ENOTECNICA PILLAN CORKER-M User manual

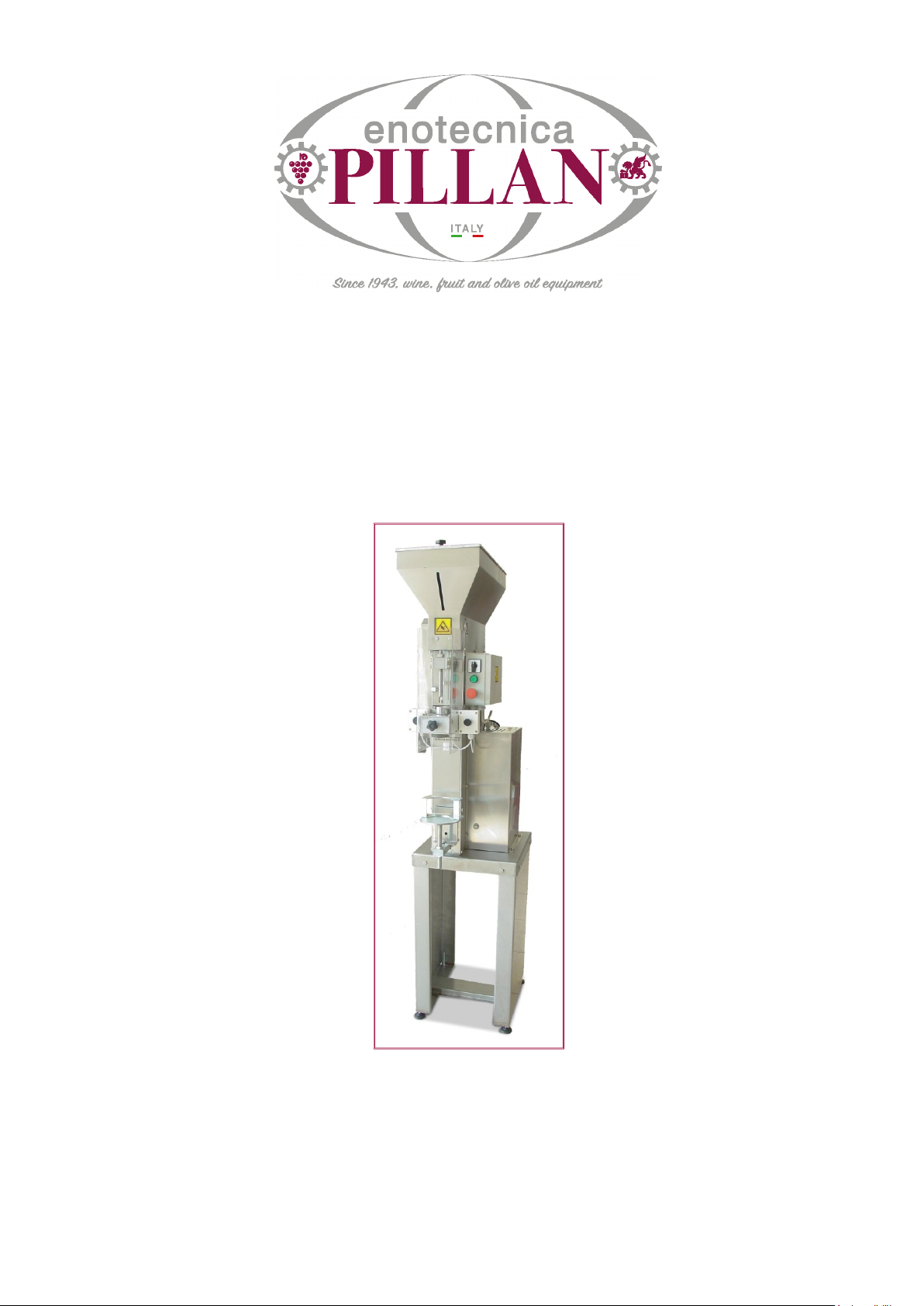

CORKING MACHINE

CORKER-M

ENGLISH TRANSLATION OF THE

INSTRUCTION MANUAL

AND SPARE PARTS

Corking Machine CORKER-M

2

INDEX

0. THE NAMEPLATE ON THE MACHINE.................................................................................3

0. COMPLIANCE WITH COMMUNITY REGULATIONS...........................................................3

1. INTRODUCTION...................................................................................................................4

1.1 MANUAL.......................................................................................................................................4

1.2 MANUFACTURER'S DATA ...............................................................................................................4

1.3 TECHNICAL SUPPORT....................................................................................................................4

1.4 LIABILITY......................................................................................................................................4

1.5 WARRANTY ..................................................................................................................................4

1.6 TRANSPORTATION ........................................................................................................................5

1.7 UNLOADING AND POSITIONING .......................................................................................................5

2. DESCRIPTION OF THE MACHINE ......................................................................................5

2.1 TECHNICAL DETAILS......................................................................................................................6

3. SAFETY REGULATIONS......................................................................................................6

3.1 GENERAL INFORMATION ................................................................................................................6

3.2 CONTROLS AND CONNECTION........................................................................................................7

3.3 SAFETY IN USE AND MAINTENANCE ................................................................................................7

3.4 SAFETY SYMBOL...........................................................................................................................7

4. OPERATING DIRECTIONS ..................................................................................................8

4.1 INSTRUCTIONS FOR USE ...............................................................................................................9

5. FAULTS AND REMEDIES CHECK LIST ............................................................................11

6. MAINTENANCE ..................................................................................................................13

