EWIKON HPS-C-E User manual

Valid for

item numbers:

66010.001 (1-zone)

66010.002 (1-zone)

67010.024 (4-zone)

67010.026 (6-zone)

67010.028 (8-zone)

67010.012 (12-zone)

HPS-C-E

Hotrunner Controllers

Operating manual

2

Analog control system 5 V

Contents

General safety notes 3

General technical data 3

Dimensions/Weights/

Connection and Power 4

Summary 5

Operation 6

Components of

the controllers 7

Start up 10

Terminal pin-out 10

Description of faults 13

3

Analog control system 5 V

General safety notes General technical data

Disconnect before working on the controller.

Mains switch most be OFF and plug disconnected.

Connection, repair and maintenance by

qualified staff only!

Before start up the controller must be checked

according to EN 60204-1:1992 or general rules

of engineering.

The power supply of the controllers should be

connected with the heating of the machine.

If the heating is switched off automatically, the

hotrunner system is likewise switched off then.

The connected parts may be hotter. Please take

all necessary precautions before starting the system.

The fan, air ducts and electronic components

should be cleaned in intervals of 3 to 6 months

(depending on pollution).

Cables, plugs and contact springs should be

checked and - if necessary - cleaned or

exchanged periodically

Field of application:

This EWIKON controller can operate our

5V hotrunner systems in dry industrial rooms.

CE declaration

The contriollers correspond to the

following standards:

DIN EN 60204-1 (11/98)

DIN EN 60742 (09/95)

EN 50081 and 50082

General technical data:

230/400V +6 / -10 %, 50 / 60 Hz

Protective system:

IP 33

Power output:

5V AC / 125A each zone

Thermocouple:

FeCuNi Type L

Decrease:

With a potential free ( NO )

relay contact in the machine.

Malfunction:

When there is a malfunction of the hotrunner system,

the cycle can be interrupted by a potential free

contact ( relay 250V/2A).Anoptical or acoustic

alarm announces the malfunction.

Temperature control:

PID with soft start:

The optimum control characteristic is achieved

with a phase proportioning control.

Operating range:

Amperage control: 10 - 125 A

Decreasing: 0 - 49 A

Thermocouple control:

90 - 399 °C

Decreasing: 0 - 99 °C

Environmental conditions:

0-50°C

Fault code

1 = Operating fault

2 = Excess current

3 = Disconnection

Broken fuse

4 = Triac defect

6 = Thermocouple defect

4

Analog control system 5 V

Dimensions, Weights,

Connection values, Power

Zone No. a mm b mm c mm kg Power

1 66010.001... 365 180 435 14 625 VA

1 66010.002... 365 180 435 14 625 VA

4 66010.024... 315 613 570 55 2.50 kVA

6 67010.026... 315 1015 570 82 3.75 kVA

8 67010.028... 315 1015 570 100 5.00 kVA

12 67010.012... 620 870 570 152 7.50 kVA

Version Mains wiring Power supply Mains plug

D - 230 Volt Schuko 16A

E - 240 Volt Schuko 16A

J - 208 Volt without

U - 240 Volt USA - Standard

B - 230 Volt without

Version Mains wiring Power supply Mains plug

D Y Star 230 Volt CEE16A

E Y Star 240 Volt CEE16A

J∆Delta 208 Volt without

U∆Delta 240 Volt USA - Standard 20A

B∆Delta 230 Volt without

Type:67010.026... / 67010.028... / 67010.012...

Type: 66010.001... / 66010.002... / 67010.024...

