epredia HM 430 Manual

Company Information

© Copyright 2022. Epredia. All rights reserved.

Epredia makes every attempt to ensure that the information

contained in this supporting document is correct and clearly

stated but

does not accept responsibility for any errors or

omissions. The development of Epredia products and services

is an ongoing pr

ocess. Please ensure that any published

information you use as a reference is up to date and relates to

the condition of the product. If necessary, check with your local

Epredia representative.

This document may not, in whole or in part, be copied,

photoco

pied, reproduced, translated, or converted to any

electronic or other form without prior written consent of Epredia.

All information contained in this manual is proprietary and

confidential, and the exclusive property of Epredia and is

protected by copyright.

These instruments conform to the general safety and

performance of:

•In Vitro Diagnostics Regulation (IVDR) EU 2017/746

Symbols

The following symbols and conventions may be used

throughout this document and on the instrument:

This symbol is used on the equipment, or in a

document, to indicate that instructions must be

followed for safe and correct operation.

This symbol is also used on the instrument, or in a

document, to indicate that irritants or potentially

harmful chemical

s are present. Refer to the Material

Safety Data Sheets for the products, and always use

Good Laboratory Practice.

If this symbol appears on the instrument always refer

to the operator guide.

Contact address

Shandon Diagnostics Limited, a subsidiary of Epredia

Tudor Road, Manor Park, Runcorn

Cheshire, WA7 1TA, UK

Tel: +44 (0) 1928 534000

Fax: +44 (0) 1928 534001

Web: www. epredia.com

This symbol is utilised

on the instrument, or in a

document, to indicate that there are potential

biological risks associated with the instrument and /

or with instrument use. Always use Good Laboratory

Practice.

USA Distributor Cutting hazard, sharp edges, watch your fingers.

Richard-Allan Scientific LLC, a subsidiary of Epredia

4481 Campus Drive

Kalamazoo, MI 49008, USA

Tel: 1-800-522-7270

Fax: +1 269-372-2674

Web: www. epredia.com

Separate taking back of electrical and

electronic

instruments in the countries of the European Union:

This is to be applied in the countries of the European

Union and other European countries with a separate

collecting system within the waste management. This

product, being an electro and/or el

ectronic

instrument, must be treated separately within the

waste management process (WEEE).

A warning is given in the documentation if there is a

potential risk of injury, equipment failure or damage to

the equipment or samples.

Note

Notes give

additional information about a job or

instruction, but do not form part of the instruction.

Manufacturer

This symbol is used on the instrument, or in the

document, to indicate that instructions for use must

be consulted

Serial number

It is stated on the product label sticker.

It is built up as follows: SYYMMXXXXEP

S=Production site, Y=year of production, M=Month of

production, X= Counter, EP=Epredia

So the serial number states the production date of the

device.

HM 430 Operator Guide Issue 03

4

Contents

Company Information 3

Symbols .........................................................3

Contact address .............................................3

USA Distributor ...............................................3

Contents 4

Safety Information 5

General Safety ................................................5

Chemical Safety..............................................6

Environment ...................................................6

Warranty Statement ........................................6

Chapter 1 - Introduction 7

Intended Purpose:...........................................7

Description of Sliding Microtome HM 430.........7

Technical Data Sheet ......................................8

Chapter 2 – Operating Instructions

9

Setting up the Microtome ................................9

Cutting Movement...........................................9

Locking the Sledge .......................................10

Specimen Feed.............................................12

Specimen Clamping......................................16

Changing Specimen Clamps .........................17

Knife Carrier..................................................18

Standard Equipment .....................................21

Additional Equipment (optional)......................21

Chapter 3 – Theory of Operation

23

Specimen Coarse Feed ................................ 23

Specimen Clamping System and Specimen

Orientation ................................................... 23

Knife Carrier................................................. 23

Microtome with Fast Freezing Unit ................ 23

Chapter 4 – Working with the

Microtome 24

Preparation and Orientation .......................... 24

Coarse Feed ................................................ 24

Sectioning Instructions ................................. 24

How to Avoid Malfunctions ........................... 24

Chapter 5 – Maintenance 25

Annual Routine Maintenance......................... 25

Service Contract .......................................... 25

Chapter 6 – Cleaning and Care 26

Cleaning Intervals......................................... 26

Cleaning Agents........................................... 26

Care ............................................................ 26

Appendices 27

Appendix A – Conditions for Transportation of the

Instrument ................................................... 27

Index 29

Revision Control For This

Document 30

HM 430 Operator Guide Issue 03

5

Safety Information

Epredia instruments are designed for convenient and

reliable service; however, improper use or handling

by a user may damage the instrument or cause a

hazard to health. The instrument must not be used

in a manner not specified by Epredia. Correct

maintenance procedures are essential for consistent

performance. It is recommended that users secure a

maintenance contract with our service department.

