EWIKON HPS III Series User manual

HPS III hot runner systems

for side gating

Operating manual

Valid for:

HPS III adapter nozzles

HPS III-MHL100/200 nozzles

HPS III-MHR100/200 nozzles

HPS III-MHR111 nozzles

HPS III-MHR112 nozzles

HPS III-MHR122 nozzles

HPS III-MH1 nozzles

HPS III-T/TE manifolds

Complete hot halves

Version: 2.0

3HPS-III-Seitenanspritzung-Heißkanalsystem_Inhalt_BA_V-2-0_EN

1. General remarks .......................................................................................................................................................... 7

1.1 Information on this operating manual ............................................................................................................................ 7

1.2 Manufacturer ................................................................................................................................................................. 7

1.3 Formal information on the operating manual ................................................................................................................ 7

1.4 Conventions .................................................................................................................................................................. 8

1.4.1 Instructions and system responses ............................................................................................................................... 8

1.4.2 Enumerations ................................................................................................................................................................ 8

1.4.3 Abbreviations ................................................................................................................................................................ 8

2. Safety instructions ...................................................................................................................................................... 9

2.1 Safety instructions and symbols used ........................................................................................................................... 9

2.1.1 Signalwordsforhazardclassication ......................................................................................................................... 10

2.1.2 Explanation of pictograms ........................................................................................................................................... 10

2.2 Intended use ............................................................................................................................................................... 11

2.3 Improper use ............................................................................................................................................................... 11

2.4 Qualicationofsta..................................................................................................................................................... 11

2.4.1 Demandsonspecialisedsta ..................................................................................................................................... 11

2.5 Personal Protective Equipment (PPE) ........................................................................................................................ 12

2.5.1 Symbols of the personal protective equipment ........................................................................................................... 12

2.6 General hazards and safety measures ....................................................................................................................... 12

2.7 Electrical equipment .................................................................................................................................................... 14

2.8 Spare and wear parts, auxiliary and operating materials ............................................................................................ 14

2.9 Limitation of liability ..................................................................................................................................................... 14

2.10 Warranty terms ............................................................................................................................................................ 15

2.11 Standards and directives ............................................................................................................................................. 15

3. Technical data ........................................................................................................................................................... 16

3.1 Mechanicalspecications ........................................................................................................................................... 16

3.1.1 Main dimensions of the HPS III hot runner system ..................................................................................................... 16

3.1.2 Operating parameters of the HPS III hot runner system ............................................................................................. 16

3.2 Electricalspecications ............................................................................................................................................... 16

3.2.1 Connections/connector pin assignment ...................................................................................................................... 16

3.3 Hydraulic/pneumaticspecications(driveunits) ....................................................................................................... 16

3.4 Operating conditions ................................................................................................................................................... 16

3.4.1 Noise emission ............................................................................................................................................................ 16

3.4.2 Cooling agent .............................................................................................................................................................. 17

3.5 Type plate .................................................................................................................................................................... 17

4. Functional description of the HPS III hot runner system ...................................................................................... 18

5. Installation ................................................................................................................................................................. 20

5.1 Transport ..................................................................................................................................................................... 20

5.1.1 Safety information on transport ................................................................................................................................... 20

5.1.2 Recommended lifting accessories and slings ............................................................................................................. 21

5.1.3 Check the lifting accessories and slings before use ................................................................................................... 21

Content

4 HPS-III-Seitenanspritzung-Heißkanalsystem_Inhalt_BA_V-2-0_EN

5.1.4 Attachment points ....................................................................................................................................................... 22

5.1.5 Working load limit for lifting accessories and slings .................................................................................................... 22

5.1.6 Removal from transport crate ...................................................................................................................................... 24

5.1.7 Transport and movement during installation ............................................................................................................... 24

5.2 General safety instructions .......................................................................................................................................... 26

5.3 Technical Requirements .............................................................................................................................................. 29

5.3.1 Tools and operating materials ..................................................................................................................................... 29

5.3.2 Standard parts ............................................................................................................................................................. 32

5.4 Checks before installation ........................................................................................................................................... 33

5.4.1 Notes on mould layout ................................................................................................................................................ 33

5.4.2 Standard dimensions of hot runner systems .............................................................................................................. 33

5.4.3 Dimensions to be checked for a hot runner system with HPS III-MHL and HPS III-MHR nozzles .............................. 34

5.5 Installation of HPS III adapter systems ....................................................................................................................... 37

5.5.1 Installation of adapter systems with nozzles for standard and front installation .......................................................... 37

