EWS ES2030 CV User manual

Control for ion exchangers and filter systems

Instructionmanual

Software version 2.03

ES2030 CV

Contents

Functional description..................................................................................................................…. 1

Illustration .....................................................................................................................................…. 2

Service and regeneration displays …………...............................................................................…. 3

LED indicator lights…...………………………………………………………………....……………. 3

LCD display………....….....………………………………………………………………....………… 3

First line…….…...……………………………………………………………………...………. 3

Second line during service…….………………………………………………………...……. 3

Second line during regeneration………………………………………………………...……. 3

Displaying and altering program values.......................................................……………………..…. 4

Hardness of supply water / filter capacity..………………………………………………………..... 4

Current time………………………………...………………………………………………………..... 4

Info key ....................................…...........................................................……………………….………. 5

Flush……….……………….………………………………………………………………........…….. 5

Regeneration time..……….………………………………………………………………........…….. 5

Regeneration restrictions…………………………………………………………………........…….. 5

Additional program run……………………………………………………………………........…….. 5

Filter capacity….………………………………………………………………………………………. 5

Water delivery…….………….………………………………………………………………………... 6

Input states……………..………………………………………………………………………..…..... 6

Output states……………..………………………………………………………………………........ 6

Service number….……….……………………………………………………………………………. 6

Software version….…………………………………………………………………………………... 6

Programmed inputs………………………………………………………………………........…….. 6

Programmed outputs……………………………………………………………………………........ 6

Last regeneration.……………………….……………………………………………………………. 6

Regeneration ratio……………………….……………………………………………………………. 6

Messages……………………......................................................................……………………………. 7

Capacity exceeded…. .……………...……………………………………………………………….. 7

Power failure…………..……………...……………………………………………………………….. 7

Refill regeneration medium.…………..……………………………………………………………... 7

Delayed regeneration…..….…......…………………………………………………………………... 7

Stop regeneration……..…....……….………………………………………………………………... 8

Stop service…….…………..……………………………....……………………………………….…. 8

Minimum regeneration interval.…………………………………………………………………….… 8

Cancel buzzer………………......................................................................……………………………. 8

Switching the OUT1 and OUT2 relays on and off .........................…..........................................… 8

Additional output function.....….……………………………………………………………………... 8

Regeneration cycle function….….…..…………………………………………………………….…. 8

Supply pulse function…………………..……………………………………………………………... 8

Warning function..………..……………….…………………………..…………………………….… 8

Desalinate function….……………………...........…………………………………………………... 8

Initiating regeneration manually...............................................................……………………………. 9

Special functions.....................................................................…...............…………………………….. 9

Filter change over without program initiation.……………..………………………………………… 9

Immediate stop…………………...…………………………..………………………………………... 9

Regeneration of standby filter……………………………..…………………………………..……… 9

Switching from parallel to alternate.……………………..…………………………………………... 10

Fast cycle..………...........……….……..………………....…………………………………………... 10

Regeneration without initialisation..…..……………..…..…………………………………………... 10

Regeneration of Filter 1 ONLY…....…..…………..……..…………………………………………... 10

Regeneration of Filter 2 ONLY…....…..………..………..…………………………………………... 10

Displaying and modification of the basic settings...............................……………………………… 11

General information on programming and language settings…….……………………………….. 11

1 Electrical control.…..………………………......………………………………………………….. 12

2 Number of valve switch phases ………….....…………………………………………………... 15

3 Pulse length……………………………...…………..……………………………………..……… 15

4 Regeneration times….…………………..…………..………………………………………..…... 15

5 Filter switching…………..…………………………………………………………………………. 15

6 Delayed regeneration.……………….……………………………………………………………. 17

Starting on real time clock…………..……………………………………………………………. 18

7 Interval start of regeneration…………...…………....................…..…………………………… 18

8 Minimum regeneration distance….....................………………………………………….……. 19

9 Definition of input functions…………………….…….…………..………………………….…… 20

10 “Water meter” input…..……...……………………..…………………..…………………….…… 21

Filter capacity…..…..……...……………………..…………………..…………………..……..… 22

11 “Stop service” input…….…...……………………..…………………..…………………..…...… 22

12 “Start regeneration” input…….…………………..…………………..…………………..…....… 23

13 “Chemical shortage” input…….…………………..…………………..…………………..…....… 23

14 “Stop regeneration” input…….…………………..…………………..…………………..…....… 23

15 Definition of output functions…………………….…….…………..…………………………..… 24

16 “Additional program” output...…………………..……………………..………………………… 25

17 “Regeneration” output.……...…………………..……………………..……………………….… 25

18 “Flow pulse” output..…………………….…………..…………………………..……………...… 26

19 “Warning” output..…………………….…………..…………………………..………………...… 26

20 “Desalinate” output………………….…………..…………………………..…………………..… 27

21 Buzzer…….…………………………………………..…………………..………………………… 27

22 Programming mode.……...…………...…..……………………………..……………………….. 27

Examples of systems……........................................................................……………….…………… 28

Typical electrical wiring diagrams............................................................……………….…………… 29

Wiring diagram ES2030 CV.......................................................................……………….…………… 31

Notes on installation and initial use........................................................……………….…………… 32

Technical data….........................................................................……………………………............… 33

Declaration of conformity...................................................…………….………………….……...…… 34

ES2030 CV Functional description 1

Functional description

The controller ES2030 CV (wall mounted) is

used for the automatic control and monitoring

of single and double filter systems.

If additional control functions are required, they

can be obtained with the IF2030 card, which

can also be installed subsequently.

The software’s flexible programming capacity

and the individually adaptable hardware make

a wide range of uses in water treatment

systems possible. In combination remote

control valves or pilot distributors, these control

units can operate water-softening systems,

partial flushing systems and filter systems.

