10

1.1 General Description, Purpose and Fea-

tures. The PowerMTS, is a CV/CC power

source capable of 5 different welding pro-

cesses at a 60% duty cycle at the full rated

power while connected to 460V 3 phase. Op-

eration in 220V 1 phase is limited to 250

amps, but is rated at 100% duty cycle at the

full 250 amps. Each process can be inde-

pendently selected. The following processes

are included on the PowerMTS series.

1) GMAW (MIG) with a standard, independent

feeder with a 4 roll heavy duty drive sys-

tem included. Includes advanced crater fill

amps and volt control in 4T, and induct-

ance control for higher quality welds.

2) FCAW (Flux Core) with a special setting on

the machine that includes improved opera-

tion and arc stability with flux cored weld-

ing wires.

3) GTAW (TIG) offers simple DC scratch start

operation includes a standard gas valve

torch. (17V compatible). Note: Unit is DC

scratch start only. No HF or LIFT start.

4) SMAW (Stick) offers excellent hot start

performance on difficult cellulose rods

such as ER 6010 and ER 6011 to prevent

sticking. Arc force control increase per-

formance, and improves out of position

welding characteristics. Smooth spatter

free welds are easily obtained on ER 7018,

309L, and many specialty rods.

5) ACAC (Carbon Arc) Allows the customer

up to 400 amps of cutting and gouging

power with a dedicated setting that pro-

vides improved performance over regular

SMAW settings. Arc force control should

be turned up to maximum to increase

gouging performance.

1.2 Basic Design and Construction. The

PowerMTS series utilizes soft switching IGBT

inverter technology. The unit can operate on

either 220/240V 1 phase power or on 460/480

V 3 phase power, allowing the welder to be

used in many places and circumstances. For

those not familiar with inverter design, the

basic principle is as follows (see following dia-

gram): Input power is rectified by the rectifier,

then inverted to high frequency AC, then

stepped down by the high frequency trans-

former, rectified again and filtered by the high

frequency rectifier, which outputs directly to

stable DC power suitable for welding. The

basic design and construction of the inverter

reduces size, weight, and power consumption,

while increasing arc stability.

1.3 Volt/Amp Curve. The function of the CC/CV

PowerMTS offers improved volt amp curves

for more control and quicker response over

what can be offered by many transformer

based welders.

1.4 Installation. The basic construction of the

PowerMTS is rugged and durable, ideal for

many locations and use. Critical components

are protected by coatings and heavy potting to

make the welder environmentally resistant.

However, some care and common sense

should be taken to make sure that the welder

offers the safest and best performance.

Please note the following items regarding safe

operation:

1) Do not use the welder in damp or wet are-

as. Perspiration and other forms of water

in contact with the body can increase the

risk of electrocution.

2) Do not use the welder in extreme corrosive

environments. To maintain optimum power

transfer, check main connections, clamps

and cables frequently to ensure that com-

ponents are not corroded. Excessive cor-

rosion and oxidation can result in an unsta-

ble arc and heat build-up.

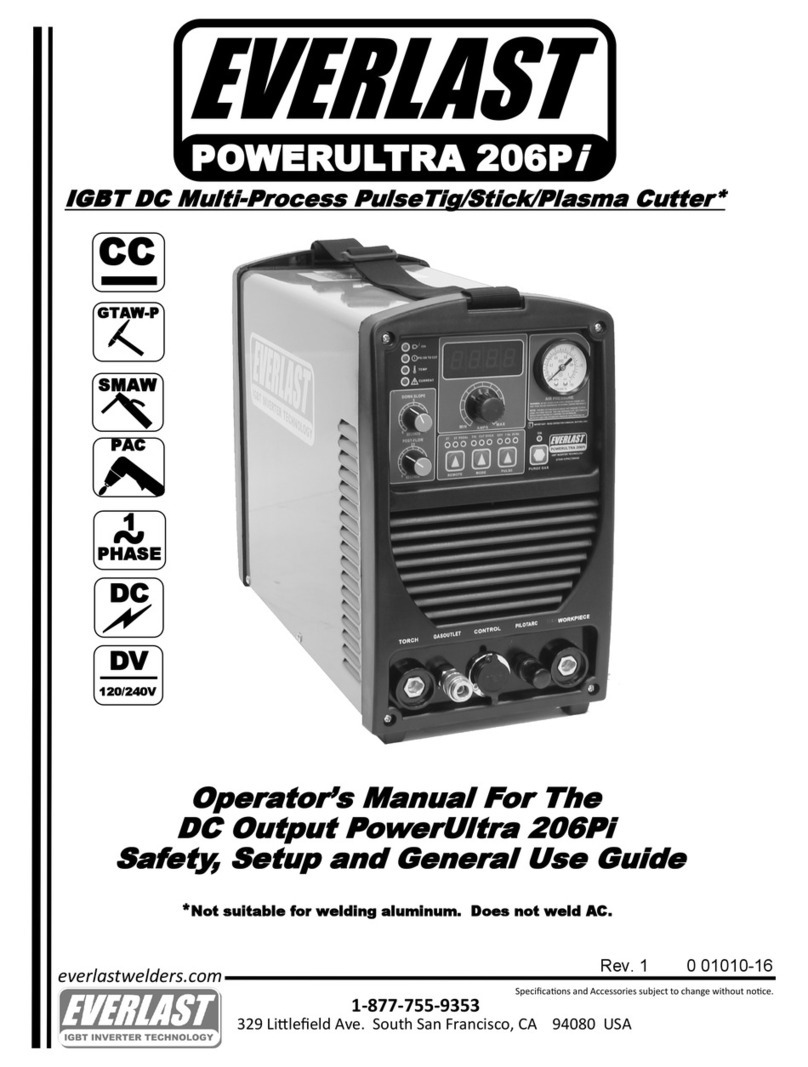

Figure 1.2.1

CV Volt/Amp Curve

CC Volt/Amp Curve

Introduction and Specifications

Section 1

Figure 1.3.1