EWIKON HPS-C User manual

HPS-C

Hotrunner controllers

Operating manual for

1-zone and 2-zone

controllers

Valid for all controllers

from software version 1.50

Item Numbers:

68010.201

68010.301

68010.302

Safety information

Before working on the plant, you must ensure that it is safely isolated from the voltage supply. Turn the equipment switch OFF

and remove the mains plug. Connection, repair and maintenance works may only be carried out by qualified personnel.

Before commissioning, the plant must be checked in accordance with EN 60204 (11:1998) and the recognised rules of sound

engineering. High temperatures arise at the connected components. Relevant precautionary measures are to be taken on

commissioning or rather during operation.

Application:

This control system from EWIKON can be used to operate EWIKON hotrunner systems in dry industrial rooms.

2

Contents

Safety information.................................................................... Page 2

Introduction............................................................................... Page 4

Overview diagram..................................................................... Page 5

Operation and adjustment of the controller

Display menu............................................................................... Page 6

Command menu.......................................................................... Page 7

Parameter menu......................................................................... Page 8

Parameter level 1........................................................................ Page 9

Parameter level 2........................................................................ Page 12

Error messages........................................................................... Page 13

Technical data............................................................................ Page 14

Connector and connection assignment.................................. Page 15

1-zone controller

Order-No.: 68010.301

2-zone controller

Order-No.: 68010.302

Controllers for 230V hotrunner systems

3

1-zone controller

Order-No.: 68010.201

Controllers for 5V or 230V hotrunner systems

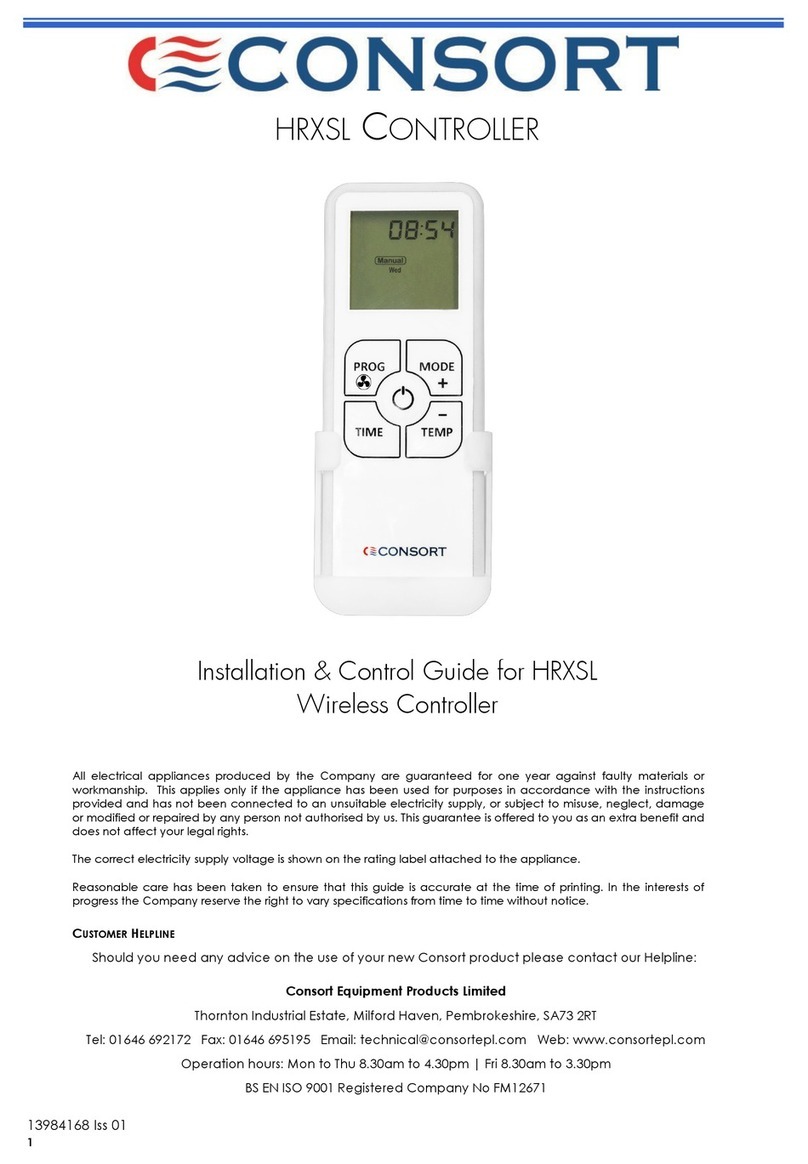

Front view with operator’s controls

Introduction

After switching on the supply voltage, the controller displays the initialisation information is displayed followed by the first

combination of the display menu (c.f.. Page 5). The power output is switched off.

The controller is operated using the 4 "Shift", "UP Arrow", "DOWN Arrow" and "Select" keys.

The display consists of two 4-digit 7-segment displays, the upper (larger) one usually shows the actual value or the parameter

name, the lower (smaller) one usually shows the

setpoint value or the parameter setting.

Furthermore, diverse LEDs are available

for displaying the:

- Operating mode (230V / 5V)

- Correct supply voltage (POWER)

- Standby (ON flashes) or

heating mode (ON continuously lit)

- Faults (ERROR)

- Increase mode ( ) or Decrease mode ( )

