ERA TOUCHKEY User manual

TOUCHKEY AUTO-FIRE LOCK

INSTALLATION GUIDE

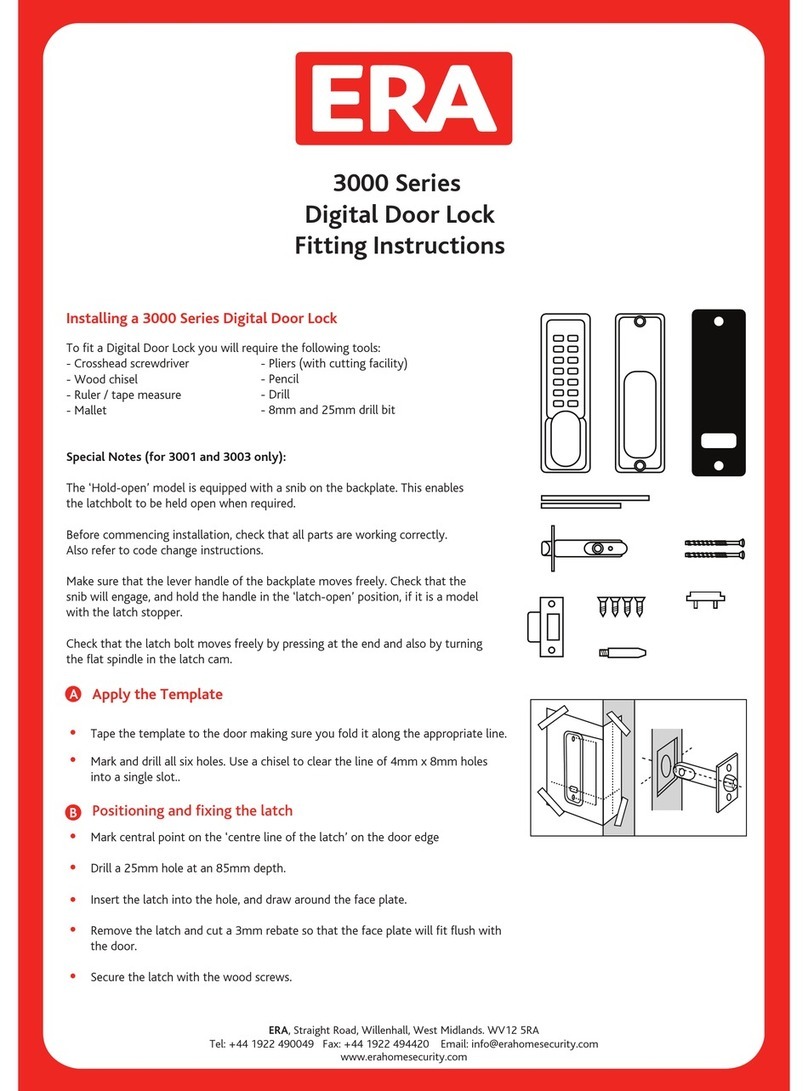

1050.00

HANDLE HEIGHT

22.00

36.00

72.00

92.00

17.00

20.00

20.00

20.00

136.00

45.00

Backset

B

BOTTOM OF DOOR

155.00 214.00

16.00

MIN

1634.10

20.20

77.50

680.00715.00

AA

65.00

47.00

47.00

126.00

SECTION A-A

SPINDLE DATUM

2.50

2.20

THIS HOLE IS ON INTERNAL SIDE ONLY.

DEPTH OF 10mm

2.20

THIS HOLE IS ON

INTERNAL SIDE ONLY.

129.50

40.00

PREPARATION DETAIL

13.00

Not to scale. All dimensions are in mm and are nominal. ERA

reserves the right to change specification without notice. It is the

responsibility of the door manufacturer to ensure that the finished

product meets any required safety and performance specification.