5

Analog control system 5 V

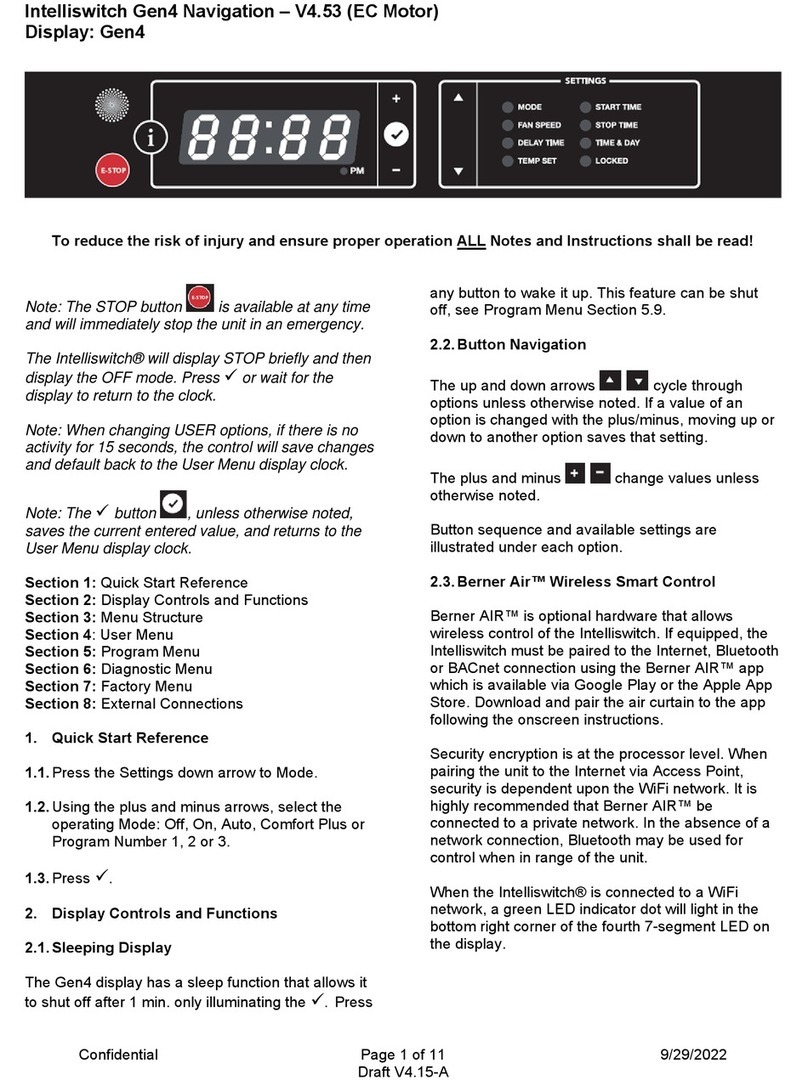

Summary

bt007-11

6

Analog control system 5 V

Operation

bt007-12

Combined module 60040.009

01: Green control light:

Operating indicator

02: Red control light:

Module defective

03: Red control light:

Defect in one ore more

control modules

04: External signal source

for decreasing current

to all control modules.

When active the red

light in the push button

is on.

05: Push button for

decreasing

06: Output fault

SR-Module 60040.011

01: Digital indicator of actual temperature

in amperes or °C

02: Set-value switch for setting of requirement

current in A or temperature in °C.

03: Set-value switch for adjustment of

current decreasing value in ampere

or temperature in °C

04: ON/OFF switch to separate the

SR-modules from the power modules.

05: Green control light as operation indicator

for mode “amperage control”. Input and

output data in A (Ampere).

06: Green control light as operation indicator for

mode “themocouple control”. All input and

output data in °C. When switching the

module on, the display flashes until the set

temperature is reached. Production can be

started after this optimization phase only.

07: Red control light as fault indicator. Fault

code appears in left portion of the display

(No.1):

1. Operating fault

2. Excess current

3. Disconnection

4. Triac defect

6. Thermocouple

defective

If during production a

thermocouple fails, the

module shows “fault”.

By switching the module

off, setting a current

value, and switching

the module on again,

production can continue.

The hotrunner system

continues operation in

“amperage control”

mode.