NOTE: For the sake of simplicity, in these

instructions the treatment process carried out

by a filter system (e.g. deferrization) is also

referred to as “REGENERATION”, as is usual

in the case of ion exchangers.

A regeneration can be initiated :

1. by manual switch

2. by remote switch (water hardness monitor,

conductivity meter, manual switch, etc..)

3. by pre selected amount (pulse water meter

required)

4. after set time intervals (e.g. every 72 hours)

5. starting on real time clock

A time window can be set to determine times

when regeneration must not take place

(delayed regeneration).

A minimum regeneration distance between

regenerations prevents regenerations being

initiated constantly if the water meter or the

remote switch is faulty.

Terminal diagram of ES 2030 CV

2 relays for remote control valves or pilot distributors (control valve 1 and control valve 2)

2 relays for service valves (service valve 1 and service valve 2)

1 relay for automatic synchronization of the remote control valves or pilot distributors, with a

connection for the message ‘program running’ (program)

1 signal input, programmable for the following functions : water meter, stop, start or chemical

shortage

1 12V= output for an external electronic application, e.g. turbines with Hall effect switch (auxiliary

power)

1 power output for “control on” message and power supply to the potential free contacts “OUT1” and

“OUT2” (power out)

Separately available card IF2030 :

1 signal input, programmable for the following functions : water meter, stop, start or chemical

shortage

2 output relays programmable for the following functions : additional program, regeneration,

flow pulse, warning or desalination. (OUT1 and OUT2).