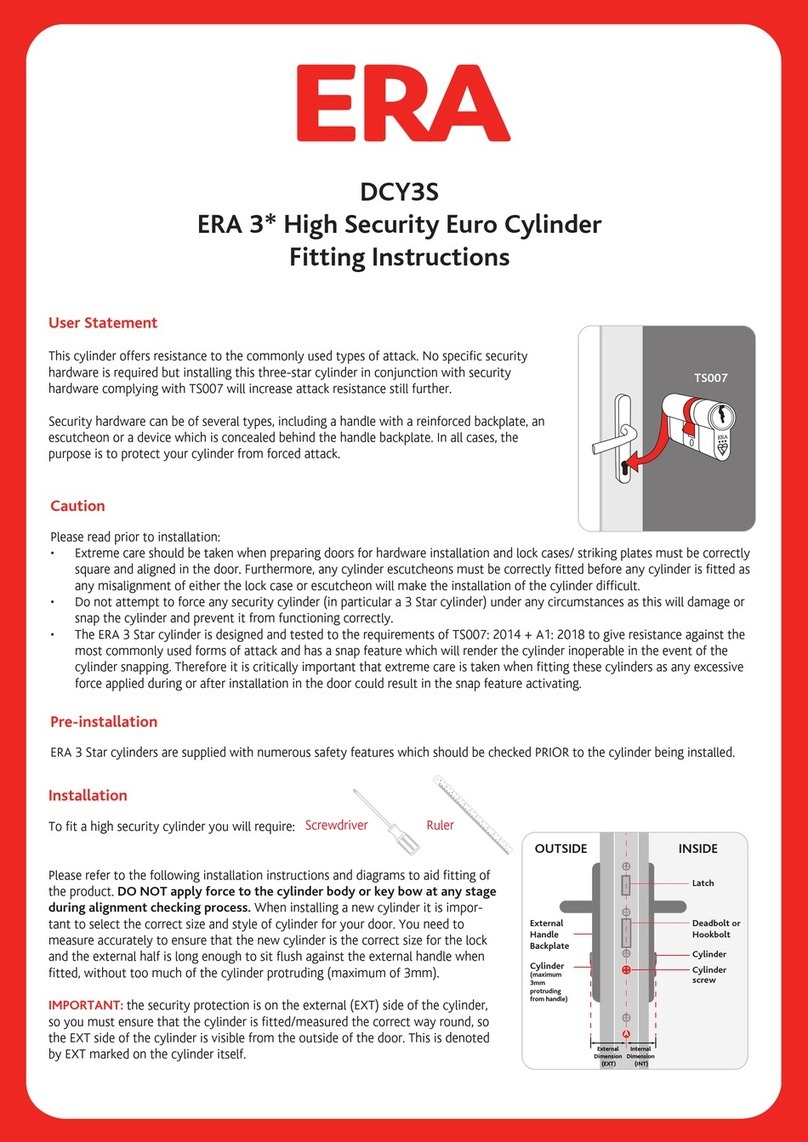

Fit the cylinder and check function of

the lock (as per steps a- cbelow):

Please note: This

is required for the

top, centre and

bottom latches.

If so, please remove the mounting bracket from

the handle box (situated underneath the

external handle in the holding pocket) and using

the two fixing screws (in the handle box) secure

the plate onto the internal face of the door, in

the highlighted holes.

1. Insert the multipoint lock into the

prepared door and fasten with

appropriate screws.

2. Set latches to left or right handed by

pulling the latch outwards and twisting

to the correct position.

3.

a. Turn the thumbturn, check

all hooks and the centre

deadbolt retract.

b. Return the cylinder to the

normal position.

c. Press the trigger on the

centre gearbox to fire the

hooks and centre deadbolt.

Please separate installation instructions for

the TouchKey door handle and cylinder. We

recommend these are fitted on site during

door installation.

4. You may choose to fit the handle

mounting bracket prior to the door

reaching the site.

MPL LOCK PREPARATION

f. Alternatively, to relieve

resistance, the centre keep

can be offset to the hook

keeps.

a. Create routing required for the keep -

use the routing jig provided if

necessary (available on request).

b. Centre line on the routing jig needs

to be lined up with centre of latches.

Centre

Keep

Hook

Keep

1

Repeat for top and bottom keeps.

b.

a. Insert the centre keep into the routed hole

and ensure it sits flush to the face of the

door frame.

It is essential the keep sits flush for stability.

e. In the event of operating

resistance you may need to

adjust the keeps, refer to 2b

d. Look for any sign off

resistance during

operation which may

indicate the fitting is not

correct.

Composite keeps are adjustable +/- 2mm

horizontally and vertically, timber keeps

are adjustable +/- 2mm horizontally.

