enphase EP200G-LITKIT User manual

Feed through header for Generator I/O

Use the 3-pin feed through header for Generator dry contact connec-

tions. It is recommended to install this feed through header in Enpower

even if you are not currently planning to use the Generator feature.

This ensures that the header will not get lost. Use pins 1 and 3 on the

header for inserting wires. Supports AWG 28 to AWG 16 wire sizes.

Torque for tightening the screws on the top is 0.22 N•m (1.9 lb•in) to

0.25 N•m (2.2 lb•in).

2. Tighten these screws to

hold the wires in place

3. Insert into I/O port on En-

power in this orientation

Insert wires in these

terminals

The Enphase Enpower Lit Kit contains screws, feed through headers, filler plates and labels that enable you to properly install Enpower and configure

features such as PCS (power control system), load control with auxiliary contacts, and generator integration.

QUICK INSTALL GUIDE Model number: EP200G-LITKIT

Instructions to use the Enphase Enpower

Literature Kit (Lit Kit)

The contents of the Lit Kit and how to use them are described below:

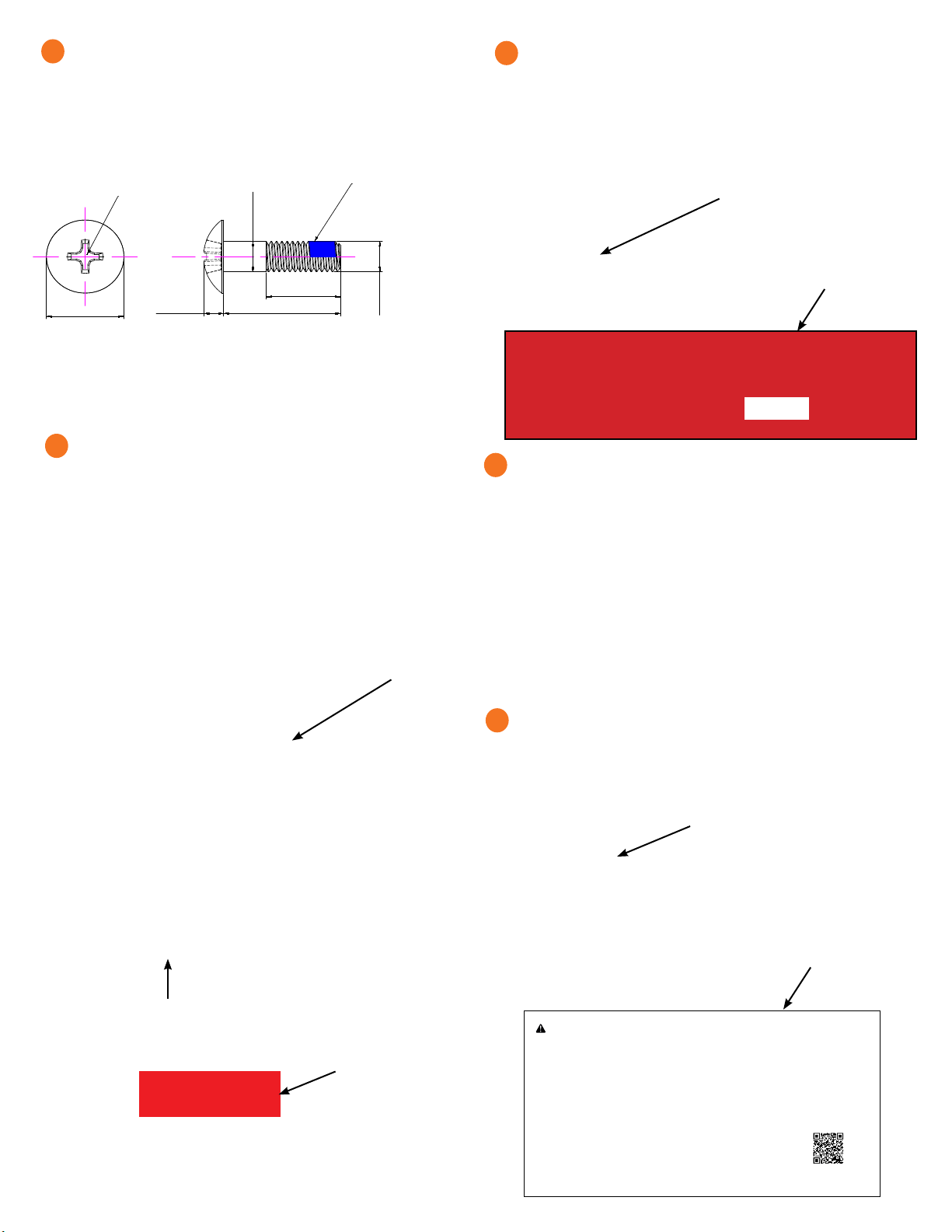

8-32 screw

Use the 8-32 screw from the lit kit to secure the mains breaker (not the load

breaker) to Enpower. Use a T20 drive to tighten the 8-32 screw to 1.5 N•m

(13.3 lb•in). Do not use any other screw.