5.6 Installation of HPS III hot runner systems for direct side gating .................................................................................. 43

5.6.1 Installation of systems with HPS III-MHL100/200 or HPS III-MHR100/200 nozzles ................................................... 43

5.6.2 Installation of systems with HPS III-MHR111 nozzles ................................................................................................. 53

5.6.3 Installation of systems with HPS III-MHR112 nozzles ................................................................................................. 59

5.6.4 Installation of systems with HPS III-MHR122 nozzles ................................................................................................ 65

5.6.5 InstallationofsystemswithHPSIII-MH1nozzlesforsidegatingwithopenowchannel .......................................... 71

5.6.6 Installation of a hot half with HPS III-MH nozzles ....................................................................................................... 78

5.7 Electrical connection of hot runner systems ................................................................................................................ 88

5.7.1 Safety instructions ....................................................................................................................................................... 88

5.7.2 General information ................................................................................................................................................... 90

5.7.3 Wiring of 1-drop hot runner systems ........................................................................................................................... 94

5.7.4 Wiring of 2-drop hot runner systems ........................................................................................................................... 95

5.7.5 Wiring of 4-drop hot runner systems (manifold with 2 control zones) ......................................................................... 96

5.7.6 Wiring of 6-drop hot runner systems (manifold with 2 control zones) ......................................................................... 97

5.7.7 Wiring of 8-drop hot runner systems (manifold with 2 control zones) ......................................................................... 98

5.7.8 Wiring of 8-drop hot runner systems (manifold with 4 control zones) ......................................................................... 99

5.8 Checks after installation ............................................................................................................................................ 100

6. Start-up and instructions for operation ................................................................................................................ 101

6.1 Safety instructions ..................................................................................................................................................... 101

6.2 Requirements for operation ....................................................................................................................................... 103

6.3 Start-up and operation of hot runner systems with HPS III-MH nozzles ................................................................... 104

6.3.1 First-timestart-upandllingofahotrunnersystemwithHPSIII-MHnozzleswithheatconductivetips ................. 104

6.3.2 Start-upofalreadylledhotrunnersystemswithHPSIII-MHnozzleswithheatconductivetips............................. 104

6.3.3 First-timestart-upandllingofahotrunnersystemwithHPSIII-MHvalvegatenozzles........................................ 105

6.3.4 Start-upofalreadylledhotrunnersystemswithHPSIII-MHvalvegatenozzles ................................................... 106

6.3.5 Colour and material changes .................................................................................................................................... 106

6.3.6 Shutdown of a system with HPS III-MH nozzles (system / single tip / single cavity) ................................................ 107

Content

5HPS-III-Seitenanspritzung-Heißkanalsystem_Inhalt_BA_V-2-0_EN

6.4 Possible malfunctions ............................................................................................................................................... 108

6.4.1 Troubleshooting ......................................................................................................................................................... 108

7. Maintenance ............................................................................................................................................................ 109

7.1 Safety instructions ..................................................................................................................................................... 109

7.2 Instructions for maintenance ..................................................................................................................................... 109

7.3 Maintenance schedule .............................................................................................................................................. 109

7.4 Deinstallation / installation of tip inserts for HPS III-MH nozzles ............................................................................... 110

7.4.1 Safety instructions ..................................................................................................................................................... 110

7.4.2 Deinstallation / installation of tip inserts for HPS III-MH nozzles ............................................................................... 111

7.4.3 Deinstallation of tip inserts ........................................................................................................................................ 112

7.4.4 Cleaning of tip inserts ................................................................................................................................................ 112

7.4.5 Installation of tip inserts ............................................................................................................................................. 112

7.5 HPS III-MHL100/200 (valve gate) nozzles – exchange of thermocouple .................................................................. 113

7.6 HPS III-MHR100/200 (valve gate) nozzles – exchange of thermocouple ................................................................. 117

7.7 Instructions for service and repair ............................................................................................................................. 122

8. Decommissioning ................................................................................................................................................... 123

8.1 Safety instructions ..................................................................................................................................................... 123

8.2 Instructions for disposal ............................................................................................................................................ 124

9. Tightening torques .................................................................................................................................................. 125

9.1 Tightening torques for socket head screws ............................................................................................................... 125

9.2 Tightening torques for manifold screw connections and retaining screws ................................................................ 127

9.3 Tightening torques for clamping covers of HPS III-MH nozzles ................................................................................ 128

Content

6 HPS-III-Seitenanspritzung-Heißkanalsystem_Inhalt_BA_V-2-0_EN

7HPS-III-Heißkanalsystem_Vorspann_BA_V-2-0_EN

General remarks

1. General remarks

1.1 Information on this operating manual

This operating manual has been created in accordance with the directive 2006/42/EC toenablethesafeandecient

operation of HPS III hot runner systems (hereinafter called hot runner system).