To remain compliant with regulatory requirements,

and to ensure that mandatory safety upgrades are

performed at the earliest opportunity, it is strongly

recommended that all service activities are

performed by Epredia-factory trained Engineers.

Warranty may be voided if service is performed by

non-factory trained Engineers.

Maintenance or repairs that are not performed by

Epredia trained Engineers with proven training may

affect the safety, performance and compliance of the

equipment.

Please consult your local sales or support teams for

more information about service contracts.

The following sections contain

important information for the safe

setup and use of the instrument and

should be read and understood by

the user before using the instrument.

General Safety

This instrument, as supplie

d, conforms

to IEC 61010-1 and IEC 61010-2-

101;

however, the addition of chemicals

introduces potential hazards. Good

Laboratory Practice must be

employed,

and consideration must be

given to the potential for hazard when

dealing with these chemicals.

Do not use the instrument in close

proximity to strong electromagnetic

radiation, as these may interfere with

the proper operation. The

electromagnetic environment should

be evaluated prior to operation of the

device.

Good Laboratory Practice must be

used when handling tissue samples to

prevent cross contamination and

infection. The user should complete a

risk assessment to determine any

potential hazards related to tissue

handling.

•

Do not introduce any source of

ignition into, or near, the

instrume

nt once it has been

loaded with reagents.

•

Do not remove any panels or

access covers, unless specifically

instructed to do so. The

instrument does not have any user

serviceable parts.

•

Use only factory approved

accessories or replacement parts

within the instrument.

•

Only use reagents recommended

in the operator guide.

HM 430 Operator Guide Issue 03

6

Chemical Safety

The introduction of chemicals creates potential

hazards. Epredia has adopted the following position

with regard to the subject of volatile chemicals used

in laboratories:

•

Customers using non-

specified

chemicals in the instrument, do so at

their own risk.

•

All chemicals recommended by

Epredia have auto-

ignition

tempera

tures considerably above any

surface temperatures that can be

reached during a single fault failure on

the instrument.

•

The instrument contains no source of

ignition in any areas of the instrument

where chemicals are stored, or likely

to leak into, in a single fault condition.

•

The operator is fully aware of the

contents of the specification

documents detailing the properties of

the chemicals they are using.

•

The operator has carried out any

legally required assessment of

chemicals used and is using Good

Laboratory Practice.

Environment

This instrument complies with the European Union's

Waste Electrical and Electronic Equipment (WEEE)

Directive 2012/19 EU. It is marked with the following

symbol:

Epredia has contracts with one or more recycling /

disposal companies in each EU Member State, and

this product and packaging should be disposed of

or recycled through them. For further information

contact your Epredia service representative.

Warranty Statement

Epredia is proud of their quality, reliability and of our

after-sales service. We continuously strive to

improve our service to our customers.

Please ask your distributor or Epredia representative

about service contracts which can help maintain

your instrument in an optimal operating condition.

Warranty provisions necessarily vary to comply with

differences in national and regional legislation.

Specific details can be found in the delivery

documentation or from your dealer or representative.

Please note that your warranty may be invalidated if:

•This instrument is modified in any way, or not

used as intended Epredia.

•Accessories and reagents which have not been

approved by Epredia are used.

•The instrument is not operated or maintained in

accordance with instructions.

•The installation of the instrument was not

conducted by a certified Epredia representative.

Any serious incident that has

occurred in relation to the device

shall be reported to the

manufacturer and the competent

authority of the Member State in

which the user/or the patient is

established.

HM 430 Operator Guide Issue 03

7

Chapter 1 - Introduction

Intended Purpose:

The Epredia sliding microtome HM 430 is an in vitro

diagnostic device, designed to take precision

sections of tissue specimens including the sectioning

of paraffin embedded samples in medical,

pharmaceutical laboratories as necessary

preparation for their examination and subsequent

diagnosis. Only qualified and trained laboratory

personnel may operate the HM 430.

The instrument may only be operated within the

scope of its intended use as described above and as

per the instructions given in this manual.

Any other use of this instrument is considered as an

improper action.