- Fuse failure (FUSE)

The key functions are kept

the same in all menus:

- The "Shift" key is used to switch between

the 2 different basic menus "Display” and

“Command", if the key is pressed for

> 2 seconds the parameter menu appears.

Pressing the Shift key in the "Error Messages"

sub-menu automatically acknowledges the error

and returns the display to the normal

display menu.

- The arrow keys are used to change values

and to switch commands On or Off. Changes

in values are automatically accepted after

2 seconds (display flashes until then),

commands are accepted directly, without a

waiting period. The old value is retained if you

page forward before accepting the value.

- The "Select" key is used to page forward within

a menu, e.g. to the next display combination or

to the next command. In the parameter menu the

"Select" key has an additional function:

After entering a valid password and pressing the Select key for > 2 seconds, the user arrives at the 1st parameter level.

If the password entered is also valid for the next level, pressing the "Select" key for > 5 seconds brings the user to the

2nd parameter level.

The sequence structure is sketched in the overview diagram on Page 5.

After approx. 30 seconds of no key being pressed, the last display menu combination is automatically shown.

Any access right set is reset after approx. 5 minutes of no key being pressed.

The setpoint values in the display menu are identified by the following preceding characters (units):

-"C" for temperature setpoint value

-"P" for percentage setpoint value 230V operation

-"A" for ampere setpoint value 5V operation

In the case of the actual values only the percentage and ampere values are preceded by the units,

not the actual temperature value.

If the temperature sensor is defective (interruption), "500" is displayed instead of the actual value.

4

“Operating mode”

“Supply

voltage”

“Stand-By-/

Heating mode”

“Error”

“Increase mode”

“Shift”

7-segment-

display

“UP arrow”

“DOWN arrow”

“Select”

“Decrease mode”

“Fuse failure”

LED´s:

Keys:

5

Overview diagram

6

Operation and adjustment of the controller

The controlled is adjusted in 4 different menus, whereby the focus is on the "Display" and the "Command" menus. If configured

correctly, all the controller operations (Switch On and Off, increase or decrease mode, changes to setpoint values) can be carried

out in these two menus.

The configuration is set in the "Parameter menu", where the basic settings (temperature control or control mode, 5V or 230V

operation, increase and decrease values) can be made. The operational performance of the controller can be significantly

influenced in the lower parameter levels, which can only be reached by entering a password.

If faults are identified, the "Error messages" menu is called up, if several errors occur, these can be displayed consecutively.

The error messages can only be called up from the "Display menu", display of the error messages is suppressed during

configuration and command input.