1.2 Manufacturer

EWIKON Heißkanalsysteme GmbH

Siegener Straße 35

35066 Frankenberg

Phone: +49 6451 501-0

Fax: +49 6451 501-202

Web: www.ewikon.com

1.3 Formal information on the operating manual

Person in charge of documentation: Henning Becker

Itemnumber: notspecied

Version: 2.0

Printing date: 21/04/2020

Language: German (original operating manual)

© Copyright, 2020

All rights reserved. Full or partial reproduction subject to prior written

approval by EWIKON Heißkanalsysteme GmbH

NOTE!

Improper operation of the device may result in severe personal injury and considerable material damage!

You must carefully read this operating manual and familiarise yourself with the safety installations before

installing,commissioningormaintainingthedevice.Donotoperatethedevicewithouthavingreceivedappropriate

training.

8 HPS-III-Heißkanalsystem_Vorspann_BA_V-2-0_EN

General remarks

1.4 Conventions

1.4.1 Instructions and system responses

Operating steps that have to be carried out by the operator are displayed as a numbered list. The sequence of the steps has

to be adhered to.

Example:

1. Operating step 1

2. Operating step 2

1.4.2 Enumerations

Enumerations without mandatory sequence are displayed as a list with bullet points.

Example:

• Point 1

• Point 2

1.4.3 Abbreviations

The following terms and abbreviations are used in the operating manual:

Abbreviation Meaning

PPE Personal Protective Equipment

HPS High Performance Systems

EU European Union

BR Installation space

H1 Manifold height

H2 Manifold height + top pressure pad

H3 Manifold height + pressure pad with

centering + top pressure pad

H4 Manifold height + top pressure pad +

bottom pressure pad

P Height of nozzle retainer frame plate

B Height of top pressure pad

KH Nozzle body height

X Nozzle length (lower edge of nozzle

body to article surface)

∆S Gap dimension Delta S

RASprue bush radius

RMMachine nozzle radius

N Height of hold-down device

HR Retainer ring height

G Height from centre axis of tip to end of

nozzle

X X dimension of nozzle

TK1 / TK2 / TK3 Standard dimensions to determine

gap dimension

G Thread

P Fit

SW Widthacrossats

T Blueing area

Abbreviation Meaning

m Mass

ρDensity

V Volume

L x B x H Length x width x height (e.g. mould

plate, hot half)

F Force

M Bending moment

THK Hot runner temperature

(processing temperature)

TWZ Mould temperature

∆T DierenceTHK -TWZ

Chart 1: Terms and abbreviations

9HPS-III-Heißkanalsystem_Vorspann_BA_V-2-0_EN

Safety instructions

2. Safety instructions

The HPS III hot runner system conforms to the machinery directive 2006/42/EG and has been designed, manufactured and

checked for safety according to the applicable safety rules and legislation and the state of the art.

The HPS III hot runner system is delivered in perfect working order.

The HPS III hot runner system may pose risks, if it is:

• notoperatedbyprofessionallytrainedsta.

• used improperly or not used as intended.

• not in perfect order regarding safety.

2.1 Safety instructions and symbols used

Signal words introduce the safety instructions and are marked by symbols. They draw the user's attention to possible

hazardous situations that may occur during installation, operation and maintenance. Safety instructions must be followed

to prevent accidents, personal injury or material damage.

Warnings

• Protect against possible personal injury and material damage when followed

• Classify the extent of hazard by the signal word

• Indicate the risk of personal injury by hazard signs

• Indicate the type and source of hazard

• Indicate the risk and possible consequences

• Show measures to prevent hazards and prohibit certain behaviours

WARNING! = signal word

Source of hazard

Possible consequences, if ignored.

• Measures/prohibitions.

The hazard sign marks warnings which warn against personal injuries.

Source of hazard

The source of hazard indicates the cause of hazard.

Possible consequences, if ignored

If the warnings are ignored, possible consequences are e. g. crushing, burnings or other severe injuries.

Measures/Prohibitions

"Measures/Prohibitions" lists actions that are to be carried out to prevent a hazard (e. g. stop a drive unit) or that are

prohibited to prevent a hazard.

10 HPS-III-Heißkanalsystem_Vorspann_BA_V-2-0_EN

Safety instructions

2.1.1 Signal words for hazard classication

HAZARD!

indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING!

indicates a potentially hazardous situation which, if not avoided, will result in death or serious injury.