Control

valve 1 Service

valve 1 Control

valve 2 Service

valve 2 Program IN1auxiliary

power IN2power

out

power

in OUT1 OUT2

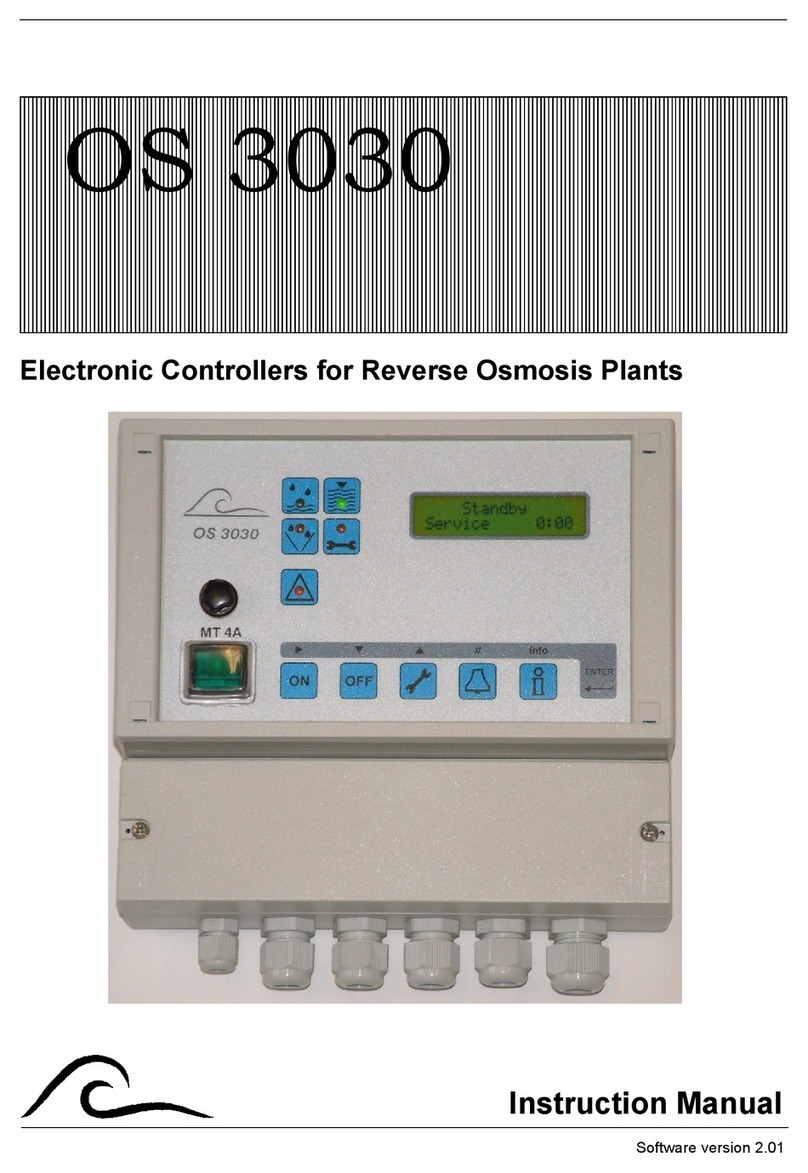

ES2030 CV Illustration 2

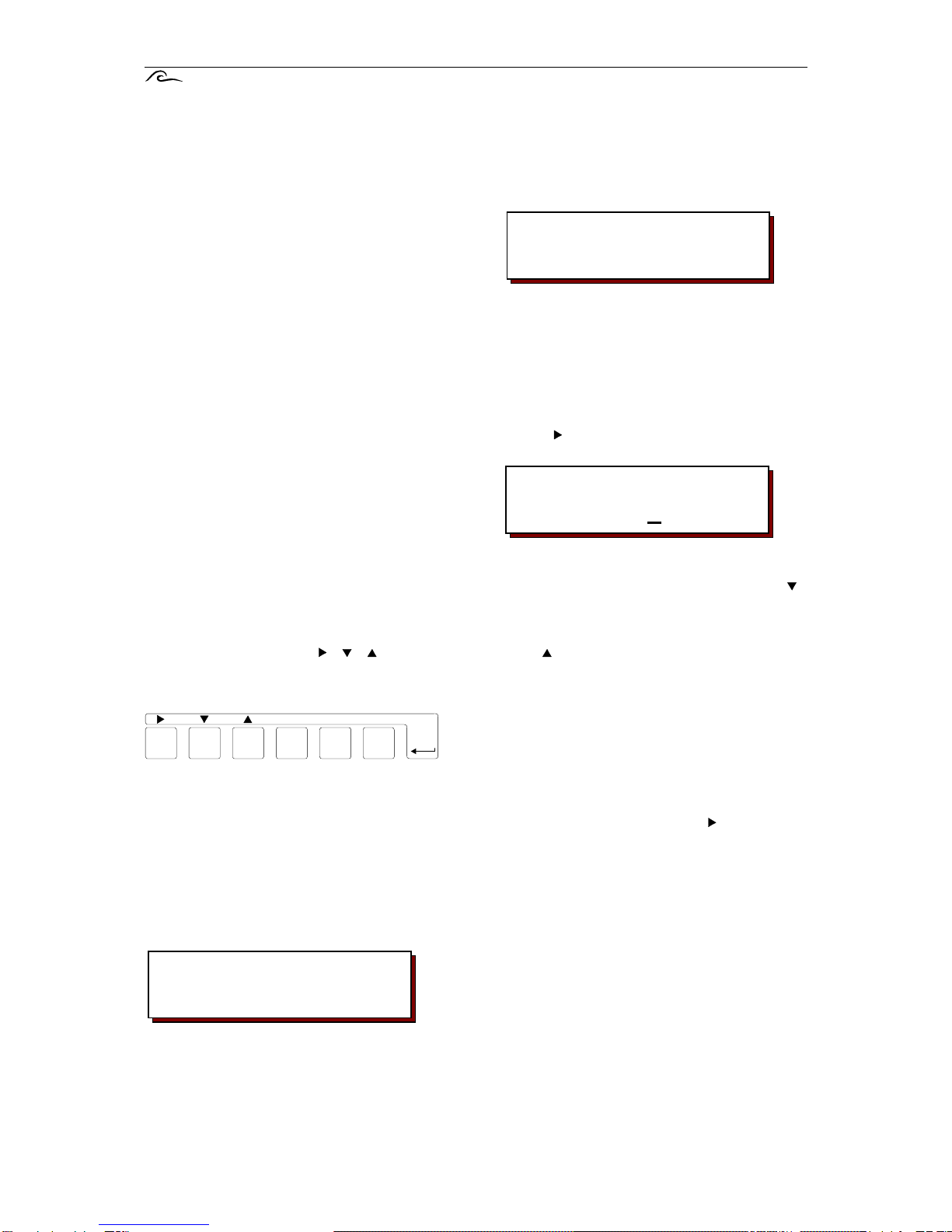

Illustration

Wall-mounted

1 Service filter 2 6 Main switch 11 Output 2 16 Input 2 LED

2 Service filter 1 7 Start regeneration 12 Information 17 Output 2 LED

3 Regeneration filter 1 8 Supply water 13 Programming 18 Output 1 LED

4 Regeneration filter 2 9 Time 14 LCD display

5 Main fuse 10 Output 1 15 Input 1 LED

Service unit 1

100.00m3 Mo17:10

MT 4A

1

2

3

4

5

6

8 9 10 11 12 13

14

12

IN1 IN2 OUT1 OUT2

#

Enter

info

OUT

1

OUT

2

7

15

16

17

18

ES2030 CV Service and regeneration display 3

Service and regeneration display

LED control lamps

Coloured control lamps show the unit’s major states :

Filter 1 service (green)

Filter 2 service (green)

Filter 1 regeneration (orange)

Filter 2 regeneration (orange)

IN1 = Input 1 active (orange)

IN2 = Input 2 active (orange)

OUT1 = Output 1 active (orange)

OUT2 = Output 2 active (orange)

LCD display

First LCD line

The first line of the LCD display shows the

present state of the system, e.g. “Filter1 in

service”, “Filter 2 in regeneration” or “not in

service”.

Second LCD line during service

The second line of the LCD display shows the

following information during service:

1. The amount of water remaining until the next

regeneration

or:

The time of the next regeneration if a

‘delayed regeneration’ has been initiated

(see program step 6).

or:

The number of hours until the next

regeneration (see program step 7).

or:

Alternating with the ‘amount of water

remaining’ of the current through flow (see

program step 10.1 : pulse count)

or:

The flushing time remaining (see program

step 19)

or:

“No Autom. Reg” if no automatic initiation of

regeneration was selected (water meter,

time interval).

2. The current time

Second LCD line during regeneration

During regeneration, the second line of the

LCD display shows the remaining time for the

current phase and after the oblique the

remaining time for the whole regeneration.

Or:

Alternating with the regeneration times, the

remaining time for the additional program (see

program step 15).

Service unit 1

100.00m3 Mo12:00

Regener.unit 1

Phase:2 80/100m

12

IN1 IN2 OUT1 OUT

2

Service unit 1

100.00m3 Mo12:00

ES2030 CV Displaying and altering program values 4

Displaying and altering program values

The main program values can be displayed

and altered if required by pressing a key.

Hardness of supply water /

filter capacity

Press the key with the symbol . In the case

of an ion exchanger the bottom line will show

the present supply water hardness, for a filter

system it will show the capacity entered. (see

program step 10.3).

If you wish to change the value shown, use the

‘ ‘ key to move the cursor under the figure to

be changed, and change the value with the

number key ( ‘#’).

The following values may be entered,

according to the units entered at phase 10.3 of

the basic programming:

Unit of the supply

water hardness : entry value :

°D 2 - 99

°F 4 - 199

°E 2 - 99

mg/l CaCO3 40 -1999

gpg 2 - 99

no unit 0,01 - 9999,99 m3

(0,02 mmol/l = 0,10°D = 0,13 °E =0,18 °F

= 1,79ppm = 0,11gpg(USA) = 0,13gpg(UK))

The calculation of the soft water quantity with

altered values is carried out at the start of each

regeneration using the formula:

NOTE: In the case of remote control valves

with water supply by-pass ports, the water

meter records the dilution amount. The

hardness of the diluted water must therefore

be subtracted from the value to be entered.

