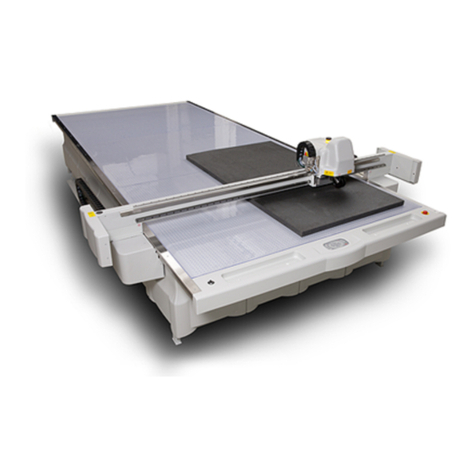

Kongsberg C-series

Contents

1. Preface........................................................................................................................................................... 4

2. Change record............................................................................................................................................... 6

3. Introduction....................................................................................................................................................7

3.1. Welcome................................................................................................................................................7

3.2. System Label........................................................................................................................................ 7

3.3. EC Declaration of Conformity............................................................................................................... 8

3.4. RoHS Compliance Declaration.............................................................................................................. 9

4. General Information..................................................................................................................................... 10

4.1. Where to find information................................................................................................................... 10

4.2. Site preparation...................................................................................................................................11

4.3. User manuals....................................................................................................................................... 11

4.3.1. User manual for cutting table.....................................................................................................11

4.3.2. User manual for iPC...................................................................................................................11

4.3.3. Get the best out of iPC............................................................................................................. 12

4.4. Installation.......................................................................................................................................... 12

4.4.1. What is received........................................................................................................................12

4.4.2. Unpack Equipment................................................................................................................... 12

4.5. Table Operation...................................................................................................................................12

4.5.1. Power On Sequence...................................................................................................................12

4.5.2. Reset Safety System................................................................................................................. 13

4.5.3. Power Off Sequence................................................................................................................. 14

4.5.4. Continue after Safety Break......................................................................................................14

4.6. Software updates................................................................................................................................ 15

4.7. Maintenance........................................................................................................................................ 15

5. Safety Regulations....................................................................................................................................... 17

5.1. Introduction..........................................................................................................................................17

5.2. Responsibilities................................................................................................................................... 17

5.2.1. The manufacturer...................................................................................................................... 17

5.2.2. The owner................................................................................................................................. 17

5.2.3. The operators............................................................................................................................18

5.3. Requirements to be met by operators.................................................................................................18

5.4. Definition of use..................................................................................................................................19

5.5. Warning sign explanation.................................................................................................................... 19

5.6. Attention areas...................................................................................................................................22

5.6.1. Mains power disconnection.......................................................................................................22

5.6.2. High voltage, laser radiation and moving parts.........................................................................22

5.6.3. Loose clothing..........................................................................................................................23

ii