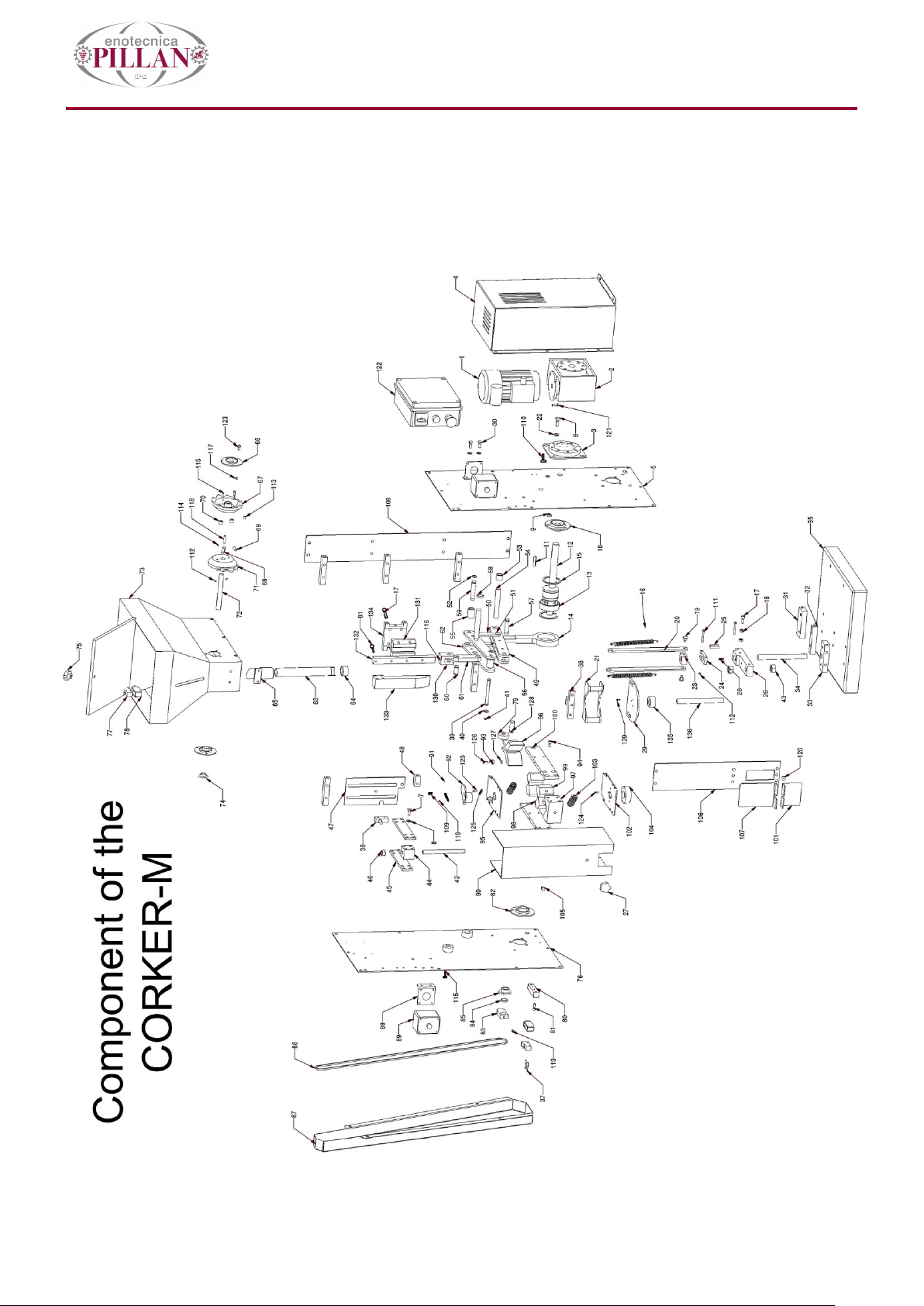

7. COMPONENTS OF THE CORKER-M ................................................................................14

7.1 SPARE PARTS.............................................................................................................................14

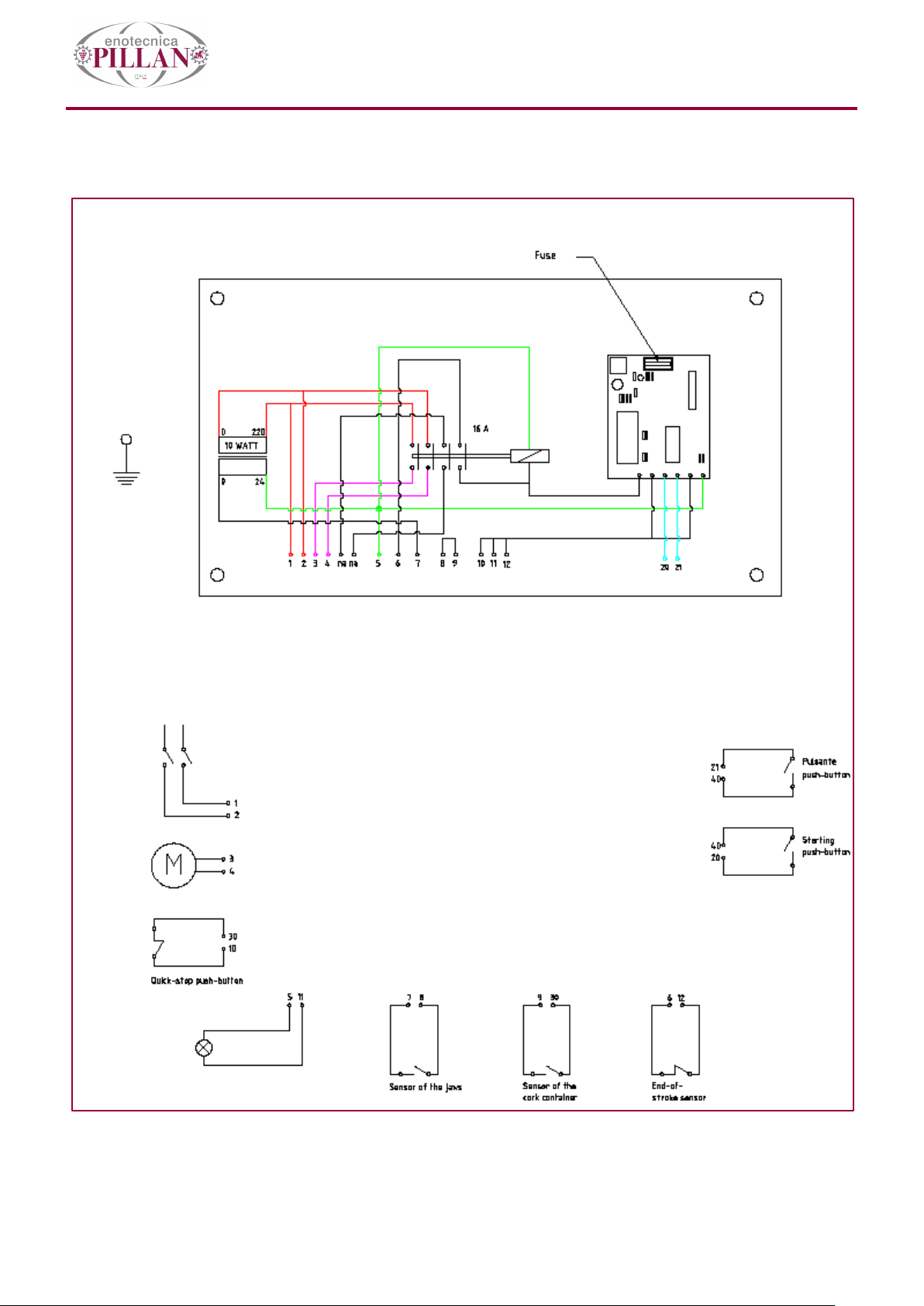

7.2 ELECTRIC SYSTEM......................................................................................................................17

8. DISPOSAL AND DEMOLITION...........................................................................................18

8.1 WASTE DISPOSAL .......................................................................................................................18

8.2 MACHINE DEMOLITION.................................................................................................................18