The menus are described in detail in the following chapters.

Display menu

Three different displays are possible in the display menu, the required combination is chosen using the "Select" key.

Depending on the display selected, the following pairs of values are shown:

1) Display of actual temperature value and the setpoint value of the operating mode set (closed-loop or open-loop control),

the possible displays are e.g.:

- for closed-loop control, 230V or 5V: " 250"

"C.250"

- for open-loop control, 5V: " 250"

"A. 80"

- in case of sensor break: " 500"

"C.250"

In this display, it is possible to change the setpoint value using the arrow keys.

2) Display of actual temperature value and manipulated variable of the power output, in percent (230V) or ampere (5V)

depending on the type of hotrunner.

3) Display of the actual temperature value and measured current value of the power output.

In 230V operation, this value equates to the power consumption of the connected heating, it is displayed with a resolution

of 0.1A (e.g. display: "A 1.5"). The channel heat output can be easily calculated or checked using the formula "P = U * I"

(where: P = heat output, U = mains voltage, I = power consumption).

In 5V operation, the displayed value equates to the power consumption of the downstream load transformer (primary side),

the value is displayed in a resolution of 0.01A (e.g. display: "A2.13").

7

Command menu

All the functions required for the operation can be activated or deactivated in the command menu, the required command is

chosen using the "Select" key. The "UP Arrow" and "DOWN Arrow" keys are used to switch the various functions On and Off.

1) "Ctrl" "Off/ On", switch the hotrunner On or Off

The heating mode is switched on using the "UP Arrow" key and off using the "DOWN Arrow" key. If the hotrunner is switched

off, "Off" appears in the display, and "On" if the hotrunner is switched on. Parallel to the input in the command menu, it is also

possible to switch the controller On and Off via the digital inputs. To do this, the 24 V DC signal socket must be connected

accordingly, see Chapter "Connector and connection assignment" on Page 15. Furthermore, the controller is also fitted with a

self-optimising function, to optimally adjust the control response to the connected heating load. In this way, both extremely fast

nozzles and slow or time lag manifolds can be precisely controlled. The necessary settings for the various types (PID

temperature control, see Section "Parameter level 1") are permanently stored in the controller, these are automatically selected

by the controller during a "learning phase".

To do this, after the controller is switched on, a defined output power is given on the heating load for a certain period of time,

depending on the heating performance, the control parameters are then adapted to the controlled system. However, the

optimisation phase is only carried out if the actual temperature lies below 100° C when the hotrunner is switched on and the

"Opti" parameter in the 1st parameter level stands at "1" (delivered condition).

2) "Ctrl" "InDe", switch increase (increment) and decrease (decrement) mode On or Off

The increase function is switched On or Off (alternating function) using the "UP Arrow" key, the "DOWN Arrow" key is used

accordingly for the decrease function. Priority is always given to a decrease adjustment. Parallel to the input in the command

menu, it is also possible to switch the increase or decrease mode On or Off via the digital inputs of the controller. To do this,

the 24 V DC signal socket must be connected accordingly, see Chapter "Connector and connection assignment" on Page 15.

In increase mode a maximum time limit continues to act to prevent a continuously excessive temperature level.

After the set time of the "tInc" parameter in the 1st parameter level has expired (delivered condition = 600 seconds), the

increase mode is automatically aborted, if it has not been quit manually beforehand. The maximum time limit function for the

increase mode is switched Off with the setting "0 seconds".

3) "Ctrl" "Save", Save function for the set values

Inputs or changes in values are first stored in the non-volatile memory (RAM) of the controller and is used as the current

operating setting. Only after a save function is this data written to the non-volatile memory (EEPROM), and is then available

later, even after the supply voltage has been switched Off and On. During the save function, the increase and decrease LEDs

flash alternately, the controller does not accept any further inputs during this time. The save can only take place if the

hotrunner is switched off, not while the heating mode is running.

The process can either be triggered manually in the command menu or automatically after the hotrunner is switched off.

