EWIKON pro CONTROL basic User manual

Hot runner controllers

Operating manual

pro CONTROL BASIC Operating manual

Page 2

Table of contents

List of Figures ..................................................................................................................... 4

1Introduction............................................................................................................ 5

1.1 Symbols used: 5

1.2 Notations 5

2Safety instructions ................................................................................................ 5

2.1 Intended use 5

2.2 Information for operators and users 5

3Structure and functionality ................................................................................... 6

3.1 General information 6

3.2 Structure 6

3.2.1 Pro CONTROL BASIC 2, 6 and 12 7

3.2.2 Operating front 7

3.2.3 LED-strip 7

3.2.4 Power card 8

3.2.5 Fuses 8

3.2.6 Notification contact / Digital input 8

3.2.7 Identification on the controller 8

3.2.8 Wiring of the plug systems 9

4Commissioning.....................................................................................................10

4.1 Electrical connection 10

4.1.1 Mains power supply 10

4.1.2 Mains connection 10

4.1.3 Connection of the mould 10

4.2 Operating and display elements 11

4.2.1 Display elements 12

4.2.1.1 Status display...........................................................................................12

4.2.1.2 Zone display.............................................................................................12

4.2.2 Operating elements 13

4.2.2.1 Main switch ..............................................................................................13

4.2.2.2 Soft keys ..................................................................................................13

5Operation ..............................................................................................................15

5.1 Zone selection 15

5.1.1 Selecting a zone 15

5.1.2 Selecting multiple zones 15

5.1.3 Selecting several consecutive zones 15

5.1.4 Selection of all zones 16

5.2 Operating mode 16

5.3 Setpoints 17

5.4 Output rate 18

5.5 Controller outputs 18

5.6 Parameter 19

5.6.1 Zone parameter 19

5.6.2 System parameter 20

5.7 Boost 21

5.8 Standby 21

6Warning and error messages...............................................................................22

6.1 Warnings 22

6.2 Alarms 23

pro CONTROL BASIC Operating manual

Page 3

7Functions and parameterization..........................................................................26

7.1 Basic settings 26

7.1.1 Access authorizations 26

7.1.2 Fahrenheit display 27

7.1.3 7.1.3 Thermocouple type 27

7.2 Control behavior 28

7.2.1 Control parameters P I D 28

7.2.2 Output level 28

7.2.3 Maximal output level 28

7.3 Heating 29

7.3.1 Softstart (Gentle heating) 29

7.3.2 Compound heating 29

7.4 Hot runner monitoring 30

7.4.1 Temperature monitoring 30

7.4.2 Average output level 32

7.4.3 Broken sensor 32

7.4.4 Heating current monitoring 32

7.4.5 Triac monitoring 33

7.5 Special functions 33

7.5.1 BOOST 33

7.5.2 STANDBY 34

7.5.3 Load detection 34

7.5.4 Default parameter 34

8Parameter overview..............................................................................................35

8.1 Zone parameter 35

8.2 System parameter 36

9Technical data.......................................................................................................37

10 Spare parts + accessories....................................................................................38

11 Appendix ...............................................................................................................39

11.1 Terminal bridges of the star-delta supply 39

11.1.1 Terminal jumpers in star network (state at delivery!) 39

11.1.2 11.1.2 Terminal bridges in delta network 39

11.2 Notification contact / Digital input 40

pro CONTROL BASIC Operating manual

Page 4

List of Figures

Figure 1 – pro CONTROL BASIC front panel 7

Figure 2 – Type label 8

Figure 3 – Wiring of plug systems 9

Figure 4 – Operating and display elements 11

Figure 5 – Zone display 12

Figure 5 – Temperature monitoring 31

Figure 6 - Star-network 39

Figure 7 - Delta-network 39

pro CONTROL BASIC Operating manual

Page 5

1 Introduction

1.1 Symbols used:

Caution/Warning Information on possible damage to property or personal injury

Information Important information

1.2 Notations

Menu structures between words are indicated by the >symbol and depicted in the same way

on the device.