CAUTION!

indicates a potentially hazardous situation which, if not avoided, will result in minor injury or material damage.

NOTE!

indicates useful additional information and tips to promote trouble-free operation and to prevent material

damage

2.1.2 Explanation of pictograms

Read

operating manual Caution!

Risk of electrocution

Caution!

Hot surface Caution!

Oxidising agents

Caution!

Suspended loads Caution!

Risk of crushing

Caution!

Explosive atmosphere Caution!

Hand injuries or cuts

Caution!

Pressurised systems Caution!

Forklift trucks operating

11HPS-III-Heißkanalsystem_Vorspann_BA_V-2-0_EN

Safety instructions

2.2 Intended use

EWIKON hot runner systems are exclusively designed for the intended use described in this manual.

Anydierentandunintendeduseisexcludedandmayresultinpersonalinjuriesandmaterialdamage.

Warranty expires in this case.

EWIKON hot runner systems and single nozzles are only to be used for injection moulding applications, assembled in an

enclosed injection mould.

They are used to process thermoplastic resins according to their individual processing requirements and to pass them gently

fromtheinjectionunittothecavitybyoptimumtemperaturedistributionandowpaths.

In order to use the hot runner system as intended it is essential that all tips and information given in this operating manual

are read, understood and followed.

To ensure safe operation of the hot runner system, the given maintenance & inspection schedule has to be adhered to.

The system is designed for an injection pressure of 2000 bar.

The resin used has to be processed according to the guidelines of the material manufacturer.

Use of the HPS III hot runner system

Use the HPS III exclusively for its intended use and in perfect condition as regards safety! This is the only way

to guarantee a reliable operation of the HPS III hot runner system.

2.3 Improper use

Anyusedeviatingfromtheusedenedunder"Intendeduse"orthatgoesbeyondthatuseisconsideredimproperuse.

2.4 Qualication of sta

Thestahastoprovethatitisqualiedtoperformassembly,maintenanceandrepair.Anylackofknowledgehastobe

eliminatedbytrainingandbriengthesta.

2.4.1 Demands on specialised sta

ImproperuseofEWIKONhotrunnersystemsmayresultinpersonalinjuriesormaterialdamage.Onlyspecialisedstais

allowed to carry out any work.

OnlyspecialisedstaisallowedtoinstallandoperateEWIKONhotrunnersystems.Specialisedstaistrained,hasproven

knowledge and experience in operating e. g. injection moulding units or electrical machines and devices as well as knowl-

edge of the relevant regulations and is able to indepently identify possible hazards and prevent them by taking protective

measures.

12 HPS-III-Heißkanalsystem_Vorspann_BA_V-2-0_EN

Safety instructions

2.5 Personal Protective Equipment (PPE)

Wear the necessary protective equipment when working on or near the machine. Special information on the personal

protective equipment in the work area has to be observed.

2.5.1 Symbols of the personal protective equipment

Always wear the following when carrying out any work:

Protective clothes:Toprotectyourbodyweartight-ttingclotheswithlowresistancetotearing,without

protruding parts and with long sleeves and long trousers. Do not wear rings, chains or any other jewelry.

Safety shoes: To protect yourself against electric shocks, melt splashes, heavy, falling objects and slips

and falls on slippery surfaces.

Always wear the following when carrying out special work:

Safety glasses: To protect your eyes

against scattering debris, heat and melt

splashes.

Ear protection: To protect your ears

against loud ambient noise.

Face mask: To protect your face against

scattering debris, heat and melt splashes. Protective helmet: To protect your head

against falling objects and sharp edges.

Protective gloves (heat resistant):

To protect your hands against extreme

heat, abrasions, punctures and more

severe injuries.

Heat resistant apron: To protect your

body against extreme heat.

2.6 General hazards and safety measures

The company operating the system must comply with the statutory obligations on occupational safety. In addition to the

safety instructions of this manual the safety, accident prevention and environment protection provisions applicable for the

system'srangeofusemustbeadheredto.Theoperatingcompanymustclearlydeneresponsibilitesandmakesurethatall

staoperatingthesystemhasreadandunderstoodthismanual.Thecompanyalsohastoinformabouthazardsatregular

intervals.Personalprotectiveequipmenthastobemadeavailabletothesta.Maintenanceintervalshavetoberespected.

Risk of physical injuries by high pressure or unexpected material leakage

• Unexpected material leakage may result in burns. There is a risk of serious injuries or death and/or

damage to the hot runner.