To this end, the "Save" parameter in the 1st parameter level must be set to "1" (delivered condition).

8

Parameter menu

The basic configuration of the controller can be adjusted in the parameter menu, so that only the display and command menu

are required for the actual operations. Changes to the controller's operating performance can continue to be made in the lower-

lying parameter levels. The required setting can be chosen using the "Select" key, the changes to the values are made using the

arrow keys.

1) "Mode", Temperature-control operating mode ("C") or manual open-loop control ("P" or "A")

Select the operating mode of the connected hotrunner, either temperature control (Select "C" for °C) or open-loop control.

In open-loop control mode, a differentiation is made between 5V operation (Select "A" for current control) and 230V operation

(Select "P" for percentage value control). The input for the setpoint, increase and decrease values is made in "°C" (C), in

percentage (P) or in amperes (A) respectively depending on the parameter "Mode" and "Type" settings. In the delivered

condition, the temperature control operating mode is set.

2) "Type", hotrunner type "5V" or "230V"

Select the operating voltage of the connected hotrunner; "5V" or "230V", for 5V operation the controller must be equipped

with an appropriate transformer (e.g. 1-zone controller 5V/230V, Art. No. 68010.201). The selected setting is signalled by

the two LEDs below the display.

ATTENTION: The "Type" parameter cannot be adjusted if the hotrunner

(heating mode) is switched on!

3) "CInc" / "PInc" / "AInc", increase value for the current operating mode

The increase value equates to a 2nd setpoint value for the closed-loop or open-loop control circuit, e.g. to set a higher

temperature level for a brief time while starting up to make it easier to open the hotrunner. The value entered is added to

the setpoint value of the increase function is switched on. The increase mode can be switched On and Off via the command

menu or the digital signal input.

Possible setting ranges for the increase value are:

- for automatic (closed-loop) mode: 0...200°C

- for controlled (open-loop) mode: 0...50% or A

4) "CDec" / "PDec" / " ADec", decrease value for the current operating mode

The decrease value equates to a 3rd setpoint value for the closed-loop or open-loop control circuit, e.g. to set a lower

temperature level for a brief time in case of malfunctions to avoid burning the material. The value entered is subtracted

from the setpoint value if the decrease function is switched on. The decrease function can be switched On and Off via the

command menu or the digital signal input.

Possible setting ranges for the decrease value are:

- for automatic (closed-loop) mode: 0...200°C

- for controlled (open-loop) mode : 0...50% or A

5) "PASS", Password for access to the other parameter levels 1 and 2

Enter the password to be able to make changes in the other parameter levels 1 and 2.

The access authorisation is automatically reset if no keys are pressed for 5 minutes.

ATTENTION: Some of the settings which can be made in the other access levels have a severe effect on the

operating performance of the controller. The values should therefore only be changed by trained,

expert personnel!

9

Parameter level 1

The user arrives at the first parameter level after entering the valid password ("11", carried out using the arrow key) and

pressing the "Select" key for at least 2 seconds.

The following lists the parameters which can be changed in this level in tabular form.

