Evolve SHOWROOMS User manual

Evolve Installation Guide

EVOLVE

Page 2 • evolvefurnituregroup.com

NOTE: Any alterations to listed components will void the manu-

facturer’s warranty. The manufacturer will not be responsible for

any damage or bodily harm caused

by alterations in accordance with national or local electrical

codes and manufacturer’s specifications. In accordance with the

manufacturer’s policy of continual product improvement, the

product presented in this document is subject to change without

notice or obligation.24

Please contact your Evolve Service Representative at

856.552.4000 for any questions or concerns.

Corner Connections – Equal Height

Corner Connections – Variable Height

Corner Connections – Corner Post Extension

Inline Connection – Equal Height

Inline Connection – Variable Height

Notched Top Cap

Inline Connection – Panel Extension Module

End-of-Run Post Kit

End-of-Run Post Kit - Wall Mount Application

End-of-Run Post Kit - O Module Application

Felt Dividers

Privacy Glass

Privacy Ceiling

Door Panel

Privacy Screen

Sliding Panel Door Lock

Evolve Panel Removal

Evolve Module Removal

Mobile/Freestanding Monolithic Privacy

Panels

4

5

6

6

7

7

8

9

10

10

11

12

19

20

22

23

24

25

26

38

39

40

41

43

43

44

45

46

46

47

48

49

50

51

53

54

55

56

57

Panels

List of Tools Storage

P.03

P.04

Wiring Schematic

Power Distribution Housing

Jumper Cables and Pass-Through Cables

Reversible Floor Power Entry

Ceiling Power Entry

Duplex Receptacle

Cable Capacity

End Panel

Corner Bracket

Cantilever

Support Leg

Worksurface Supporting Pedestals

Laminate End panels

Optional Accessory Rail

28

28

29

30

31

32

33

34

34

35

35

36

37

37

Electrical

Worksurfaces

P.16

P.22

P.26

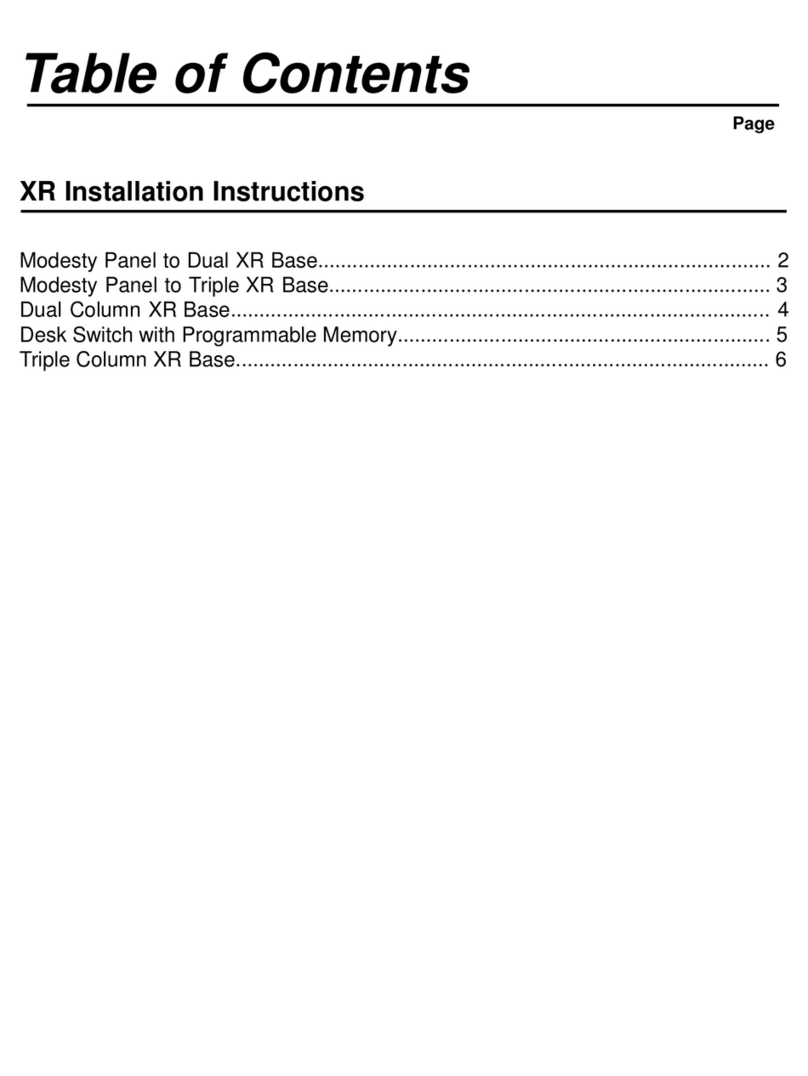

TABLE OF CONTENTS

Overhead Flipper Door Storage Unit

Corner Shelf

Low-Profile Shelf

Top Mount Overhead

Panel Mounted Overhead Storage Unit - ADA Compliant

Up-Mount Overhead Storage Unit - ADA Compliant

Up-Mount Conversion Kit

Fine Tuning of Up-Mount Overhead Storage Unit

e-STOR - Two Lateral Cabinet Assembly

e-STOR - Two Lateral Cabinet and Panel Assembly

Storage Cabinets with Pass Through Cables

Double Wall Overhead

Double Wall Overhead Glazed Door

“J” Bars for Double Wall Overhead - Wall Mount

Double Wall Cabinet

O Module Worksurface Bracket

Lock Clip Installation

Pass Thru Sliding Door

Name Plate

Accessory Retainer

EVOLVE

evolvefurnituregroup.com • Page 3

* These Items are available through customer service at

856.552.4000.

