4L4748_a

• Never apply more hydraulic pressure to any tool,

hose, fitting or accessory than the maximum

allowable pressure as stated in the manufacturer’s

specifications. The system operating pressure

must not exceed the pressure rating of the lowest

rated component in the system.

• Be sure the operator has completed safety induction

training, specific to the work surroundings. The

operator should be thoroughly familiar with the

controls and the proper use of the tool.

• The operator must be of at least the minimum age

required by applicable local regulations, laws and

the facility standard operating procedures.

• Do not abuse or overstress the hoses in any way.

Do not bend the hoses excessively.

• Take every precaution to prevent oil leaks from

occurring. High pressure oil leaks can penetrate

the skin, resulting in serious injury.

• Never strike the tool while it is pressurized or under

load. Components under tension may become

dislodged, allowing them to become dangerous

projectiles. Uncontrolled release of pressurized

hydraulic oil could also occur.

• Avoid striking the tool at any time, even when it is

not pressurized or under load. Striking the tool could

cause permanent damage to cylinder components

and may affect the cylinder calibration.

• Be certain that no persons are working on or near

any cylinders before moving of the load begins.

Alert all personnel in advance that the procedure

is about to occur.

• Move only dead weight loads, avoid live weight

loads.

• Be especially careful when moving loads such as

partially filled storage tanks, in which the center

of gravity could move or shift during procedure.

Be aware that the distribution of some loads can

change quickly and without warning.

• Always maintain communication with the operator

during procedure to avoid accidents. Use hand

signals, two- way radios or other appropriate forms

of communication (as required by applicable laws

and regulations) if the load is not visible to the

operator.

• Operate pump and valve as required to ensure that

the load is moved evenly and at a controlled rate.

• Closely watch the load at all times during operation.

Stop work immediately if the load becomes

unstable or appears to be moving unevenly.

• Never allow persons to work under or near the load

while the load is being supported hydraulically.

After the load has been moved, it always must be

blocked mechanically by the cylinder’s lock nut or

via suitable cribbing.

Failure to observe and comply with the following

precautions could result in minor or moderate

personal injury. Property damage could also occur.

CAUTION

• Be careful to avoid damaging hydraulic hoses.

Avoid sharp bends and kinks when routing hydraulic

hoses. Do not exceed the minimum bend radius

specified by the hose manufacturer. Using a bent

or kinked hose will cause severe backpressure.

Sharp bends and kinks will internally damage the

hose, leading to premature hose failure.

• Keep hydraulic equipment away from flames and

heat. Excessive heat will soften packings and

seals, resulting in fluid leaks. Heat also weakens

hose materials and packings.

• For optimum performance, do not expose hydraulic

equipment to temperatures of 150˚F [65˚C] or

higher. Protect all hydraulic equipment from weld

spatter.

• Immediately replace worn or damaged parts with

genuine Enerpac parts. Enerpac parts are designed

to fit properly and to withstand high loads. Non-

Enerpac parts may break or cause the product to

malfunction.

Failure to observe and comply with the following

precautions could result in property damage and/or

void the product warranty.

• Never carry the cylinder by its hoses.

• Always use Enerpac pumps and hoses.

• In severe service conditions, be aware that the

cylinder must be inspected, cleaned and lubricated

more frequently than normal.

• If oil leakage is present from cylinder, replace seals

as required before placing the cylinder back into

service.

• If the cylinder is dropped from a significant height,

have the tool inspected and checked for proper

operation before placing it back into service.

• Hydraulic equipment must only be serviced by a

qualified hydraulic technician. For repair service,

contact the Enerpac Authorized Service Center in

your area.

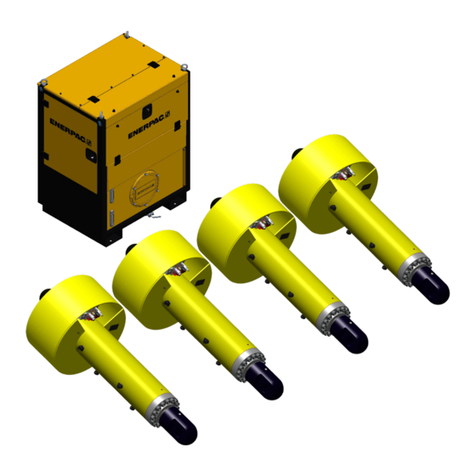

1.2 Crush and Pinch Point Hazard

Never reach in between the cylinder lock nut and

the top of the cylinder base. Serious personal in-

jury can occur if cylinder is retracted and hands,

fingers or other body parts are present in this

area.

Figure 1: Crush and Pinch Point Hazard