Display Designation Unit Min. value Max. value Preset value

"tbOn" Tolerance band function ON/OFF - - - - - 0 1 0

"tbC1" Upper temperature fault limit °C 0 200 10

"tbC2" Upper temperature warning limit °C 0 100 5

"tbC3" Lower temperature warning limit °C 0 100 5

"tbC4" Lower temperature fault limit °C 0 200 10

"tbA1" Upper current fault limit A 0 50 10

"tbA2" Upper current warning limit A 0 25 5

"tbA3" Lower current warning limit A 0 25 5

"tbA4" Lower current fault limit A 0 50 10

"tbdy" Release delay time Min. 0 30 0

"Cdry" Softstart temperature °C 100 150 120

"Pdry" Softstart power % 20 50 50

"tdry" Softstart time Sek. 300 1800 600

"Crmp" Ramp temperature °C/Sek. 0.1 5.0 1.0

"Armp" Ramp current A/Sek. 0.1 5.0 2.0

"Prmp" Ramp output %/Sek. 0.1 5.0 5.0

"tInc" Maximum increase time Sek. 0 900 600

"Opti" Start with load type recognition - - - - - 0 1 1

"Save" Save when switched off - - - - - 0 1 1

"Unit" Temp. unit °C (0) or °F (1) - - - - - 0 1 0

"t-vp" P component temperature control - - - - - 0.10 50.00 15.00

"t-tn" I component temperature control Sek. 0.0 300.0 90.0

"t-tv" D component temperature control Sek. 0.0 10.0 0.3

"Load" Load type (230V: 0-4; 5V: 5-9) - - - - - 0 / 5 4 / 9 2

"tC" Thermocouple type (0=K / 1=J / 2=L) - - - - - 0 2 2

"Lead" Lead channel - - - - - 0 0 0

The settings are described on the following pages.

10

Tolerance band monitoring ("tbOn", "tbC1" - "tbC4", "tbA1" - "tbA4" and "tbdy")

Tolerance band monitoring enables automatic monitoring of the injection moulding process with respect to compliance with the

setpoint values entered. In this way, various reciprocal actions can be triggered in the open communications network with the

injection moulding machine, e.g. decreasing the hotrunner in case of machine faults or interruption to the injection operation in

case of faults in the hotrunner. To do this however, the link between the control device and the machine must be made via the

24V signal cable, Art. No. 60070.019.

The monitoring function is switched On by the "tbOn" = "1" parameter (delivered condition "0").

Tolerance band windows can be entered for temperature ("tbC1" to "tbC4") and current ("tbA1" to "tbA4"), furthermore it is also

possible to set a release time lag ("tbdy", delivered condition "0 minutes"). This is used for delayed switching off of an error

message in case of tolerance band deviations, to allow the hotrunner system sufficient time after the heating up phase to

develop an adequately stable thermal condition.

There are two pairs of limiting values each available for the temperature and the current monitoring, this enables a differentiation

to be made between warning messages (in case of slight deviations) and fault messages (in case of larger deviations). The set

limiting values apply relative to the set setpoint value, so that if the latter are changed the tolerance band values are automatically

adjusted accordingly. The warning messages and fault messages are displayed in the error messages.

Drying function ("Cdry", "Pdry" and "tdry")

A drying phase is always run through in 230V heaters following the switching on process to remove any residual moisture in

the hotrunner system. Here the controller works in phase angle control mode, to avoid damage to the connected heating loads.

Compared to the pulse package mode used in normal mode, smaller voltage peak values are shifted to the heating in phase

control, thereby avoiding arcing due to moisture.

In the drying phase the heaters are controlled with an adjustable maximum output ("Pdry", delivered condition "50 %") for a

minimum period ("tdry", delivered condition "600 seconds") to a preset maximum temperature ("Cdry", delivered condition

"120 °C"), only then is the setpoint value entered started up.

The drying phase is bypassed if the actual temperature value is above the set drying temperature when the control device is

switched on.

Ramps function ("Crmp", "Armp" and "Prmp")

When switching on the hotrunner system or if changes are made to the setpoint values, the ramp set determines the slope or

speed (change per second), with which the new setpoint value is started up. This makes it possible to influence the heating speed

of the hotrunner system. When making the adjustment, it should be remembered that sluggish heating loads, e.g. manifolds,

cannot achieve rapid temperature changes due to physical restrictions.

Separate adjustment possibilities are available for each of the operating modes temperature control ("Crmp", delivered condition

"1°C / second"), current control 5V operation ("Armp", delivered condition "2A / second") and percentage value control 230V

operation ("Prmp", delivered condition "5% / second).

11

PID temperature-control ("t-vp", "t-tn", "t-tv" and "Load")

The HPS-C control system is equipped with a PID control algorithm, which guarantees optimum control performance and small

deviations between the actual and setpoint value during operation. During the system's heating up phase, special additional

supporting functions act, as the connected controlled system (hotrunner) performance mostly deviates here from the subsequent

operation.