Interaction with the operator is denoted by the finger symbol.

2 Safety instructions

Please read this document completely and carefully before commissioning or

operating the device.

2.1 Intended use

The hot runner controller is used to control the temperature of heating circuits and is designed

for use under precisely defined conditions, such as supply voltage and temperature. The op-

erator must therefore ensure that the controller is only used under operating conditions that

comply with the technical data. The manufacturer is not liable for damage resulting from non-

compliance with the intended use.

The hot runner controller is not suitable for use beyond the limits defined in the technical data

and during its design. In addition, the use of spare parts from third parties and the implemen-

tation of non-described maintenance activities constitute failure to comply with the intended

use.

Alterations, conversions and other modifications are made exclusively at the operator’s own

risk and could pose safety hazards. The manufacturer and distributor of this device cannot be

held liable for direct and indirect damage resulting from improper handling or treatment.

2.2 Information for operators and users

The controllers are operated on the low-voltage network. The relevant safety regulations must

be observed when connecting up the controller and performing maintenance on it. In addition,

the local and general safety regulations must be observed for its installation and operation.

The operator is responsible for compliance with these regulations. The operator must addition-

ally make this documentation available to the user and provide instruction in the correct

operation of the device. The user must be familiar with this documentation. In order to ensure

reliable and safe operation, the individual user is required to observe the information and warn-

ings.

The controllers may only be brought into operation by authorized specialist personnel. Under

the terms of these operating instructions, specialist personnel are persons who can recognize

and assess the dangers associated with the work entrusted to them on the basis of their spe-

cialist training, their experience and their knowledge of standards.

pro CONTROL BASIC Operating manual

Page 6

The device is checked carefully prior to delivery and has passed the tests specified in the test

plan for its production, in conformity with the manufacturer’s valid quality guidelines. To prevent

any damage to the controller, it must be transported and stored in the correct manner. Further

safety-related notices are marked in the individual sections of this documentation.

3 Structure and functionality

3.1 General information

The pro CONTROL BASIC hot runner controllers are especially suited to the temperature con-

trol of hot runner molds on injection molding machines. In use, the controllers are connected

directly to the mold via cables.

During operation, the hot runner controllers deliver electric current to the heating units for an

injection mold. The so-called heating current leads to an adjustable temperature increase in

the heating units and hence in the mold. Continuous temperature monitoring takes place in

parallel via connected thermocouples. In the event of deviations between the actual tempera-

ture recorded and the temperature set on the hot runner controller, the heating current is

automatically adjusted until the two temperatures are identical.

The controllers are available in different variants. These differ solely in terms of the number of

control circuits that are possible – which are also referred to as heating zones. Depending on

the variant, hot runner controllers are available with 2 to 12 heating zones (in steps of 2).

3.2 Structure

Housing front: The pro CONTROL BASIC hot runner controller is operated from the housing

front. In addition to the main switch for switching on and off, the controllers have 12 keys for

convenient operation. Furthermore, the front contains all visualization elements. The setpoint

and actual values of the individual zones are displayed via 7-segment displays. If required, the

display can be switched over to heating current and output rate. In addition, status LEDs pro-

vide information about operating modes and messages of the individual zones. The controller

status is visualized in color via a led strip visible from afar. In control mode, without a current

error or warning message, this display lights up green. In case of a warning or alarm, the

display changes to yellow or red (traffic light status). This allows a quick assessment of the

controller status even from a distance. A detailed description of the display and operating func-

tions can be found in chapters 4.2 and 5.