Evolve

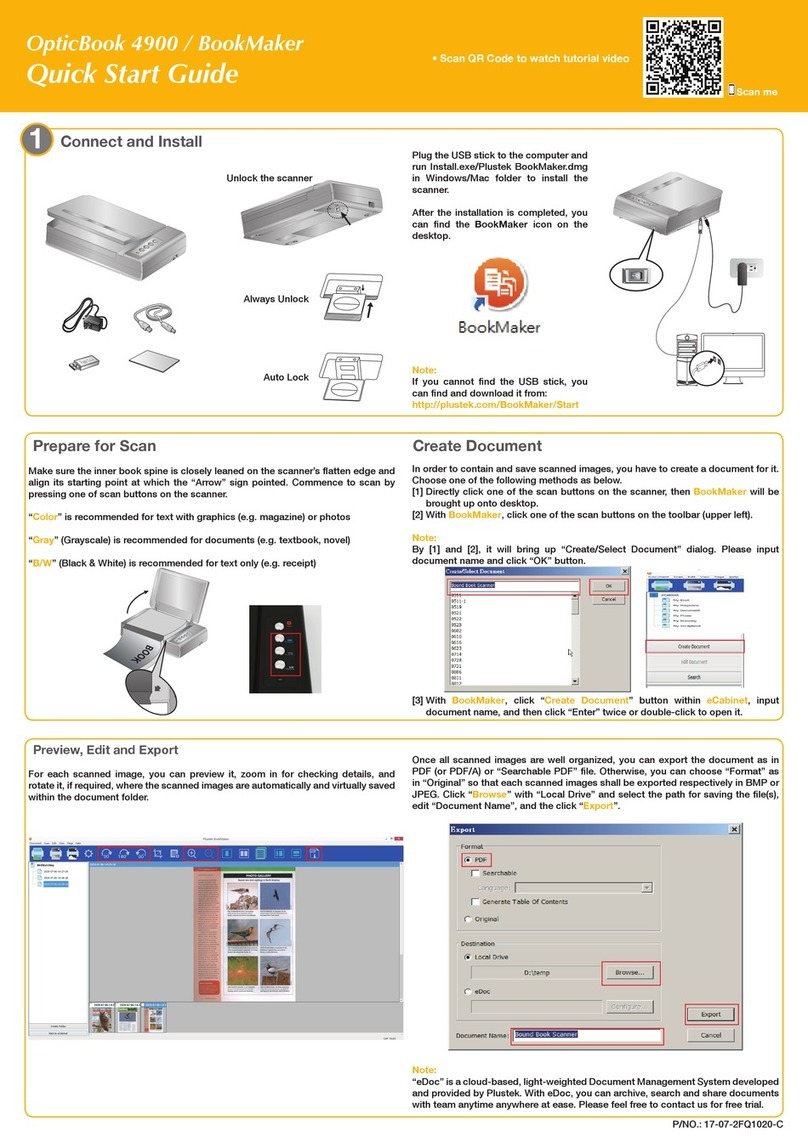

Safety Glasses #2 Phillips Screwdriver

Adjustable 8” Wrench

General Purpose Prybar

1/2” Pan Head Screw

1/2” Pan Head Tapping Screw

Fabric Spline Roller*

5/16” Nut-Driver

Large 1/4” Blade Screwdriver

Tape Measure

Rubber Mallet #3 Phillips Screwdriver

Needlenose Pliers

Power Prill (var speed, rev)

3/8” Nut-Driver

3/16” Diamiter Punch

Gloves

1/2” Wrench

Large Channel Lock Pliers

Magnetic drill bit holders

#2 Robertson Screwdriver

Utility Knife

Metal Pick*

9/16” Wrench

Fine tooth Saw (Hacksaw)

1/4” Nut-Driver

#3 Robertson Screwdriver

48” Long Level

Required Tools Additional items you may find useful:

Screws Used During Installation

Installation Sequence

Panels

Corner Connections – Equal Height (EVPCPA2, EVPCPA3, EVPCPA4)

Corner Connections – Variable Height (EVPVPA2, EVPVPA3, EVPVPA4)

Corner Connections – Corner Post Extension (EVPCEPA2, EVPCEPA3,

EVPCEPA4)

Inline Connection – Equal Height (EVPIC)

Inline Connection – Variable Height (EVPVC)

Notched Top Cap (EVPTNTA, EVPTDNTA)

Inline Connection – Panel Extension Module (EVPIEC)

End-of-Run Post Kit (EVPERA)

End-of-Run Post Kit – Wall Mount Application

Electrical

Wiring Schematic

Power Distribution Housing (EVE8PD)

Jumper Cables and Pass-Through Cables (EVE8CP)

Reversible Floor Power Entry (EVE8FR1, EVE8FR2)

Ceiling Power Entry (EVE8EC1, EVE8EC2)

Duplex Receptacle (EVE8RD)

Worksurfaces

End Panel (EVHEP)

Corner Bracket (EVHCB)

Cantilever (EVHC)

Support Leg (EVHS)

Worksurface Supporting Pedestals (EVS12BBF, EVS12FF)

Storage

Overhead Flipper Door Storage Unit (EVSOF)

Corner Shelf (EVSSC)