Description of Sliding

Microtome HM 430

The sliding microtome HM 430 from Epredia is a

highly efficient instrument for sectioning paraffin in

routine and research. The main applications are in

human and veterinary medicine. Large and hard

specimens from pharmaceuticals industry or from

quality assurance labs can also be sectioned.

The cross-roller bearings on sledge and block allow

non-tiring working and a smooth sliding movement

with optimal stability.

The HM 430 will cut sections from 1 µm to 60 µm.

The specimen clamping can be moved up and

downwards via the coarse feed wheel with crank

handle on the left side of the instrument. This way,

specimen and knife edge distance can be adjusted

quickly.

The knife carrier is designed so the knives can be

easily clamped in place and adjusted.

The coaxial specimen orientation allows orientation

with one hand.

HM 430 Operator Guide Issue 03

8

Technical Data Sheet

Microtome

Section thickness range 0.5 - 60 µm

Resolution 0.5 µm for 0 ... 5 µm

1 µm for 5...10 µm

2 µm for 10...20 µm

5 µm for 20...60 µm

Vertical feed range max. 40 mm

Horizontal knife stroke max. 190 mm

Cutting drive manual sliding movement

Coarse feed manual via coarse feed wheel

Feed automatic via sliding movement or manual via feed lever

Specimen size up to max. 80 x 60 mm

Specimen orientation x - and y - axes universal 8°

Transportation- & storage conditions:

Storage temperature

range -20°C up to +50°C

Operating conditions:

+5°C up to +35°C

(at a max. rel. humidity of 60%)

for indoor use only

Floor loading requirements: 150 kg/m2

Dimensions wide: 360 mm, deep: 490 mm, high: 320 mm

Weight 23 kg

HM 430 Operator Guide Issue 03

9

Chapter 2 – Operating Instructions

Setting up the Microtome

Note

The kind of the used examination materials and all

special conditions for their processing, pre-

treatment and, if necessary, storage as well as

instrument controls for correct and safe operation is

in the responsibility of the operator. The operator is

also responsible for special equipment and materials

and/or reagents for the operation of the instrument.

•Unpack the microtome and remove the

wrapping.

•To carry the instrument, lift it on the front and rear

side from the lower side.

Do not carry the instrument on the

handle of the knife sledge!

•Place the instrument on an even surface in a way

that the knife guidance is moved towards the

user and away from him.

•The coarse feed wheel should show to the left

side and the knife carrier handle to the right side.

Note

Sectioning can be influenced by nearby instruments

which generate vibrations. For this reason, the

microtome should be placed on a stable and

vibration free table.

The standard equipment includes four rubber feet

which are smaller than the ones that were installed

in our factory. Should the working height be too high

when setting up the microtome, unscrew the original

feet and replace them with the lower ones.

Cutting Movement

•To start the cutting movement of the microtome,

move the sledge horizontally.

•The knife (or blade) which is clamped into the

knife carrier is drawn horizontally over the

specimen towards the user. This way, sections

are produced.

•In the front reversal point of the sliding

movement, i.e. when the sledge is moved again

backwards, the preselected section thickness is

delivered either manually via a lever or

automatically by moving over the advance

position.

•This way, the specimen is moved in vertical

direction towards the knife with the selected

section thickness and a new section can be

made.

HM 430 Operator Guide Issue 03

10

Locking the Sledge

For the protection against injury by unintended

movements of the knife sledge, the microtome is

equipped with a lock of the sledge in any position.

Figure 1

The sledge should be locked for the

user's personal safety, e.g. when new

specimens are clamped into position,

knives are exchanged, the instrument is

cleaned, or other adjustment processes

are carried out.

•The lock is released via a lever on the rear side of

the sledge and is easily accessible from the right

side behind the handle.

Locking the sledge

•Swivel the locking lever from the upper position

(Figure 1.1) into the lower position (Figure 1.2).

•Then the red marked lever surface becomes

visible to show the clamped state (Figure 2).

Figure 2

Loosening the sledge

•Swivel the lever from the lower position (Figure

1.2) into the upper position (Figure 1.1) until the

red mark cannot be seen anymore.

•The knife sledge can be moved again.