9. GENERAL CONDITION OF SALE ......................................................................................18

Corking Machine CORKER-M

3

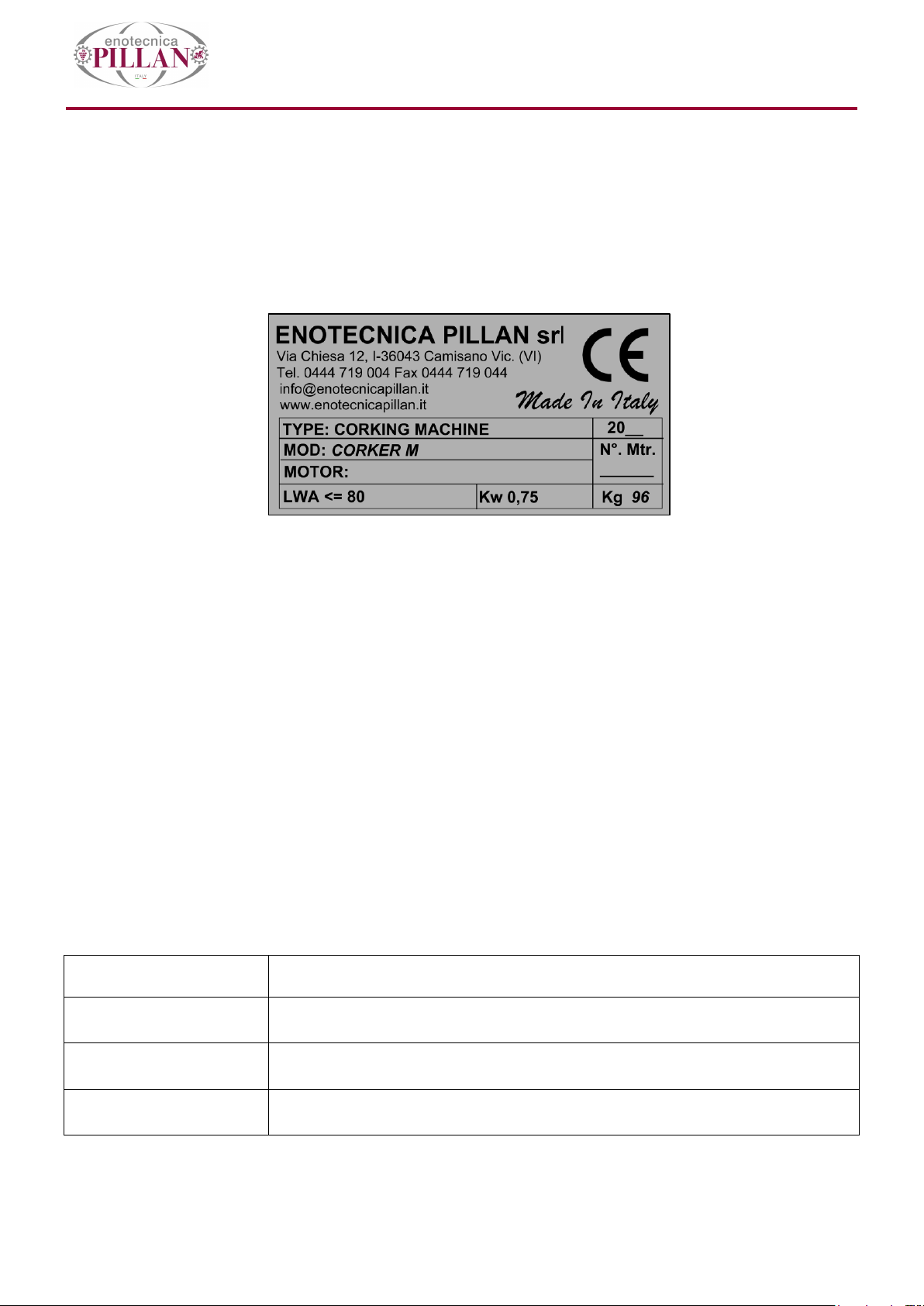

0. THE NAMEPLATE ON THE MACHINE

CE PLATE

IMPORTANT: THIS MANUAL IS THE PROPERTY OF THE MANUFACTURER.

ANY REPRODUCTION, EVEN PARTIAL, IS PROHIBITED.

DOCUMENT TYPE: INSTRUCTION MANUAL AND SPARE PARTS.

MACHINE TYPE: CORKING MACHINE “CORKER-M”

0. COMPLIANCE WITH COMMUNITY REGULATIONS

REFERENCE

TITLE

Directive no.

2006/42/EC

Known as the "Machinery Directive"

Directive no.

2006/95/EC

Relating to Low Voltage Directive (LVD)

Directive no.

2004/108/EC

Relating to Electromagnetic Compatibility (EMC)

Corking Machine CORKER-M

4

1. INTRODUCTION

1.1 MANUAL

The manual is considered an integral part of the machine and as such:

It must be preserved intact (in all its parts);

It must accompany the machine until demolition (even in case of movements, sale, rental, etc.).

1.2 MANUFACTURER'S DATA

Manufacturer: ENOTECNICA PILLAN srl

Via Chiesa R. 4/6, Loc. Rampazzo

36043 Camisano Vic. (VI)

Tel.: +39 0444-719004

Fax: +39 0444-719044

e-mail: info@enotecnicapillan.it

Website: www.enotecnicapillan.it

1.3 TECHNICAL SUPPORT

The technical support service is available to customers for:

Clarifications and information;

Interventions at the customer's premises, through the sending of specialist personnel with the

charging for transportation and labour expenses;

The sending of spare parts.

ATTENTION It should be remembered that:

The customer must always buy spare parts that are original or authorised by the manufacturer.

The use of non-original parts and/or defective or incorrect installation exempt the manufacturer

from all liability.

1.4 LIABILITY

The manufacturer declines all liability in case our manual is not carefully complied with or in the

event of improper use of the machine. Before carrying out any operation, read the manual or

contact the manufacturer or authorised dealer.

1.5 WARRANTY

The company ENOTECNICA PILLAN SRL ensures that the machine has been built in compliance with

current regulation.

The product warranty is 12 months from delivery.

The manufacturer guarantees only the replacement or repair of damage parts at its headquarters. Any

shipping costs and labor are at the buyer’s charge.

Corking Machine CORKER-M

5

The warranty excludes all the parties which by their nature are subject to wear.

The warranty is void for errors due to incorrect electrical connection, the lack of adequate protection,

incorrect action, improper use, use of non-original parts, disassembled component, repaired and/or

altered by persons not authorized by the company manufacturer.

1.6 TRANSPORTATION

The machine is shipped assembled, packed and secured on pallets (unless otherwise agreed with the

customer).

Upon delivery the customer must check the integrity of the packaging of the machine, ensuring that

it has not been damaged during transportation. If any damage is discovered, this must be

communicated to the carrier and the manufacturer or the independent reseller must be warned

immediately.