Back of housing: All connections are located on the back of the housing. In addition to the

connecting cable, which is used for connection to the supply voltage, the controllers offer a

further connection for a potential-free alarm contact and a 24V digital input for external control

of the set-back operation. The connection to the hot-runner mold is established via plug-in

systems.

pro CONTROL BASIC Operating manual

Page 7

3.2.1 Pro CONTROL BASIC 2, 6 and 12

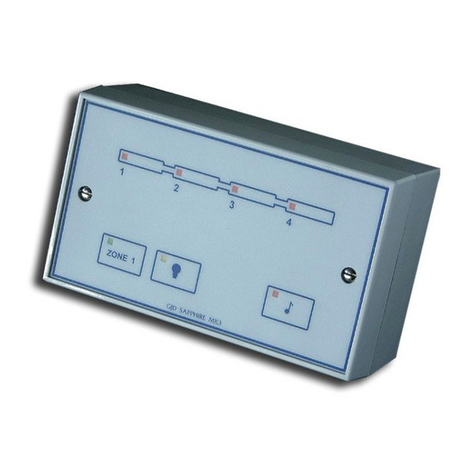

Figure 1 – pro CONTROL BASIC front panel

3.2.2 Operating front

The convenient operation of the pro CONTROL BASIC hot runner controller is carried out on

the front panel (Figure 1) via 12 keys. The front also contains all visualization elements. The

setpoints and actual values of the individual zones are displayed via 7-segment displays. If

required, the display can be switched over to heating current and output level.

3.2.3 LED-strip

The status of the controller is displayed in color via a strip of LEDs visible from afar. This

enables a quick assessment of the current controller or tool status.

pro CONTROL BASIC Operating manual

Page 8

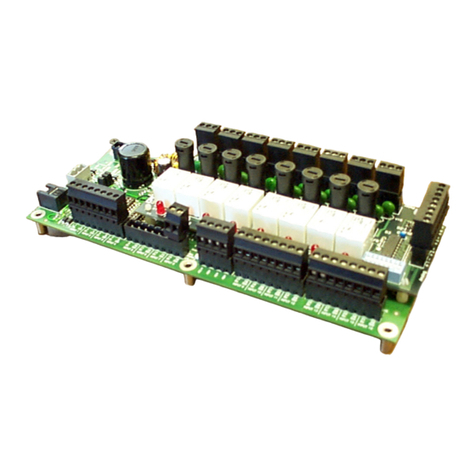

3.2.4 Power card

Inside the housing there are power cards which control connected heaters and record meas-

ured temperatures of the thermocouples. Each zone is switched individually via relays on the

power cards, so that individual zones can be switched off separately and a seamless produc-

tion process is always guaranteed.

3.2.5 Fuses

The controllers have three different types of fuses inside the housing. Each zone has two fuses

on the power card. One fuse is used to protect the load output (fuse in the fuse holder below

the heat sink). The second fuse, on the other hand, is required for use in delta networks. In

addition, another control fuse is located in a terminal on the bottom of the housing.

3.2.6 Notification contact / Digital input

The pro CONTROL BASIC hot runner controllers have a potential-free message contact and

a digital control input, which are brought out via a 7-pin plug on the rear of the unit. A contact

diagram of the built-in plug is given in chapter 11.2.

The control input is PLC-compatible, i.e. it operates over a voltage range of 13…30 VDC with

a typical current consumption of approx. 8.5 mA. The controller can be switched to standby

mode via the input. The controller remains in this mode as long as the signal is present. Deac-

tivation via the standby button on the device is not possible.

The potential-free notification contact is used to transmit the controller status to an injection

molding machine. When warnings or alarms occur, the contact opens. Accordingly, the contact

is normally closed (NC) and opens as soon as an alarm or warning is present. Chapter 6

provides an overview of the behavior when messages occur.

3.2.7 Identification on the controller

The type label is mounted on the side of the controller housing. It contains the type designation

with the number of zones, the electrical connection data and the manufacturer’s data.