Install 8-32 screw

with 1.5 N.M

torque

Feed through header for I/O-1 and I/O-2

Use the two 4-pin feed through headers shipped with the lit kit for

making auxiliary contact connections for load control and excessive

PV shedding. It is recommended to install these feed through headers

in Enpower even if you are not currently planning to use load control

and PV shedding features. This ensures that these headers will not get

lost. Supports AWG 28 to AWG 16 wire sizes. Torque for tightening the

screws on the top is 0.22 N•m (1.9 lb•in) to 0.25 N•m (2.2 lb•in).

Lit Kit label

If Enpower is installed as service equipment:

• Connect a grounding electrode conductor to the grounding bar.

• From the lit kit, place the label “GROUNDING ELECTRODE TERMI-

NAL” adjacent to the grounding bar.

• From the lit kit, place the label “SUITABLE FOR USE AS SERVICE

EQUIPMENT”/ “MAIN SERVICE DISCONNECT” on the deadfront

near the main breaker/service disconnect.

• If Enpower is not used as service equipment, these labels should

not be used.

© 2021 Enphase Energy. All rights reserved. Enphase, the Enphase logo, Enpower smart switch, Encharge storage system, Envoy, Combiner, Microinverter,

Installer Toolkit, Enlighten and other trademarks or service names are trademarks of Enphase Energy, Inc. Data subject to change. 04-16-2021

rev. Modificaton ECN Date Drawing Approved

Material

Hardness

Finish

Description

Stainless steel A2-70 Customer Code

Customer P/N

& drawing no.

Drawing No.

Article No.

Scale

Size

UNSPECIFIED TOLERANCES

Version

QP Level Q2

02

All dimensions are in inch

Third angle projection

00 Created N/A

2019/12/4

Mary He Don Tang

A4

Not ot Scale

6358144

Business Unit

BOC

Important Disclaimer

The technical recommendations contained in this publication are necessarily of a general nature and should not be relied on for specific applications without first

securing competent advice. Whilst Bossard has taken all reasonable steps to ensure the information contained herein is accurate and current, Bossard does not

warrant the accuracy or completeness of the information and does not accept liability for errors or omissions.

Hexalobular socket pan head machine

screw #8-32UNCX0.63

0.306-0.322

0.105-0.115 0.63

0

-0.03

#8-32UNC

Hexalobular Drive X20

Note:

1.Without burr,Sharp edges or other disfigurements.

2.The part is RoHS compliance.

3. Refer ASME B18.6.3.

4. Comply with thread locking standard IFI 124.

Passivation

02

Q2

Mary He

Mary He

2019/12/9

6358144

0.055-0.070

01 Add nylon patch. N/A

2019/12/5

Mary He Don Tang

Nylon blue patch (half circle

90° ~180° ), cover 4-6

threads, 1-2 lead thread

free of locking material

02

Change nylon patch standard to IFI 124 for inch screw, was IFI 524.

