10

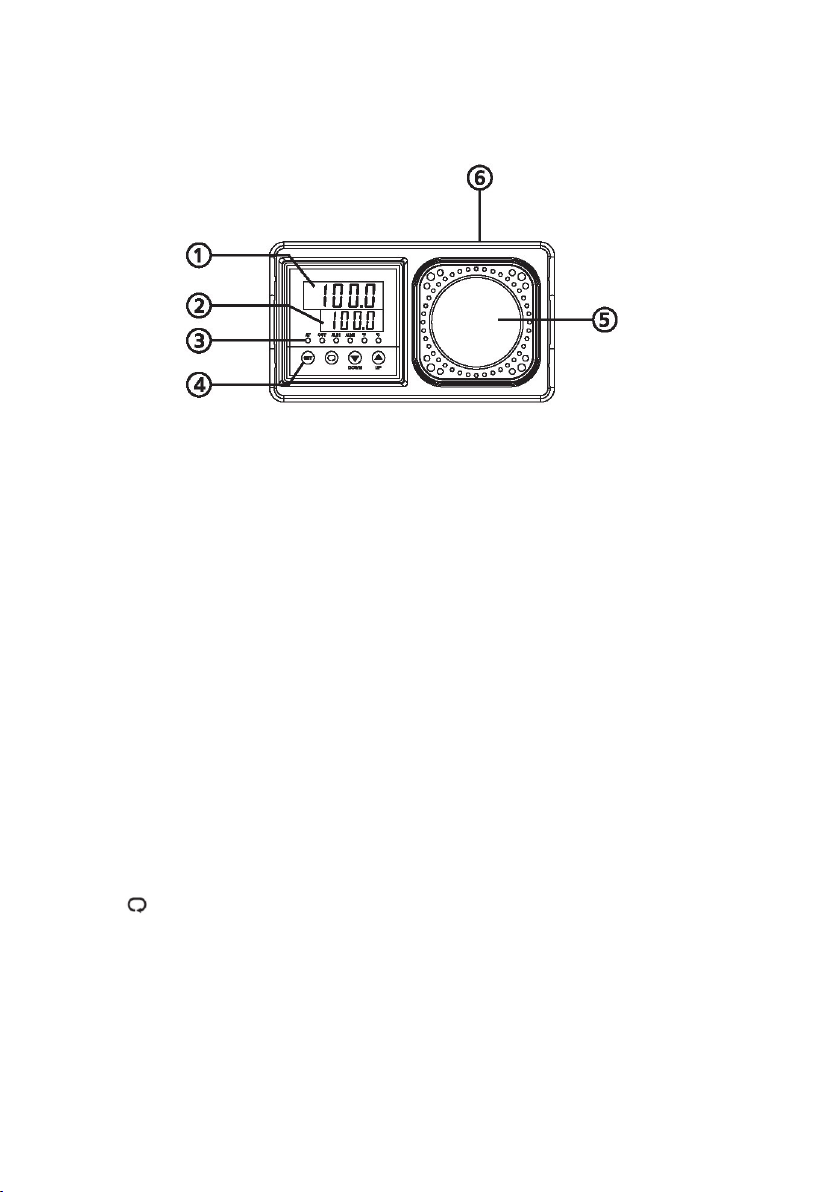

This section shows you in detail how to operate the instrument temperature

controller using the front control panel. Using the front panel key-switches

and LED display the user may monitor the well temperature, the heater output

power and adjust the controller proportional band. The control buttons (SET,

DOWN, UP) are used to set the calibrator temperature set-point.

The digital LED display on the front panel allows direct viewing of the actual

well temperature. This temperature value is normally shown on the display.

The temperature is displayed in units, °C or °F, to the right.

The temperature set-point can be set to any value within the range and with the

resolution as given in the specications. Be careful not to exceed the safe upper

temperature limit of any probe inserted into the well.

• Press "UP" to increase temperature, or press "DOWN" to lower the temperature.

The temperature will be changed in 0.1° increments every time the button

is pressed.

Pressing and holding down the button the temperature will change in

1° increments.

The green LED display on the front panel will indicate the actual set

temperature.

When the set temperature changes, the values will ash.

• Release the "UP" or "DOWN" button and then press the "SET" button.

The calibrator will automatically control the target assembly temperature to

reach the set temperature in the stated time. The red LED display will indicate

the temperature of the target assembly.

The calibrator has been designed with the utmost care. Ease of operation

and simplicity of maintenance have been a central theme in the product

development. Therefore, with proper care the instrument should require

very little maintenance. Avoid operating the instrument in dirty or dusty

environments.

If the outside of the instrument becomes dirty, it can be wiped clean with a

damp cloth and mild detergent. Do not use harsh chemicals on the surface, as

they may damage the paint.

The calibrator should be handled with care. Avoid knocking or dropping the unit.

If the instrument is used in a manner not in accordance with the equipment

design, the operation of the instrument may be impaired and/or safety hazards

may arise.