1.7 UNLOADING AND POSITIONING

ATTENTION: unloading must take place with means suitable for the size and the weight of the

machine.

Perform unloading via a forklift truck, being careful not to damage protruding parts of the machine and

apply the grip points in such a way that the weight is balanced.

Unloading must be carried out by qualified staff and ensuring there are no children or other

persons within the perimeter of movement of the suspended loads.

2. DESCRIPTION OF THE MACHINE

Our CORKER-M corking machine meets the requirements of those wine-growers who need a rapid

and precise corking.

Our CORKER-M corking machine is almost entirely made of stainless steel to make cleaning easier.

Moreover all those parts which could come into contact with the corks are made of materials that do

not react with the air (such as stainless steel, plexiglass, chromium-plated steel), in order to prevent all

chances of polluting corks with rust splinters or whatever other substances bad for health. Even the

internal mechanisms, such as connecting rods and levers, are galvanized. All the parts which come

into contact with the bottle are made either of rubber or pvc to avoid the breaking off of splinters from

the glass.

All moving gears are protected by safety guards and those parts which the operator must reach often,

such as the cork container and the jaws, are fitted up with easily removable safety guards. The latter

are equipped with a sensor so that the corking machine cannot work when these guards are removed.

Corking Machine CORKER-M

6

2.1 TECHNICAL DETAILS

Standard equipment:

- cork size diameter 22-26 x 50 mm.

- bottle height up to 390 mm.

- corking time approximately 1,8 seconds

Optional equipment:

- cork descent duct and cork pusher for corks with diameter up to 28 mm.

- stainless steel base BTM

CORKER-M dimensions

Height: 1210 mm.

Width: 430 mm.

Length: 560 mm.

Weight: 96 kg.

CORKER-M equipped with base BTM dimensions

Height: 1810 mm.

Width: 520 mm.

Length: 560 mm.

Weight: 115 kg.

Motor

Feeding: See machine’ s data sheet

Speed rotation: 1380 r.p.m.

Power: 0,75 Kw

Screw reducer without end: reduction ratio 1/40

N.B. The data in the tables is not binding. The manufacturer reserves the right to make changes without duty of notification.

3. SAFETY REGULATIONS

3.1 GENERAL INFORMATION

The aim of the following chapter is to inform operators of possible risks and safety regulations to keep

in mind when using the machine. However, such regulations must be respected in any working

environment.

Responsibility of the operator

Each operator must look after their own health and safety and that of other people present at work.

In particular, operators must:

use the machine correctly following the instructions in the user’s manual;

not remove or modify the safety or signalling devices;

not execute on their own initiative operations not within their competence;

wear clothing and any personal safety devices that comply with existing norms at the work

place.

Corking Machine CORKER-M

7

3.2 CONTROLS AND CONNECTION

Always check, before each use, the integrity of the electrical cables and in case of injury or

abrasion, replace the cables.

Do not route electrical cables below machines or tools that could damage their integrity.

Do not place the power cable on wet or muddy surfaces.

Switches and plugs must be protected from moisture.

Always check, before connecting any equipment, that the mains voltage is the same as that

indicated on the nameplates of the machines.

The system of the residence or of the winery must be equipped with a differential circuit breaker

and a magneto-thermal switch in order to ensure, in the event of failure, the safety of persons.

Keep children and unauthorised persons away from the electrical equipment.

Check always that the direction of rotation of the machine is correct.

3.3 SAFETY IN USE AND MAINTENANCE

Do not perform operations or interventions that are not covered in the manual.

Before starting up the machine, check the correct positioning and operation of the safety

mechanisms and of the safety devices.

During operation, ensure that anyone that is not authorised to use the machine, remains at an

appropriate distance.

Do not remove any safety mechanism without having removed the power supply.

In case of machine faults contact the manufacturer.

3.4 SAFETY SYMBOL

General danger

Caution: refer to the

operator's handbook

Caution: electric voltage

Caution: rotating gears.

Severing of fingers

Corking Machine CORKER-M

8

4. OPERATING DIRECTIONS

Our CORKER-M corking machine is provided with an upper cork container which is fitted up with a

mechanical mixing device that lines the corks up and pushes them through the descent duct for the

corking to be carried out successfully. This corking machine positions the cork within jaws which

squeeze it down to the size of the neck of the bottle. In this way less stress is needed to push the cork

down into the neck of the bottle with the advantage of not damaging the cork itself that will expand

once it is inserted and ensure a good seal.

To start the corking machine a bottle must be placed on the bottle platform, the two starting push-

buttons located on the sides of the machine must be kept pressed simultaneously for a couple of

seconds (see picture 1). In this way the working cycle starts off: the bottle platform goes up, the jaws

go down and compress the cork which is afterwards inserted into the neck of the bottle by the cork-

pushing pin (see picture 1).

At this point the two push-buttons can be released to start the cycle of return off. This means the

lowering of the bottle platform, the ascent of the cork-pushing pin and the rotation of the cork pusher

which picks up a cork from the cork descent duct and drives it into the jaws ready to be used next time.

Picture 1

Corking Machine CORKER-M

9

4.1 INSTRUCTIONS FOR USE

Positioning. The CORKER-M corking machine should be placed on a steady support in a lit up

room. In case the CORKER-M corking machine is fitted up with a base BTM, make sure it is

placed on an even ground. Make sure that the screws which hold the safety guards are

screwed tight, especially those which hold the switch-board.

Clean all the parts that come into contact with the corks, such as cork descent duct, cork

pusher, jaws, cork-pushing pin and cork container (see picture 1).

Check that no foreign matters which could compromise the good functioning of the machine are

either inside the cork container or inside the jaws.

Take off the antiscratch blue nylon film from the front plastic safety guard, tighten the fasteners

and make sure the pin can activate the safety sensor (for the sensor of the jaws and the plastic

