4

The HPS-C-SLOT+controller is shipped

to the customer so that no setup work is

required for basic operation. Set points

in automatic and manual may be entered

and the zone will be controlled by turning

“On” the power. Many customers require

advanced features to satisfy their opera-

tion. This page will describe the basics

of “Advanced Setup”. Please note that

security level codes are not standard.

To place security on the HPS-C-SLOT+

controller you must activate security by

selecting your own personalized security

codes (network module required).

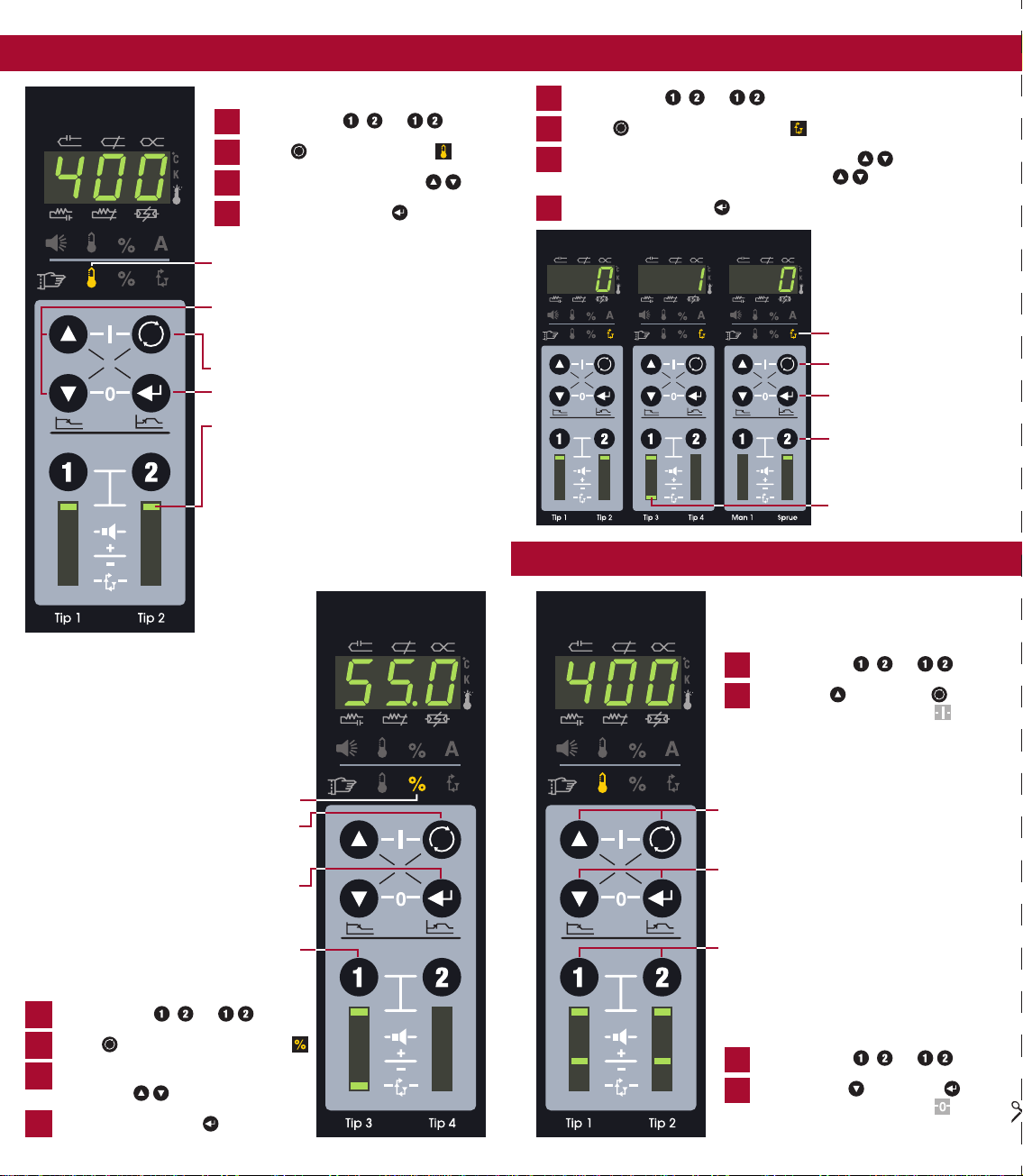

Advanced Setup Why Standby?How to Activate Alternate Standby Inputs

Why Boost?How to Boost How to View All Zones Quickly

General Troubleshooting – Turn “Off” Main Disconnect

Basic Troubleshooting

Advanced Setup Guide - Level 2 Security to Change

Advanced

setup

number

Press

“Select”

and “Enter”

together

Advanced

setup

setting

Press “Select”

and “Enter”

together

again

Toggle

between

number and

setting

Press

“Select”

to exit

advanced

setup

Alarm

status

Select

Zone

select

Select zone(s) to put into standby ,

or . Press “down” and

“select” together

The selected zone(s) will

go to the standby temperature

Hotter zones will cool to the

standby temperature

Colder zones will heat to

the standby temperature

Automatic zones = 220 ºF/104 ºC (default)

Manual zones = half of the manual set point

The outer decimal points will ash

during standby

To cancel standby,

press “down” and “select” together

The original standby source must be cancelled

to clear standby. Please reference alternate

standby inputs, shown to the right

Select zone(s) to boost ,or

Press “up” and “enter” together

Enter boost amount . Press enter

Zone(s) will boost 36 ºF/20 ºC (default)

for 120 seconds (default)

The 7 segment display will ash during boost

To cancel boost,

press “up” and “enter” together

1Tip 1 – in alarm, select zone

Select alarm status

Thermocouple open

2Tip 2 – normal operation

Zone is on, in automatic

and at or near set point

3Tip 3 – in manual,