Example :

Supply water hardness = 15 °D

Diluted water = 6 °D

This gives an input value of :

15 °D – 6 °D = 9 °D

Current time

Press the time key with the symbol . The

current time appears in the lower line.

If you wish to change the value shown, use the

‘ ‘ key to move the cursor under the digit to be

changed, and change the value with the

number key ( ‘#’).

Water hardness:

18°D

Current time

Mo 15:50

#

Exhanger capacity (°D m

3

) .

Supply water hardness (°D) = soft water quanitity (m

3

)

#

ES2030 CV Info 5

Info key

The information key is used to display various

information and values. Only the service

telephone number can be changed using the

info key.

If the info key is pressed during programming,

the full texts of some abbreviated texts are

shown in the LCD display.

Flushing

The following values are shown :

Top right : Flush time in seconds

Bottom left : quantity of water remaining

before flushing

Bottom right : quantity of water between two

flushes.

NOTE: This display shown only if the flushing

function is selected (see program step 15).

Regeneration time

The total time for a regeneration cycle is

shown.

Regeneration restrictions

NoReg 16:00 – 18:00

If “delayed regeneration” was selected during

programming at step 6, the period in which no

regeneration is to occur is shown.

Otherwise “NoReg ----“ is displayed.

IntRg 72

If “interval start” was selected during

programming at step 7, the time interval in

hours is shown.

Otherwise “IntRg --“ is displayed.

MinRg 4

If a “minimum regeneration distance” was

selected during programming at step 8, the

time interval in hours is shown.

Otherwise “MinRg --“ is displayed.

Additional program

Bottom left : the starting point of the additional

program is shown.

Bottom right : the start time entered is shown

or the time remaining if the additional

program is currently running.

If phase ‘0’ is displayed, the additional program

will first run for its full time, followed by the

regeneration program.

If phase ‘E’ is displayed the regeneration

program will first run completely, then the

additional program.

NOTE: If the additional program function was

not selected during programming at step 14,

“no additional program” will be displayed. If the

IF card is not fitted this display will be omitted.

Filter capacity

The water quantity delivered by a filter

between two regenerations is shown. In the

case of ion exchangers, the calculation is

always carried out using the currently entered

values for filter capacity and the supply water

hardness.

NoReg16:00-18:00

IntRg72 MinRg4

Additional prog.

Phase: 2 20

Unit capacity

100m3

Flushing

500l 500l 20s

info

Regen.time

Σ95m rest.0m

ES2030 CV Info 6

Water delivery

The total quantity of water delivered by the

system is shown.

Input states

Indicates the current state of each input.

(- = Input not activated, | = Input activated)

WM = Water meter SP = Stop service

ST = Start regeneration CH= Chemicals shortage

HO = Stop regeneration

Output states

The current switch states of the output relays

are shown. Each figure has a relay allocated to

it (see switching diagram on p.31).

A horizontal stroke ‘-‘ under a figure means

‘relay switched off’.

A vertical stroke ‘ | ‘ under a figure means

‘relay switched on’.

NOTE: Relays 7 and 8 are only shown if an IF

card is fitted.

Service number

A service phone number is displayed. You can

also change the number here.

Change the phone number :

Select number :

Lower number :

Higher number :

Software version

The software is continuously updated by the

factory. Where necessary changes are made

to reflect new technology and customer

requirements.

The number of the version currently installed is

displayed.

Programming the inputs

The programmed functions of input IN1 (and

IN2 if the IF2030 card is fitted) are displayed.

Programming the outputs

The programmed functions of output OUT1

and OUT2 are displayed.

NOTE: This display is only shown if the IF2030

card is fitted.

Last regeneration

The display shows how much time has passed

since the last regeneration.

For example : 3d 12h 15min

It has been 13 days, 12 hours and 15 minutes

since the last regeneration.

Regeneration ratio

The regeneration ratio entered is displayed,

and after the oblique the current state if filter

2’s regeneration counter is shown.

Example 1: 1:3/2

Regeneration ratio of filter 1 : filter 2 = 1:3

Filter 1 has already been regenerated once.

Example 2: 1:3/1

Regeneration ratio of filter 1 : filter 2 = 1:3

Filter 1 has already been regenerated twice.

Both filters will be regenerated at the next

regeneration.

NOTE: This display only appears where a

connection in series with two filters and a

regeneration ratio greater than 1:1 has been

selected.

Service

0031 73 443755

Softwareversion

ES2030cv2.03.00g

IN1=Water meter

IN2=prog.initi

OUT1=Add. Progra

OUT2=Status

last regenera.

3d 12h 15Min.

Treated water

0.1m3

Output 12345 78

-|--- --

Relation

1:3/3

Input

WM-ST-

ES2030 CV Messages 7

Messages

During service and during the regeneration of

the system, various signals are given

depending on the type of controller and its

programming.

These signals can be signalled with the built-in

buzzer and displayed in the LCD display. If the

extension card IF2030 is installed an additional

relay can be selected as warning relay (step

15).

Press the key OUT1 or OUT2 to clear the

buzzer and any activated warning relay. The

LCD display is only cleared when the warning

signal is no longer active.

Capacity exceeded

This display can only appear with a double

filter system.

While one of the filters is regeneration, the

other was also called on to regenerate. The

warning in the LCD display is cleared when

this filter starts regeneration.

Possible causes where activated by the water

meter :

Incorrect setting of capacity, supply water

hardness or of the water meter itself.

Overloading of the system e.g. by filling a

large container.

Possible causes where activated externally by

a water analysis device :

Saturation of a system newly put into use,

caused by the negative ion effect.

Solution : fit a flushing valve or circulation

pump. Reduce the sensitivity of the analysis

Device.