HM 430 Operator Guide Issue 03

11

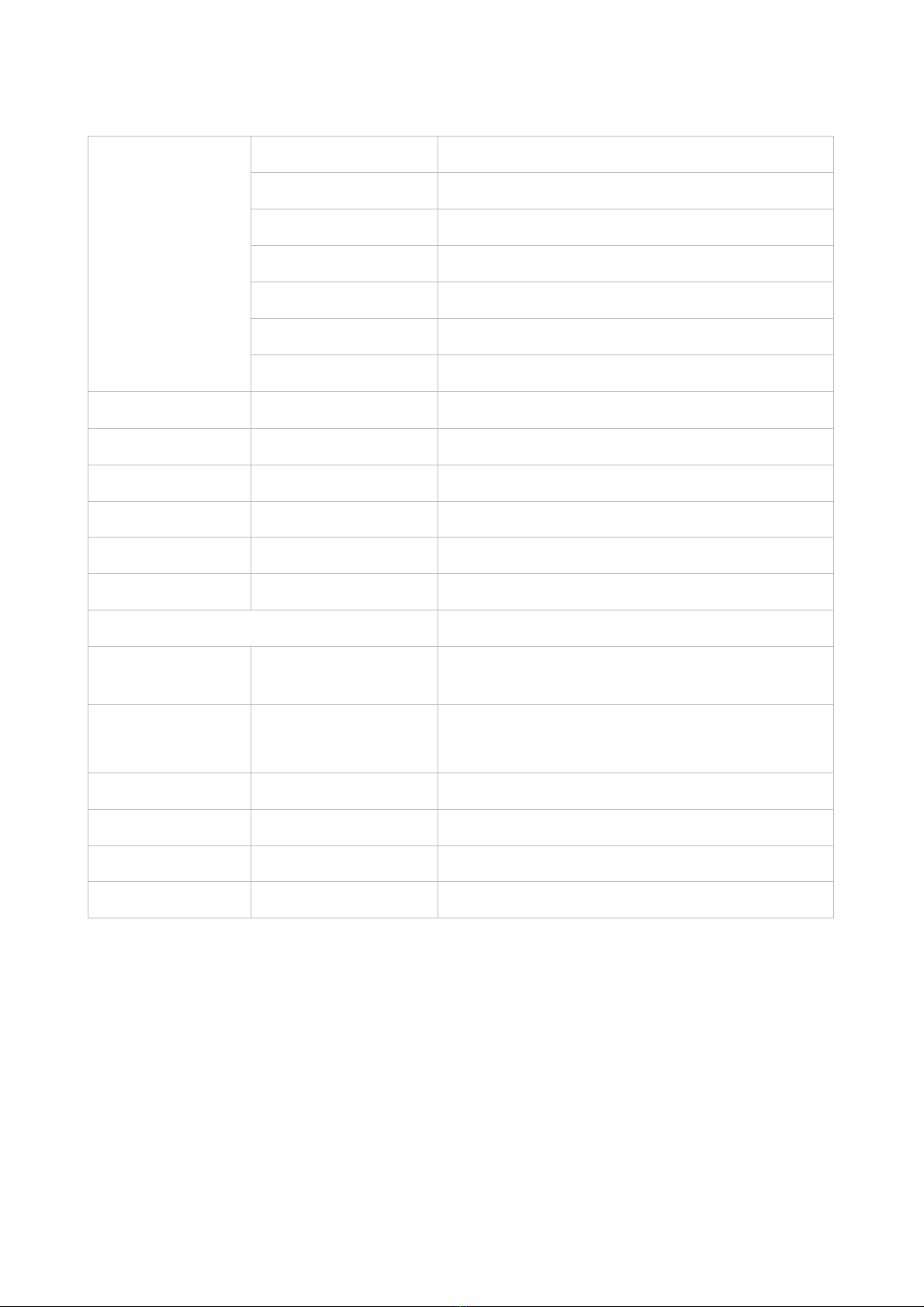

Additional Ballast for Sledge

As required by users to vary the weight of the sledge,

we have included additional ballast (Figure 3) into the

standard equipment.