N/A

2019/12/9

Mary He Don Tang

730-00305

1. Insert wires here

4. Tighten these screws to se-

cure the feed-through header

to the I/O ports on Enpower

Feed through headers for

I/O-1 and I/O-2

Feed through header

for Generator I/O

2

3

4

1

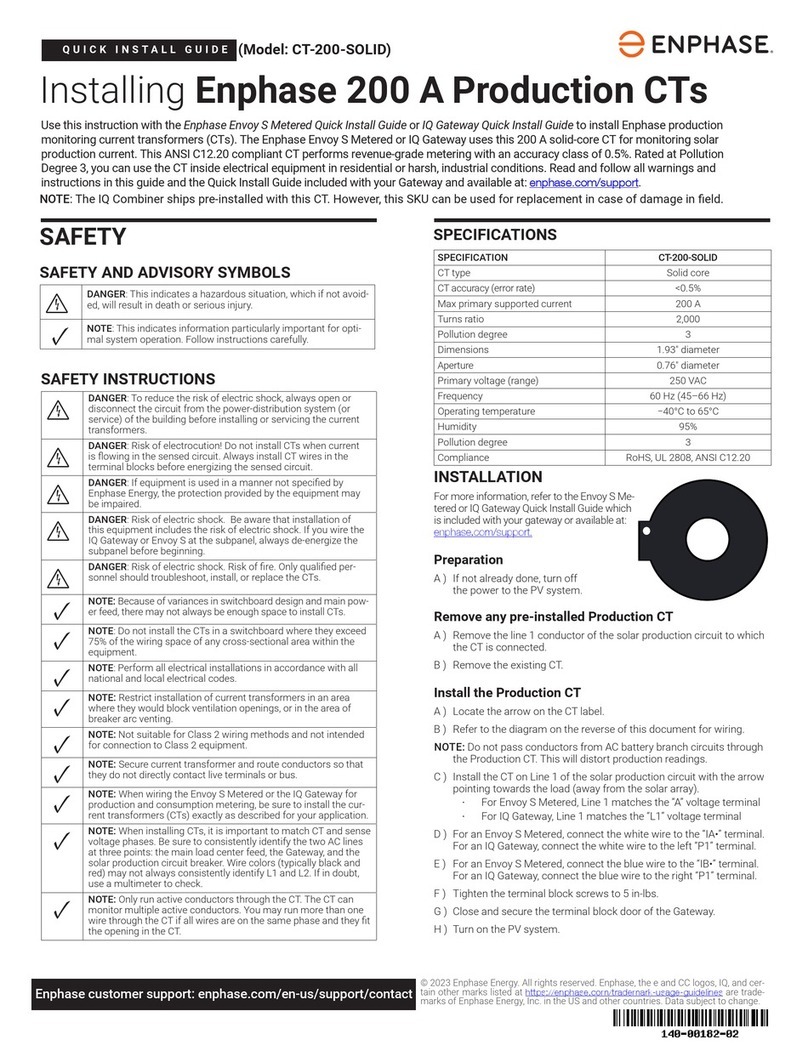

CT Label

For Production as well as Consumption/PCS CTs, you must apply

the following label to each CT when the system is congured to use

PCS-based current limiting.

The available space on the CTs for labeling is as follows

Consumption/PCS CT (CT-200-SPLIT):

• Left side: 20mm(vertical) x 14mm (Horizontal)

• Back side: 20mm (vertical) x 20mm (Horizontal)

Production CT (CT-200-SOLID):

• 9mm(vertical) x 30mm(horizontal)

THE MAXIMUM CURRENT BACKFED BY THIS SYSTEM TO THE MAIN

PANEL MAY BE CONTROLLED ELECTRONICALLY. REFER TO MANU-

FACTURER’S INSTRUCTIONS FOR MORE INFORMATION

PCS CONTROLLED CURRENT SETTING: ___________ AMPS

Manual Override Label

This is to be applied to be above (north of) the manual override switch

on the Enpower deadfront.

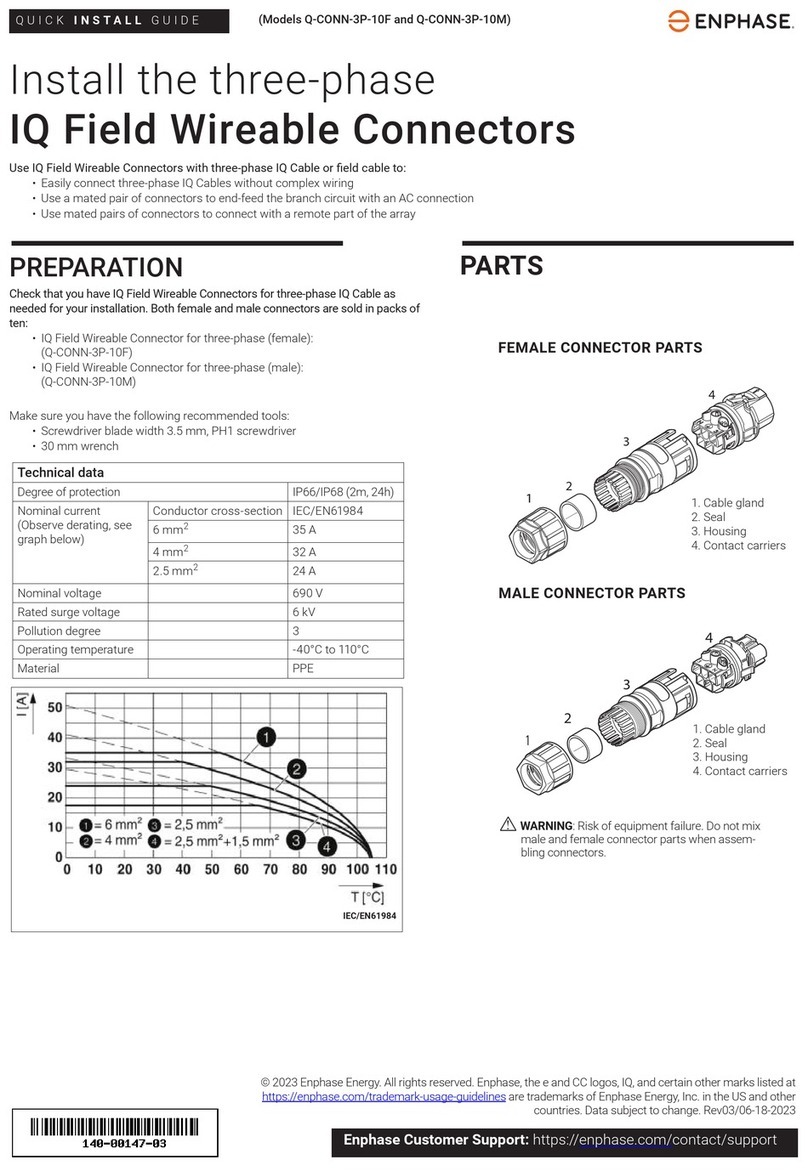

M6screwsandllerplates

During Enpower installation, after sliding in Enpower on the wall-

mount bracket shelf, remove the lift handles and on the bottom

handle mounts, use the two provided partial-threaded custom M6

screws to secure each side of the Enpower and tighten to 0.5 N•m

(4.4 lb•in) or less. The threaded portion of the screw engages with the

bracket, while the unthreaded portion of the screw engages with the

hole in the bracket to prevent vertical movement of the bracket.

