TABLE OF CONTENTS

0463 930 001 -4- © ESAB AB 2023

1 SAFETY ...................................................................................................................................... 6

1.1 Meaning of symbols .................................................................................................... 6

1.2 Safety precautions ...................................................................................................... 6

2 INTRODUCTION ......................................................................................................................... 9

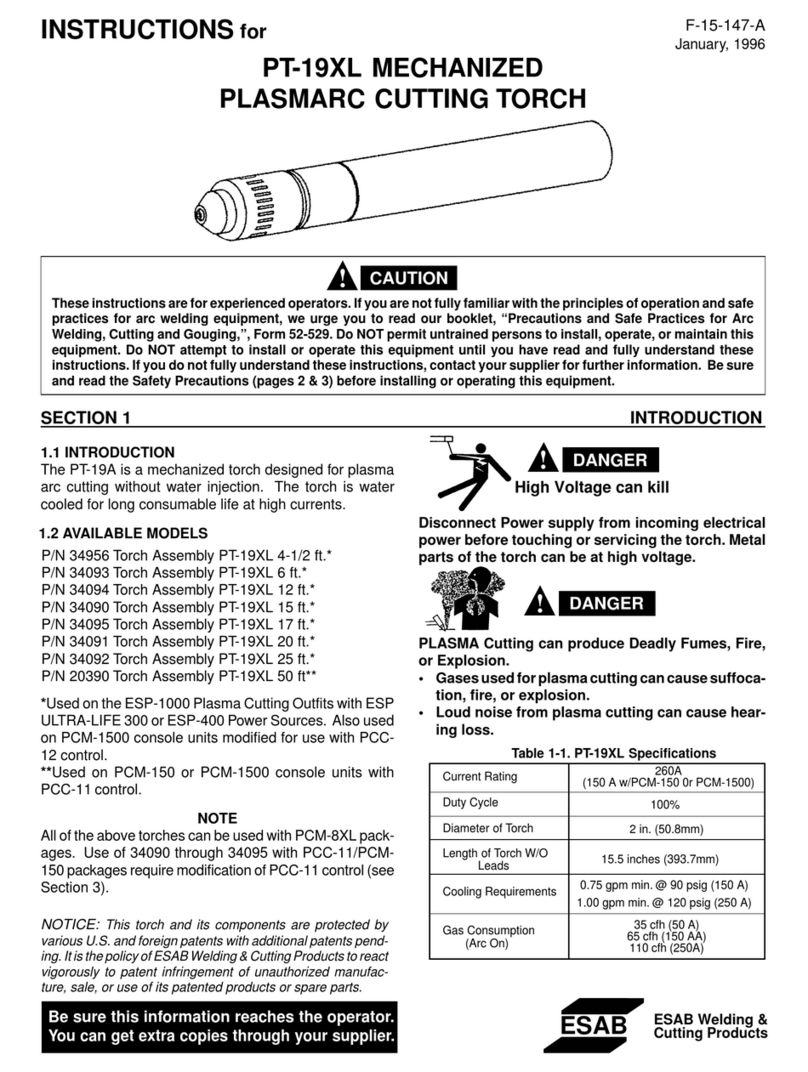

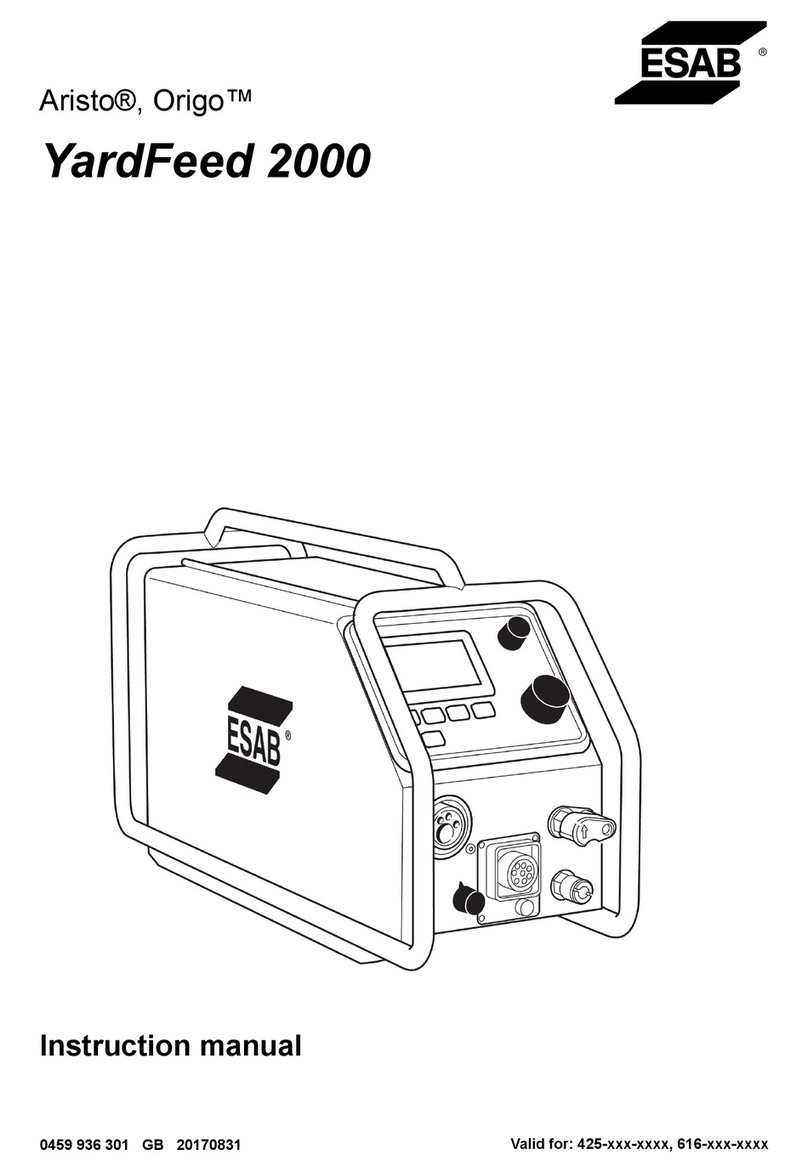

2.1 Equipment.................................................................................................................... 9