Figure 3

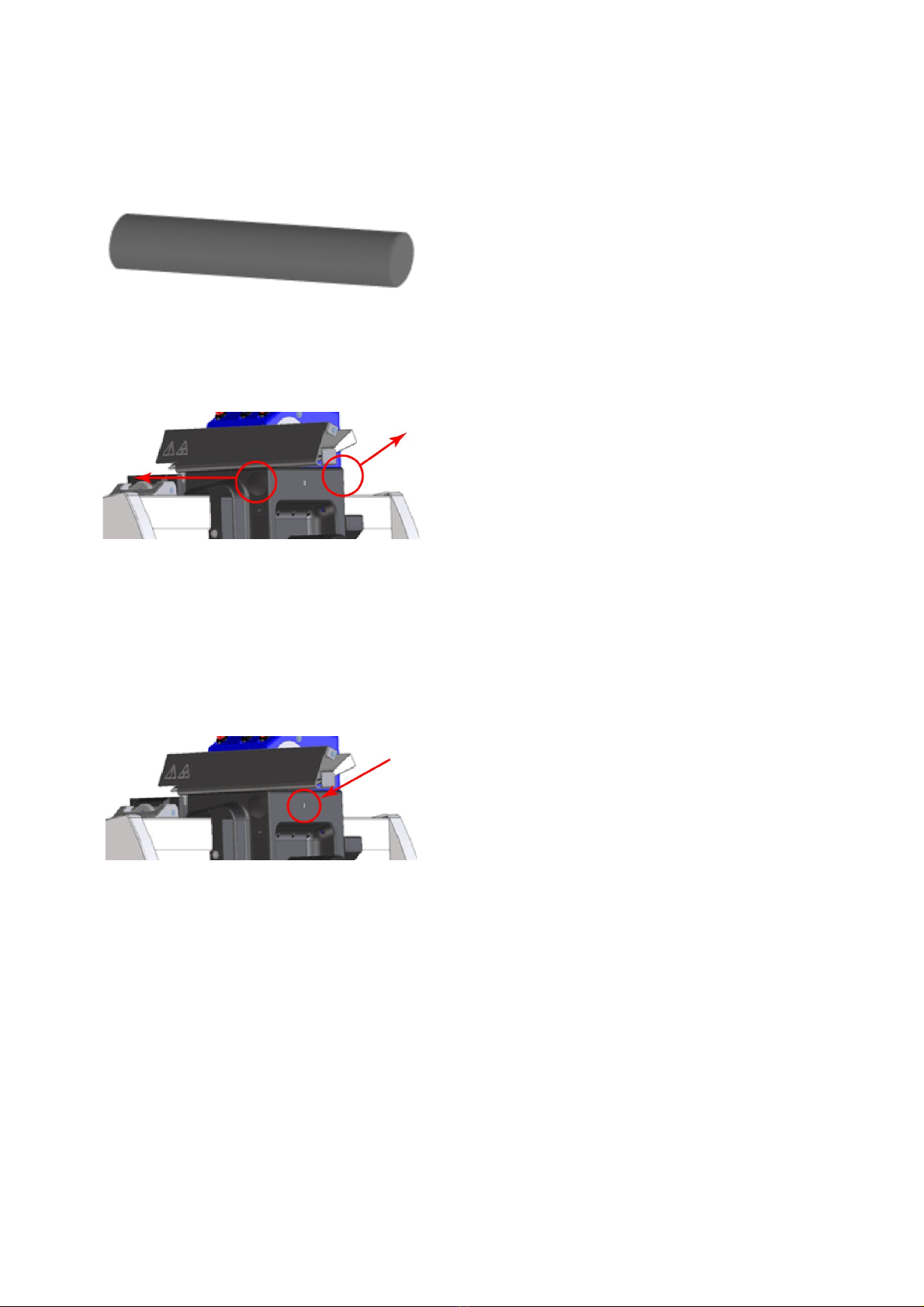

To assemble the additional ballast, please proceed

as described below:

Figure 4

Remove the two cover caps, located sideways at the

sledge (Figure 4).

Insert the ballast (Figure 3) into the opening and close

it again by using the two cover caps (Figure 4).

Fix the ballast with the laterally set-screw (Figure 5)

Figure 5

To remove the ballast, please execute this procedure

in reverse order.

HM 430 Operator Guide Issue 03

12

Specimen Feed

Setting Section Thickness

The required section thickness is set by turning the

scaled wheel on the front side of the instrument to

left or right side. The setting is locking and the

currently selected value can be read on the highest

point of the scale opposite the index marking (Figure

6.1).

Figure 6

The graduation of the section thicknesses is divided

into four ranges:

Range

Graduation

from 0.5 µm to 5 µm 0.5 µm

from 5 µm to 10 µm 1 µm

from 10 µm to 20 µm 2 µm

from 20 µm to 60 µm 5 µm

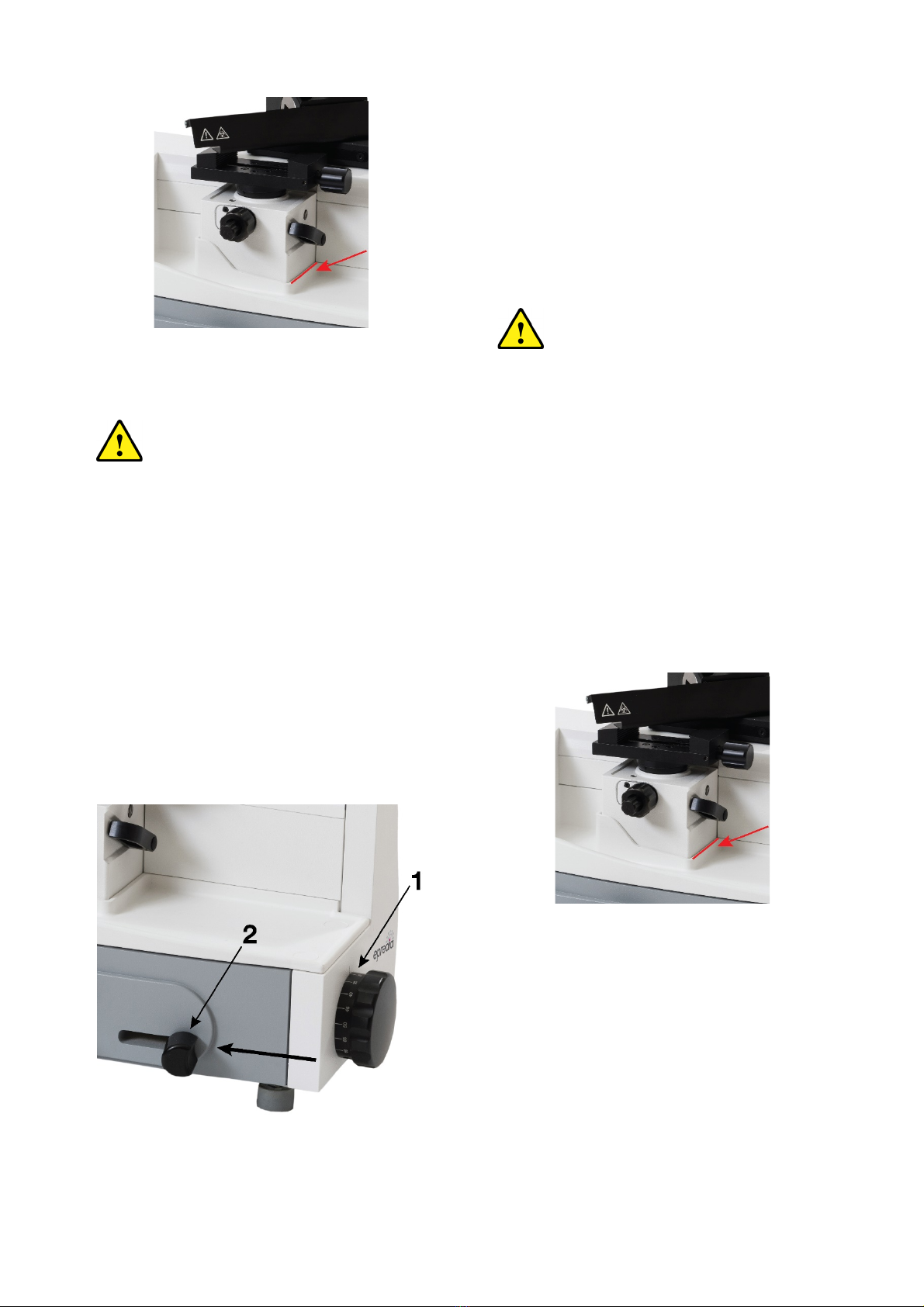

Coarse Feed

For the fast up and downward travel between

specimen and knife edge as well as for trimming, the

microtome has a coarse feed with vertical direction.

Figure 7

•The specimen clamping can be moved 40 mm

vertically up or downwards via the coarse feed

wheel (Figure 7).

•Turn the wheel in a clockwise direction, the

specimen clamping moves upwards towards the

knife.

•Turn the wheel in a counter-clockwise direction,

the specimen moves downwards away from the

knife.

If the specimen clamping is moved

upwards until a red line (Figure 8) can be

seen, the end of the feed range is nearly

achieved. Approx. 3 mm of feed range is

still available.

HM 430 Operator Guide Issue 03

13

Figure 8

Do not cross over this upper end

position by applying more force. Non-

observance leads to damage on the

instrument!!!

Fine Feed, Manual

After having adjusted knife and specimen as well as

having trimmed the specimen, sectioning can be

started.

•The feed of the section thickness which was

preselected on the scaled wheel (Figure 9.1) is

carried out either automatically by moving the

knife sledge over integrated, selectable feed point

or by manually activating the feed device.