* WARNING! Risk of injury and equipment damage. Do not skip this

step. Without these screws in place, the Enpower may fall and cause

injury or damage if bumped or shaken.

Use the four ller plates, provided in the lit kit, to cover the screws.

rev. Modificaton ECN Date Drawing Approved

Material

Hardness

Finish

Description

Phillips truss head machine screw

M6x25

Passivation

Stainless steel 304, A2-70 Customer Code

Customer P/N

& drawing no.

Drawing No.

Article No.

Scale

Size

UNSPECIFIED TOLERANCES

Version

QP Level Q2 00

All dimensions are in mm

Third angle projection

00 Created 13-Nov-19 Mary He Don Tang

A4

Not ot Scale

6355781

Business Unit

BOC

Important Disclaimer

The technical recommendations contained in this publication are necessarily of a general nature and should not be relied on for specific applications without first

securing competent advice. Whilst Bossard has taken all reasonable steps to ensure the information contained herein is accurate and current, Bossard does not

warrant the accuracy or completeness of the information and does not accept liability for errors or omissions.

Note:

1. Without burr, sharp edges or other disfigurements.

2. The part is RoHS compliance.

3. Comply with thread locking standard IFI 524.

00

Q2

Mary He

Mary He

2019/11/13

6355781

M6xP1.0

Ø6

0

-0.18

13.87-14.55 3.38-3.81

Phillips Drive #3

Nylon blue patch (half circle

90° ~180° ), cover 4-6

threads, 1-2 lead thread

free of locking material

25±0.42

20Ref

730-00296

01 INITIAL RELEASE - ECO-005109 MN

17 FEB 21

M. Nagy 17 FEB 21

780-00568

1 1

Label, Enpower, CT, Field

01

D

C

B

A

B

A

1

3

45

678

12

34

56

78

1420 N. McDowell Blvd.

PETALUMA, CA 94954

(707) 763-4784

The information contained in this document is the

proprietary and confidential information of ENPHASE

ENERGY, Inc.. You will not provide, make available

or disclose (or use for any purpose other than that

contemplated by this document) any such information

to any other party without the express, written consent

of ENPHASE ENERGY, Inc.

D

C

SIZE

SHEET OF

REV

DRAWING NO.

2

DWN BY

ENGR

MFG TITLE

THIRD ANGLE PROJECTION

3D MODEL

REVISIONS

REV DESCRIPTION CHKD DATE

APPROVALS DATE

B

DO NOT SCALE THIS DRAWING

Scale: 2:1

25.00

8.00

This sensor is part of a

Power Control System.

Do not remove or disable.

Replace with the same type and rating.

7. LABEL MUST BE UL RECOGNIZED (PGDQ2) AND CSA

ACCEPTED AS SUITABLE FOR OUTDOOR USE AT

TEMPERATURES FROM -40°C TO +65°C AND SUITABLE

FOR THE SURFACE TO BE APPLIED (PER UL RECOGNIZED

COMPONENT DIRECTORY). EACH LABEL MUST BE MARKED

WITH VENDOR’S MARK AS DEFINED IN THE CSA LIST OF

ACCEPTED ADHESIVE-TYPE NAMEPLATES. THE SMALLEST

SHIPPING PACKAGE MUST BE MARKED WITH SUPPLIER’S

NAME AND UL DESIGNATION.

1. MATERIAL: 3M 7871 POLYESTER, 3M 350 ADHESIVE

WITH CLEAR OVERLAY ON FRONT.

2. USE UV RESISTANT INK.

3. DIE CUT LABEL AND SHIP IN SHEETS OR ON ROLL.

4. ARTWORK SUPPLIED IN ILLUSTRATOR FORMAT.

5. COLORS: BACKGROUND RED (RGB: 255, 0, 0) TEXT WHITE

6.VENDOR HAS THE AUTHORITY TO MODIFY COLORS

SLIGHTLY TO SUIT AVAILABLE INKS.

Auxiliary Contact Labels

This label can be applied on top of the existing label for the lugs in

Enpower.