Other possible causes :

Poor regeneration of the filter due e.g. to

regeneration medium not being present or

being incorrectly primed.

NOTE: In two-filter systems, after a flow

dependent regeneration activation the

regeneration of the second filter will follow

immediately the current regeneration ends.

However in the case of external activation of

the regeneration, e.g. by a water analysis

device, the regeneration does not follow, as it

can be assumed that the hardness warning

occurred as a result of a standstill hardening of

the standby filter. The second filter is only

regenerated if the relevant start signal is still

present at the end of the current regeneration

or if it reset.

In the case of ion exchangers with a salt

release valve, if no brine has yet formed for the

second filter, stop the regeneration by

switching off the unit.

Power failure

No data are lost if there is a power failure.

When power is restored the control panel will

return to the same setting with the same

values. Only the current time must be reset

after a longer power loss.

NOTE: If the system is at the regeneration

setting when power is lost, the filter may

become over saturated again if the water

pressure continues during this time and it is

washed by supply water over a period of

hours.

If so, stop the regeneration and then re-start.

Refill regeneration medium

Refill regeneration medium.

NOTE: An imminent regeneration will not be

carried out unless either regeneration medium

is again available or the “start regeneration”

key with the symbol is pressed.

In the case of alternately operating two filter

systems, the unit switches over to the standby

filter.

Delayed regeneration

The required regeneration will not start until the

time shown in the LCD display. However the

regeneration can be started immediately by

pressing the “start regeneration” key ( ).

This display is only shown if activation of

“delayed regeneration” was selected in step 19

or 21.

S T A T U S

Instal.exceeded

S T A T U S

Supply failure

OUT

1

OUT

2

S T A T U S

Refill RegMedium

S T A T U S

Prohibited Reg.

ES2030 CV Messages / Cancel Buzzer / Switching OUT1 and OUT2 8

Stop regeneration

This warning may have various causes

depending on the function of the switch contact

connected, for instance two controls may be

blocking each other, or the control pressure for

a pneumatic valve may have been cut off. Find

the cause.

In alternately operating two filter systems, if the

“Stop” warning is already displayed at the start

of a regeneration cycle the unit switches over

to the standby filter.

NOTE: The stop signal can be cancelled for

the duration of the regeneration cycle by

pressing the ‘start’ key with the symbol.

Regeneration then continues.

Stop Service

This display only appears if activation of “stop

service” was selected at program step 19 or

20. The LCD display is cleared automatically

as soon as the input signal is no longer

present.

Minimum regeneration distance

Possible causes if activated by the water

meter:

Incorrect setting of capacity, supply water

hardness or of the meter itself. Overloading of

the system e.g. by filling a large container.

Possible causes where activated externally by

a water analysis device.

Saturation of a system newly put into use,

caused by the negative ion effect.

Solution: fit a flushing valve or circulation

pump. Reduce the sensitivity of the analysis

device.

NOTE: You determine at program step 8.3

whether regeneration is to follow automatically

at the end of set “minimum regeneration

distance” or whether the next regeneration has

to be started manually.

NOTE: The message in the LCD display is not

cleared until regeneration is started.

Cancel buzzer

If the built-in buzzer sounds, it can be cancelled immediately by pressing the ‘OUT1’ or ‘OUT2’ key.

Switching the OUT1 and OUT2 relays on and off

If the controller has been fitted with the IF

expansion card, the two additional relays with

the functions selected at program step 14 may

be switched on and off manually by pressing

the relevant key for approx. 5 seconds.

The ‘OUT1’ key is assigned to relay 7 and the

LED display ‘OUT1’. The same applies to

‘OUT2’ and relay 8.

‘Additional program’ function

The relay can be switched on and off during

the ‘service’ or ‘regeneration’ phases. The test

function is automatically deactivated at the

beginning and end of a regeneration.

‘Regeneration’ function

The relay can be switched on and off (e.g. for

control purposes) during the ‘service’ phase. It

is switched off automatically at the end of a

regeneration.

‘Flow pulse’ function

The relay is switched on for the length of time

set at program step 17.

‘Warning’ function

The relay is switched on (e.g. for control

purposes) for as long as the key is pressed. If

the relay has been switched on by a warning

the relay is cleared.

‘Flush’ function

The relay is switched on for the length of time

set at program step 19.

If a flush cycle is already running, it can be

stopped prematurely.

S T A T U S

StopRegeneration

S T A T U S

Stop service

S T A T U S

Min.regen.period

OUT

1

OUT

2

ES2030 CV Initiating regeneration manually / Special functions 9

Initiating regeneration manually

A regeneration cycle can be initiated manually

at any time pressing the ‘Start’ key with the

symbol . Regeneration of the filter in service

commences after six seconds.

- In the case of systems operating alternately,

the standby filter is put into service.

- If ‘delayed regeneration’ was selected at

step 6.1 of the programming, the time

function is activated and the time at which

the delayed regeneration will be initiated

automatically is displayed at the bottom left

of the LCD display.

- No regeneration is yet initiated.

- If the time function for ‘delayed regeneration’

has already been activated (and the time

regeneration will be initiated is already

displayed at the bottom left of the LCD

display), regeneration will be initiated after

four seconds regardless of the time shown.

- The filter’s flow counter is reset to full

capacity after regeneration.

- If initiation at intervals was selected at step

7.1 during the input of basic values, the hour

interval meter is set to its preset interval.

- If a minimum regeneration interval was

selected at step 8.1 during the input of basic

values, the timer for the regeneration interval

is reset.

Special functions

These functions should only be used by a professional water treatment specialist, as their improper

use may lead to malfunctions.

Filter change over without program

initiation

Simultaneously press the function keys with

the symbols and . Change over of the

filters will take place after 4 seconds on two

filter systems.