Low-Profile Shelf (EVSSL)

Panel Mounted Overhead Storage Unit - ADA Compliant (EVADA-PM)

Up-Mount Overhead Storage Unit - ADA Compliant (EVADA-UM)

Up-Mount Cantilever Kit (EVADA-KIT)

Fine Tuning of Up-Mount Overhead Storage Unit

e-STOR - Two Lateral Cabinet Assembly Instructions

e-STOR - Two Lateral Cabinet and Panel Assembly Instructions

Storage Cabinets with Pass Through Cables

INSTALLATION GUIDELINES

EVOLVE

Page 4 • evolvefurnituregroup.com

Corner Connections - Equal Height

Parts List

1 Aluminum corner post

1, 2, 3 or 4 slotted posts with leveling glide (attached to aluminum

corner post)

1, 2, 3 or 4 single clamps

Appropriate trim, 1 Top cap

Corner Posts are used to connect panels of equal height at a

corner.

45º and 60º posts are installed in the same manner.

Always start the installation of panels at a corner.

STEP 1: Partially attach a slotted post to one end of the panel to

be installed. Do this by engaging the down-hook at the bottom of

the panel (above the raceway channel) over the up-hook on the

slotted post.

STEP 2: Attach the opposite end of this panel to one face of the

Corner Post by engaging the down-hook at the bottom of the panel

(above the raceway channel) over the up-hook on the slotted post.

(The slotted post is secured to the face of the Corner Post.)

STEP 3: Connect the top of the Corner Post to the panel by

engaging the single clamp through the slotted post and into the

panel liner. Secure the single clamp by bolting it to the top of the

panel using two (2) quarter 20 1/2” flat head screws.

STEP 4: Repeat the above procedure to attach the second, third

and fourth panel to the Corner Post.