A

Centre

Line

Position the keep and fasten to the

frame with the appropriate screws for

the substrate being used.

Once keeps are fitted, open and close

the door to check it is working correctly:

c. Rotate thumbturn, key or

handle to ensure all locking

points fully retract to allow

the door to open.

b. Ensure the thumbturn or

key rotates 360° towards

the keep making sure the

deadbolt is fully engaged.

a. Close door and check the

hooks and latches engage

fully within top, centre and

bottom keeps.

Centre

Line

1.

2.

3.

4.

5.

KEEP PREPARATION

Depress trigger to ensure hooks drop fully.

Insert cylinder and lock to make sure the deadbolt throws and retracts.

Make sure the hooks and latches retract fully with cylinder.

Pre-installation checks:

Check the functions of the lock as above.

Make sure that the keeps are in the nominal position with full

adjustment if required.

Close door and activate the lock. The hooks should fall into the keeps.

Make sure the deadbolt works with the cylinder.

Undo the deadbolt and retract the hooks and latches to open the door.

Post installation checks:

1.

2.

3.

1.

2.

3.

4.

5.

AUTO FIRE MPL

With the door in the closed position and

standing on the opening side. Check that there

is a 3-4mm gap between the edge of the leaf

and the edge of the frame. The air gap must be

consistent from the top to the bottom of the

lock jamb.

Please note: If the gap is greater than 4.00mm

the trigger will not meet the ramp on the keep

and prevent the door from closing correctly.

To check the alignment of the keeps. Open the

door slightly and visually check the centre of

the latches line up with the centre of the rollers

on the keeps, the keeps have a +/- 2.00mm

horizontal and vertical adjustment if they

require repositioning.

Check that there

Is a 4mm gap

Between the edge

of the leaf and the

edge of the frame

Open the door, depress the steel trigger

between the latch and deadbolt in the centre

gearbox, both top and bottom hooks and

centre deadbolt will be thrown into the locked

position. To retract the deadbolt and hooks

rotate the thumbturn cylinder away from the

lock jamb.

If the lock operates with the door open but has

a stiff key operation with the door closed this

may indicate that the centre and hook keeps

require adjusting (see item 2).

If the lock has a stiff key operation with the

door open this, this may indicate a problem

with the lock or cylinder. If this is the case,

please refer to the trouble shooting guide.

Latches should

line up with centre

line on the keeps

2 Hooks should

fall into the locked

position

Centre

Line

1. 2.

3.

Check gap between door leaf and frame Check lock and keep alignment

Check lock operation

LEAF AND LOCK SET UP

Depress trigger to

activate lock

Roller plate

adjustment

screws

Check hook operation

As stated, the latches are the compression

points and when the trigger is depressed and

the hooks drop, the hooks should not come into

contact with the keeps. Please ensure that the

door is fully closed, to check that the hooks are

correctly fully engaged. However, it is important

that the door is pushed or pulled fully closed to

check the hooks are fully engaging.

Remove the tape temporarily holding the

hooks. Close the door until it latches and fires

the hooks and centre deadbolt. Unlock the door

by rotating the thumbturn cylinder away from

the lock jamb.

Setting the latch operation

In order to ensure that the door latches

correctly, it is important to temporarily disable

the hooks. To do this, please use a piece of tape

placed over the hooks aperture on the face bar,

to hold them into the retracted position. It is

also important that compression of the gaskets

is achieved on the latches only. The hooks and

deadbolt are security measures and should

operate “in fresh air”.

With the hooks disabled, please close the door

until it latches. Check that the leaf is flush with

the frame on the opening side of the door. If you

need to adjust the keep for compression, then

open the door and adjust the roller plates on the

centre keep first by undoing the adjustment

screws and moving the plates until you achieve

a smooth latching operation. Repeat the

process on the top and bottom hook keeps until

the desired compression is achieved.

Please note: Contact of the hooks with the

keeps will result in increased operating forces

and therefore, a stiff key operation.

1.

2.