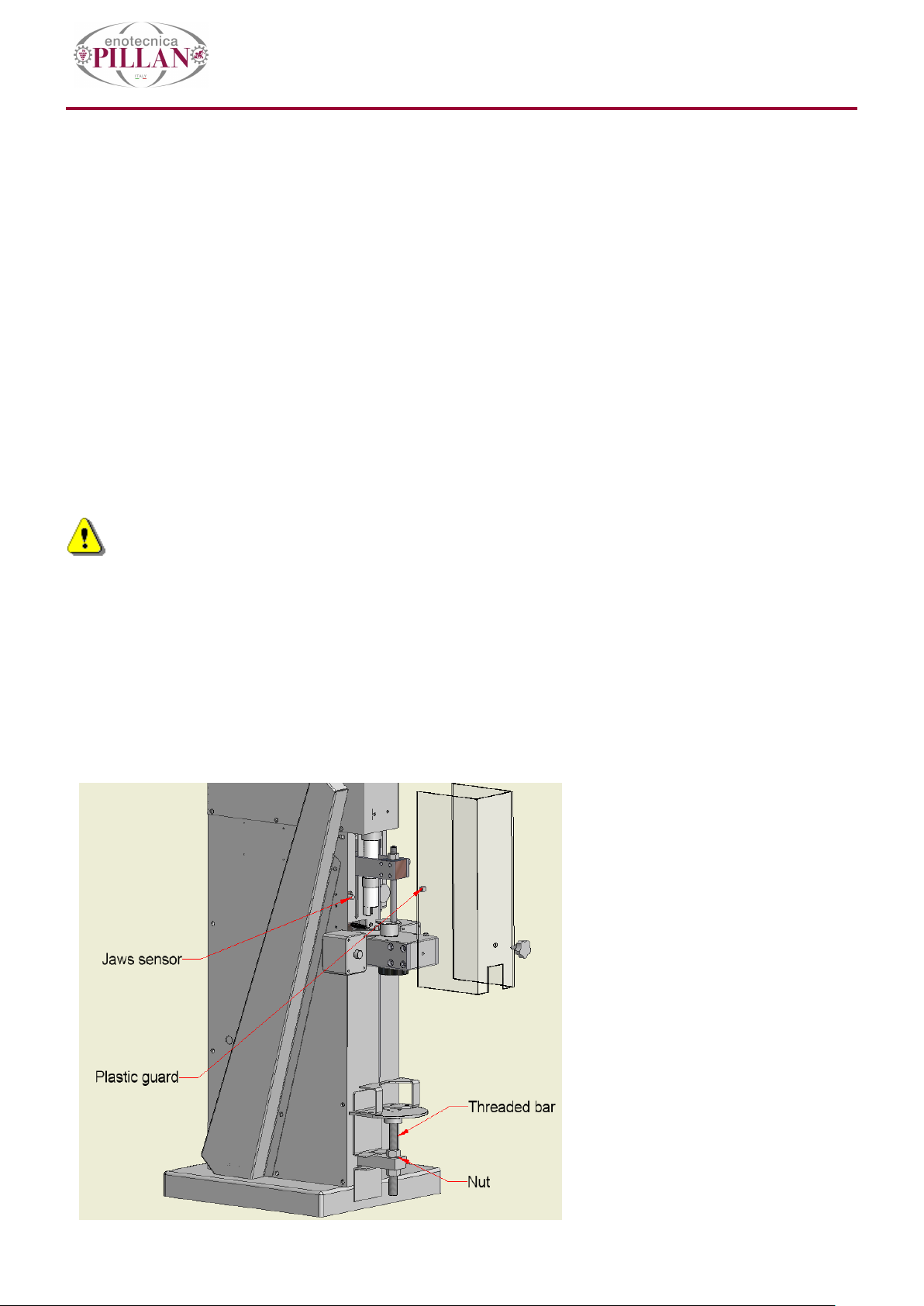

pin of the safety guard, see picture 2).

Adjust the height of the bottle platform by undoing the two bolts (see picture 2) which hold it

tight, then re-tighten the bolts so that the top of the bottle is near the bottle-height line

underneath the jaws.

CAUTION:

When the bottle platform is at its lowest position (that is, when the upper bolt is screwed near the

bottle platform), the threaded bar of the bottle platform itself is near the surface where the

machine is placed. The front of the corking machine must then be positioned near the end of the

support so that the threaded bar comes out of it.

Fill up the cork container and close the lid. When the lid is open, the respective sensor is not

operated (see picture 3) and the corking machine cannot start.

Connect the feeding cable to a 230 volt current-tap, turn clockwise the quick-stop button of the

switch-board and turn the starting switch to position 1 (see picture 4). Now a green light should

be lit and the corking machine can be started by pressing the two starting push-buttons located

on the sides of it (see picture 1).

Picture 2

Corking Machine CORKER-M

10

Picture 3

Picture 4

CAUTION:

The corking machine can be used by only an operator at a time and no one else should be near

when the feeding cable is connected and the corking machine is operating.

In order to prevent any accident the two starting push-buttons must be kept pressed and both

hands must be kept in this position until the corking operation has been carried out.

Corking Machine CORKER-M

11

5. FAULTS AND REMEDIES CHECK LIST

When the machine is operating the green light (see picture 4) must be on. If it is not so, you must

check that the pin of the plastic front guard starts the respective sensor in the correct way and the lid of

the cork container is closed.

It should be noted that once the quick stop push-button is pressed, it stays pressed and in order to

release it, it must be turned clockwise. For this reason, if the machine doesn't start, it may have been

pressed the push-button by mistake; in this case, turn it and try again.

If one tries to remove the plastic guard or to open the lid, the green light goes off, the machine stops

immediately and the bottle-stand remains half-way of its stroke. In order to bring the bottle-stand to its

starting position, one must relocate the guards or the lid and press the starting push-button.

IMPORTANT

Before intervening on the machine always bring the starting switch back to the "0" position and

disconnect the feeding cable.

If at the end of the corking operation the bottle-stand doesn't go to the lower position of its stroke,

open the left side of the machine (it is meant left being in front of the machine). Loosen the grain

of the end-of-stroke-element (see picture 5) and try to turn it; if one turns it clockwise the end of

the corking cycle is anticipated (the bottle-stand reaches its lower point and tends to go up), if you

turn it anti-clockwise the end of the corking cycle is delayed (the bottle-stand doesn't reach its

lower point). Re-tighten the side down and re-start the machine.

Picture 5

Corking Machine CORKER-M

12

If the corks don't go down the cork descent duct correctly open the lid of the cork container and

mix the corks.