NOTE: Separate flow counters are used for

each filter. Where an almost saturated filter is

switched into the standby position, it may

happen that regeneration becomes necessary

shortly after it has been brought into service,

and this may be at a time when the other filter

is still regenerating. In this event, the fault

warning ‘capacity exceeded’ appears.

Immediate Stop

Simultaneously press the function keys with

the symbols and .

Any regeneration program running will stop

after 4 seconds and the system will be

switched into service position.

NOTE: Multi stage valves which have no

connection to return them automatically to the

service setting will remain at a regeneration

setting and are no longer synchronized with

the control panel.

Regeneration of standby filter

Simultaneously press the function keys with

the symbols and .

The regeneration of the standby filter will begin

after 4 seconds on two filter systems

NOTE: this only applies for alternate filter

service (program step 5.3 = YES).

OUT

1

OUT

1

OUT

1

OUT

1

OUT

1

OUT

1

ES2030 CV Special functions 10

Switching from parallel to alternate

If parallel switching was selected when

programming filter switching at program step

1.4 then it is possible to switch over to

alternate service. When this is done, the filter

which has the least capacity remaining is first

to regenerate.

Bear in mind that the other filter has also

become partially saturated, so that the system

may become overloaded after it is switched to

alternate service. It is therefore best to start a

regeneration manually after switching over.

Press the ‘OUT1’ and ‘OUT2’ keys

simultaneously.

Fast cycle

Simultaneously press the function keys with

the symbols and .

After 3 seconds the internal program clock

switches over from minute pulses to second

pulses. The fast cycle activated only affects the

current regeneration phase, the following

phases will run at normal speed.

NOTE: If you want to cycle through the various

regeneration phases using the fast cycle, wait

for two or three minutes after each stage to

allow all the valves to move into their new

positions.

NOTE: If regeneration medium has already

been primed, the filter must be rinsed before

the system is put into service.

Regeneration without initialisation

For maintenance purposes it is sometimes

necessary to check the regeneration program

without initialising the pulse counter or

recalculating the filter capacity. Simultaneously

press the function keys with the symbols

and .

In single filter system, the service filter will be

regenerated after 4 seconds without

initialisation and without recalculation of the

filter capacity.

In two filter systems the standby filter will be

regenerated and the displayed capacity values

will not be changed.

If the service filter is to be regenerated., a ‘filter

exchange without program initiation’ must be

carried out first.

NOTE: This only applies for single filter and

alternating filter service.

(Program steps 5.1, 5.2 or 5.3 = YES).

Regeneration of Filter 1 ONLY

Simultaneously press the function keys with

the symbols and .

After 4 seconds, Filter 1 only will be

regenerated without initialisation and without

recalculation of the filter capacity.

NOTE: This only applies for series or parallel

connection (program steps 5.4 or 5.6 = YES).

Regeneration of Filter 2 ONLY

Simultaneously press the function keys with

the symbols and .

After 4 seconds, Filter 2 only will be

regenerated without initialisation and without

recalculation of the filter capacity.

NOTE: This only applies for series or parallel

connection (program steps 5.4 or 5.6 = YES).

OUT

1

OUT

2

OUT

1

OUT

1

OUT

2

OUT

2

ES2030 CV Display and modification of the basic settings 11

Display and modification of the basic settings

General information on programming and language selection

On first use, the controller is adjusted to the

operating data of the water treatment system

by entering basic settings. These settings can

be changed and are not lost if power is cut off.

NOTE: All the relevant data can be changed in

programming mode 0. In programming mode 1

only some of the data can be changed, and in

programming mode 2 the cannot be changed

without specialist knowledge (see program

step 22).

- Any alteration to the basic settings should be

carried out by an authorized specialist

engineer.

- Make a note of the basic settings in the

empty spaces in the flowcharts below and

keep this manual carefully for the use of

service and maintenance staff.

- The basic settings can be changed at any

time. However most changed settings can

only be activated after the start of the next

regeneration.

- Some keys have a double function. In

programming modes, the , ,

and # keys are used in combination with the

Enter key.

1. Press the Enter key.

To avoid accidental programming changes,

the key has to be held down for 4 seconds

before the basic values are released for

change.

The LCD display first shows the following

message.

After 4 seconds this changes to:

NOTE: Continue to hold down the Enter key for

functions 2 and 3.

2. At this point you can change the language of

the LCD display as follows:

Press ‘#’ key.

Use the key to move the cursor under the

abbreviation for the desired language.

3. You can move on to the first and

subsequent programming steps using the

key

4. You can move back to previous steps with

the key.

NOTE: The controller is now in programming

mode, and the Enter key should now be

released. To leave programming mode,

press the Enter key again. The controller will

also exit programming mode automatically

approximately 2 minutes after the last key

has been pressed.

5. The cursor is moved with the key.

Yes/No questions are answered by placing

the cursor under Y for Yes and N for No.

For numerical entries use the cursor to

select the digit to be changed.

6. The numerical settings selected with the

cursor can be changed within the preset

values by pressing the ‘#’ key.

NOTE: Programming must be carried out with

the filter in the service position. During a

regeneration there is no programming

possible.

English

D Nl E F

Attention!

Programmechange

Start

Programmechange

#

Enter

ES2030 CV Display and modification of the basic settings 12

1. Electrical control

IMPORTANT!

When valve systems operate at 24 V, current loading may be very high especially if the

regeneration valve and several service valves are actuated simultaneously.

It is possible to switch on the motor(s) and valve(s) with a time delay of 30 seconds.

This time delay feature can be selected as follows:

1. Switch the power on to the controller while the key is pressed.

the display indicates Motor valve Y/N.

2. Use the key to enter "Y" for the time delay and "N" for simultaneous switching of the

motor(s) / valve(s).

3. Press the key once again.

Alternate switching

In alternate switching (also known as follow on control) the voltage changes

between terminals 5-6 and 5-7 (12-13 and 12-14) as soon as the next switching

stage is triggered.