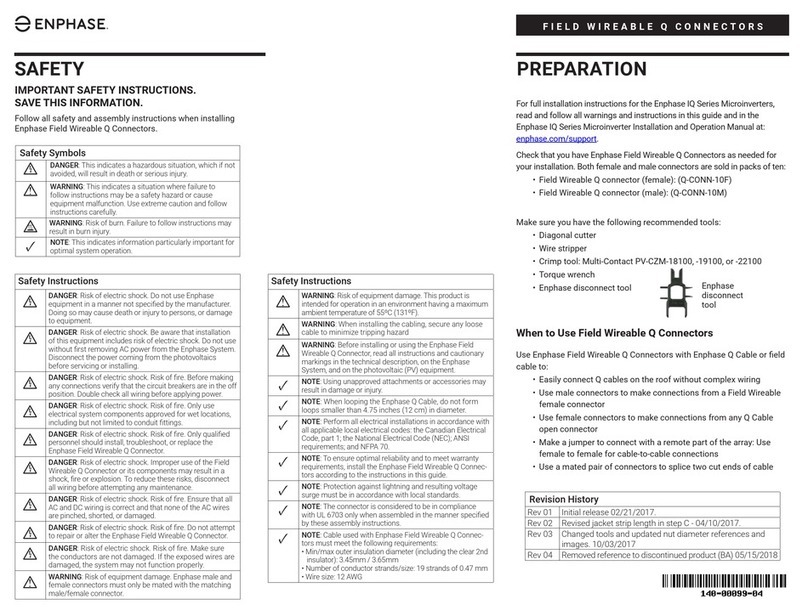

Stick Manual Override

label here

01 INITIAL RELEASE - ECO-005109 MN

26 FEB 21

M. Nagy

18 FEB 21

780-00669

1 1

Label, Enpower R1, MOR

01

D

C

B

A

B

A

1

3

45

678

12

34

56

78

1420 N. McDowell Blvd.

PETALUMA, CA 94954

(707) 763-4784

The information contained in this document is the

proprietary and confidential information of ENPHASE

ENERGY, Inc.. You will not provide, make available

or disclose (or use for any purpose other than that

contemplated by this document) any such information

to any other party without the express, written consent

of ENPHASE ENERGY, Inc.

D

C

SIZE

SHEET OF

REV

DRAWING NO.

2

DWN BY

ENGR

MFG TITLE

THIRD ANGLE PROJECTION

3D MODEL

REVISIONS

REV DESCRIPTION CHKD DATE

APPROVALS DATE

B

DO NOT SCALE THIS DRAWING

Scale: Full

200.00

Manual Override Instructions:

Contact Enphase customer support at (877) 797-4743 and confirm before following instructions below.

Steps for Initiating Manual Override (Tied to Grid)

1. OPEN the breakers for Encharge, Mains, and Auto Transformer in Enpower (The mains breaker could be located inside the main service panel).

Note: No need to open PV combiner and load side breaker inside Enpower.

2. Turn OFF all Encharge units by turning OFF the DC switches on each Encharge base unit.

3. Disable the generator. Turn off generator output breaker inside the generator. Ensure your generator is turned off.

4. Wait for 2 minutes.

5. Remove the sticker from the manual override section of the Enpower. Use a Philips head screwdriver to remove the screw on the plastic cover.

Then remove the plastic cover to make the small manual override toggle visible.

6. Turn the toggle to the left to manually CLOSE the MID relay.

7. CLOSE the mains breaker.

The Enpower system is now in manual override mode and grid tied.

Steps for Exiting Manual Override:

1. OPEN the breakers for Encharge, Mains, and Auto Transformer in Enpower.

2. Turn OFF all Encharge units by turning OFF their DC switches.

3. Wait for 2 minutes.

4. Turn the manual override toggle to the right to manually OPEN the MID relay.

5. CLOSE all the breakers in sequence:

a. NFT breaker inside Enpower

b. Mains breaker (In Enpower or main panel)

c. Encharge breaker inside Enpower

6. Turn ON all Encharge units by turning ON their DC switches.

The Enpower system is now no longer in manual override mode and is fully fuctional.

7. LABEL MUST BE UL RECOGNIZED (PGDQ2) AND CSA

ACCEPTED AS SUITABLE FOR OUTDOOR USE AT

TEMPERATURES FROM -40°C TO +65°C AND SUITABLE

FOR THE SURFACE TO BE APPLIED (PER UL RECOGNIZED

COMPONENT DIRECTORY). EACH LABEL MUST BE MARKED

WITH VENDOR’S MARK AS DEFINED IN THE CSA LIST OF

ACCEPTED ADHESIVE-TYPE NAMEPLATES. THE SMALLEST

SHIPPING PACKAGE MUST BE MARKED WITH SUPPLIER’S

NAME AND UL DESIGNATION.

1. MATERIAL: 3M 7871 POLYESTER, 3M 350 ADHESIVE

WITH CLEAR OVERLAY ON FRONT.

2. USE UV RESISTANT INK.

3. DIE CUT LABEL AND SHIP IN SHEETS OR ON ROLL.

4. ARTWORK SUPPLIED IN ILLUSTRATOR FORMAT.

5. COLORS: BACKGROUND WHITE, BLACK C

6.VENDOR HAS THE AUTHORITY TO MODIFY COLORS

SLIGHTLY TO SUIT AVAILABLE INKS.

100.00

Scan QR code to view

instruction videos

Label Sample

Label Sample

Stick PCS label here

PCS Label

Apply the PCS label on the deadfront. Record the maximum operating

amps value on the label. This value indicates the maximum current

57

8

9

6

Stick CT label

for PCS here

Stick CT label

for PCS here

Label Sample

Enphase Customer Support: enphase.com/en-us/support/contact

Safety and Advisory Symbols

+DANGER: This indicates a hazardous situation, which if not avoided, will

result in death or serious injury.