•The manual feed is carried out by press the feed

lever (Figure 9.2).

Figure 9

•For this, the knife sledge is moved behind the

specimen and the feed lever is activated once in

the direction of arrow.

•Afterwards pull the knife sledge towards the front

to generate a section.

•Press the feed lever several times, the set section

thickness can be multiplied accordingly.

If a red line (Figure 10) c

an be seen

during sectioning, the end of the feed

range is nearly achieved. Approx. 3 mm

of feed range is still available.

Afterwards, the end of the feed range

can be noticed by a higher force

application on the feed lever.

Do not carry out feed by applying more

force. However, move the specimen

clamping again into a deeper position via

the coarse feed wheel as soon as

possible.

Non-

observance leads to damage on

the instrument!!!

Figure 10

HM 430 Operator Guide Issue 03

14

Fine Feed, Automatic

•The feed of the section thickness which was

preselected on the scaled wheel (Figure 9.1) is

carried out either automatically by moving the

knife sledge over integrated, selectable feed point

or by manually activating the feed device.

Figure 11

•The automatic feed is carried out by moving the

knife sledge into a selectable position behind the

specimen. This feed process can be noticed by a

slight resistance when moving the knife sledge.

•The automatic feed can easily be turned on and

off.

•For this, turn the turning knob (Figure 11.1)

behind the coarse feed wheel forwards or

backwards to the respective stop.

•When the index mark on the turning knob shows

towards the front and thus visible for the operator

(position Automatic), the automatic feed is turned

on.

•When the index mark shows on the knob shows

towards the rear, the automatic feed is turned off

(position Manual).

Note

For optimal sections, always move the sledge

together with the knife to the rear side over the entire

specimen and then move it forwards.

Turning on and off the automatic

position is not possible when the knife

sledge is in the rear position.

If a red line (Figure 12) is seen during

sectioning, the end of the feed range is

nearly achieved. Approx. 3 mm of feed

range is still available.

Do not apply more force for carrying

out the feed. However, move the

sp

ecimen clamping again into a

deeper position via the coarse feed

wheel as soon as possible.

Non-observance leads to damage on

the instrument!!!

Figure 12

HM 430 Operator Guide Issue 03

15

Moving the Automatic Feed Position

The automatic feed is carried out by moving the knife

sledge into a selectable position behind the

specimen.

The knife sledge position, on which the feed of the

preselected section thickness is carried out, can be

chosen within a wide range to accommodate various

specimen sizes. Therefore, it is possible to set the

automatic advance position close behind the

specimen to avoid useless sledge travel distances.

Figure 13

•For this move the knife sledge into the position

where the automatic feed is to be carried out.

•Secure the knife sledge via the locking lever into

position.

•Loosen the clamping lever on the lower side of

the knife sledge and move the entire lever

mechanism forwards and backwards until a slight

resistance can be noticed.

•Tighten the clamping lever again.

•Loosen the sledge lock and move over the

specimen.

•When returning again over the specimen, a feed

is carried out in new selected position.

HM 430 Operator Guide Issue 03

16

Specimen Clamping

To clamp specimens, different specimen clamping

systems are available. With the orienting adapter it is

simple to align the specimen properly in relation to

the knife.

Standard SPECIMEN CLAMP (Cat. no.

715480)

The standard specimen clamp is used for

rectangular and square paraffin blocks.

Figure 14

•Insert the specimen on the front fixed jaw (Figure

14.2) and tighten it via the clamping screw (Figure

14.3) with the movable jaw (Figure 14.1).

For the stability of the specimen, do not

let it project over the clamping jaws too

much!

Standard Specimen Clamp

•This specimen clamp is used in the same way as

the above-described standard specimen clamp

(see cat. no. 715480).

•The clamping screw and thus the clamping

direction of this clamp is arranged transversely in

relation to the sectioning direction.

•Specimens with a size up to 45 x 60 mm can be

inserted.

For the stability of the specimen, do not

let it project over the clamping jaws too

much!

Universal Cassette CLAMP (Cat. no.

715500)

The universal cassette clamp represents a quick-

change system for standardized embedding

cassettes.

Figure 15

•To insert or remove cassettes, press the lever

(Figure 15.1) upwards.

HM 430 Operator Guide Issue 03

17

Changing Specimen Clamps

Due to the quick-change system of the specimen

clamping’s, specimen clamps can be easily and

rapidly changed without needing any tools.

Figure 16

•Loosen the clamping of the specimen clamp

(Figure 16.1).