STEP 5: Add spacer clips.

STEP 6: Press fit the top cap down onto the top of the Corner

Post.

STEP 7: Reattach the panel tops caps.

INSTALLATION GUIDELINES

EVOLVE

evolvefurnituregroup.com • Page 5

Corner Connections - Variable Height Two-Way, Three-Way and Four-Way, Corner Posts

Parts List

1 Aluminum corner post

1, 2, 3 or 4 slotted posts of varying heights with levelling glide

(attached to aluminum corner post)

1, 2, 3 or 4 single clamps

Appropriate trim, 1 Top cap

Variable-Height Corner Posts are used to connect panels of dif-

ferent heights at a corner.

Always start the installation of panels at a corner.

STEP 1: Partially attach a slotted post to one end of the panel to

be

installed. Do this by engaging the down-hook at the bottom of

the

panel (above the raceway channel) over the up-hook on the slot-

ted post.

STEP 2: Attach the opposite end of this panel to the correspond-

ing face of the Variable-Height Corner Post by engaging the

down-hook at the bottom of the panel (above the raceway chan-

nel) over the up-hook on the slotted post. (The slotted post is

secured to the face of the Variable-Height Corner Post.)

STEP 3: Connect the top of the Variable-Height Corner Post to

the panel

by engaging the single clamp through the slotted post and into

the panel liner. Secure the single clamp by bolting it to the top of

the panel using two (2) 1/2” flat head screws.

STEP 4: Repeat the above procedure to attach the second, third

and fourth

panel to the Variable-Height Corner Post.

STEP 5: Snap the vertical corner trim pieces onto the corner

post. Start at the top and align corner trim with panel top cap.

STEP 6: Press fit the top cap down onto the top of the Variable-

Height Corner Post.

STEP 7: Reattach the panel top caps.

INSTALLATION GUIDELINES

EVOLVE

Page 6 • evolvefurnituregroup.com

Corner Connections - Corner Post Extension Two-Way, Three-Way and Four-Way

Inline Connections - Equal Height

Parts List

1 Aluminum corner extension post

1, 2, 3 or 4 non-slotted posts (attach to aluminum corner post)

1, 2, 3 or 4 variable-height clamps

Appropriate trim

Corner Post Extensions are used to connect Panel Extension Modules at

a corner. The combination of one 66” panel and three 12” Panel Extension

Modules has been tested and U.L. Approved. Special care should be taken

to ensure stability when exceeding 90” in height.

STEP 1: Remove the post top cap.

STEP 2: Remove the single clamp that attaches the panel to the corner

post.

STEP 3: Reconnect the top of the panels to the slotted corner posts by

engaging the variable-height clamps through the slotted post. Rotate the

variable-height clamps down onto the top horizontal tubes of the panels.

Secure the variable-height clamps by bolting each to a panel using two

1/2” flat head screws.

STEP 4: Insert the Corner Post Extension into the existing Corner Post,

making sure that it is fully seated.

STEP 5: Position the Panel Extension Module on top of the desired, cor-

responding panel and against the Corner Post Extension.

STEP 6: Connect the top of the Corner Post Extension to the Panel Exten-

sion Module by engaging the single clamp through the slotted post and

into the panel liner. Secure the single clamp by bolting it to the top of the

panel using two 1/2” flat head screws.

STEP 7: Repeat the above procedure to attach the second, third and

fourth panel to the Corner Post Extension.

STEP 8: Attach the Corner Post top cap.

STEP 9: Reattach the panel top caps.

Parts List

1 Slotted post with levelling glide

1 Double clamp

The Inline Connector is used to connect two panels of equal height in a

straight line.

STEP 1: Partially attach the slotted post to one end of the panel to be

installed by engaging the down-hook at the bottom of the panel (above

the raceway channel) over the up-hook on the slotted post.

STEP 2: Attach the opposite end of this panel to the slotted post of the

run of panels. Do this by engaging the down-hook at the bottom of the

panel (above the raceway channel) over the up-hook on the opposite side

slotted post.

STEP 3: Connect the two panels and Inline Connector by engaging the

double clamp through the slotted post and into the panel liner. Secure the

double clamp by bolting it to the top of the panel using four (4) 1/2” flat

head screws.