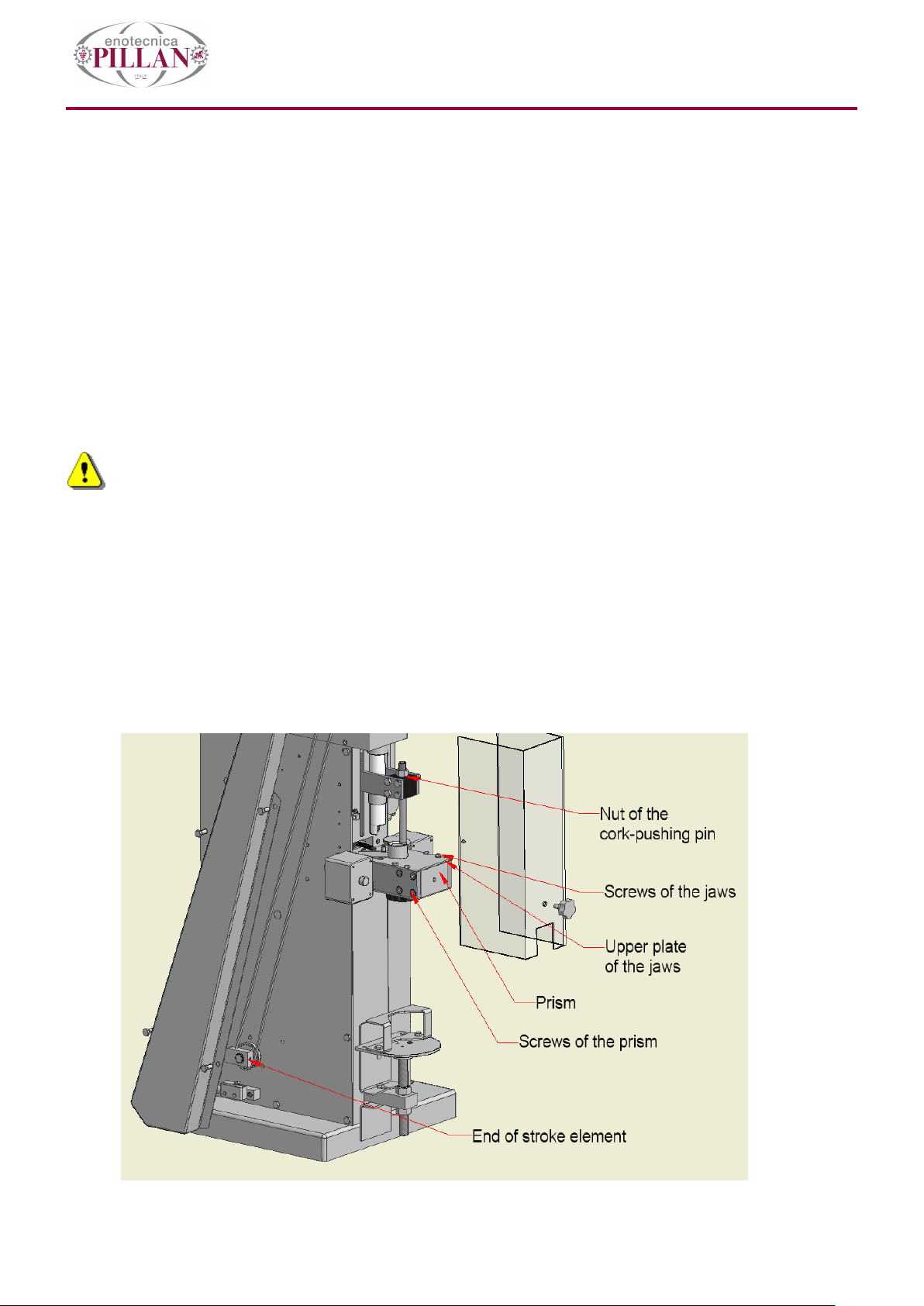

In case the corks are not picked up precisely by the cork pusher, it is necessary to adjust the

stroke of the cork pusher itself (the cork pusher is fastened to the upper plate of the jaws) (see

picture 4). To do this, the six upper screws of the jaws must be loosened and the upper plate of

the jaws can be moved towards the corking machine or in the opposite direction. Tighten the

screws and start the machine; if the result is not satisfying, repeat the operation.

If it is needed the cork to be inserted deeper or higher in the neck of the bottle, the fastening nut

must be loosened and the cork-pushing pin turned: the last is threaded then it can be moved up

and down. Before starting the machine again, the fastening nut must be tightened (see picture 5).

In case one does not succeed in carrying out the above mentioned adjustment (especially it could not

be successful with synthetic stopper) it is advisable to adjust the tightening of the jaws.

Our CORKER-M corking machine is set to compress the corks up to a diameter of 16 mm. To use it

with synthetic stopper or particularly strong corks, it is advisable to adjust the diameter of tightening to

15 mm.

To carry out this operation, the screws which fasten the prism of the jaws (see picture 5) must be

loosened and the prism itself must be moved 1 mm. towards the corking machine.

The above mentioned screws are tightened inside buttonholes so that the adjustment of the prism is

easier. At the end of this operation the screws of the prism must be tightened once again.

When the jaws are tightened and the cork-pushing pin starts to push a cork down, it may happen that

the bottle-stand cannot keep its position and tends to go down so that it doesn't allow the cork to be

fully inserted. In this case it is the ascent system of the bottle stand that needs maintenance. It is

necessary to remove the bottle stand by loosening the bolts; the mobile guard plates and the lower

guard plate must be removed too (see picture 6): the cylindrical rod on which the bottle stand moves

up and down must be cleaned (see picture 6). It is advisable to use a dry cloth and rub vigorously to

remove whatever dust. Then it's a good rule to lubricate the cylindrical rod with a drop of oil (and not

more, one should never exaggerate with the lubrication). In case the machine vibrates a little one

should lubricate the inside of the jaws and let the machine do a couple of blank strokes. Before starting

work it is better to clean the jaws to prevent the oil from dirting the corks (see picture 1).

If the vibrations continue it is advisable to loosen the bolts of the back guard (reference 108 on the

table "Components of the CORKER-M corking machine") and lubricate all the pins and bearings inside.

In case the problem persists turn to the manifacturer.

Corking Machine CORKER-M

13

Picture 6

ATTENTION

In the event of strong vibrations of the machine immediately push the quick-stop push-button and

contact the local dealer.

6. MAINTENANCE

A long machine working life is dependent upon constant and methodical compliance with the following

instructions:

take off the back plate (reference 108 on the table "Components of the CORKER-M corking

machine") and lubricate the bearings, the slide and the pins inside the machine;

clean the jaws from any cork dust;

lubricate the inside of the jaws and remove the excess oil before starting work.

At the end of each season we recommend to:

carefully clean the machine and the jaws;

store the machine in a dry place and cover it up with a cloth or a nylon film in order to prevent

the dust from crusting over the corking machine.