OPERATION

ERA, Valiant Way

Wolverhampton

West Midlands

WV9 5GB

Contact Us

T : +44 (0) 1922 490049

E : info@erahomesecurity.com

W: www.eraeverywhere.com

Hooks not firing when

door is shut

Air gap between frame and

sash too wide (lock trigger

not hitting the keep ramp)

Adjust the hinges or frame fixings to

give a 4mm air gap between the sash

and frame

Incorrectly adjusted keeps The latches are the compression points.

Adjust the keeps as necessary

Incorrect positioned keeps Check keep alignment as

detailed in the installation guide

Cylinder incorrectly installed

Remove the handle and check if the

lock functions with the cylinder in

place. If the lock functions without the

handle, then the handle may be

twisting the cylinder. Refit the handle

taking care not to twist the cylinder.

Lock drive bars cannot

operate in router groove

Remove lock from door and check

independently. Locate the cause of

resistance and rectify by removing material

Stiff key operation Door not latched correctly Relieve pressure on latches by gently

pushing or pulling the door closed

Too much compression

on hinges

Adjust hinges to release

compression from frame

Air gap between sash and

frame too wide

Adjust the hinges or frame fixings

to give an optimum 4mm air gap

between the sash and frame

Cylinder malfunctioning

Remove cylinder from lock and check

operation. Discard and replace cylinder

if it malfunctions. Check lock operation

using an alternative cylinder. If lock still

doesn’t operate remove lock from door

and check lock independently.

