1

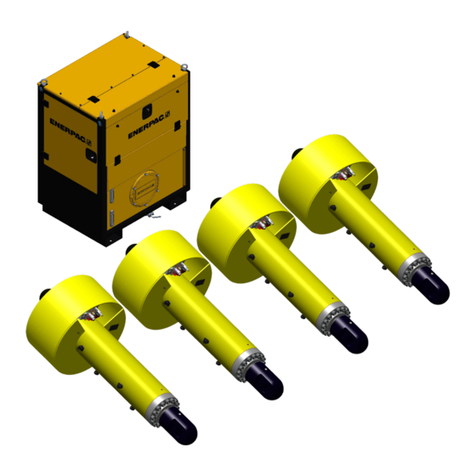

EPH Series Hydraulic

Puller Systems

INSTRUCTION & REPAIR PARTS SHEET

IMPORTANT RECEIVING INSTRUCTIONS:

Visually inspect all components for shipping damage. Shipping

damage is not covered by warranty. If shipping damage is found

notify the carrier at once. The carrier is responsible for all repair

and replacement costs resulting from damage in shipment.

READ CAREFULLY! SAVE THESE INSTRUCTIONS FOR

FUTURE USE.

SAFETY FIRST:

It is impossible to predict the exact force needed for every

pulling situation. The amount of press-t and force of removal

can vary greatly between jobs. The set-up requirements along

with the size, shape and condition of the parts being pulled

are all variables which must be considered. Remember that a

signicant amount of force can be exerted with a puller. Respect

this force and always observe safety precautions. Failure to

comply with the following cautions and warnings could cause

equipment damage or personal injury.

WARNING: DO NOT touch or handle hydraulic hoses or

ttings with pressure in the system. Escaping oil under

pressure may cause serious injury. If oil is injected under the

skin see a doctor immediately.

DO NOT make any electrical adjustments with electrical power

active in the system.

DO NOT make or break any hydraulic connections with pressure

in the system.

DO NOT overload the equipment. Use the right size puller.

DO NOT stand on, under or near the puller while in use. Keep

hands, feet and clothing away from moving parts.

To avoid personal injury and equipment damage, make sure

all hydraulic components withstand the maximum hydraulic

pressure of 10,000 psi [700 bar].

Make sure all system components are protected from external

sources of damage, such as excessive heat, ame, moving

machine parts, sharp edges and corrosive chemicals.

Always check to ensure that all cylinders and components are

securely fastened.

IMPORTANT: Inspect puller for dents, cracks, or

excessive wear before each use. Immediately replace

worn or damaged parts.

Cover application with a protective blanket before applying

force. Since high force is applied on the part being pulled,

breakage may occur and user may be exposed to ying debris.

Use hydraulic gauges in each hydraulic system to indicate safe

operating loads.

Apply force gradually. Be sure the puller is square with the

component to be pulled.

Wear safety glasses or other approved eye protection.

Keep hands away from possible pinching points.

Always make sure the puller is aligned with the shaft.

Select the appropriate pushing adaptor for each application

(refer to page 4).

Always place the puller in the lowest position and remove

pushing adaptors while transporting.

Keep slide rollers and mast clean and lubricated.

Always keep puller hoist vertical and the control valve closed

when not adjusting vertical position.

A small amount of oil seepage is normal from breather vent on

hoist cylinder.

Use only genuine Enerpac parts and endorsed hydraulic

components.

CAUTION: Make sure that all items being pulled are

supported by a means other than the puller. When

using a puller in excess of 50 pounds [19 kg], support puller by

other means than a single person. Do not use the puller for

lifting or supporting objects.

Avoid sharp bends and kinks in hoses as they may lead to

premature hose failure. Inspect hoses and ttings for leaks or

damaged areas. Immediately discard and replace damaged

components.

L4385 Rev. B 12/20 EN