• There is also a risk of burns, if water gets onto or into the hot runner. If the water reaches dangerous-

ly high temperatures, the metal housing may burst and cause serious injuries due to emerging water

vapour or melting resins.

Safety measures

• Make sure the hot runner system heats up evenly. Particularly for large manifolds it may be necessa-

ry to switch on nozzle and sprue bush heaters simultaneously, but later than the manifold heaters.

• Makesurethenozzletipsand/orthegatesarenotblockedbysolidiedresinthathasahighermel-

ting pont and that there is no humidity on the hot runner system, e.g. caused by a leaky temperature

control circuit (please see chapter „6.3 Start-up of a HPS III hot runner system“).

13HPS-III-Heißkanalsystem_Vorspann_BA_V-2-0_EN

Safety instructions

Risk of burns

• Hot surfaces

Many components of the hot runner systems get very hot and may cause severe skin burns when

being touched.

• Hot material (plastic melt)

Never touch material leaking from the nozzle/the mould/the hot runner or the material inlet. Even

material that seems to be cooled down already may still be hot inside the core and cause burns.

Safety measures

• Please make sure you wear your personal protective equipment (PPE) when working near or on a

hot runner system. Pay special attention to warnings indicating hot surfaces. All components have

to be cooled down to ambient temperature before you start working. Exceptions to these rules are

explicitly mentioned.

Risk of electric shocks

• Danger to life by electric shock.

Touching live surfaces may result in severe or even lethal injuries.

• Always keep water away from live components and the hot runner. There is a risk of short circuits!

Safety measures

• Electrical systems have to be disconnected from the mains and secured against being switched on

again before any work is carried out. Only authorised electricians are allowed to carry out any work

on electrical systems.

• All components have to be connected to a suitable power source according to the wiring diagrams

and under consideration of the applicable local regulations. Injection moulding machine and hot run-

ner systems have to be grounded.

Risk of physical injuries by suspended/heavy loads

• Onlytrainedstaisauthorisedtooperateliftingdevicesandforklifttrucks.Proceedslowlyandwith

care. Prevent the uncontrolled swinging of the loads (e. g. the manifold).

Safety measures

• Lifting devices and forklift trucks have to be designed to bear the weight and the size of the hot run-

ner system/manifold. Make sure to use the marked lifting points.

Risk of physical injuries by pressurised connecting lines

(e.g. air, hydraulics, water)

• All supply lines for the medium supply of the hot runner and/or the hot runner system or the hot half

havetobelongenoughtopreventanystresswhenthemouldhalvespart.Theymustnotbeaected

by moving parts of the mould or of the machine. Prevent the hoses from rubbing over the edges of

the mould as they may be damaged because this might cause a spontaneous leakage of pressurised

process media (pressurised air, hydraulic oil, water).

Safety measures

• Make sure you have depressurised all supply lines before carrying out any work.

Only skilled personnel is allowed to carry out work on the supply lines. Please wear your personal

protective equipment (PPE).

Risk of physical injuries by sharp edges and corners

• Sharp edges and corners pose a risk of injury, possibly resulting in skin abrasions and cut injuries.

Safety measures

• Make sure you wear protective gloves when working near sharp edges and corners.

Proceed with care.

• Make sure the system is clean and free of burrs.

14 HPS-III-Heißkanalsystem_Vorspann_BA_V-2-0_EN

Safety instructions

Risk of physical injuries by crushing of extremities

• There is a risk of injury when lifting heavy loads during assembly operations, possibly resulting in

crushing of hand or other parts of the body.

Safety measures

• Wear protective gloves to prevent injuries while working around heavy loads.

• Make sure all body parts are kept away from the hazardous area while setting down heavy loads.

2.7 Electrical equipment

HAZARD!

Residual voltage after activation

Risk of death by electric shock and severe injuries caused by live components.

• Check for zero potential before performing any work!

Anyworkonelectricalequipmentmustbecarriedoutbyqualiedelectricians.Alwaysapplythe5safetyruleswhenworking

with electrical components:

• Disconnect from the mains

• Secure against reconnection (by activating the repair switch and installing a safety lock at the same time, if necessary)

• Verify that the installation is dead

• Carry out grounding and short circuiting

• Provide protection against adjacent live parts

Maintenanceworkmustbecarriedoutbyqualiedandtrainedstaormaintenancesta.NeverusetheHPSIIIhotrunner

systemwithfaultyorinoperableelectricalconnections.Incaseofenergysupplydisruptionsimmediatelyswitchothe

HPS III hot runner system. The maintenance & inspection schedules regarding electrical components given by the manufac-

turers have to be adhered to. Check for damaged insulation at regular intervals.