STEP 4: Reattach the panel top caps.

INSTALLATION GUIDELINES

EVOLVE

evolvefurnituregroup.com • Page 7

Inline Connection - Variable Height

Parts List

1 Slotted post with levelling glide

2 Variable-height clamps

A Variable-Height Connector is used to connect two panels of diering heights in a

straight run.

A Variable-Height Connector must match the height of the taller panel.

STEP 1: Partially attach a same-height slotted post to one end of the panel to be

installed. Do this by engaging the down-hook at the bottom of the panel (above

the raceway channel) over the up-hook on the slotted post.

STEP 2: Partially attach the slotted post to the taller panel by engaging the

down-hook at the bottom of the panel (above the raceway channel) over the up-

hook on the slotted post.

STEP 3: Connect the taller panel to the slotted post by engaging the single vari-

able height clamp through the slotted post and into the panel liner. Secure the

single clamp by bolting it to the panel using two (2) 1/2” flat head screws.

STEP 4: Partially attach the lower panel by engaging the down-hook at the bot-

tom of the panel (above the raceway channel) over the up-hook on the opposite

side slotted post.

STEP 5: Connect the top of the lower panel to the slotted post by engag- ing the

variable-height clamp through the slotted post. Rotate the variable-height clamp

down onto the top horizontal tube of the panel. Secure the variable-height clamp

by bolting it to the top of the panel using two (2) 1/2” flat head screws.

STEP 6: Add spacer clips.

STEP 7: Reattach the panel top caps.

Notched Top Cap - For PVC Top trim Only

When two panels of dierent heights are joined in a run of panels,

the top cap of the lower panel must be notched to allow it to go

around the Inline connector that extends to the top of the taller

panel.

STEP 1:

INSTALLATION GUIDELINES

EVOLVE

Page 8 • evolvefurnituregroup.com

Inline Connection - Panel Extension Module

Parts List

1 Non-slotted post with attached aluminum inserter

2 Variable-height clamps

An Inline Panel Extension Connector is used to attach the panel

extension modules to the top of an existing run of panels. The

combination of one 66” panel and three 12” Panel Extension

Modules has been tested and U.L. approved. Special care should

be taken to ensure stability when exceed- ing 90” in height.

STEP 1: Remove the double clamp that bridges the two panels.

STEP 2: Reconnect the top of the panels to the slotted post by

engaging the variable-height clamps through either side of the

slotted post. Rotate the variable-height clamps downward and

bolt each to a panel using two 1/2” flat head screws.

STEP 3: Insert the Inline Extension Connector into the existing

Inline Connector, making sure that it is fully seated. Option A

a) Repeat 1 through 4 along the top of the panel run

where the Panel Extension Modules

are required.

b) Slide the Panel Extension Modules down between the

Inline Extension Connectors.

c) Connect the two panels and Inline Connector by en-

gaging the double clamp through the

slotted post and into the panel liner.

d) Secure the double clamp by bolting it to the Panel

Extension Module using four

(4) 1/2” flat head screws.

e) Add spacer clips.

f) Reattach the panel top caps.

Option B: Where the Panel Extension Modules are close to the

ceiling, the installation must be accomplished progressively. e.g.

post – panel – post – etc.

INSTALLATION GUIDELINES

EVOLVE

evolvefurnituregroup.com • Page 9

INSTALLATION GUIDELINES

End of Run Post Kit

Parts List:

1 Slotted post with levelling glide

1 Single clamp

1 End trim kit

2 Metal Clips per each trim.

An End-of-Run Kit is used at the end of each panel run.

STEP 1: Attach the End-of-Run Trim Kit. Continue to the end of

the run of panels by engaging the lance at the top of the end trim

extrusion into the top cap. Press the extrusion onto the slotted

post.

EVOLVE

Page 10 • evolvefurnituregroup.com

End of Run Post Kit, O Module Application

End-of-Run Kit - Wall Mount Application

Parts List

1 Slotted post with levelling glide

1 Single clamp

1 End trim kit

A Wall Mount is the same as an End-of-Run Post Kit. It is used to attach a

panel run to a fixed wall.

STEP 1: Select the panel that starts at the fixed wall.

