Technical Manual Kongsberg XE/i-XE

3

2.9.17 Tool selection...................................................................................................................... 27

2.9.18 Tool identifier...................................................................................................................... 27

2.9.19 Laser pointer....................................................................................................................... 27

2.9.20 Camera.................................................................................................................................. 27

2.10 FUSES.............................................................................................................................................. 28

2.10.1 MPU fuses............................................................................................................................. 28

2.10.2 Motor fuses.......................................................................................................................... 29

2.10.3 Vacuum motor overload protection ........................................................................... 30

2.11 XE SAFETY SOLUTION................................................................................................................... 31

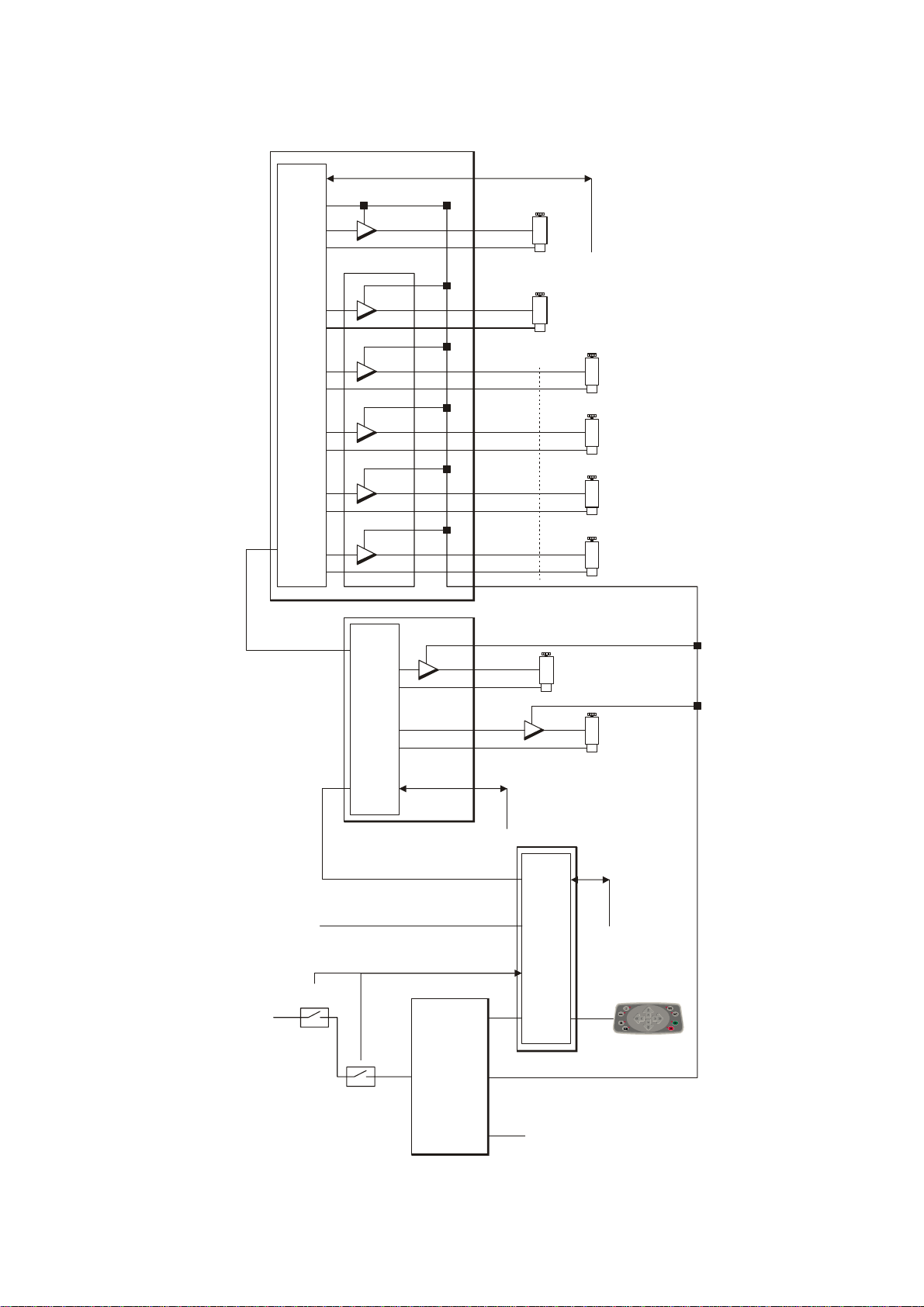

2.11.1 Safety system blocked schematic .............................................................................. 31

2.11.2 DynaGuard with LE20 controller, detailed description....................................... 31

2.12 TROUBLESHOOTING THE GC900SM CONTROLLER ................................................................... 32

2.13 XE SYSTEM PARAMETERS.............................................................................................................. 33

2.13.1 System id definitions....................................................................................................... 33

2.13.2 Tool id definitions.............................................................................................................. 33

2.13.3 Tool series id definitions................................................................................................. 34

2.14 MOTOR /ENCODER SPECIFICATIONS.......................................................................................... 35

3. SIGNAL LISTS ................................................................................................................................. 36

3.1 SIGNALS TO/FROM CU-MODULES................................................................................................ 36

4. CABLES................................................................................................................................................ 36

4.1 XE10/I-XE10 WITH LE20 SAFETY RELAY................................................................................. 36

5. XE WITH XL-REGISTER.............................................................................................................. 37

6. XE WITH I-CUT (I-XE)............................................................................................................... 37

7. HOW TO... PROCEDURES .......................................................................................................... 38

7.1 INSTALLATION ................................................................................................................................38

7.2 MAINTENANCE................................................................................................................................38