SYMPTOM POSSIBLE CAUSE SUGGESTED REMEDY

TROUBLESHOOTING GUIDE

V1

Other manuals for TOUCHKEY

3

Table of contents

Other ERA Door Lock manuals

Popular Door Lock manuals by other brands

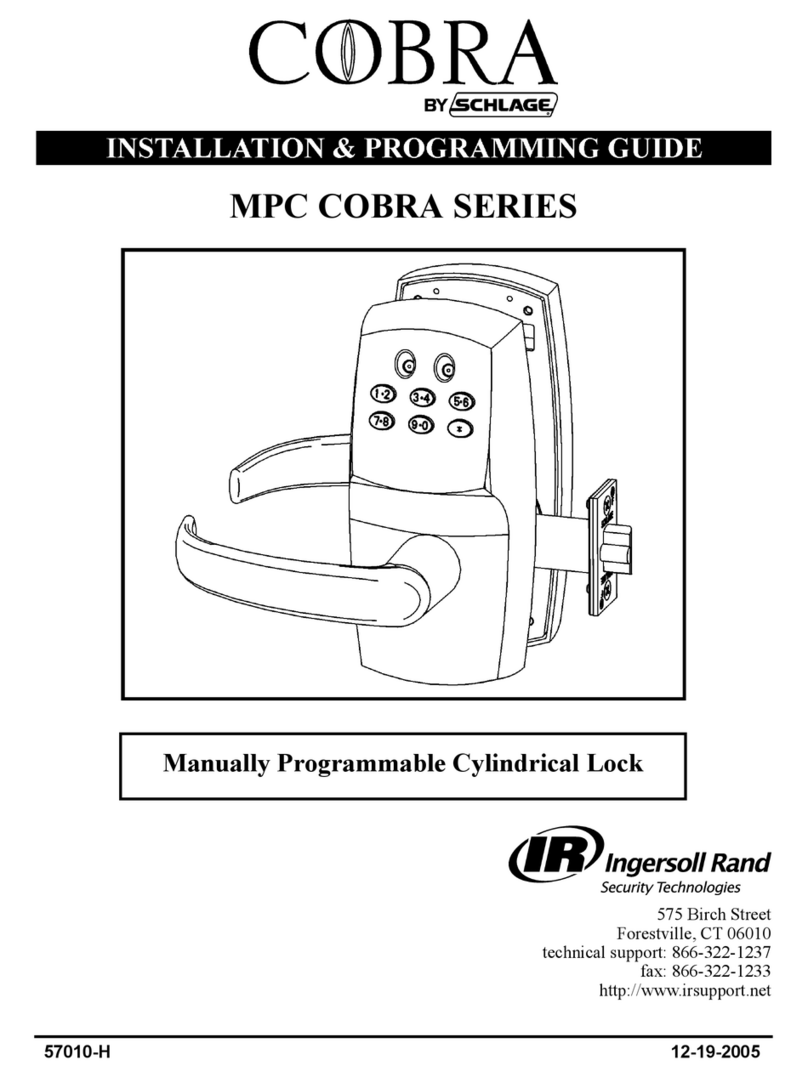

Schlage

Schlage L9000 Series installation instructions

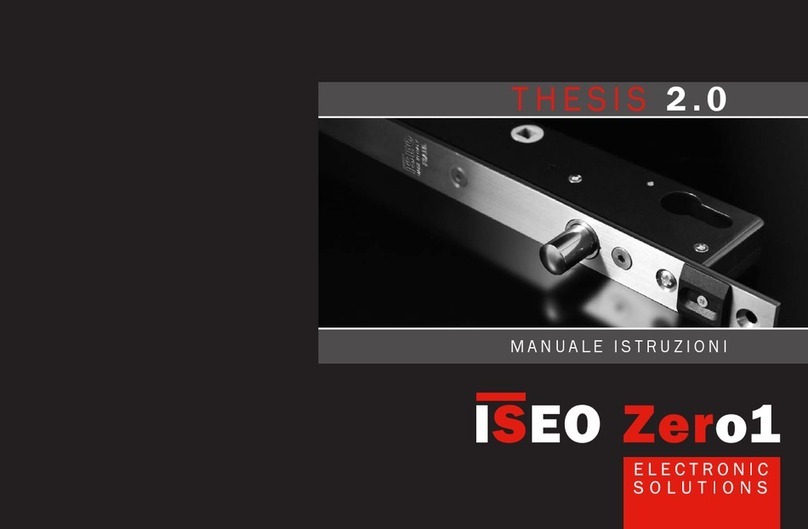

Iseo

Iseo Zero1 Thesis 2.0 Standard instruction manual