The "Load" type is determined in the normal case by the controller itself for each channel and depends on the type of heating

connected. In total, a sub-division is made into 10 different types, for each of which certain controller presets are stored in the

system. The following table shows reference values for the various settings, although the controller can contain deviating values:

Load type Hotrunner type t-vp (amplification) t-tn (reset time) / s t-tv (lead time) / s

0 230V, very slow performance 25.00 150.0 0.5

1 230V, slow performance 20.00 120.0 0.4

2 230V, average performance 15.00 90.0 0.3

3 230V, fast performance 10.00 60.0 0.2

4 230V, very fast performance 5.00 30.0 0.1

5 5V, very slow performance 1.10 60.0 6.4

6 5V, slow performance 1.05 48.0 6.4

7 5V, average performance 1.00 36.0 6.4

8 5V, fast performance 0.95 24.0 6.4

9 5V, very fast performance 0.90 12.0 6.4

If necessary, the control characteristics can also be adjusted manually, if the automatic identification does not achieve a good

controlled result. Here, either the load type can be changed, whereby the settings stored in the system are automatically

accepted. Alternately, it is also possible to individually adjust each of the 3 control parameters.

Thermocouple type ("tC")

The HPS-C controller temperature measurement is designed for the connection of a thermocouple, in total, 3 different types of

thermocouple can be connected. When the device is delivered, the type Fe-CuNi "L" (setting "2") according to DIN 43710 is set;

the types Fe-CuNi "J" (setting "1") and NiCr-Ni "K" (setting "0") according to DIN IEC 584 can also be used.

The assignment of the setting and thermocouple type is listed in the following table:

Setting Thermal element Type Sleeve colour *) Plus leg *) Minus leg*)

0 NiCr-Ni K green green white

1 Fe-CuNi J black black white

2 Fe-CuNi L blue red blue

*) Colour coding of the thermocouple connection cable, deviations from this are possible.

Parameter level 2

Parameter level 2 is only accessible to the manufacturer. However, the possible settings and limiting values are listed here for

information purposes. Parameter level 2 is reached by pressing the "Select" key for at least 5 seconds in Parameter level 1,

if the valid password has been entered.

The following lists the parameters which can be changed in this level in tabular form.

Display Designation Unit Min value Max value Preset value

"CLdn" Lower temp. set limit °C 50 150 50

"CLup" Upper temp. set limit °C 250 500 450

"ALdn" Lower current set limit A 10 50 10

"ALup" Upper current set limit A 50 125 125

"PLdn" Lower percentage set limit % 0 25 0

"PLup" Upper percentage set limit % 50 100 100

"ILim" Maximum current 5V A 50.0 125.0 125.0

"I-vp" Current control P component - - - - - 0.00 5.00 0.40

"I-tn" Current control I component Sek. 0.0 30.0 6.0

"I-tv" Current control D component Sek. 0.0 10.0 6.4

"IMdn" Lower measured value current calibration A 10.0 50.0 10.0

"ICdn" Lower adjustment value current calibration A 10.0 50.0 10.0

"IMup" Upper measured value current calibration A 100.0 150.0 100.0

"ICup" Upper adjustment value current calibration A 100.0 150.0 100.0

Set limits ("CLdn", "CLup", "ALdn", "ALup", "PLdn" and "PLup")

The setpoint values for the corresponding operating modes can only be changed within the specified limits.

This means that the available adjustment range can be limited, e.g. for critical materials.

The limiting values can be changed within the ranges given in the table.

Maximum current 5V ("ILim")

Here the maximum current can be limited in 5V operation, e.g. to avoid damage to critical hotrunner systems. The controller

complies with this limiting value in temperature controlled and in current controlled mode.

Current control parameter ("I-vp", "I-tn" and "I-tv")

Apart from the temperature control, the controller also has a current control with PID characteristic, which is used in 5V operation.

