5.5.12.1 Device Information............................................................................................ 50

5.5.12.2 RPDO Mapping ................................................................................................51

5.5.12.3 TPDO Mapping.................................................................................................54

5.5.12.4 Manager Settings..............................................................................................57

5.5.12.5 SYNC / Emergency........................................................................................... 59

5.5.12.6 Heartbeat / Guarding........................................................................................61

5.5.12.7 Object Lists.......................................................................................................63

5.5.12.8 EDS Device Info ............................................................................................... 64

5.5.12.9 EDS File Info ....................................................................................................64

5.5.12.10 EDS Comments................................................................................................ 64

5.5.13 Output......................................................................................................................65

5.6 Module In- and Output....................................................................................................66

5.6.1 Overview..................................................................................................................67

5.6.2 CANopen Manager..................................................................................................67

5.6.3 CANopen Devices ...................................................................................................68

5.7 Diagnostics.....................................................................................................................70

5.7.1 Alarms.....................................................................................................................70

5.7.2 Provider and Consumer Status................................................................................75

5.8 Records..........................................................................................................................76

5.8.1 SDO Upload (0xB711).............................................................................................78

5.8.2 SDO Download (0xB713).........................................................................................81

5.8.3 Configure SDO Timeout (0xB715)...........................................................................82

5.8.4 Start CANopen Device (0xB731) .............................................................................82

5.8.5 Stop CANopen Device (0xB732)..............................................................................82

5.8.6 Set CANopen Device to PRE-OPERATIONAL (0xB733).........................................83

5.8.7 Reset CANopen Device (0xB734)............................................................................83

5.8.8 Reset Communication (0xB735)..............................................................................83

5.8.9 Initialize Gateway (0xB751) .....................................................................................83

5.8.10 Set Heartbeat Producer (0xB754)............................................................................84

5.8.11 Set Node ID (0xB755).............................................................................................. 85

5.8.12 Start Emergency Consumer (0xB756) .....................................................................85

5.8.13 Stop Emergency Consumer (0xB757)......................................................................85

5.8.14 Read Version (0xB762)............................................................................................86

5.8.15 Reset CANopen Manager (0xB771).........................................................................86

5.8.16 Start CANopen Manager (0xB772) ..........................................................................86

5.8.17 Stop CANopen Manager (0xB773)...........................................................................87

5.8.18 Reset CANopen Device EMCY (0x003A).................................................................87

5.8.19 PLC Function Blocks ...............................................................................................88

5.8.19.1 Read Records...................................................................................................88

5.8.19.2 Write Records...................................................................................................89

5.9 CANopen-PN/2 Object Directory.....................................................................................90

5.9.1 Objects of CiA Specification CiA 301.......................................................................90

5.9.2 Objects of CiA Specification CiA 302-2....................................................................91

6Firmware Update...................................................................................................................92

7CAN Monitoring ..................................................................................................................... 93

8Compatibility..........................................................................................................................95

8.1 CANopen-PN Compatibility Mode...................................................................................95

9Troubleshooting.....................................................................................................................96

9.1 Faulty PROFINET Connection........................................................................................96

9.2 Faulty CAN Bus.............................................................................................................. 96

9.3 Faulty CANopen Device.................................................................................................. 97

9.4 Invalid CAN Busload.......................................................................................................98

9.5 Support by esd................................................................................................................98

10 Technical Data....................................................................................................................... 99

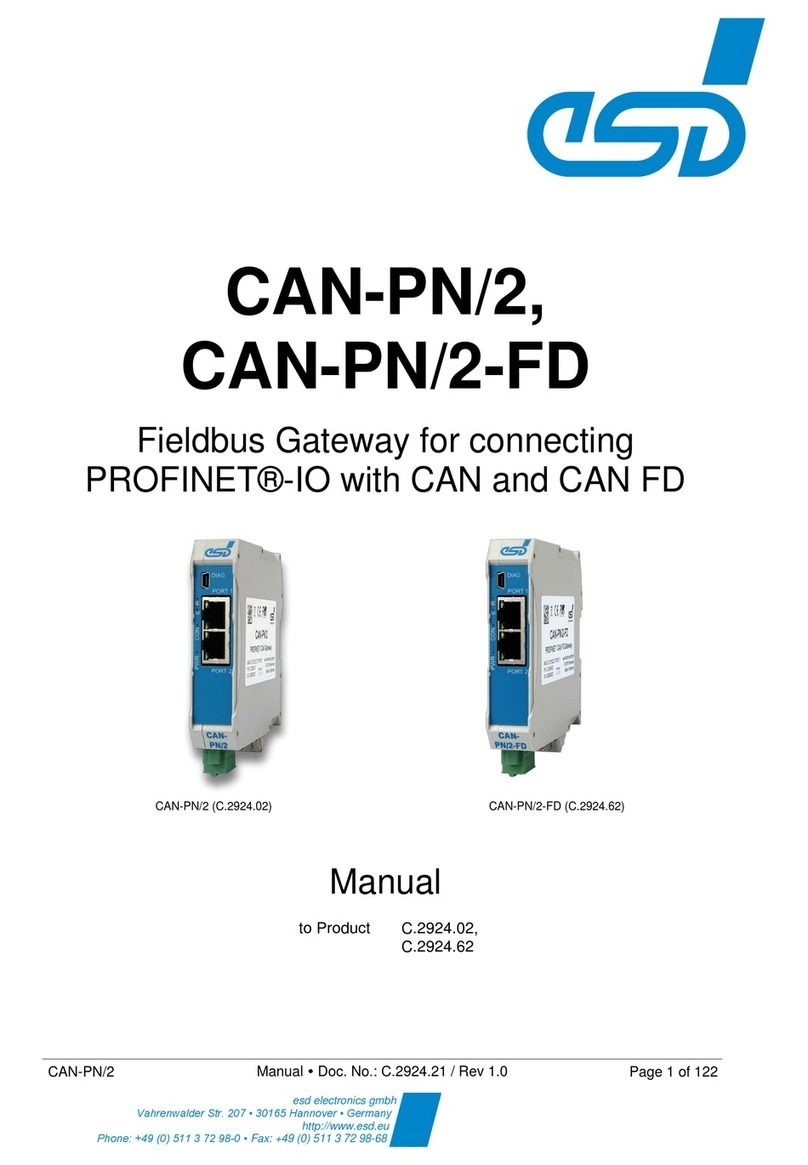

10.1 General Technical Data.................................................................................................. 99

10.2 CPU and Memory...........................................................................................................99

10.3 Connectors accessible from Outside.............................................................................100

10.4 PROFINET IO Interface................................................................................................ 100