Thermocouple may be open

Module applying a constant

% output to the heater

4Tip 4 – in automatic,

High temperature alarm

(+20 ºF/11 ºC default)

5Man 1 – normal operation

6Sprue – low alarm

Boost temporarily raises a zone(s)

temperature (typically tips) to clear

a cold slug on start up.

Some processors like to maintain a

lower set point on command for all zones

while they are working on something.

Standby switch on enclosure

(if available) all zones go to standby mode

Standby

input

• 24 or 120 VAC/VDC input

to activate

• All zones go to standby mode

(network module required)

• Standby button from

external software

• Selected zone(s) go to standby

mode (network module required)

Thermocouple pinched - The T/C is pinched

or the controller thinks it is pinched.

(Default: ≥9% output, must see +20 ºF/11 ºC

in 5 minutes). True pinch - the T/C is sensing

the temperature further away from the heat

source than intended. Without alarm, tem-

perature reads low, controller applies power,

runaway heat.

Thermocouple (T/C) open - the T/C connection

is broken, follow general troubleshooting.

Open heater - The heater connection is broken,

follow general troubleshooting.

Shorted heater - The heater is shorted or

exceeds the maximum rating of the module,

follow general troubleshooting.

Open fuse - fuse on module bad. Turn “Off” main

disconnect. Remove top cover, locate module,

check all fuses (4 per module, 2 per zone).

Thermocouple reversed – The T/C connection is

wired + to - at some point. Visually inspect each

connection. Make sure that only wires

of the same colour are connected.

Critical over temperature – The temperature

of a zone exceeded the alarm limit. (Default:

779 ºF/415 ºC). Both zones on the module

shut “off” automatically. To clear the alarm,

select alarm status and press enter. Noted by

vertical indicator segment.

Uncontrolled output – The module has an

unregulated output. Both zones on the module

shut “off” automatically. To clear the alarm, select

alarm status and press enter. Noted by vertical

and horizontal indicator segment (shown).