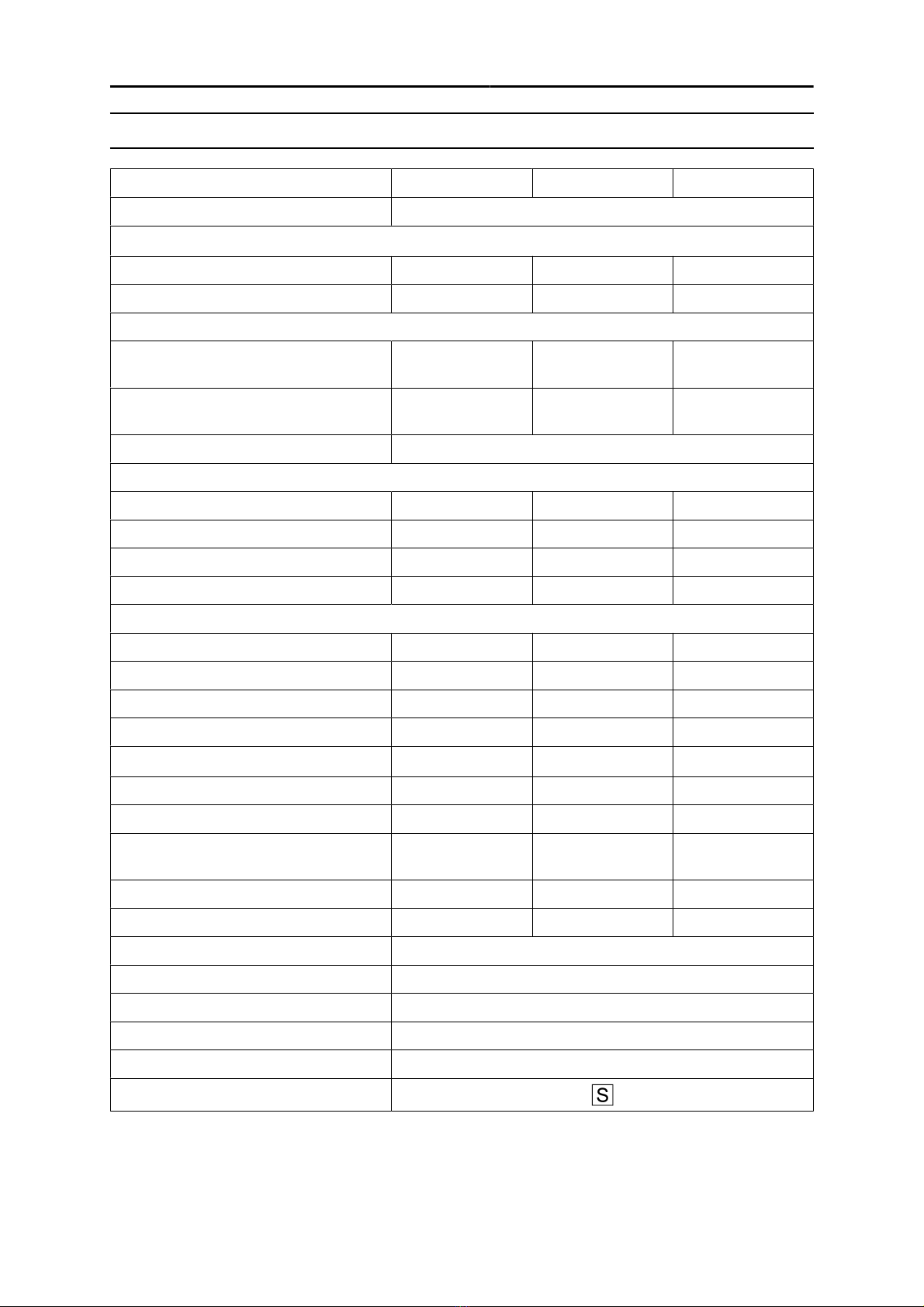

3 TECHNICAL DATA ..................................................................................................................... 10

3.1 ECO design information ............................................................................................. 11

4 INSTALLATION........................................................................................................................... 12

4.1 Location........................................................................................................................ 12

4.2 Move instructions (No lifting)..................................................................................... 12

4.3 Mains supply................................................................................................................ 13

5 OPERATION ............................................................................................................................... 14

5.1 Connections and control devices .............................................................................. 14

5.2 Recommended maximum current values for connection cables set ..................... 15

5.3 Connecting welding and return cables ..................................................................... 15

5.4 Polarity change............................................................................................................ 15

5.5 Turning the mains power on/off ................................................................................. 16

5.6 Bobbin brake................................................................................................................ 16

5.7 Changing and loading wire......................................................................................... 16

5.8 Changing feed rollers.................................................................................................. 17

5.9 Changing the wire guides........................................................................................... 17

5.9.1 Inlet wire guides ................................................................................................. 18

5.9.2 Middle wire guide ............................................................................................... 18

5.9.3 Outlet wire guide ................................................................................................ 18

5.10 Roller pressure ............................................................................................................ 19

6 CONTROL PANEL...................................................................................................................... 20