7.3 TRAVERSE BEAM /X-CARRIAGE FIXTURE ON XXE32/54......................................................... 38

7.4 MOTOR ASSEMBLY ON XE10/I-XE10......................................................................................... 39

7.5 HOW TO REMOVE X1/X2 COVERS,XXE10................................................................................ 40

7.6 HOW TO REMOVE X1/X2 GEARBOX,XXE10.............................................................................. 42

7.7 HOW TO REMOVE X1/X2 COVERS,I-XE32/54........................................................................ 43

7.8 HOW TO REMOVE THE Y-CARRIAGE COVER................................................................................. 44

7.9 HOW TO REMOVE THE Z-AXIS MOTOR AND SCREW................................................................... 45

7.10 GEAR ADJUSTMENT,BASIC PRINCIPLES ...................................................................................... 47

7.11 MOTOR PINION ADJUSTMENT........................................................................................................ 48

7.11.1 General.................................................................................................................................. 48

7.11.2 Y-axis motor pinion.......................................................................................................... 49

7.11.3 X-axis motor pinion, XE10 and i-XE10..................................................................... 49

7.12 RACK PINION ADJUSTMENT........................................................................................................... 50

7.12.1 Adjusting X-axis rack pinion on xXE10 .................................................................... 50

7.12.2 Adjusting X-axis rack pinion on xXE32/54.............................................................. 52

7.12.3 Adjusting Y-axis rack pinion on xXE10/32/54....................................................... 53

8. ELECTRICAL DRAWINGS, INDEX......................................................................................... 54

9. MECHANICAL DRAWINGS, INDEX....................................................................................... 55

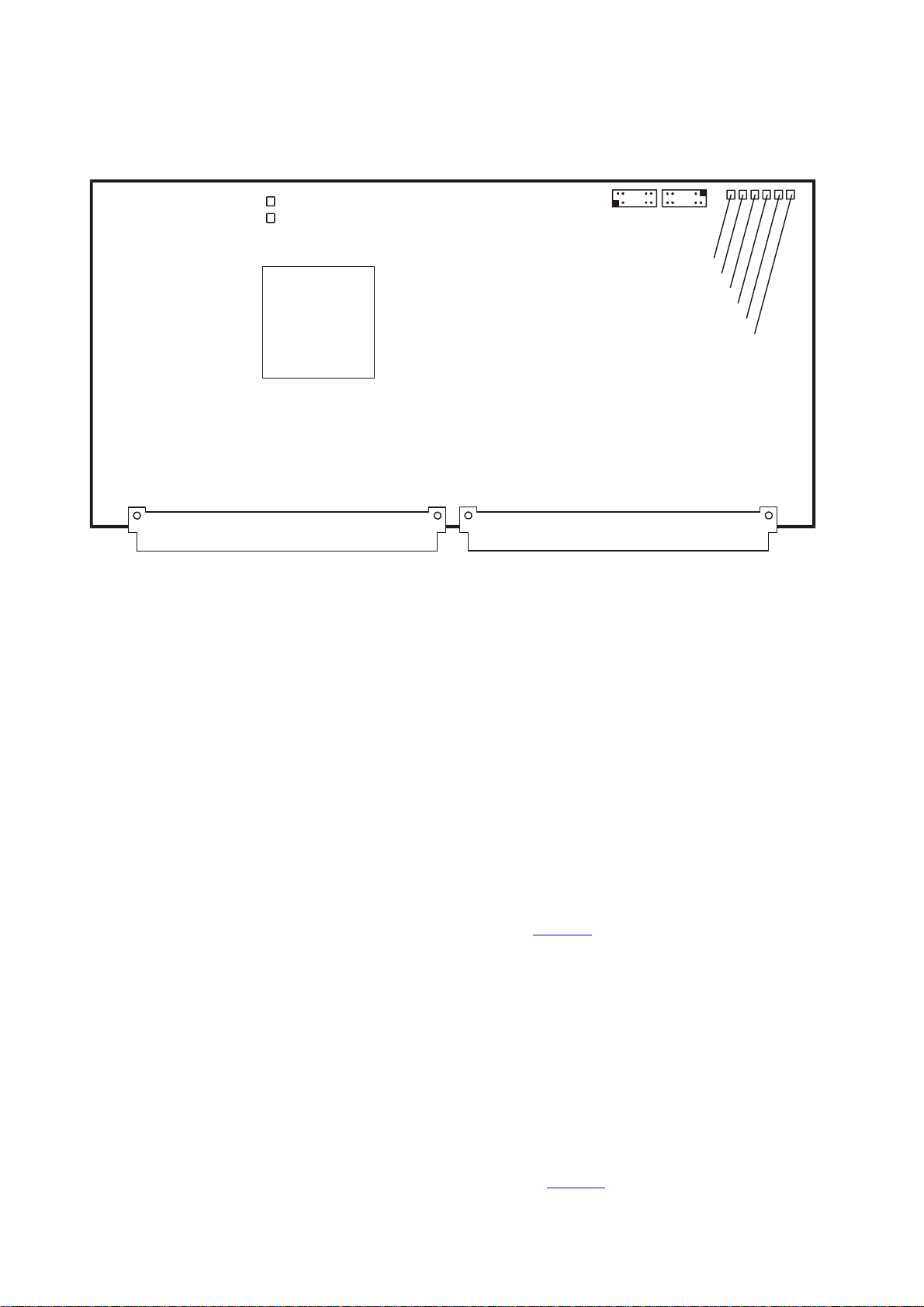

10. APPENDIX – VACUUM ZONES............................................................................................ 57

11. APPENDIX – HOUR COUNTER AND MAINTENANCE TRACKING..................... 58