•Set the specimen clamp horizontally by means of

the set screws of the orientation device.

•To replace the specimen clamp turn the eccentric

lever downwards (Figure 16.1) to the stop and

pull it off (Figure 16.2).

•Now the specimen clamp can be removed and

replaced with another one.

Note

Before inserting another clamp, please note the

position of the hole in the adapter! It must be aligned

in longitudinal direction of the instrument so that the

eccentric lever can be pushed in again.

•Again, push the eccentric lever into the specimen

block.

•Then press the eccentric lever upwards to fix the

specimen clamp in position.

HM 430 Operator Guide Issue 03

18

Knife Carrier

Due to moving parts in connection also

with the microtome knife, a danger area

arises, which might lead to hand injuries

in case of non-

compliance with the

safety features of the microtome and

when disregarding the instruction

manual.

Figure 17

The knife carrier of the microtome is easy to use and

equipped with a knife guard for user safety while

adjusting knife and specimen.

While working on the knife carrier, it

should be locked with the locking device

of the sledge (see part 2-4).

Inserting the knife

•To insert the knife, slightly unscrew the two

clamping screws (Figure 17.1) until the knife can

be pushed in from the side.

•Then tighten the two clamping screws to fix the

knife in its position.

Clearance angle adjustment

The clearance angle between cutting edge and

specimen can be adjusted very easily to the

respective requirements of the tissue to be sectioned

without loosening the clamping of the knife.

•For this, use the two coaxial screws (Figure 17.2

and Figure 17.3) on the upper side of the knife

carrier.

•Loosen the clamping screw (Figure 17.3) in a

counter-clockwise direction and adjust the

clearance angle by means of the set screw

(Figure 17.2).

•The adjusted clearance angle can be read on the

scale which is on the right side of the knife carrier.

•Then tighten the screw Figure 17.3) in a

clockwise direction to fix the clearance angle.

Note

By experience, usable cuts are only achieved at a

clearance angle of 10° or more.

HM 430 Operator Guide Issue 03

19

Protection Against Injury

•The knife carrier is equipped with a knife guard

(Figure 17.4) which should be used while knife or

specimens are adjusted.

Please note that knives with a length of

more than 16 cm (e.g. 22 cm) and/or if

it is clamped too much on one side,

projects over the knife guard resulting in

possible hazards of being injury

although the knife guard is used.

Moving the knife sideways

•If the cutting edge of the knife is blunt, loosen the

clamping screws (Figure 17.1) and move the knife

to the left or right side.

•This process can also be used to protect the

knife, as for trimming and fine sectioning different

parts of the knife can be used.

Diagonal position of the knife

After having loosened the central fastening screw of

the knife carrier (Figure 17.5) via the attached hex

head wrench (size 6), the knife can be adjusted

diagonally according to the tissue to be sectioned.

This is called "angle cut".

However, please note that due to the diagonal

positioning the usable width of the specimen

decreases!

Height adjustment plates (optional)

•In case the height adjustment of the specimen

block is not sufficient for cutting high specimens,

a height adjustment plate can be mounted

between knife carrier and sledge.

•Height adjustment plates are available with 5 mm,

10 mm and 20 mm.

Knife profile

Knives with profile c and d are available. The

opposite figure (Figure 18) shows schematically the

angles on the cutting-edge profiles of c- and d-

knives.

Figure 18

HM 430 Operator Guide Issue 03

20

Blade Holder for Disposable Blades

Two different types of disposable blades are

available: low-profile blades (height: 8 mm) and

high-profile blades (height: 14 mm). When using

disposable blades, a blade holder together with a

disposable blade is clamped into the knife carrier.

Insert the Blade

•Insert the blade holder into the knife carrier from

the left side and tighten the two clamping screws

on the knife carrier.

•The clamping lever on the blade holder can be

positioned in two ways: 0 = loosened, 1 =

clamped.

•To insert the blade, turn the clamping lever to 0

(Figure 19).

•Please note that locating and clamping surfaces

are clean!!

•To clamp the blade, turn the clamping lever to 1.

Clearance angle adjustment

•The clearance angle between blade and

specimen must be adjusted in the same way as

the clearance angle between knife and specimen

is adjusted.

Protection against injury

•The knife carrier of the instrument is equipped

with a knife guard which can be moved sideways.

•This knife guard should be used while knife and

specimen are adjusted.

•This reduces the danger of injury considerably!

Figure 19

This manual suits for next models

3

Table of contents

Other epredia Medical Equipment manuals