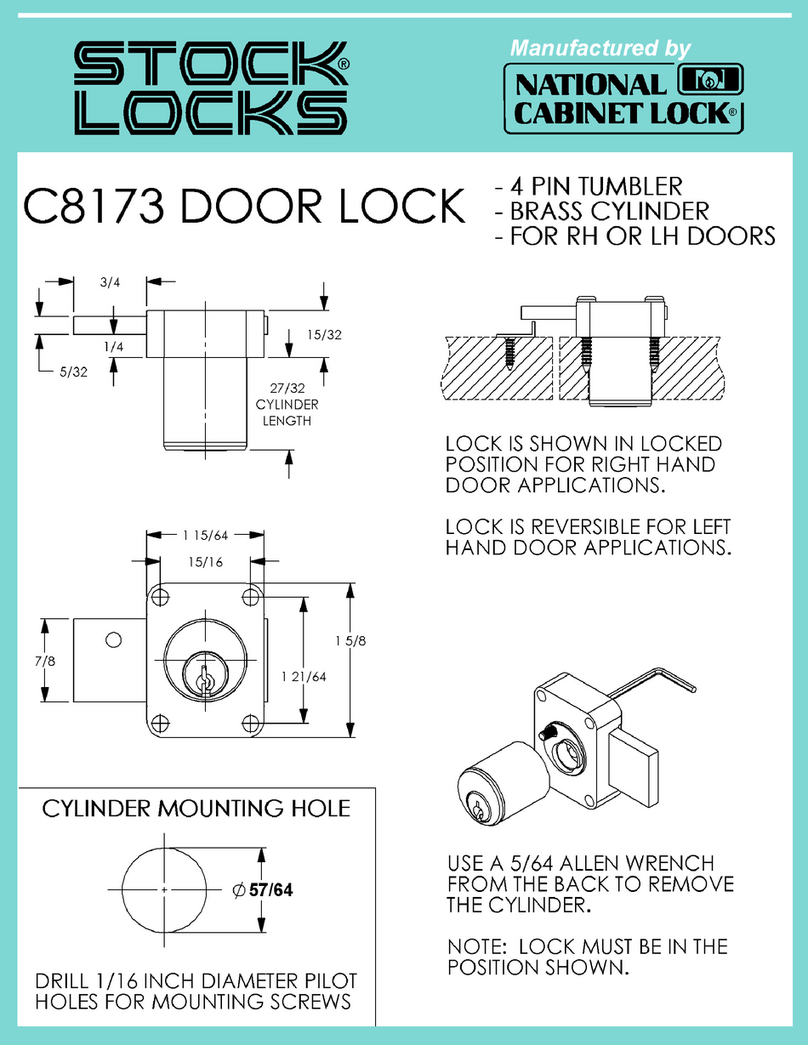

National Cabinet Lock

National Cabinet Lock C8173 Dimensional drawing

PBB

PBB CH531 installation instructions

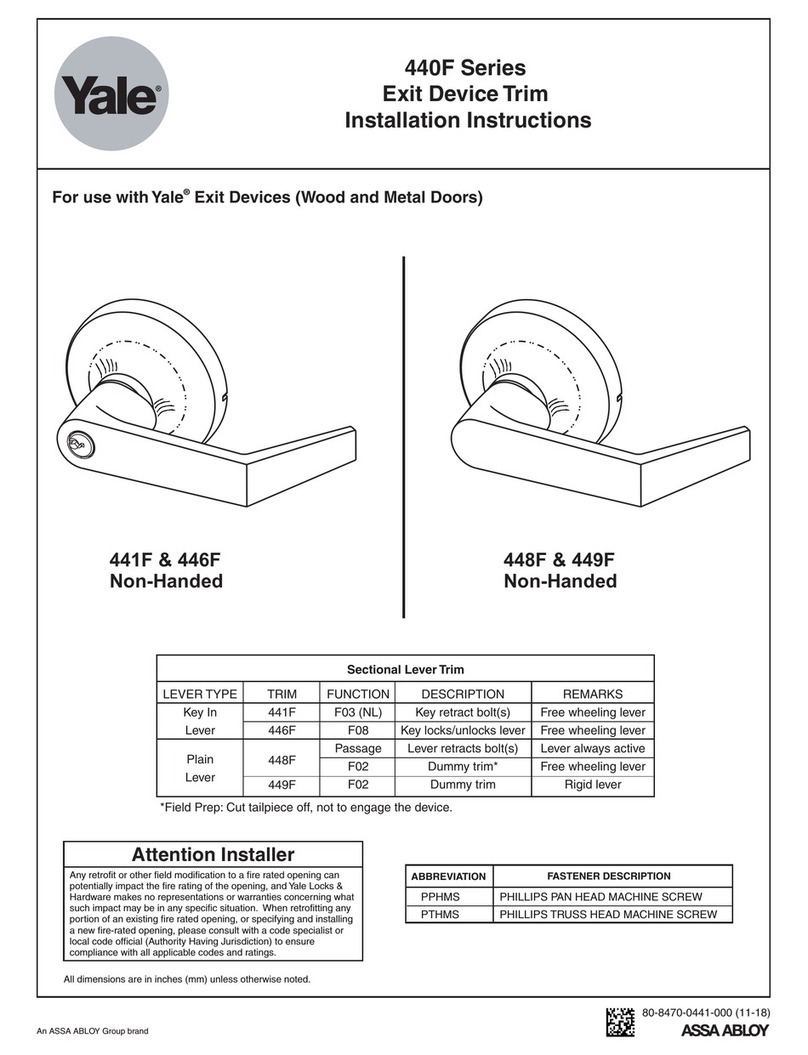

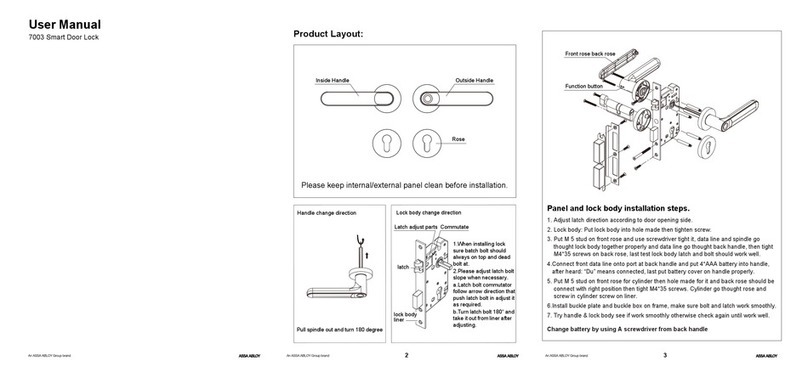

Assa Abloy

Assa Abloy 7003 user manual

Schlage

Schlage Touch FE695 Lever installation instructions