Over-Voltage – The module line

voltage exceeded 20 VAC for

1 minute (informational only).

1Check resistance from pin to pin, at the mold. T/C should read 3 – 50 ohms at room

temperature. Heater should read greater than 16 ohms. If there is no continuity

(open line) = broken connection, open heater or open T/C.

2Check resistance from pin to ground, at the mold. Heaters only – no continuity

(open line) = good. Some resistance is bad, heater shorted.

3Reattach the cable to the mold, detach the cable from the controller.

Check resistance from pin to pin on the cable. T/C should read 3 – 50 ohms at

room temperature. Heater should read greater than 16 ohms. If there is no continuity

(open line) = broken connection, open heater or open T/C. The connection is broken

in the cable set or the connectors/pins are not making contact.

4Reattach the cable to the mold, detach the cable from the controller.

Check resistance from pin to ground on the cable. Heaters only – no continuity

(open line) = good. Some resistance is bad, heater shorted. The wires are either

shorted in the cable set or the connectors are shorted to ground.

5At this point if everything is ne, the problem is in the controller. (1) turn “Off”

main disconnect, (2) locate problem module, (3) check fuses on module,

(4) swap bad module into a known good location, (5) turn “On” main disconnect,

(6) test the zone. If the problem follows the module = bad module. If the alarm

stays with the original zone, the problem is between the module and the

connectors on the rear of the enclosure.

6If the problem is not explained, or you need spare parts please contact:

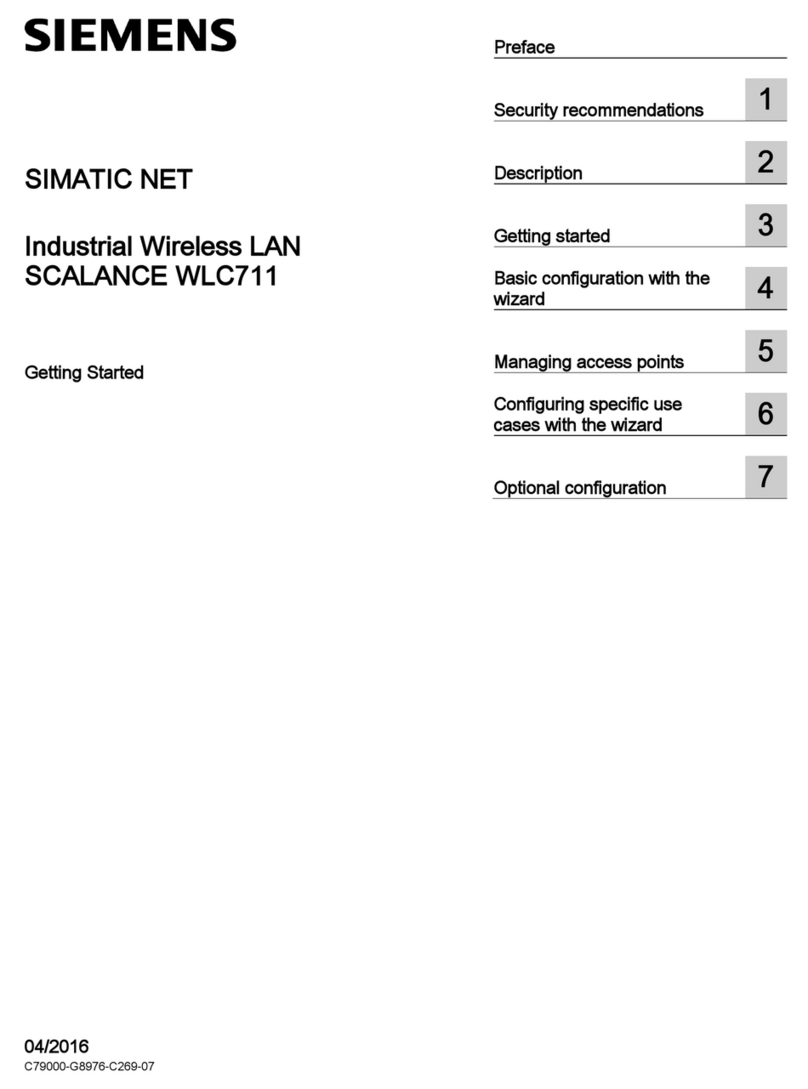

1

1

2

3

3

2

13

13

12

12

14

14

10

10

11

11

9

9

5

5

4

4

7

7

6

6

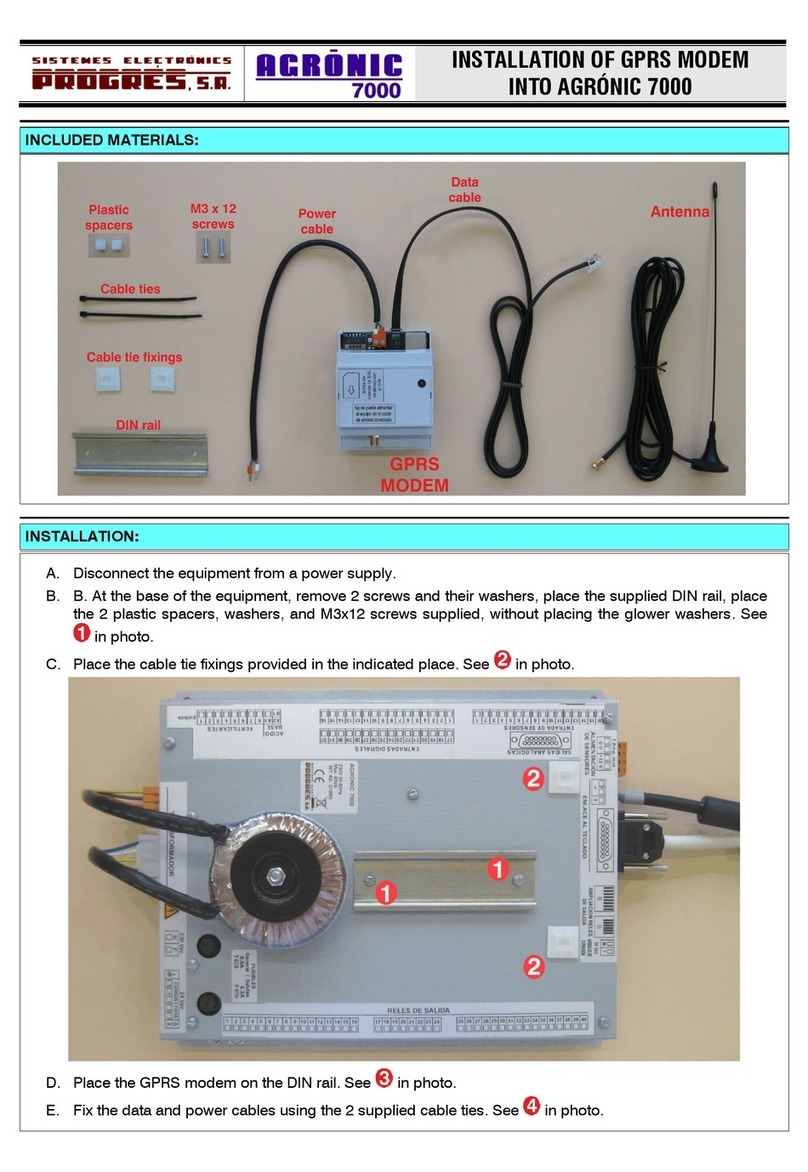

Output module

Module thermocouple/

communications cable

Module power input/

output connector

(base of module)

Input power cable

Main disconnect (circuit breaker)

Thermocouple input connector

Power output connector

Auxiliary input/output connector

Enclosure link connector

Communications port

Ground stud

Fan

System wide standby switch

(on front)