*WARNING: This indicates a situation where failure to follow instructions

may be a safety hazard or cause equipment malfunction. Use extreme

caution and follow instructions carefully.

✓NOTE: This indicates information particularly important for optimal system

operation. Follow instructions carefully.

Safety Instructions

+DANGER: Risk of electric shock. Risk of re. Only qualied electricians should

install, troubleshoot, or replace the Enpower.

+DANGER: Risk of electric shock. Risk of re. Do not attempt to repair the

Enpower. Tampering with or opening the Enpower will void the warranty.

If the Enpower fails, contact Enphase Customer Support for assistance at

enphase.com/en-us/support/contact.

+DANGER: Risk of electric shock. Do not use Enphase equipment in a manner

not specied by the manufacturer. Doing so may cause death or injury to

persons, or damage to equipment.

+DANGER: Risk of electric shock. Do not install the Enpower without rst

removing AC power from the photovoltaic system and ensuring that the DC

switch on the Enphase Encharge batteries are off. Disconnect the power

coming from the photovoltaics and ensure that the DC switch on the En-

charge batteries are off before servicing or installing.

+DANGER: Risk of electric shock. Risk of re. Do not work alone. Someone

should be in the range of your voice or close enough to come to your aid

when you work with or near electrical equipment.

+DANGER: Risk of re. Do not allow or place ammable, sparking, or explosive

items near the Enpower.

+DANGER: Risk of electric shock. In areas where ooding is possible, install

the Enpower at a height that prevents water ingress.

*WARNING: Risk of equipment damage. Enpower is shipped and stored on its

back. The upright position is only needed when installed.

*WARNING: You must install the Enpower only on a suitable wall using an

Enphase wall-mount bracket.

*WARNING: Before installing or using the Enpower, read all instructions and

cautionary markings in this guide and on the equipment.

*WARNING: Do not install or use the Enpower if it has been damaged in any

way.

*WARNING: Do not sit on, step on, place objects on, or insert objects into the

Enpower.

*WARNING: Do not place beverages or liquid containers on top of the

Enpower. Do not expose the Enpower to ooding.

✓NOTE: Perform installation and wiring, including protection against lightning

and resulting voltage surge, in accordance with all applicable local electrical

codes and standards.

✓NOTE: Because Encharge is grid forming, you must install signage in accord-

ance with NEC articles 705, 706, and 710.

✓NOTE: Using unapproved attachments or accessories could result in dam-

age or injury.

✓NOTE: Install properly rated over current protection as part of the system

installation.

✓NOTE: To ensure optimal reliability and to meet warranty requirements, the

Enpower must be installed and/or stored according to the instructions in this

guide.

✓NOTE: The Enpower is compatible only with the IQ Envoy or Envoy

S-metered communications gateway properly tted with USB hub, USB

radios, and production and Consumption/PCS CTs. The Envoy is required

for operation of the Enpower. Earlier versions of the Enphase Envoy commu-

nications gateway are incompatible.

✓NOTE: The Enphase Enpower is intended to operate with an Internet connec-

tion through the Envoy. Failure to maintain an Internet connection may have

an impact on the warranty. See Limited Warranty for full terms and services

(enphase.com/warranty).

✓NOTE: When replacing an Enphase Enpower, you must replace it with an

Enpower of the same type, with the same AC current rating.

✓NOTE: Properly mount the Enpower. Ensure that the mounting location is

structurally suited to bearing the weight of the Enpower.

✓NOTE: During use, storage, and transport, keep the Enpower:

• Properly ventilated

• Away from water, other liquids, heat, sparks, and direct sunlight

• Away from excessive dust, corrosive and explosive gases, and oil smoke

• Away from direct exposure to gas exhaust, such as from motor vehicles

• Away from falling or moving objects, including motor vehicles. If mounted

in the path of a motor vehicle, we recommend a 91cm (36-inch)

minimum mounting height

• In a location compliant with re safety regulations

• In a location compliant with local building codes and standards

1NOTE: While Enpower provides capability for connection of a generator, it

does not presently support use with generators. Do not attempt to connect a

generator until Enpower is ready to support a generator. This functionality is

reserved for future use and will require an upgrade process to be followed by

a qualied electrician.

2NOTE: Enpower is not suitable for use as service equipment in Canada.

SAFETY

IMPORTANT SAFETY INSTRUCTIONS. SAVE THESE INSTRUCTIONS. This guide contains important instructions that you must follow during installation

and maintenance of the Enphase Enpower. Failing to follow any of these instructions may void the warranty (enphase.com/warranty).

In Case of Fire or Other Emergency

In all cases:

• If safe to do so, switch off the AC breaker for the Enpower circuit, and if an

isolator switch is present, switch off the AC isolator for the Enpower circuit.

• Contact the re department or other required emergency response team.

• Evacuate the area.

In case of re:

• When safe, use a re extinguisher. Suitable types are A, B, and C dry chemical

re extinguishers. Additional extinguishing media include carbon dioxide, or

alcohol-resistant foams.