STEP 2: Partially attach an Inline Connector to the end of the panel furthest

from the wall by engaging the down-hook at the bottom of the panel

(above the raceway channel) over the up-hook on the slotted post.

STEP 3: Attach the End-of-Run Post Kit to the end of the panel that will be

against the wall. (See END-OF-RUN POST KIT opposite.)

STEP 4: Level the panel (consider the height of the rest of the run of pan-

els)

STEP 5: Locate the prepared panel at the desired position on the wall and

mark the location.

STEP 6: Remove trim from the slotted post attached to the panel.

STEP 7: Drill 1/4” holes through the trim at 18” intervals.

STEP 8: Place trim on wall at marked location and mark holes.

STEP 9: Drill holes in wall

STEP 10: Attach trim to wall. (Evolve does not supply mounting hardware)

STEP 11: Reattach the panel top cap.

STEP 12: Slide the panel onto the trim Wall Mount.

INSTALLATION GUIDELINES

EVOLVE

evolvefurnituregroup.com • Page 11

INSTALLATION GUIDELINES

Felt Dividers

STEP 1: Place Blocks (4) into position

STEP 2: Remove strips o of tape underneath 12” Spacer Clip

(3) and locate in middle of panel

STEP 3: Align felt evenly within the channel

STEP 4: Push felt down firmly and evenly into the channel.

1

2

4

3

EVOLVE

Page 12 • evolvefurnituregroup.com

Privacy Glass installation with new seals

Parts List

1 Glass

2 Aluminum Top Trim with channel

3 12” Spacer Clip

4 Block

5 Glass Seal

6 End Cap

7 Small Glass Seal in middle

A Wall Mount is the same as an End-of-Run

Post Kit. It is used to attach a panel run to a

fixed wall.

STEP 1: Remove strips o of tape under-

neath 12” Spacer Clip (#3) and locate in

middle of panel.

STEP 2: Remove existing pan head screws

just outside the single panel clamps, from

the top horizontal rail. Place Blocks (#4)

into position

over screw hole and secure using the same

screw previously removed.

STEP 3: Position Top Trim (#2) so the ends

of trim align with the center of the connec-

tor slots. The holes in the channel that holds

the glass,

should align with the screws holding the

blocks below. Snap top trim on securely.

a. Note: To remove the Top Trim, the

screws in the blocks below must be loos-

ened first. After removing the Top Trim, the

blocks can be slid to the side, to remove and

reuse.

STEP 4:Place the Seal (#5) over each hole,

and seal (#7) in middle, in the Top Trim

extrusion channel, symmetrically so the

cutouts align with the top of the extrusion

channel, and the same amount sticks above

the extrusion on each side.

STEP 5: Align glass evenly within the chan-

nel.

STEP 6: Push Privacy Glass down firmly and

evenly into the channel.

STEP 7: Using an exacto knife, cut the ex-

cess material on the Seal (#5) that is stick-

ing up above the channel.

STEP 8: Push Cap(#6) in top tim channel at

ends to close open ends, see details

INSTALLATION GUIDELINES

EVOLVE

evolvefurnituregroup.com • Page 13

Privacy Glass Installation Instructions

STEP 1: Remove screw

STEP 2: Install block and screw back using the same screw. It is

important to start the installation from the middle panel.

STEP 3: Blocks installed

STEP 4: Peel o double sided tape

INSTALLATION GUIDELINES

EVOLVE

Page 14 • evolvefurnituregroup.com

STEP 5: Install PVC spacer in the middle

STEP 6: Locate top trim and adjust sideways to the middle of the

slot

STEP 7: Snap on block

STEP 8: Install next top trim while ensuring that both trims are fully

aligned

INSTALLATION GUIDELINES

Privacy Glass Installation Instructions

EVOLVE

evolvefurnituregroup.com • Page 15

Privacy Glass Installation Instructions

STEP 9: Plastic seal with grooves on the top side. For ease of

installation, use 1/2” plastic seal.

STEP 10: Plast plastic seal on the head of the block screw with

grooves facing down. Adjust the plastic seal symmetrically on the

top of the trim on both sides.

STEP 11: Place thin seal in middle of trim

INSTALLATION GUIDELINES

EVOLVE

Page 16 • evolvefurnituregroup.com

STEP 12: Hold privacy glass from both ends (2 people) and install

privacy glass ensuring that the glass seal is fully aligned.