Corking Machine CORKER-M

14

7. COMPONENTS OF THE CORKER-M

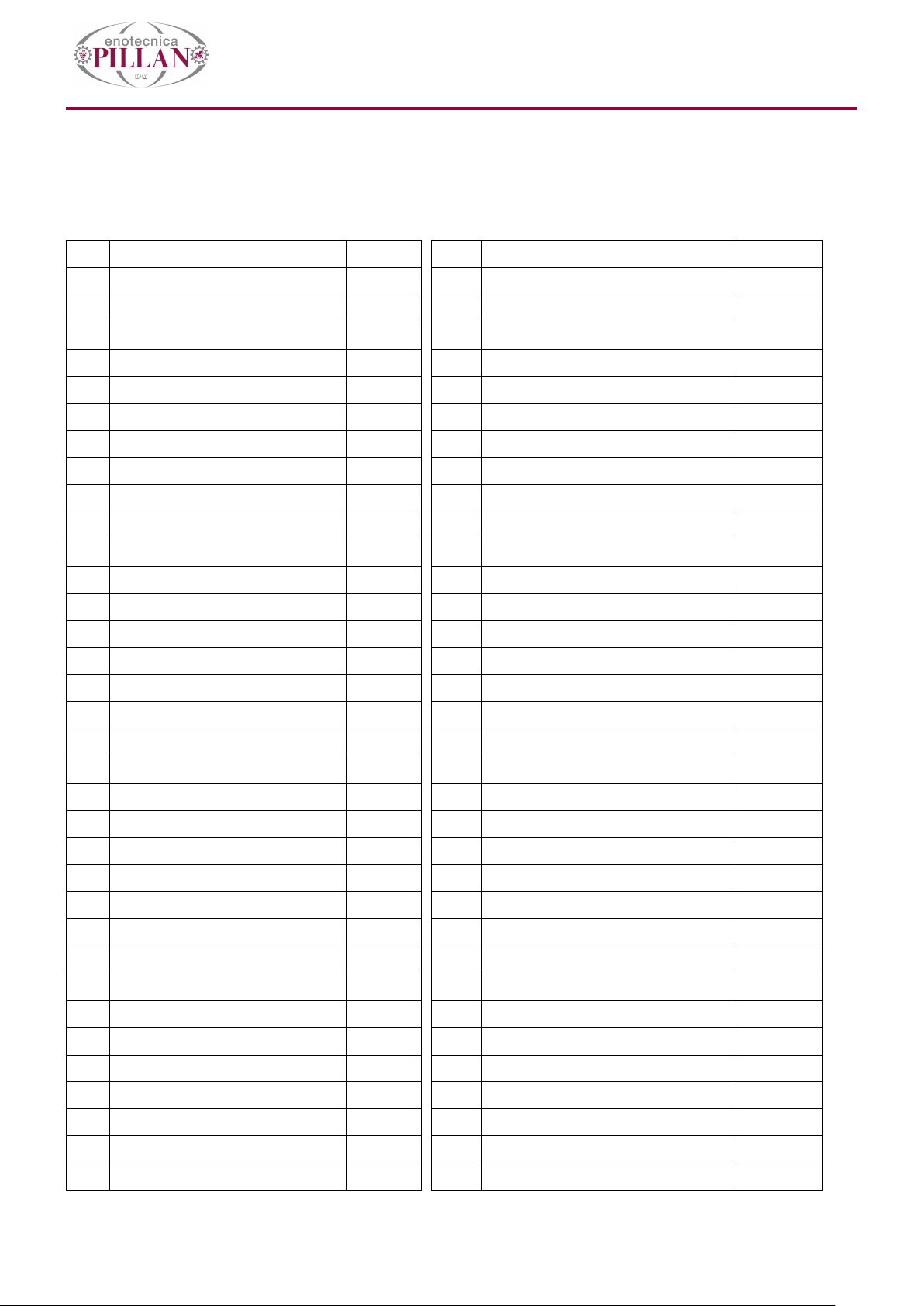

7.1 SPARE PARTS

POS.

DESCRIPTION

REF.

POS.

DESCRIPTION

REF.

1

0,75 KW motor

tap0201

35

Base

tap1028

2

Reducer

tap0202

36

Push-button sensor

tap0225

3

Flange

tap0203

37

M4x30 screw

tap0309

4

Motor guard

tap1317

38

Support

tap0502

5

Right side plate

tap1301

39

10 mm. diam. pin

tap1024

6

M10x25 screw

tap0301

40

M10 washer

tap0310

7

M8x16 screw

tap0302

41

10 mm. diam. elastic ring

tap0210

8

Washer

tap0303

42

Cork-pushing pin

tap1315

9

M10 nut

tap0304

43

M18 nut

tap0326

10

SBPF 205 support

tap0204

44

Connection

tap1313

11

8x7x40 tongue

tap0205

45

Side plates

tap1312

12

Cam shaft

tap1031

46

M12 nut

tap0311

13

HK 6020 roller-shell

tap0206

47

Upper safety guard

tap1319

14

Engine connecting rod

tap1005

48

Connection

tap1043

15

60 mm. diam. elastic ring

tap0207

49

Lever

tap1304

16

Spring

tap0005

50

Connecting rods

tap1336

17

M8x30 cylindrical head screw

tap0305

51

15 mm. diam. pin

tap1023_2

18

M8 nut

tap0306

52

15 mm. diam. elastic ring

tap0211

19

M6 threaded pin

tap0513

53

Spacer

tap1007

20

Connecting rod

tap1308

54

18 mm. diam. pin

tap1003

21

Reference for bottle

tap0508

55

Spacer

tap1322

22

M10 washer

tap0307

56

Spacer

tap1323

23

Connection

tap0505

57

15 mm. diam. pin - short model

tap1023_1

24

Brake

tap0506

58

Spacer

tap1329

25

Brake connecting rod

tap0507

59

15 mm. diam. pin - long model

tap1324

26

Bottle platform-holder

tap0504

60

Pin

tap1325

27

Handgrip with M8x16 screw

tap0208

61

Connecting rod

tap1307

28

Spring

tap0006

62

Lever

tap1305

29

Bottle platform

tap0509

63

Cork descent duct

tap1213

30

M8x20 screw

tap0308

64

Connection

tap0213

31

Back plate

tap1032

65

Slide

tap1211

32

Threaded spacer

tap1036

66

SBPF 203 support

tap0214

33

Front plate

tap1025

67

Right side plate

tap1214

34

Cylindrical rod

tap0501

68

Tongue

tap1210

Corking Machine CORKER-M

15

POS.

DESCRIPTION

REF.

POS.

DESCRIPTION

REF.