2.8 Spare and wear parts, auxiliary and operating materials

The use of non-OEM spare and wear parts as well as auxiliary material may pose risks. Only use original parts or parts

approved by EWIKON Heißkanalsysteme GmbH. Only use auxiliary and operating materials which are suitable for their

intended use (compare chapter „5.3 Technical Requirements“).

2.9 Limitation of liability

All information and instructions given in this manual have been compiled in consideration of the applicable standards and

regulations, state of the art as well as our know-how and experience.

EWIKON does not assume liability for any damage caused by:

• Non-observance of this manual

• Improper use

• Useofunskilledsta

• Unauthorisedretrottingortechnicalmodications

• Use of non-approved spare parts as well as inappropriate auxiliary and operating materials

15HPS-III-Heißkanalsystem_Vorspann_BA_V-2-0_EN

Safety instructions

The technical service provided verbally, in writing or on the basis of tests represents our best knowledge but is not binding

and does not release you from carrying out additional tests on the products supplied by us regarding their suitability for the

intended use.

The use of the products is beyond our control. Therefore, it is your own responsibility to ensure that the products meet your

specicrequirements.Nevertheless,shouldanissueofliabilityarise,alldamageshallbelimitedtothevalueoftheproducts

supplied by EWIKON and used by you.

We guarantee the perfect quality of our products in accordance with our general terms and conditions of sale and payment

as well as the extended warranty conditions.

These are available on our homepage www.ewikon.com.

The statutory provisions prevailing at the time of conclusion of the contract shall apply.

We reserve the right of technical alterations to develop our products and enhance their performance properties.

2.10 Warranty terms

For warranty conditions of cold and hot runner systems and components please refer to the terms and conditions of

EWIKON.

2.11 Standards and directives

EWIKON hot runner systems conform to the following European directives:

• Machinery Directive 2006/42/EC

• Low Voltage Directive 2014/35/EU

• EN ISO 12100:2010 Safety of machinery -

General principles for design - Risk assessment and risk reduction

• EN 60204-1:2007-06 Safety of machinery -

Electrical equipment of machines - Part 1: General requirements

16 HPS-III-Heißkanalsystem_Vorspann_BA_V-2-0_EN

Technical data

3. Technical data

3.1 Mechanical specications

3.1.1 Main dimensions of the HPS III hot runner system

Description Quantity/size (approx.) Unit

Dimensions See catalogue / PO-related documents mm

Weight See catalogue / PO-related documents kg

Chart 2: Main dimensions of the HPS III hot runner system

3.1.2 Operating parameters of the HPS III hot runner system

Description Quantity/size (approx.) Unit

Maximum injection pressure 2000 bar

Maximum operating temperature Depending on order °C

Chart 3: Operating parameters of the HPS III hot runner system

3.2 Electrical specications

3.2.1 Connections/connector pin assignment

Description Quantity/size (approx.) Unit

Voltage 230 V

Frequency 50 Hz

Chart 4: Electrical data (only valid within the EU)

3.3 Hydraulic / pneumatic specications (drive units)

Description Quantity/size (approx.) Unit

Maximum hydraulic pressure (normal operation: 30 bar) 50 bar

Maximum pneumatic pressure (normal operation: 8 bar) 10 bar

Chart 5: Hydraulic / pneumatic data

3.4 Operating conditions

Operating conditions Size (approx.) Unit

Ambient temperature (maximum value) 40 °C

Ambient temperature (minimum value) 10 °C

Relative humidity during operation (no condensation!) 20 to 80 %

Chart 6: Operating conditions

3.4.1 Noise emission

Determining the sound power level of noise sources based on noise pressure measurements acc. to DIN EN ISO 3741

Operating conditions Size (approx.) Unit

Distance to device * mm

Noise pressure level (operation) * dB (A)

Chart 7: Noise emission

* Values can be determined only after the entire system has been started up.

17HPS-III-Heißkanalsystem_Vorspann_BA_V-2-0_EN

Technical data

3.4.2 Cooling agent

The use of unsuitable cooling agents may result in deposits and corrosion in the component to be cooled. This will negatively

aectthefunctionalityofthehotrunnersystem.Componentsofthehotrunnersystemmaybedamagedbyareducedcoo-

ling performance in the worst case. Cooling agents (water) have to satisfy the following minimum requirements:

• Cooling by tap water is not recommended since hard water can cause deposits and corrosion.

• The water has to be clear, colourless and odourless.