In case of ooding:

• Stay out of water if any part of the Enpower or wiring is submerged.

• If possible, protect the system by nding and stopping the source of the

water, and pumping it away.

• If water has contacted the UNIT, call your installer to arrange a inspection.

If you are sure that water has never contacted the battery, let the area dry

completely before use.

In case of unusual noise, smell or smoke:

• Ensure nothing is in contact with the Enpower or in the venting area on top of

the Enpower.

• Ventilate the room.

• Contact Enphase Customer Support at enphase.com/en-us/support/contact.

Safety Instructions, continued

Environmental Protection

ELECTRONIC DEVICE: DO NOT THROW AWAY. Waste elec-

trical products should not be disposed of with household

waste. Refer to your local codes for disposal requirements.

Other enphase Cables And Connectors manuals

enphase

enphase CT-200-SOLID User manual

enphase

enphase Ensemble COMMS-KIT-01 User manual

enphase

enphase QD-CONN-10F User manual

enphase

enphase Q-CONN-3P-10F User manual

enphase

enphase Q-CONN-3P-10F User manual

enphase

enphase IQ Series User manual

enphase

enphase Engage Cable User manual

enphase

enphase ET17-240-40 User manual

enphase

enphase Q Series User manual

Popular Cables And Connectors manuals by other brands

Nordost

Nordost NORSE 2 instruction manual

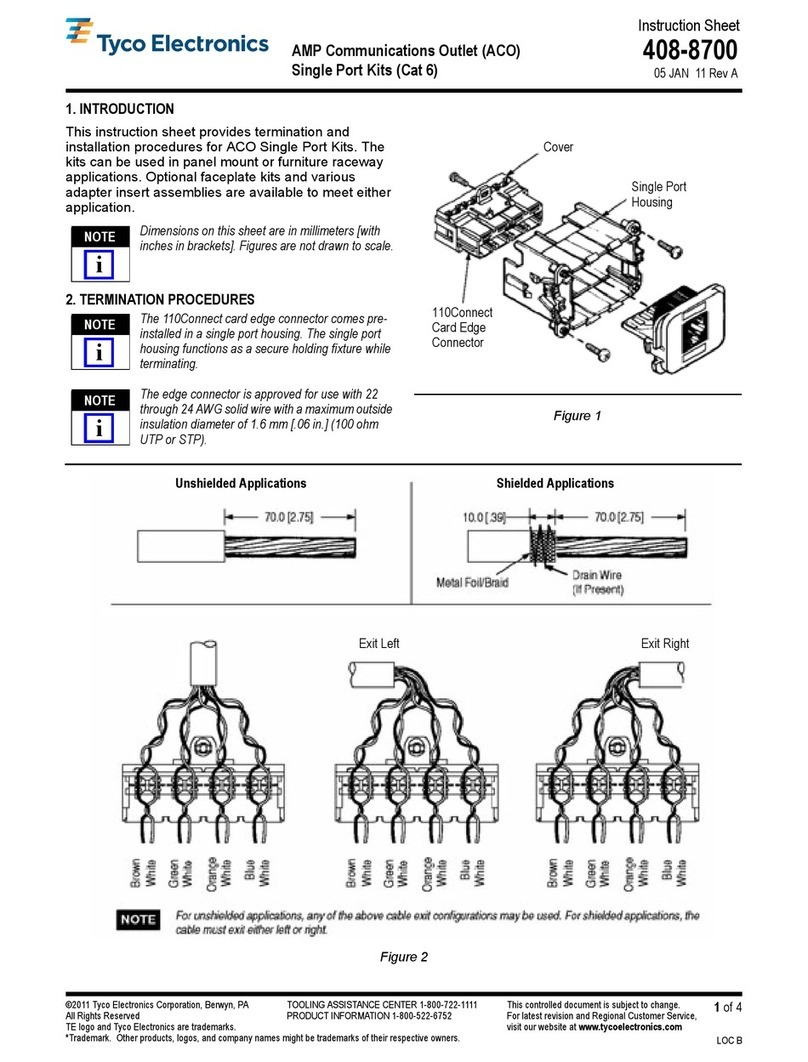

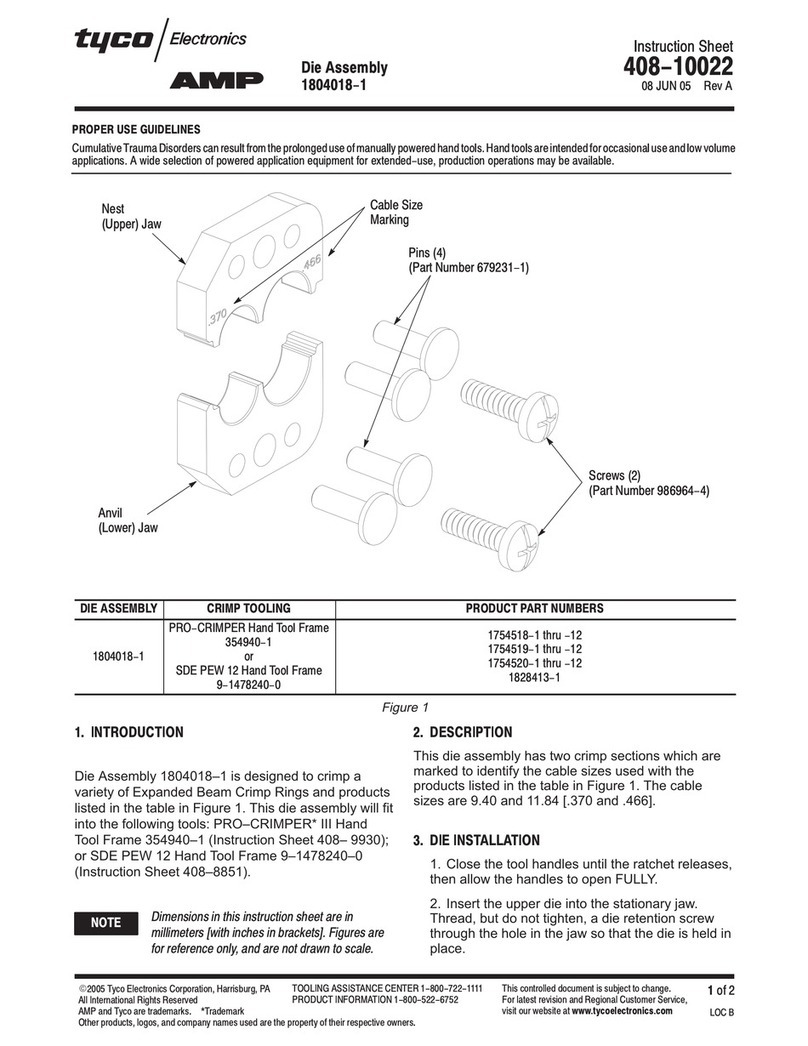

Tyco Electronics

Tyco Electronics AMP 1804018-1 Installation sheet

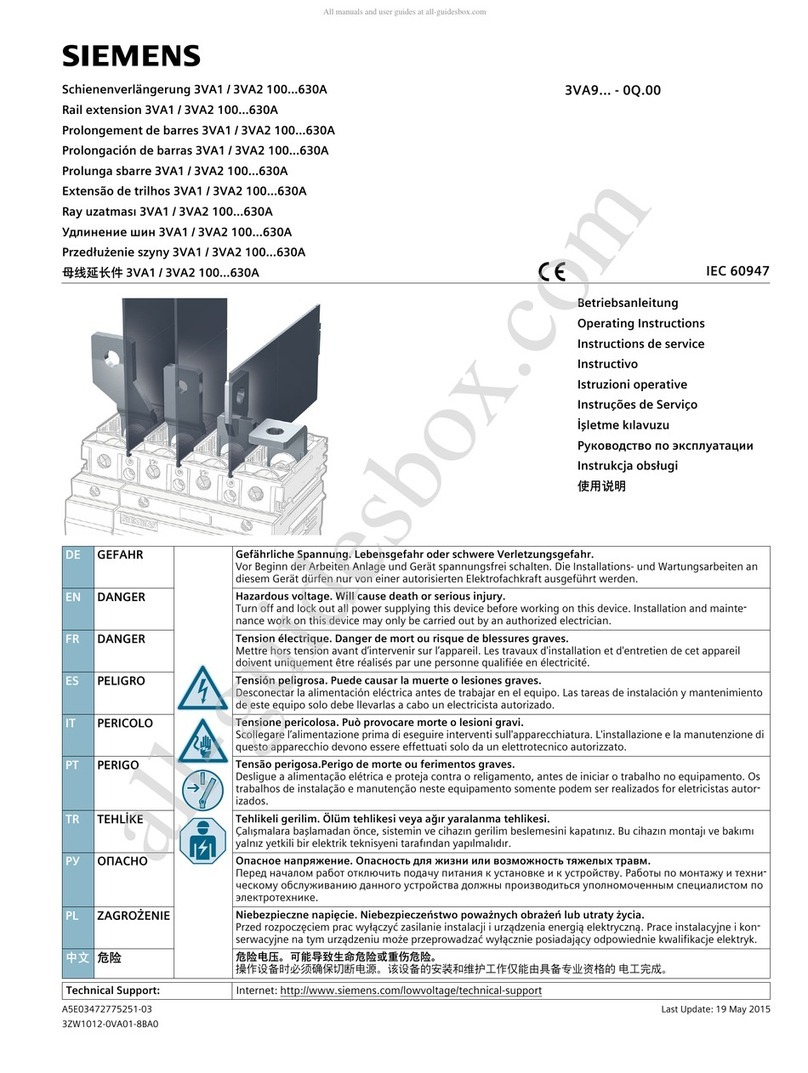

Siemens

Siemens 3VA1 100 630A Series operating instructions

PCB Piezotronics

PCB Piezotronics IMI SENSORS 009M205/100 Installation and operating manual

IOGear

IOGear GHSP8422 quick start guide

Griven

Griven AL4750 instruction manual