SETTING –UP PRODEDURE

1. Set the MIAN SWITCH to position “ON”.

2 .Press the button of START/STOP to make the

lamp light

3 .Set the SEAL TIMER .The digital readout 5

shows the value of the seal time (see page 5)

Press the choosing key the second time. 5 will

flash. Then using or to adjust the time to

suitable value. Pull the leading edge of the film

into the chamber and cross the sealing blade.

close the hood and check if the film cuts and

seals cleanly. If not , increase the setting of the

SEAL TIMER until a good seal and clean cut

are obtained. Always set this timer at lowest

value where good sealing occurs .

4 Set machine in “SEAL&SHRINK” mode .

the digital readout 5(see page 5)will show the

preset temperature .Press the choosing key the

first time ,5will flash ,Then using or to

adjust the temperature to suitable setting for

your

film-usually 03-05 for PVC film07-09for POF

films Operating experience will soon tell you

the optimum for the film you use.

You are told about the preset temperature as

following:

00- the temperature is 0℃

01- the temperature is 102℃

02- the temperature is 114℃

03- the temperature is 126℃

N- the temperature is 90+12×N℃

5. The digital readout5 (see page5)show the

preset magnet closed time. Press the choosing key

the fourth time,5 will flash , The using or to

adjust the time. Next, close the hood , the magnets

will clamp the hood whilst the fans circulate

heated air. The hood whilst the fans

circulate heated air. The hood will open

automatically when the sequence is finished.

Again, operating experience will quickly show

Whether longer or shorter magnet/shrink cycle

Times are required to successfully shrink wrap

Your produces.

6 Press the choosing key the third time

(see page5) 5 will flash, Then

using or to adjust the cooling time:

show:00 means :sealing and shrinking is

working at the same time.

show 0 1means :starting shrinking immediately

after sealing

show N (2≤N≤9)means: when the sealing is

finished, start shrinking after

(N-1) seconds(cooling time).Operating

experience will soon tell you the shrink

mode(cooling time) for the film you use

The REEL and FILM DIVIDING TABLE slide

forwards and backwards to suit the size of film

and product being used. The WIRE

PRODUCT TRAY can be raised or lowered

inside the chamber using the hooks at the

back and the 2 screws at the front. The tray

should normally be positioned so that the

seal appears about half-way up the side of

the product

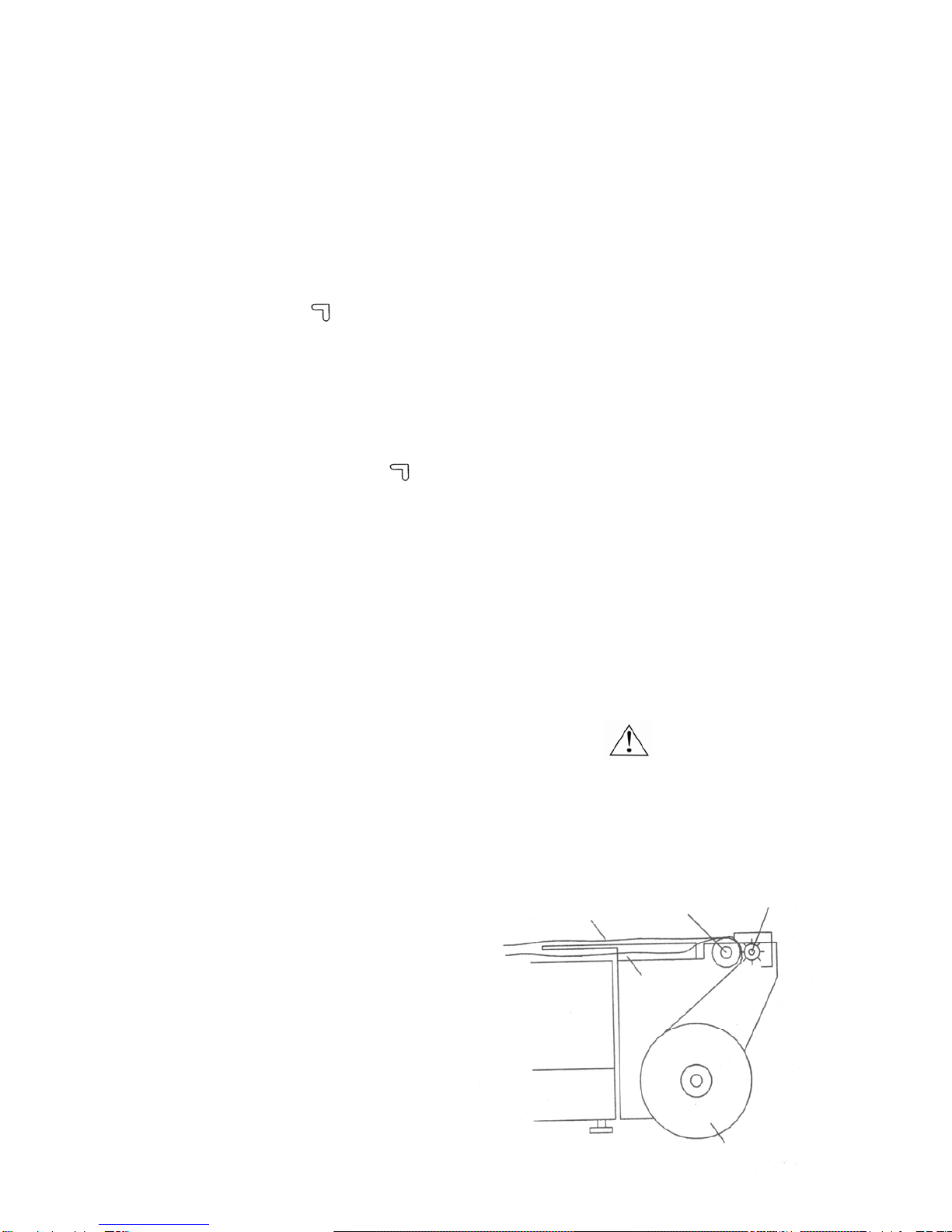

Micro Switch StrikerAdjustment

The adjustable pin which operates the

machine micro-switch has been pre-set and

its adjustment locked by means of two nylon

nuts. If for any reason this adjustment should

be lost or altered during operation then the

striker should be reset GENTLY to strike the

micro-switch, IF THE MICRO-SWITCH

STRICKER IS SET TOO LOW IT WILL

DAMAGE THE OPERATING

MICRO-SWITCH