If necessary, the control parameters can be optimised here manually.

Current calibration ("IMdn", "ICdn", "IMup", "ICup")

In certain cases, it can be necessary to adjust the recording of the measured current values in 5V operation, e.g. if an 8V type is

used in place of the transformer with 5V output voltage (for high heating conductor resistances). Here both the rate (slope) as well

as the level of the measuring range can be changed, however, a separate current measuring device (clip on amperemeter or

multi-meter with current clamp) and with appropriate accuracy must be available for the calibration.

The measured controller values which have been read off at the lower and upper point of the measuring range are entered as

the lower and upper measured value. The values which were measured at the same position using the separate current

measuring device are entered as the lower and upper calibration values. The calibration should be carried out at 10A and 100A,

so that the measuring inaccuracy is kept as small as possible over the whole working range.

12

Error messages

Apart from the normal operating functions, the HPS-C control system also provides other extensive monitoring functions in order

to identify problems or errors in the hotrunner system or in the controller at an early stage.

Errors or warnings are displayed in the "error messages" menu, if the hotrunner system (heating mode) has been switched on,

the fault and warning message output is also set and the red "ERROR" LED is switched on.

If several errors have been identified, these can be displayed consecutively by pressing the "Select" key. The "Shift" key is used

to return to the display menu and the error is thus automatically acknowledged. If the cause of the error is not found and removed,

the error message is displayed again after approx. 5 seconds.

In case of error messages, "Err" is always overlaid in the lower line, the corresponding error designation is displayed in the top

line. The displays have the following meanings:

Display Meaning Possible cause

"SYS1" Leakage current in system exceeds the Residual moisture in the hotrunner system due to lengthy

set limiting value. storage; water entry

"SYS2" Network synchronisation measurement Fuse defective;

of the controller module is faulty Malfunctions in the supply voltage

"SYS3" Internal fault in the controller module Internal controller data transmission faulty,

(ASR communications fault) Number of faults exceeds the limiting value

"SYS4" Internal fault in the controller module Writing or reading error during access to the EEPROM memory of

(EEPROM fault) the controller module, possibly caused by voltage failure during

writing process

"tb 1" Tolerance band fault: Severe malfunctions in cyclic operations (e.g. friction)

Upper malfunction limit exceeded Start up of a new set value

Sequential fault of a load circuit fault

"tb 2" Tolerance band-fault: Malfunctions in cyclic operations (e.g. friction)

Upper warning limit exceeded Start up of a new set value

Sequential fault of a load circuit fault

"tb 3" Tolerance band-fault: Malfunctions in cyclic operations (e.g. friction)

Value below lower warning limit Start up of a new set value

Sequential fault of a load circuit fault

"tb 4" Tolerance band-fault: Severe malfunctions in cyclic operations (e.g. friction)

Value below lower malfunction limit Start up of a new set value

Sequential fault of a load circuit fault

"tC 1" Thermocouple fault: Thermocouple defective

Interruption Plug in or screwed connection interrupted

"tC 2" Thermocouple fault: Thermocouple defective

Short circuit Short circuit in the wiring

"tC 3" Thermocouple fault: Thermocouple connected the wrong way round

Polarity reversal (Plus and minus legs reversed)

"Ld 1" Load circuit fault: Interruption of the heating or the line links

Interruption Fuse has tripped; wrong hotrunner type (5V / 230V)

Output controller (Triac) defective

"Ld 2" Load circuit fault: Heating or wiring short circuit;

Short circuit Output controller (Triac) defective

"Ld 3" Load circuit fault: Failure of a heater in heating elements switched in parallel, e.g.

Partial interruption distributor zones

ATTENTION: The controllers may only be opened by a qualified electrician after the mains voltage has been

switched off or the mains connection plug has been removed!