• Ithastobefreefromanyoatingorsuspendedmatters.

• A warranty on the resistance of components to be cooled against corrosion attacks cannot be given.

However, the use of suitable cooling agents can considerably enhance this resistance.

3.5 Type plate

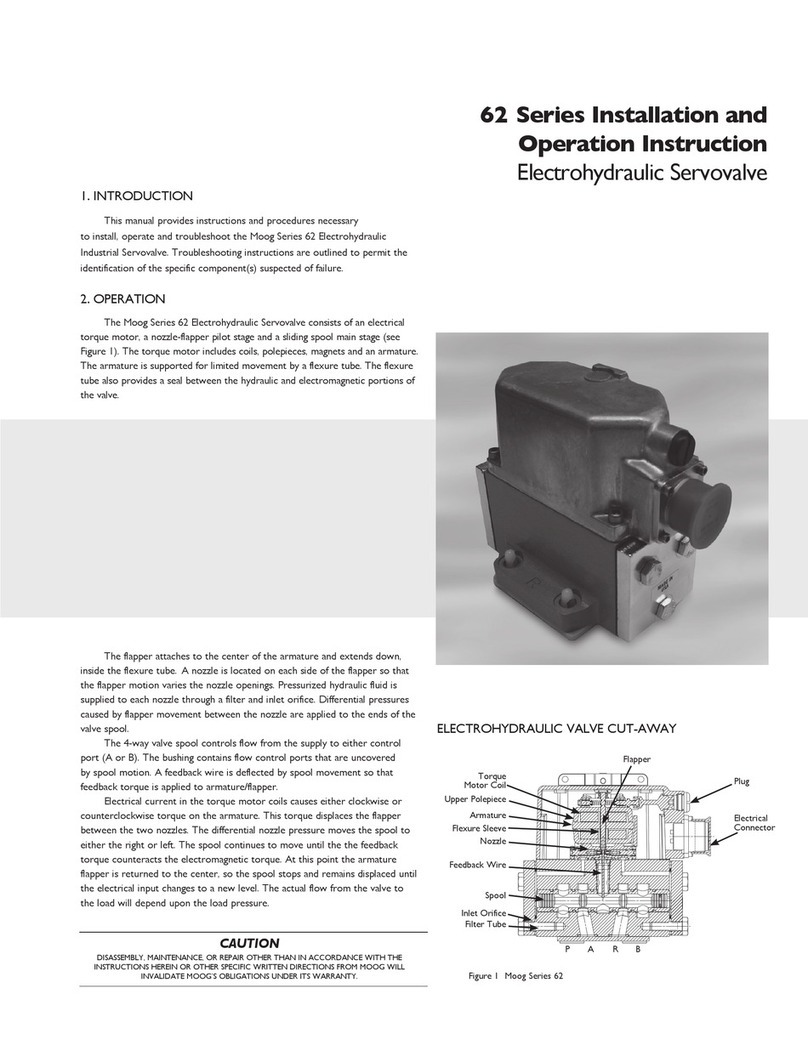

Picture 1: Type plate

The system type plate is to be displayed prominently on the

operator side of the mould. Hot halves are delivered with the

type plate already mounted.

The type plate indicates project number, order number, type

of hot runner system, overall performance, drive unit type,

nozzlesusedand,ifnecessary,otherimportantspecica-

tions.

For the exact allocation of heater zones and contact pins

in the plugs please refer to the wiring scheme in the order

specicdocuments.

Respect operating temperatures

Each hot runner system is individually designed for the material to be

processed.Therefore,thespeciedoperatingtemperaturesmustbe

observed.Thetemperaturedierence∆Tbetweenhotrunnertempe-

rature THK (processing temperature) and mould temperature TWZ,

must be strictly adhered to.

• Non-observance may cause an escape of melt inside the mould

(∆Ttoolow)ordamagetocomponents(∆Ttoolarge).

CAUTION!

18 HPS-III-Heißkanalsystem_Vorspann_BA_V-2-0_EN

Functional description of the HPS III hot runner system

4. Functional description of the HPS III hot runner system

The schematic diagrams of the components of a HPS III hot runner system and the installation space shown in this docu-

mentshouldnotberegardedastheonlyvalidgenerallayoutbutonlypresentoneofmanypossibleassemblycongura-

tions.