69

Spring

tap0008

103

Spring

tap0004

70

Spacer

tap1212

104

Cone

tap0713

71

Left side plate

tap1215

105

Block

tap0719

72

Shaft

tap1209

106

Lower safety guard

tap1320

73

Cork container

tap1201

107

Mobile upper safety guard

tap0510

74

Pinion

tap0215

108

Back safety guard

tap1321

75

Threaded handgrip

tap0216

109

M4x10 cylindrical head screw

tap0327

76

Left flank

tap1302

110

M8x20 cylindrical head screw

tap0334

77

Sensor

tap0217

111

M5x45 cylindrical head screw

tap0315

78

Sensor guard

tap0218

112

M5 nut

tap0316

79

SKF 4302 bearing

tap0226

113

M8x10 screw without head

tap0317

80

Sensor support

tap1018

114

M4x6 countersunk head screw

tap0336

81

M6x20 cylindrical head screw

tap0312

115

M5x30 screw

tap0319

82

SBPF 204 support

tap0219

116

M10x20 cylindrical head screw

tap0328

83

End of stroke cam

tap1019

117

M6 nut

tap0321

84

Spacer

tap1029

118

5x30 elastic pin

tap0224

85

Pinion

tap0220

119

M4 nut

tap0329

86

8 mm. - pitch chain

tap0221

120

M8x8 countersunk head screw

tap0322

87

Chain guard

tap1316

121

M6x25 screw

tap0335

88

Connection

tap1337

122

Electric panel

89

Push-buttons

tap0227

123

M6x12 screw

tap0324

90

Plaastc guard

tap0714

124

M4x16 contersunk head screw

tap0325

91

Spring

tap0007

125

Washer for M16 screw

tap0330

92

Cork pusher

tap0801

126

M5x20 cylindrical head screw

tap0331

93

SKF 625-2Z bearing

tap0228

127

Spacer

tap0716

94

M8x16 cylindrical head screw

tap0313

128

M6x8 screw without head

tap0332

95

Upper plate

tap0709

129

M5x12 countersunk head screw

tap0333

96

Fork

tap0702

130

Fork

tap1310

97

Prism for jaws

tap0701

131

Moving part

tap0229

98

Spring-loaded angle bar

tap0705

132

Slide

tap0230

99

Threaded angle bar

tap0704

133

Wedge

tap1309

100

Side plate

tap0706

134

Plate

tap1314

101

Lower mobile guard

tap0512

135

Bushing

tap0514

102

Lower plate

tap0708

136

M18 threaded bar

tap0231

Corking Machine CORKER-M

16

Corking Machine CORKER-M

17

7.2 ELECTRIC SYSTEM

Corking Machine CORKER-M

18

8. DISPOSAL AND DEMOLITION

8.1 WASTE DISPOSAL

During the use of the machine as part of the work process, waste substances or scrap are

produced that must be collected, recycled and disposed of according to the laws in force in the

country where the machine is installed. The parts of the machine that are being replaced must be

treated in the same way.

8.2 MACHINE DEMOLITION

At the moment of the demolition of the machine, it is necessary to separate the plastic and

electrical components which must follow recycling norms in accordance with local regulations.

Regarding the metal mass, simply separate the steel parts from those in other materials or alloys,

to allow a correct recycling for melting.

ATTENTION: any drained fluids should not be mixed together and should be stored in closed

containers to avoid contamination with foreign substances. Their disposal must be entrusted to

special waste disposal consortiums.

9. GENERAL CONDITION OF SALE

TRANSPORTATION: to be borne by the purchaser.

COMPLAINTS: complaints will not be accepted after eight days from receipt of the goods and returns

will not be accepted without our authorisation and being free of charge. The goods travel at the

customer's risk.

RESERVATIONS: the manufacturer is not liable for breakage or damage resulting from uses that are

different from those for which the goods are intended. The warranty does not cover deficiencies and

defects due to the consumption of those parts that by their very nature are subject to wear or in cases

where the parts returned have in any case been disassembled, tampered with or repaired outside of our

premises.

WARRANTIES: the company ENOTECNICA PILLAN SRL ensures that the machine has been built in

compliance with current regulation. The product warranty is 12 months from delivery. The manufacturer

guarantees only the replacement or repair of damage parts at its headquarters any shipping costs and

labor are at the buyer’s charge. The warranty excludes all the parties which by their nature are subject to

wear. The warranty is void for errors due to incorrect electrical connection, the lack of adequate

protection, incorrect action, improper use, use of non-original parts, disassembled component, repaired

and/or altered by persons not authorized by the company manufacturer.

COMPLAINTS: the place of jurisdiction is the Court of Vicenza.

TECHNICAL DATA: the technical data contained in this manual is for information purposes and is not

binding. The company reserves the right to make changes without duty of notification.

Redatta dalla / Issued by / Ausgestellt durch ENOTECNICA PILLAN srl

Via Chiesa R. 4/6 –36043 Camisano Vic.no (VI) –Italy –Tel. 0444.719004 –Fax 0444.719044

DICHIARIAMO SOTTO LA NOSTRA RESPONSABILITÁ CHE IL PRODOTTO:

WE DECLARE UNDER OUR RESPONSIBILITY THAT THE PRODUCT:

WIR ERKLÄREN UNSERE VERANTWORTUNG, DASS DIE MASCHINE:

Macchina/Machine/Maschine: TAPPATORE / CORKING MACHINE

Modelli/Models/Modelle: CORKER-M

Matricola/Serial number/Seriennummer: ____________________________________

Anno di costruzione/Year of manufacture/Baujahr ____________________________________

È CONFORME ALLE SEGUENTI DISPOSIZIONI

IS IN RESPECT TO

STEHT IM EINKLANG MIT

Machine Regulation 2006/42/CE, assimilated in Italy through D.Lgs dated 27/01/2010

Regulation LVD 2006/95/CE

Regulation EMC 2004/108/CE, assimilated in Italy through D.Lgs. dated 09/11/2007

and that this machine was manufactured according to the provisions of the following norms:

EN 292-1* Safety of the machine –Basic concepts, general design principles. Part 1: terminology, base methodology.

EN 292-2* Safety of the machine –Basic concepts, general design principles. Part 2: technical principles.

EN 294* Safety of the machine –Safety distances to prevent the arms from reaching dangerous areas.

EN 349* Safety of the machine –minimal openings to prevent parts of the human body from being crushed.

EN 418* Safety of the machine –Emergency stop system, functional aspects. Design principles.

EN 953* Safety of the machine –General requirements to design and manifacture fixed and mobile safety guards.

EN 954-1* Safety of the machine –Parts of the control system correlated to safety. Part 1: general design principles.

EN 982* Safety of the machine –Safety requirements for fluid-hydraulic powered systems and components.

EN 1088* Safety of the machine –Interlock devices. General principles and design provisions.

EN 50100-1* Safety of the machine –Electrosensitive safety devices –Part 1: general requirements.

EN 1037 Safety of the machine –Energy sectioning and dissipation. Prevention of unexpected starting.

EN 999* Safety of the machine –Hand-arm speed –Approaching speed of some parts of the body for the positioning of

safety devices.

Amministratore Legale Enotecnica Pillan

Legal Administrator Enotecnica Pillan Camisano Vicentino li, _____________

Rechtliche Administrator Enotecnica Pillan

Il responsabile del Fascicolo Tecnico

Responsible for the Technical Dossier

Verantwortlich für die Technischen Beschreibungen

DICHIARAZIONE

DI CONFORMITÁ

Date

_________

Mod. __________

Serial no

__________

Table of contents

Popular Packaging Equipment manuals by other brands

AirSaver

AirSaver F2 Safety instructions, setup & installation manual

HUALIAN

HUALIAN M-PE Series Operation manual

Pro Pack Solutions

Pro Pack Solutions Eagle 710 Operation manual

Oliver

Oliver 1808-D User's operation

Kronos

Kronos H-46 Series Operation, safety and spare parts manual

Robopac

Robopac ROBOT S7 Use and maintenance manual