bt007-13

7

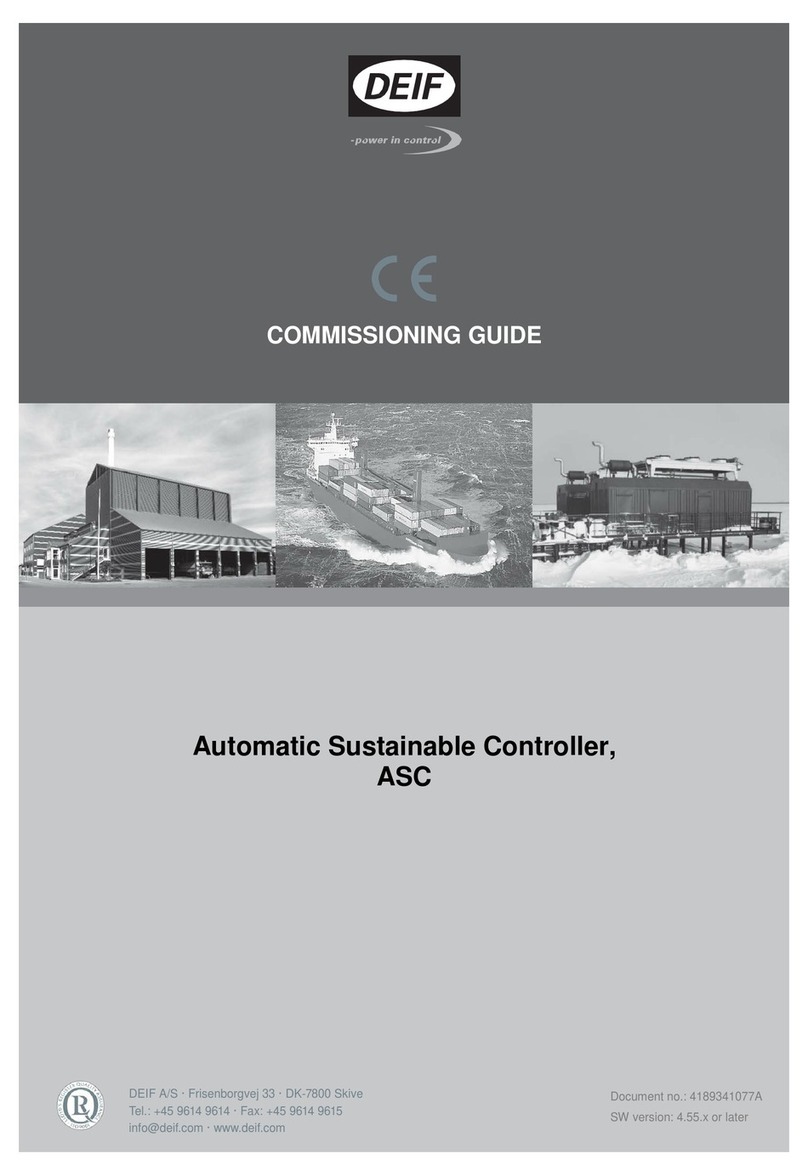

Analog control system 5 V

Components of the controllers

bt007-05

bt007-14

01: Combined module

02: SR-modules

03: Binding post 5V

connection

04: Thermocouple

connection zone 1

05: Main switch

06: Fuse T10A

07: Power cable

08: Circuit breaker

09: Thermocouple

connection

Zones 1-8

8

Analog control system 5 V

Components of the controllers

bt007-15

01: Combined module

02: SR-module

03: Binding post 5V

connection

04: Thermocouple connection

Zone 1

05: Main switvh

07: Power cable

08: Circuit breaker16 A

09: Thermocouple connection

Zones 1-8

9

Analog control system 5 V

01: Combined module

02: SR-module

03: Binding post 5V

connection

04: Thermocouple

connection zone 1

05: Main switch

09: Themocouple

connection

Zones 1-12

Circuit breaker is

positioned inside

the controller.

Remove top of case.

10

Analog control system 5 V

Start up

Hotrunner 5 V

Connect the thermo collective cable or the

thermo cable for zone 1.

Connect power cable.

Check that all connections are fastened tight.

Otherwise the components can be damaged

due to the high output current.

Heat up each zone seperately for a short while

to check if the power- and thermocouple zones

are assigned properly.

For operation of modules see page 6.

