ESAB MIG400iCCCV User manual

Other ESAB Welding System manuals

ESAB

ESAB EM235ic User manual

ESAB

ESAB PowerCut 1600 User manual

ESAB

ESAB Caddy Professional 250 User manual

ESAB

ESAB MXH 300PP User manual

ESAB

ESAB A6 DK User manual

ESAB

ESAB 653 cvcc User manual

ESAB

ESAB PKB 250 User manual

ESAB

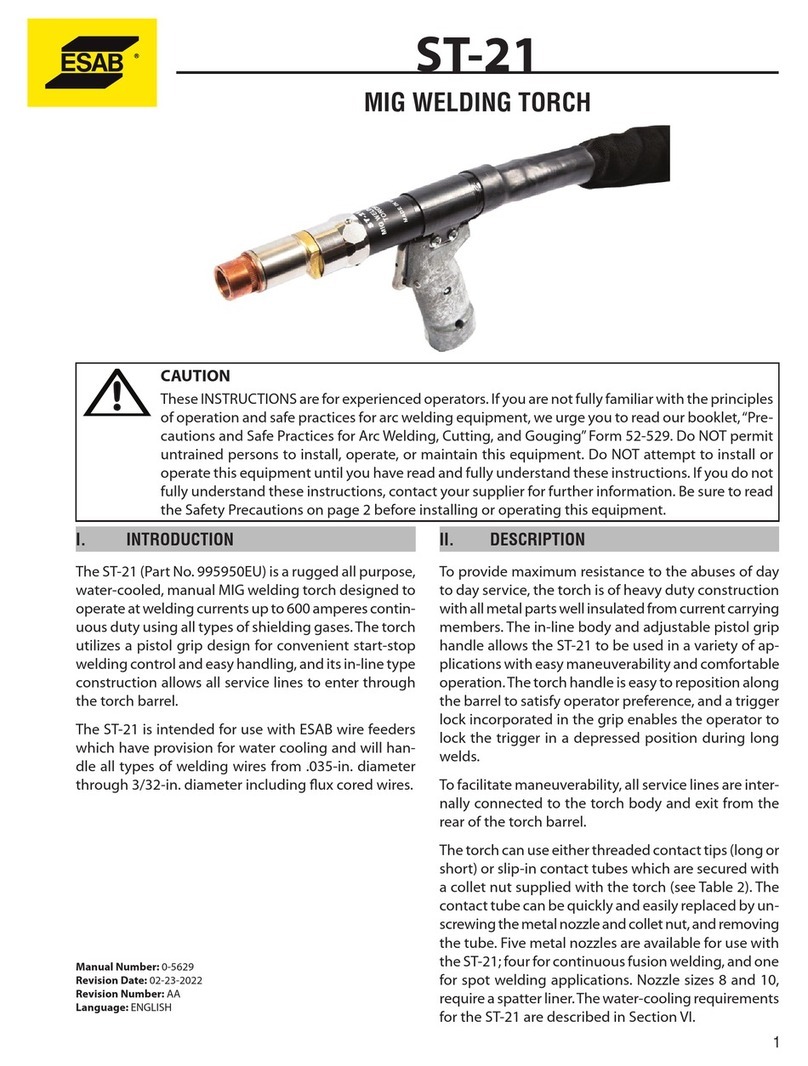

ESAB ST-21 User manual

ESAB

ESAB PLASMAWELD 202 User manual

ESAB

ESAB ES 180i Pro User manual

ESAB

ESAB OrigoFeed 30-4 User manual

ESAB

ESAB Caddy Tig 2200iw User manual

ESAB

ESAB Aristo Origo Feed 3004 User manual

ESAB

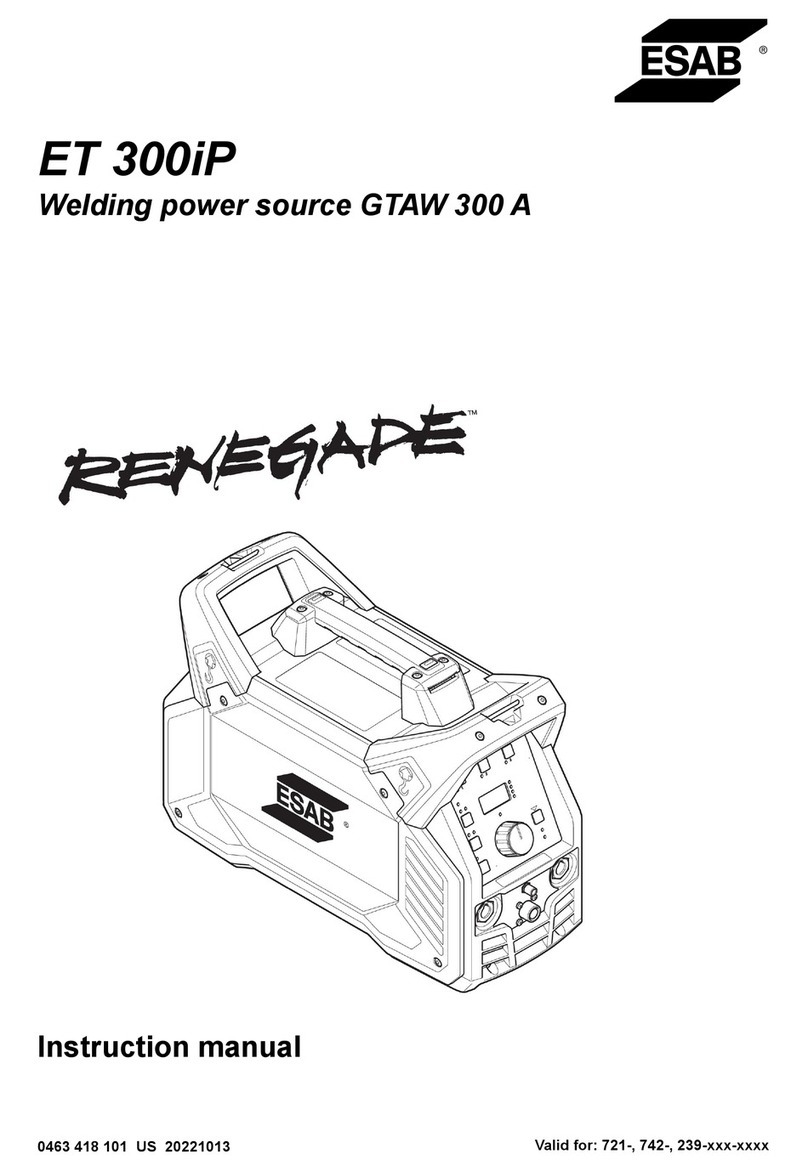

ESAB Renegade ET 300iP User manual

ESAB

ESAB Mig 4004 iMV Guide

ESAB

ESAB PUA 1 User manual

ESAB

ESAB ES 300i User manual

ESAB

ESAB Origo Arc 256 Guide

ESAB

ESAB Origo Mig 4001i User manual

ESAB

ESAB A6S Compact 300 User manual

Popular Welding System manuals by other brands

TAFA

TAFA 30*8B35 owner's manual

Lincoln Electric

Lincoln Electric INVERTEC V350-PRO CE Technical specifications

CIGWELD

CIGWELD 636804 use instructions

Red-D-Arc

Red-D-Arc DC-400 Operator's manual

Hobart Welding Products

Hobart Welding Products Spool Gun DP 3035-10 owner's manual

Elettro

Elettro HI-MIG 3000 SYNERGIC instruction manual