NOTE: In the case of 5-phase alternate switching, the fifth switch stage is triggered

by applying voltage to terminals 5-8 (12-15).

The following diagram shows the triggering voltage on terminals 5-6 and 5-7 (12-13

and 12-14) in a four-stage valve. The fourth stage, “Service“ or “Standby“, which

follows on at the end of regeneration, is not shown.

Example : 4-stage alternate switching

The number of stages is determined at program step 2.1, and the length of the

individual regeneration phases at program step 4.1.

Pulse switching

In pulse switching a pulse is sent to terminals 5-7 (12-14) immediately the next

switching phase is triggered.

The following diagram shows the triggering voltage on terminals 5-6 and 5-7 (12-13

and 12-14) in a four-stage valve. The fourth stage, “Service“ or “Standby“, which

follows on at the end of regeneration, is not shown.

Example : 4-stage pulse switching

The number of stages is determined at program step 2.1, the length of the triggering pulse

at program step 3.1 and the length of the individual regeneration phases at program step 4.1.

NOTE: The length of the individual regeneration phases is increased by the length

of the triggering pulse.

Step no.: 1.1

Changeover Y/N

Step no.: 1.2

Pulse Y/N

Start

Yes No

1.1

2.1

Yes No

1.2

2.1

1.3

Phase1 Phase2 Phase3

Electrical signal

Stages

2

min

Regeneration endRegeneration start

Phase1 Phase2 Phase 3

Electrical signal

Stages

Regeneration endRegeneration start

Adjustable pulse length

ES2030 CV Display and modification of the basic settings 13

External triggering

In external triggering, one pulse is sent to terminals 5-7 (12-14). The valve then

independently cycles through all the regeneration phases in accordance with the

times set on the valve. These times are normally set on a drum switch on the

remote control valve. The same times must additionally be entered at program step

4.1 so that the controller can follow the progress of the regeneration. An exact

synchronization of the controller display and the valve settings cannot be

guaranteed.

The following diagram shows the triggering voltage on terminals 5-6 and 5-7 (12-13

and 12-14) in a four-stage valve. The fourth stage, “Service“ or “Standby“, which

follows on at the end of regeneration, is not shown.

The number of stages is determined at program step 2.1, the length of the

triggering pulse at program step 3.1 and the length of the individual regeneration

phases at program step 4.1.

NOTE: The length of the first regeneration phases is increased by the length of the

triggering pulse.

Valve 9000

The valve 9000 is a remote control valve used to regenerate the two sides of a

double filter system alternately. In its electric triggering, voltage changes between

terminals 5-6 and 5-7 immediately the next phase is triggered. The fourth switching

phase is triggered by applying voltage to terminals 5-8.

The following diagram shows the triggering voltage on terminals 5-6 and 5-7 (12-13

and 12-14) in a four-stage valve. The fourth stage, “Service“ or “Standby“, which

follows on at the end of regeneration, is not shown.

The number of stages is automatically set at five stages when this valve is

selected. The length of the individual regeneration phases at program step 4.1.

NOTE: There are some restrictions with this valve for technical reasons:

- If “Filter change over without program initiation“ is selected, only the display

changes.

- The functions “Regeneration of standby filter”, “Regeneration of Filter 1 Only” and

“Regeneration of Filter 2 Only” are not available.

- Program step 5 cannot be selected (always double filter system).

Step no.: 1.3

External Y/N

Step no.: 1.4

Valve9000 Y/N

Yes No

1.3

2.1

Yes No

1.4

1.5

2.1

1.2

Phase1 Phase2 Phase3

Electrical signal

Stages

Adjustable pulse length

Regeneration start Regeneration end

Phase2 Phase3

2

min

Regeneration endRegeneration start

Phase4

Control voltage to terminals 5-8

Electrical signal

Stages

Phase1

ES2030 CV Display and modification of the basic settings 14

“SIATA“ control

In “SIATA“ control a pulse is sent to terminals 5-7 (12-14) immediately the next

switch phase is triggered.

At the end of the last phase, no further pulse is sent to switch to the “Service“ or

“Standby“ setting. This setting is achieved by applying voltage to terminals 5-8

(12-15) (automatic resetting).

The following diagram shows the triggering voltage on terminals 5-6 and 5-7 (12-13

and 12-14) in a four-stage valve. The fourth stage, “Service“ or “Standby“, which

follows on at the end of regeneration, is not shown.

Example : 4-stage-valve “SIATA“

The number of stages is determined at program step 2.1, the length of the

triggering pulse at program step 3.1 and the length of the individual regeneration

phases at program step 4.1.

NOTE: The length of the individual regeneration phases is increased by the length

of the triggering pulse.

Step no.: 1.5

SIATA Y/N Yes No

1.5

1.12.1

1.4

Phase1 Phase2 Phase 3

Electrical signal

Stages

Regeneration endRegeneration start

Adjustable pulse length

ES2030 CV Display and modification of the basic settings 15

2. Number of valve switch stages

Remote control valves and pilot

distributors are available in versions

with 2 to 8 stages.

The number of switch stages is set at this program step.

NOTE: Remote control valve manufacturers describe their products e.g. as 5-stage

valves with 4 switch settings, as at the settings “prime chemicals” two phases of

the process are distinguished: prime “chemicals with motive water” and “wash

slow” (only motive water flows).

Indicate the number of switch stages.

NOTE: Not selectable for “Valve 9000”, as the number of switch stages is set to 5

when this special valve is selected.

3. Pulse length

Where “pulse switching”, “external

switching “ or “SIATA” control was

selected at program step 1, the pulse

lengths of the individual pulses must

also be entered. Values between 1` and 999 seconds may be set.

4. Regeneration times

In this program step the appropriate

times required for the regeneration

phases of the switch stages entered at

program step 1 must be programmed in.