Typ / Type

Pro Control Basic 6

S/N

2009

1

Prod. KW /

CW

03 / 2020

Code

E7H1-AKB4-C1Z6-87A

Versorgung / Supply

●

Y 230/400 VAC 50/60 Hz

○

∆230 VAC 50/60 Hz

Belastung / Load

3x 16 A

Schutzart / IP Class

IP20

Temp. Fühler / Sensor

Fe-CuNi Type J

EWIKON Heißkanalsysteme

GmbH

Made in Ger-

many

Meldebuchse / Message Socket

Pin

1+3

Relay Sammelmeldung / collective message

Pin

2+6

Steuereingang / Digital input

Figure 2 – Type label

pro CONTROL BASIC Operating manual

Page 9

3.2.8 Wiring of the plug systems

The plugs for connecting the temperature sensors and heating elements to a hot runner are

available on the rear of the controller. The customer-specific wiring plan for the plug systems

is located on the side of the controller housing (see Figure 3 for an example).

Figure 3 – Wiring of plug systems

pro CONTROL BASIC Operating manual

Page 10

4 Commissioning

4.1 Electrical connection

Important! Before the device is connected to the supply voltage, a check must first

be performed to ensure that the mains electricity conditions comply with the spec-

ifications on the type plate.

The electrical connections must be performed by a qualified electrician. Commis-

sioning and operation while the controller is running are only to be carried out by

authorized qualified personnel!

Switching off all the outputs or individual zones will not protect any of the outputs

against hazardous voltages. Before working on the connected heating elements,

the associated connections must be unplugged, or the entire device disconnected

from the mains power.

Before the device is opened, it must be disconnected from the mains power!

4.1.1 Mains power supply

Before connecting the device to the supply voltage, a check must be conducted to ensure that

the mains electricity system is correct. The hot runner controllers are prepared by default for

operation in a star network (3x400VAC + N + PE) but can also be operated in a triangular

network (3x230VAC + PE). For operation in a triangular network without a neutral conductor,

it is essential to follow the local regulations for the installation of electrical systems. The termi-

nals in the controller must be bridged accordingly for use in a star or triangular network. Annex

11.1 contains a clear terminal connection diagram.

4.1.2 Mains connection

To ensure correct operation, the hot-runner controller is connected to the low-voltage mains

by using the connecting cable connected to the unit.

4.1.3 Connection of the mould

To connect the individual control zones to the corresponding injection mold, use must be made

of appropriate leads for the sensor and heating unit connection.

Please note: it must always be ensured that the internal wiring, the wiring of the

cable set and the wiring in the mold are suitably coordinated with each other.

Important! To exclude any effects of potential shifts, the injection molds that are

connected up must be properly earthed in all cases.

pro CONTROL BASIC Operating manual

Page 11

4.2 Operating and display elements

The operation as well as all display elements of the hot runner controllers is carried out via

the soft keys on the front of the housing. The following illustration shows the front view of a 6-

zone controller, from which all operating and display elements are shown.

Figure 4 – Operating and display elements

pro CONTROL BASIC Operating manual

Page 12

4.2.1 Display elements

4.2.1.1 Status display

The status of the controller is indicated by a LED strip in the front. In control mode, this indicator

lights up green. In case of a warning or alarm, the display changes to yellow or red (traffic light

status).

Green signals all is well. The controller operates in

normal mode.

Yellow indicates warning messages that indicate a

deviation from the normal state.

Red indicates alarms. Depending on the fault, outputs

of corresponding zones are also deactivated.

4.2.1.2 Zone display

Each heating zone has two 7-segment displays and four LEDs for status indication. The 7-

segment displays show either the setpoint and actual value or the heating current and degree

of operation. In addition, the four LEDs can also be used to display the states shown below.

Figure 5 – Zone display

pro CONTROL BASIC Operating manual

Page 13

4.2.2 Operating elements

4.2.2.1 Main switch

The main switch is located on the back of the hous-

ing. The switch must be operated to switch the

controller on and off.

4.2.2.2 Soft keys

Operating element

Description

Selection of zones

Each time the arrow keys are pressed, the display jumps

one zone further.

Change in value

Confirm button / Acknowledge error

Boost

Standby

Change operating mode

Parameterization / System information

Basic view: Display of all zones / Reject input

pro CONTROL BASIC Operating manual

Page 14

Shift key for the zone display

Display: actual value (ACT) and setpoint (SET)

Display: Current (I[A]) and output level (Y[%])

Activating / deactivating the controller outputs

Temperature unit of the display

pro CONTROL BASIC Operating manual

Page 15

5 Operation

5.1 Zone selection

5.1.1 Selecting a zone

Step

Operation

Description

1.