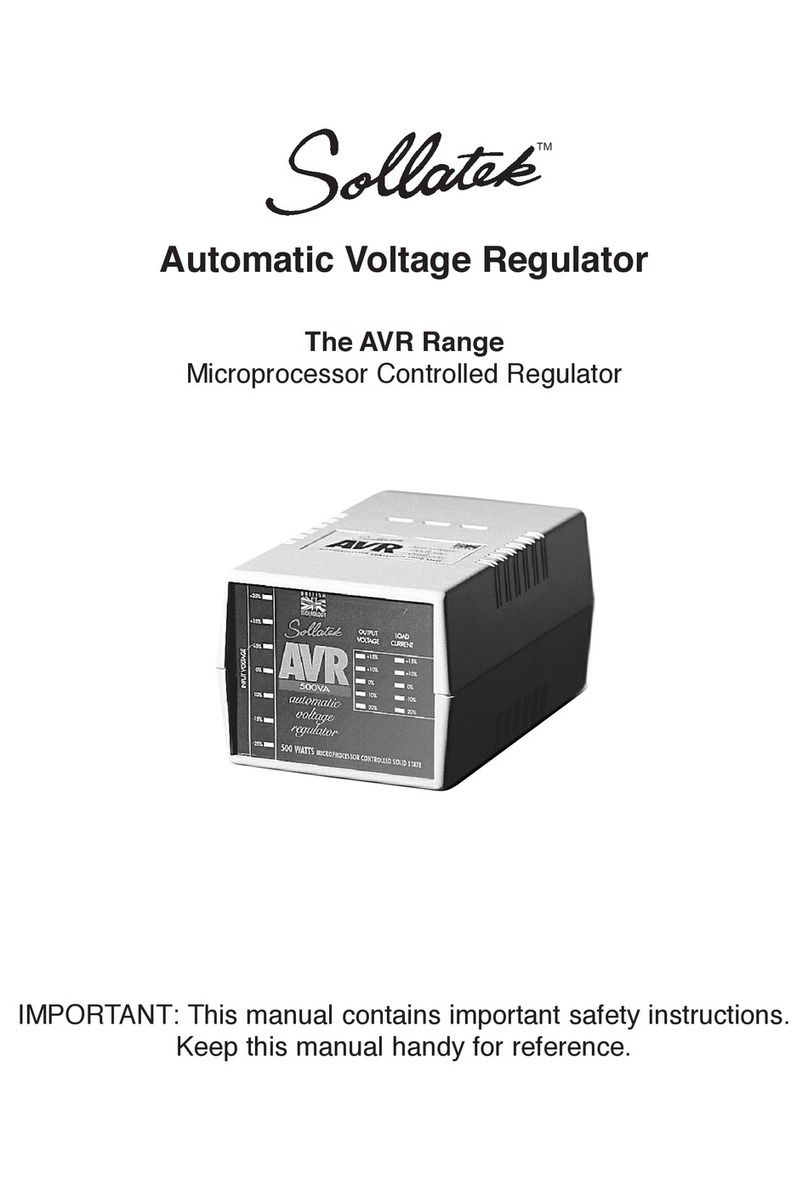

Terminal pin-out

bt007-17

Power case

Analog control system 5 V

Zone + red - blue

1 1 + 9

2 2 + 10

3 3 + 11

4 4 + 12

5 5 + 13

6 6 + 14

7 7 + 15

8 8 + 16

9 17 + 25

10 18 + 26

11 19 + 27

12 20 + 28

Thermo connection

Plug with pin insert

bt006-09

Pin assignment of the

socket-error signal

1 (-) blue (Konstantan)

2 (+) red (Iron)