6.1 External control panel................................................................................................. 20

6.2 LED indicators description......................................................................................... 21

6.3 Internal control panel .................................................................................................. 25

6.4 Menu selection ............................................................................................................ 26

6.4.1 MIG/MAG and MIG/MAG SYN ........................................................................... 26

6.4.2 Hidden functions for MIG/MAG and MIG/MAG SYN .......................................... 26

6.4.3 MIG SPOT.......................................................................................................... 27

6.4.4 Hidden functions for MIG SPOT......................................................................... 28

6.4.5 MMA ................................................................................................................... 28

6.4.6 Hidden functions for MMA .................................................................................. 29

7 MAINTENANCE.......................................................................................................................... 30

7.1 Routine maintenance .................................................................................................. 30

7.2 Power source............................................................................................................... 31

7.3 Inspection, cleaning and replacement ...................................................................... 31

8 ERROR CODES.......................................................................................................................... 32

8.1 Error code descriptions .............................................................................................. 32

9 TROUBLESHOOTING ................................................................................................................ 34

10 CALIBRATION AND VALIDATION............................................................................................. 35

10.1 Measurement methods and tolerances ..................................................................... 35

10.2 Requirements specifications and standards ............................................................ 35

11 ORDERING SPARE PARTS ....................................................................................................... 36