No times are entered for the service or standby phases.

Enter the switch stage and the required time within the range 1-999 minutes.

Example for number of switch stages = 4 :

Backwashing switch stage 1 : 10 minutes

Desalination switch stage 2 : 105 minutes

Washing out switch stage 3 : 15 minutes

5. Filter switching

Single filter 1

If you enter “Y” the system consists of 1 filter. The remote control valve is

connected to connector “CV1” and the service valve to “SV1”.

If program step 5.1 and 5.2 are programmed at “Y” the outputs “CV2” and “SV2”

are controlled parallel to the outputs “CV1” and “SV1”.

Single filter 2

If you enter “Y” the system consists of 1 filter. The remote control valve is

connected to connector “CV2” and the service valve to “SV2”.

The ability to select between “Filter1” and “Filter2” allows a two filter system to be

reset quickly to single filter service (for repair work or low water demand).

Step no.: 4.1

Time phase1: 10m

Step no.: 2.1

Stage 4

Step no.: 3.1

Long.peri.1: 50s

Step no.: 5.1

SingleFilter1Y/N

Step no.: 5.2

SingleFilter2Y/N

1.*

Switch stages

2.1

4.1

Phase length

1 m

2 m

3 m

4 m

5 m

6 m

7 m

8 m

3.1

Pulse length

1 s

2 s

3 s

4 s

5 s

6 s

7 s

8 s

9 s

Yes No

5.1

Yes No

5.2

6.1

5.3

ES2030 CV Display and modification of the basic settings 16

Alternating service

A two filter system normally runs in

alternating mode, with one filter

supplying treated water while the other

filter is in reserve (standby) or is being

regenerated.

Parallel service

If high output performance is required

over a short period, a two filter system

can also be run in parallel. Here both

filters supply treated water at the same

time except during regeneration.

When the controller is programmed for parallel service, it can be switched back and

forward between alternating and parallel modes using the special function

“Switching from parallel to alternate”.

For parallel service you can determine

whether the filters are to be regenerated

one after the other or at offset intervals.

If you select “Y” both filters will be

regenerated immediately one after the other, since both filters are saturated.

For example: silica filter systems activated by time intervals or differential pressure

gauges.

NOTE: For water softening systems it must be ensured that brine is available

(reservoir tank).

If you select “N” only the saturated filter in service will be regenerated. At this point

the other filter still has 50% of its capacity.

For example: quantity controlled water softening systems with a shared brine

container.

Series switching

Select series switching when the filters

in a two filter system were set up in

series.

For example: single flow partial

desalination system with an H exchanger and a Na exchanger.

For partial desalination systems the

service life of the Na exchanger can be

several times longer than that of the H

exchanger.

You can therefore enter a regeneration relation between 1:1 and 1:9.

For example, if you enter “1:2” the Na exchanger is only regenerated after every

second regeneration of the H exchanger.

Service valve

In alternating service or offset parallel

service one filter continues to supply

treated water while the other is

regenerating.

If it too becomes saturated because the amounts drawn off are too large, the

message “capacity exceeded” is displayed. You can determine whether in that

case the second valve is to stay open, with the possibility that it will supply

incompletely treated water (Y/N) or whether tat the valve should close (Y/N), with

the result that no water flows to the user until the regeneration is completed.

Step no.: 5.3

2-tank alt. Y/N

Step no.: 5.4

Parallel servY/N

Step no.: 5.5

Reg.Fi.1+2 Y/N

Step no.: 5.6

Series connecY/N

Step no.: 5.7

Relation 1:1

Step no.: 5.8

Main valve onY/N

6.1

Yes No

5.8

5.3 / 5.5

Yes No

5.6

Relation

1 :

5.7

5.1

5.4

6.1

Yes No

5.3

5.8

Yes No

5.4

5.6

Yes No

5.5

5.86.1

5.*

ES2030 CV Display and modification of the basic settings 17

6. Delayed regeneration

A regeneration can be initiated at any time during the day. But it is often desirable

not to have a regeneration during production times, since for instance the water

pressure then may be insufficient for regeneration.

When ‘delayed regeneration’ is selected, a two filter system alternating service will

switching to the standby filter.

Select the day(s) when the function ‘delayed regeneration’ must be activated.

( “-“ = not activated; “|” = activated).

Enter the first time, after which no regeneration is to be initiated.

Enter the second time, after which regeneration is again permitted

Example 1: Time1 = 6:00 Time2 = 18:00

No regenerations are initiated automatically between 6 a.m. and 6 p.m. of the same

day.

Example 2: Time1 = 17:00 Time2 = 5:00

No regenerations are initiated automatically between 5 p.m. and 5 a.m. of the

following day.

With a 1 filter system, a 2 filter system connected in series and with a 2 filter

system operating in parallel with sequential regeneration. It can be determined

whether the service valve(or both service valves) should stay open until the

regeneration time entered (Main valve on Y/N) or should be shut immediately

(Main valve on Y/N).

If the service valve remains open, it should be ensured that the system can still

supply treated water until the regeneration time.

In the case of a 2 filter system operating in parallel with delayed regeneration it is

determined whether the service valve of the saturated unit remains open until the

delayed regeneration (Main valve on Y/N) or if the service valve closes and only

one filter is in service until the end of the delayed regeneration

(Main valve on Y/N)

A 2 filter system in alternating service always switches over to the standby filter,

and program step 6.5 cannot be selected.

Step no.: 6.1

Time Delayed Y/N

Step no.: 6.3

Time1 6:00

Step no.: 6.4

Time2 18:00

Step no.: 6.5

Main valve onY/N

MoTuWeThFrSaSu

|| | | | | |

Yes No

6.1

Time 1

:

6.3

6.6

5.1

Time 2

:

6.4

Yes No

6.5

6.6

MoTu Fr

6.2 We Th SaSu

Table of contents

Other EWS Controllers manuals