marked accordingly, and the PV modules shall be

marked to prevent confusion when they are taken

out of the packaging box and stacked. According to

the system design requirements, the color of

photovoltaic modules in the same row or square

array should be the same.

6 Mechanical installation

6.1 Installation conditions

•Recommended ambient temperature: -20°C to

+50°C;

•Extreme working environment temperature of

photovoltaic modules: -40°C to +85°C.

•Photovoltaic modules mechanical load: Under

standard installation conditions, the maximum

test snow/wind load is 5400Pa/2400Pa, and the

design load (considering a safety factor of 1.5)

is 3600Pa/1600Pa.

For specific installation methods and mechanical

load values of photovoltaic modules, please refer to

Table 2 for detailed installation instructions for

photovoltaic modules.

Photovoltaic modules are strictly prohibited to be

installed and used in excessive environments such

as hail, snow, hurricane, sandstorm, dust, air

pollution, and soot. It is strictly forbidden to install or

use photovoltaic modules in an environment with

strong corrosive substances (such as salt, salt spray,

salt water, active chemical vapor, acid rain, strong

steam, or any other substances that will corrode

photovoltaic modules and affect the safety or

performance of photovoltaic modules).

If photovoltaic modules will be installed in special

environments such as high temperature and high

humidity environment, wet salt fog environment (C3

and above areas specified in ISO 9223), water and

breeding farms, etc., the purchaser or user must

inform 8 Star Energy in advance. The types of

photovoltaic modules, BOM, and quality assurance

issues shall be decided by the two parties through a

joint agreement and understanding.

If the above precautions are not followed, the

warranty will be invalid.

6.2 Installation angle selection

•The tilt angle of the modules is measured

between the surface of modules and a

horizontal grounding face, as shown in figure 1.

The modules generate maximum power output

when it faces the sun directly.

•In the northern hemisphere, modules should

typically face south, and in the southern

hemisphere, modules should typically face

north. Dust building up on the surface of the

modules can impair module performance, 8

Star Energy recommends installing the modules

with a tilt angle of at least 10 degrees, making it

easier for dust to be washed off by rain. At the

same time, it is conducive to the flow of

accumulated water on the surface of the