Pos. 1 Injection mould with hot runner system

Pos. 1.1 Moving mould half (ejector side)

Pos. 1.2 Fixed mould half (nozzle side)

Pos. 1.3 Hot half (nozzle side without contour plate)

Pos. 2 Locating ring

Pos. 3 Sprue bush

Pos. 4 Hot runner manifold

Pos. 5 Hot runner nozzles

Pos. 50 Insulating plate (optional)

Pos. 51 Clamping plate

Pos. 51.1 Clamping plate

with drive unit for valve gate nozzles

z349-03

Picture 2: Layout of an injection mould with HPS III hot runner system for the processing of thermoplastic resins

Pos. 52 Nozzle retainer frame plate

Pos. 53 Contour plate

Pos. 54 Guide bolts

Pos. 55 Moulded part

Pos. 56 Cavity

Pos. 57 Contour plate

Pos. 58 Riser

Pos. 59 Ejector plates

Pos. 60 Ejector pins

Pos. 61 Clamping plate

Pos. 62 Ejector bolts

19HPS-III-Heißkanalsystem_Vorspann_BA_V-2-0_EN

Functional description of the HPS III hot runner system

Picture 3: Injection moulding cycle * for valve gate systems

** recommended for open systems

A hot runner system is used to distribute plastic melt between the injection moulding unit of an injection moulding machine

and the cavities of an injection mould (compare picture 2). The plastic material remains permanently molten until it enters the

cavities.

The plastic melt made available by the injection moulding unit is guided through the sprue bush to the manifold during the

injection moulding cycle. In the manifold the melt stream for the individual cavities is split and fed to the hot runner nozzles.

The hot runner nozzles guide the melt stream to the cooled cavities (compare picture 3).

If a valve gate system is used, the valve pins are opened when injection starts. While the moulded parts continue to cool

down a holding pressure phase to compensate shrinkage follows after the injection phase with a continued, usually pressu-

re-regulatedmelttransportintothecavity(comparepicture3).Afterthemouldedparthassolidiedtosuchanextentthatno

newmaterialcanenterthecavity,theholdingpressurephasehasnishedandthemouldedpartscooldownuntiltheyreach

a safe demoulding temperature.

If a valve gate system is used the opening towards the cavity (gate) will be closed again by a movement of the valve pins

aftertheholdingpressurephasehasbeennished(comparepicture3).Ifopensystemsareused,adecompressionphase

will follow to prevent plastic melt from leaking from the gate area. While the moulded parts continue to cool down in the

cavity the injection moulding machine can prepare the melt for the next cycle. After the demoulding temperature has been

reached,theinjectionmouldopensandthesolidiedpartsareejected.

Cooling

Start of cycle

Valve gate nozzle(s)

open(s)*

Valve gate nozzle(s) close(s)*

Mould closing

Buildup of barrel

pressure

Injecting

Holding pressure

Reduction of barrel

pressure

Dosing

Mould opening,

ejecting Decompression**

20 HPS-III-Heißkanalsystem_Vorspann_BA_V-2-0_EN

Installation

5. Installation

ThefollowinginformationisintendedtohelpyouinstalltheHPSIIIhotrunnersystem.Inaddtion,theassemblystahasto

have the know-how required to install an HPS III hot runner system.

The described installation processes are examples for standard nozzles and standard systems.

Special systems may require dierent procedures! Please observe the instructions in the order specic documents.

5.1 Transport

This chapter describes how to transport a hot runner system without damaging it and how to ensure occupational safety for

thesta.

5.1.1 Safety information on transport

NOTE!

Inappropriate transport

Damage to the HPS III hot runner system.

• OnlyspeciallytrainedstaisauthorisedtotransporttheHPSIIIhotrunnersystem.

• Only use designated attachment points to attach lifting devices.

• Exercise greatest caution when transporting the HPS III hot runner system. Handle with care.

Pendular motion while lifting the hot runner systems with a lifting device (e.g. overhead crane)

Damage to the HPS III hot runner system and/or injection mould.

• Avoid pendular motions! Move HPS III hot runner system slowly and with care.

• When using the lifting device to connect heavy components avoid tilting while lifting and lowering.

WARNING! PPE

Suspended loads

Death and severe crushing of body or extremities.

• Keep clear of and do not pass under suspended loads.

• Keep clear of suspended loads while they are being transported.

• Do not touch lifting devices and lifting accessories while lifting the load.

• Only lift, transport and set down loads, if you have received appropriate training.

• Only use suitable and undamaged lifting devices and lifting accessories which

are checked regularly.

• Do not exceed the maximum load limit of lifting accessories.

Sharp edges and heavy components

• Cut injuries to body and extremities, mainly to the hands.

• Crushingofngersorhand.

Other manuals for HPS III Series

1

This manual suits for next models

10

Table of contents

Other EWIKON Control Unit manuals