Capacitors

# Limit (default) Explanation

(0) 0 – 4 (0) Power Priority™. 0 = (off). 1 – 4 = increased smoothing of power output. A = Power Priority™ is active (setup number)

(1) 0 – 999 (0) * Reset advanced setup to default values – enter 321; press enter to conrm

(2) 0 – 100 ºF/55 ºC (20 ºF/11 ºC) Temperature deviation alarm set point (individual)

Actual temperature activates individual zone alarm at this amount +/- set point

(3) -31 to 27 (0) Control algorithm adjustment (individual). 0 = auto selection. To view actual tuning value select code 4

Manual Selections: 10 to 17 fast tuning with increasing lag. 20 to 27 slow tuning with increasing lag

-17 to -10 fast manifold tuning with increasing lag. -27 to -20 very fast tuning with increasing lag.

-30 and -31 ultra fast low mass tuning. P = auto selection tune performed (setup number)

(4) -31 to 27 (none) Algorithm set point (view only). View auto tuning selection or manual tuning value

(5) 0 – 932 ºF/500 ºC (220 ºF/104 ºC) Standby set point (individual). When standby is activated, all automatic zones selected will control to this set point

Entering “1” will inhibit the module (both zones), when activated the relays will open, turning “off” the module power

(6) 0 to 54.0 minutes (5.0) T/C pinched detection time (individual)

9+% output, 20 ºF/11 ºC in 5 minutes – default. Change alarm timer amount. 0 = disabled

(7) 32 – 999 ºF/0 – 537 ºC (779 ºF/415 ºC) * Critical over temperature alarm. To clear the alarm, select alarm status and press enter

If this temperature is exceeded for seconds both zones turn “Off”. Max. 999 ºF (537 ºC) = disabled

() 32 – 932 ºF/0 – 500 ºC (752 ºF/400 ºC) * Automatic set point limit. The maximum set point an operator can enter in automatic on both zones

(9) 0 – 99.9% (99.9%) * Manual set point limit. The maximum set point an operator can enter in manual on both zones

(10) 0 – 999 ºF/537 ºC (100 ºF/55 ºC) * Boost limit. The maximum amount of degrees an operator can raise or lower the zone(s) during a boost

(11) +/-99 ºF/55 ºC (36 ºF/20 ºC) * Initial boost set point. Amount of degrees added to automatic set point, module adjustable within the boost limit

(12) 0-999 seconds (120) * Boost time set point. The amount of time boost is active

(13) 0 or 1 (0) * Degree F or C selection. 0 = “degree F”; 1 = “degree C”

(14) 0 or 1 (0) * Type J or K thermocouple selection. 0 = “type J”; 1 = “type K”

(15) 0 or 1 (0) * Zone power status on power up. 0 = all zones turned “Off”; 1= zones “On” when shut down last, stay “On”

†(16) 0 or 1 (0) * Enable slaved power-up. 0 = “Off”; 1 = “On”. All zones heat within 20 ºF/11 ºC of one another until set point

†(17) 0 – 999 (none) * Security code level 1. You must be in level 2 to change. Refresh procedure available, call EWIKON

†(1) 0 – 999 (none) * Security code level 2. You must be in level 2 to change. Refresh procedure available, call EWIKON

(19) - - - Output module controller software version/revision number (display only), select zone, version/revision displayed

(20) - - - Temperature controller software version/revision number (display only), select zone, version/revision displayed

(21) 0 (0) LED test. To activate enter 0. Turns “On” all LED’s for troubleshooting

†(22) 000 – 999 (level 2) Security level indicated. 0 = lockout; 1 = operator; 2 = supervisior. 0 - enter, drops one level

Elevate one security level at a time with your customized code

† Network module required * Network module distribution or value applies to both zones on the module

EWIKON Heißkanalsysteme GmbH

Siegener Straße 35, 35066 Frankenberg

Tel: +49 (0)64 51/50 10 ∙ Fax: +49 (0)64 51/50 12 02

Set individually by zone 1

2 3

G