13

Technical data

Operating voltage: 230V +6/-10%; 50 / 60 Hz

Degree of protection: IP 33

Output power: 230V: PMax = 3500VA per channel

5V: PMax =625VA per channel (Transformer dependent)

Output signal: 230 V: Phase angle control while drying out, Pulse package during normal operations

5 V: Phase angle control

Fuses: G-fuse link 6.3 x 32mm; F 16A (Type A 12 BK, supplier: Schurter)

Thermocouple input: Fe-CuNi Type L or J; NiCr-Ni Type K

Signal input 24V: External decrease, external increase, external switching On, 1 free input

Signal output 24V: Fault message, warning message, hotrunner ON, and 1 free output

Data memory: EEPROM, Data retained for at least 10 years

Ambient conditions: Working temperature range 0 - 50 °C

Control performance: PID temperature control with adaptive parameter determination and possible

manual optimisation

PID current control with possible manual optimisation

Control accuracy: - Temperature-control: ±1 °C

- Current-control: ±1 A

Start up functions: - Drying operation for 230 V hotrunners

- Setpoint value ramps with freely selectable increase

Measurement and

working ranges: - Temperature: Range: 0 - 500 °C

Resolution: 1°C

- Current 5V: Range: 0 - 125 A

Resolution: 1 A

- Current 230V: Range: 0 - 16 A

Resolution: 0.01 A

Measurement accuracy: - Temperature: ±3 °C (at 300 °C)

- Current 5V: ±3 A (at 100 A)

Additional functions: - Load error detection interruption, short circuit and partial load failure

- Thermo error detection interruption, short circuit, or polarity reversal

- Setpoint value provision for thermocouple failure in %/A (after min. 5 mins

in set value mode)

- Setpoint value monitoring with 2 tolerance bands for fault and warning messages

- Decrease function

- Increase function with maximum time delimitation

The Series HPS-C controllers comply with the standards DIN EN 55011 (05/2000),

DIN EN 61000-6-2 (03/2000), DIN EN 60204-1 (11/1998) and DIN EN 60742.

14

Connector and connection assignment

Connection jack 230V

Contact Use

1 230V (L) Circuit 1

2 - - - - -

3 230V (L) Circuit 2

4 Thermocouple (+) Circuit 2

5 Thermocouple (+) Circuit 1

6 230V (N) Circuit 1

7 - - - - -

8 230V (N) Circuit 2

9 Thermocouple (-) Circuit 2

10 Thermocouple (-) Circuit 1

The contacts 3, 4, 8 and 9 are only assigned in the

2-zone controller, Art. No. 68010.302.

Signal jack 24V DC

Contact/Core Use Title

1 Decrease Input 1

2 Increase Input 2

3 Switch on Input 3

4 Not used Input 4

5 Fault message Output 1

6 Warning message Output 2

7 Hotrunner ON Output 3

8 Not used Output 4

9 +24V DC Supply voltage

(for inputs)

10 GND Supply voltage

(for inputs and outputs)

11 - - - - - - - - - -

12 PE Protective earth conductor

Each output can be loaded with max. 200 mA, however, the total load of the connection plug must not exceed 0.5 A.

All inputs and outputs work at the 24 V DC voltage level.

15

Technical information subject to changes. EWIKON 08/2002

EWIKON Heißkanalsysteme

GmbH & Co. KG

Siegener Straße 35

35066 Frankenberg

Tel: (+49) 64 51 / 50 10

Fax: (+49) 64 51 / 50 12 02

E-mail: [email protected]

www.ewikon.com

Your EWIKON partner:

This manual suits for next models

3

Table of contents

Other EWIKON Controllers manuals

Popular Controllers manuals by other brands

Global Manufacturing

Global Manufacturing Quiet Thunder QT2-40X operating instructions

Dynamite

Dynamite FUSE DYN4955 instruction manual

TCS Basys Controls

TCS Basys Controls SZ1143b product manual

Milesight

Milesight UC300 user guide

YASKAWA

YASKAWA MOTOMAN FS100 Option addendum

ETC

ETC Expression User's manual supplement