bt007-18

Connection

11

Analog control system 5 V

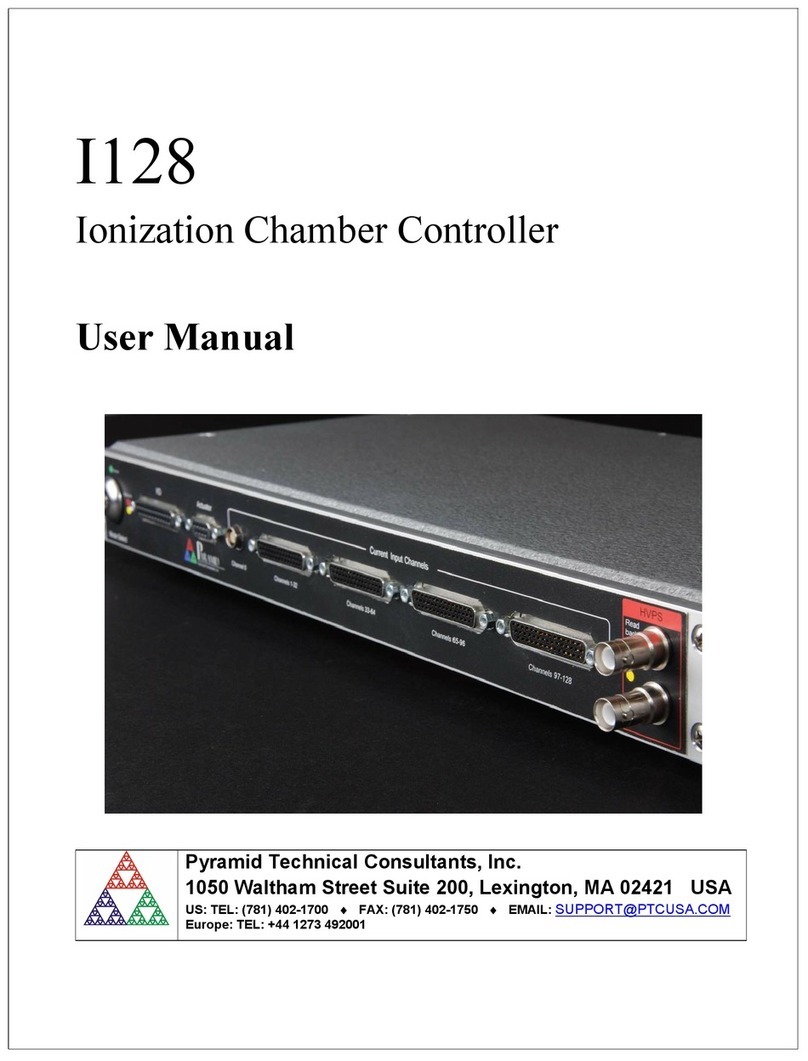

12

Pin assignment

of decreasing socket

Pin assignment

of the socket-error signal

bt002-05 bt002-06

A: Decreasing socket

B: Machine or

C: Limit switch

1 + 2 : Potential free (NO)

relay contact of the

machine or limit

switch with NO

contact.

3: Vacant

In case of malfunction of the machine the

decreasing of all zones can be activated.

Decreasing is active as long as the contact

remains closed.

Attention!

Do not connect other voltage.

Connecting cable external decreasing,

lenght 3m, with plug (No. 10694)

A: Socket-error signal

Potential free (NO + NC)

contact of the single zone

controller. Max. power 2A/250V

1 + 2 : Closed in case of fault, hotrunner “OFF”

or power supply failure.

2 + 3: Closed under all other

operating conditions

In case of a malfunction of the hotrunner system

and in case of disconnection from mains a signal

can be given to the injection moulding machine

(e.g. machine STOP or an optical or acoustical

signal).

Connecting cable fault registration, lenghts 3m,

with socket (No. 10693)

Analog control system 5 V

13

Fault description

In case the module recognizes a fault, the zone

or the controller is switched off.

The fault code is displayed in the left segment

of the actual value display.

Fault codes:

Display in the SR-module (left display segment)

1 Operating fault

Check setting values

2 Excess current

Check connections and

cables

3 Open circuit or fuse

Check cable and electrical

connection, check fuse

4 Triac defect

Exchange module

6 Thermocouple defective

Check thermocouple and

connections

EC - Declaration of Conformity

We hereby conrm that the products described below conform to the essential protection requirements

of the following European Directives

2006/95/EC „Low Voltage Directive“

and

2004/108/EC „EMC directive“

with respect to their design type. This requires that the products are used for their intended purpose

and that the assembly and operating instructions are observed.

Alterations made to the product will void the declaration of conformity.

Producer: EWIKON Heißkanalsysteme GmbH

Siegener Straße 35

35066 Frankenberg / Germany

phone: +49 (0) 6451 / 501-0

Product: HPS-C-E hotrunner controllers for the operation

of 5 V hotrunner systems - analogue control system

Type: 66010.001 ; 1-zone controller without combined module

66010.002 ; 1-zone controller with combined module

67010.024 ; 4-zone controller

67010.026 ; 6-zone controller

67010.028 ; 8-zone controller

67010.012 ; 12-zone controller

Applied standards: DIN EN 61010-1: 2011-07 “Safety requirements for electrical equipment for

measurement, control, and laboratory use - part 1”

DIN EN 61000-6-2: 2006-03 “Immunity for industrial environments”

DIN EN 61000-6-4: 2007-09 “Emission for industrial environments”

Note: It is necessary to use genuine connecting cables outside the device to meet

the requirements according to DIN EN 61000-6-2 and DIN EN 61000-6-4.

Frankenberg, 02 April 2012

Dr. Peter Braun

Managing Director

EWIKON

Heißkanalsysteme GmbH

Siegener Straße 35

35066 Frankenberg

Tel: (+49) 64 51 / 50 10

Fax: (+49) 64 51 / 50 12 02

www.ewikon.com

tem number: 13820E Technical information subject to alteration. EWIKON 06/2013

Table of contents

Other EWIKON Controllers manuals