Each time the arrow keys are pressed, the display jumps

one zone further.

All other zones that are not selected are hidden.

5.1.2 Selecting multiple zones

Step

Operation

Description

1.

Select zone

2.

Press confirmation key

... repeat 1. and

2.

To select any zones

5.1.3 Selecting several consecutive zones

Step

Operation

Description

1.

Selection of the 1st zone to be selected

2.

Keep confirmation key pressed

3.

With each keystroke a zone is added to the selection

4.

Release the confirmation key

pro CONTROL BASIC Operating manual

Page 16

5.1.4 Selection of all zones

Step

Operation

Description

1.

The basic rule is:

In the basic view, all zones can be operated and are virtu-

ally already selected for a value change.

"The Zones that you see can also be operated."

5.2 Operating mode

Step

Operation

Description

1.

Select the zone(s) as described in 5.1

2.

Selection of the operating mode

The display switches between

Manual mode

Control mode

Zone off

Note: The display flashes and must be confirmed within 5

seconds.

3.

Confirm the entry

The display stops flashing

4.

Press the Home button to return to the overall display of all

zones.

pro CONTROL BASIC Operating manual

Page 17

5.3 Setpoints

Step

Operation

Description

1.

Select the zone(s) as described in 5.1

2.

Use the buttons to set the setpoint to the desired value.

The display flashes, indicating that the value has not yet

been accepted.

3.

Confirm the entry

The display stops flashing

4.

Press the Home button to return to the overall display of all

zones.

pro CONTROL BASIC Operating manual

Page 18

5.4 Output rate

Step

Operation

Description

1.

Select the zone(s) as described in 5.1

2.

Selection of the operating mode.

Operate until manual mode is displayed.

3.

Confirm selection

4.

Switching the zone display to

Current (I) and output rate (Y)

5.

Use the buttons to set the output level to the desired value.

The display flashes, indicating that the value has not yet

been accepted.

6.

Confirm the entry.

The display stops flashing.

7.

Press the Home button to return to the overall display of

all zones.

5.5 Controller outputs

Step

Operation

Description

1.

Activating / deactivating the controller outputs either

switches on all heating zones in control mode and manual

operation or switches off all zones.

pro CONTROL BASIC Operating manual

Page 19

5.6 Parameter

5.6.1 Zone parameter

Step

Operation

Description

1.

Select the zone(s) as described in 5.1

2.

Press key to change to the parameterization level

3.

Select parameter.

Each time the arrow keys are pressed, the parameter is

incremented or decremented.

4.

Use the buttons to set the value of the selected parameter

to the desired value.

Note! Password entry required before parameterization

(default "22"). Set the current password with the keys and

confirm. The parameter can then be changed

The display flashes. This means that the value has not yet

been accepted.

5.

Confirm the entry.

The display stops flashing.

6.

Press the Home button to return to the overall display of

all zones.

pro CONTROL BASIC Operating manual

Page 20

5.6.2 System parameter

Step

Operation

Description

1.

… 2s

Press and hold for 2s.

The display changes to the system parameter level.

This level contains system information that cannot be

changed:

System Information

However system parameters and system functions can

be changed. The representation is made as or

:

System Parameter

System Function

2.

Select system parameters.

3.

Set the value of the selected parameter to the desired

value using the arrow keys.

Note!

Password entry required before parameterization

(default "22"). To do this, set the current password with the

keys and confirm. The parameter can then be changed

The display flashes, indicating that the value has not yet

been accepted.

Example: System parameter with value 500

4.

Confirm the entry.

The display stops flashing.

5.

Press the Home button to return to the overall display of

all zones.

Other manuals for pro CONTROL basic

1

Table of contents

Other EWIKON Controllers manuals