STEP 13: If glass seal slides o place, pull glass up and re-install as

indicated in the previous step.

STEP 14: Logo should always be consistently on the same bottom

corner. Ensure consistency with having the shiny sides of the

privacy glass on the same side.

INSTALLATION GUIDELINES

Privacy Glass Installation Instructions

EVOLVE

evolvefurnituregroup.com • Page 17

Privacy Glass Installation Instructions

STEP 15: Ensure that the 2 adjacent privacy glass pieces are aligned

and a tight gap is left between the 2 edges (3/32”)

STEP 16: Installation of privacy glass is complete with shiny side out

and logo on the bottom left corner

INSTALLATION GUIDELINES

EVOLVE

Page 18 • evolvefurnituregroup.com

STEP 17: Check the squareness of glass

STEP 18: If needed, pull in the opposite direction and check again

STEP 19: When installation is fully satisfactory, cut protruding

plastic seal with exacty knife

INSTALLATION GUIDELINES

Privacy Glass Installation Instructions

EVOLVE

evolvefurnituregroup.com • Page 19

Privacy Ceiling filler Install

Parts List

1 Felt

2 Aluminum Top Trim with channel

3 12” Spacer Clip

4 Block

5 Ceiling filler PVC Cap

STEP 1: Ceiling filler includes standard felt

divider and PVC cap

STEP 2: Try top trim on top of panel without

blocks installed and measure distance from

top trim to ceiling

STEP 3: With sharp knife using straight

ruler cut felt to a little smaller than required

height

STEP 4: On firm surface assemble felt with

trim then push PVC cap on felt

STEP 5: Align Felt evenly within the channel

STEP 6: Push Felt down firmly and evenly

into the channel.

STEP 7: Push PVC cap on Felt top

STEP 8: Remove strips o of tape under-

neath 12” Spacer Clip (#3) and locate in

middle of panel.

STEP 9: Remove existing pan head screws

just outside the single panel clamps, from

the top horizontal rail. Place Blocks (#4)

into position over screw hole and secure us-

ing the same screw previously removed.

STEP 10: Tilt assembled felt with trim to one

side and start putting it on top of panel on

blocks, then rotate it to be straight on panel

top and push trim down on both sides until

trim snaps on blocks. Make sure that ends of

trim align with center of connector slots.

STEP 11: Align felt and then push up PVC

cap against ceiling to close gap

Note.

Felt height should be such that it easily

clears ceiling during installation

INSTALLATION GUIDELINES

EVOLVE

Page 20 • evolvefurnituregroup.com

Door Panel Installation

STEP 1: The door is ordered with either a left or a right swing. Check layout

for proper placement and swing. It can be easily changed on site from one

side to another. Please see the instructions below.

STEP 2: Attach door panel to an existing run as you would any other panel.

Door must be in the closed position (inside the frame) during installation.

STEP 3: Level the door using glides on the connectors.

Ensure that the door frame is spread out to maximum width at the thresh-

old before locking.

There is no lateral adjustment of the threshold.

Door MUST be perfectly level and square to work properly.

STEP 5: Install lever hardware.

STEP 6: Upon completion of door installation, check entire installation to

ensure all panel to panel connectors are in place for a structurally sound

wall and door unit. What to do if door is not closing properly:

STEP 1: Door MUST be perfectly level and square.

STEP 2: Ensure that the door frame is spread out to maximum width at the

threshold before locking.

STEP 3: Ensure the hinges that are attached to the door are fl ush with the

edge of the door. If this is not the case, solid doors can be turned upside

down, hinges and lever can be reversed.

INSTALLATION GUIDELINES

Table of contents

Other Evolve Office Equipment manuals

Popular Office Equipment manuals by other brands

OCEE DESIGN

OCEE DESIGN DEN.Curve Assembly instructions

Sharp

Sharp EL-2901E Service manual

BDI

BDI KRONOS 6752 owner's manual

Acroprint

Acroprint ELECTRIC STAMPS General service instructions

Office Star Products

Office Star Products Space Seating 13-V22N1WA operating instructions

Workrite Ergonomics

Workrite Ergonomics FDEX54-72-X Assembly/installation instructions