- 2 -

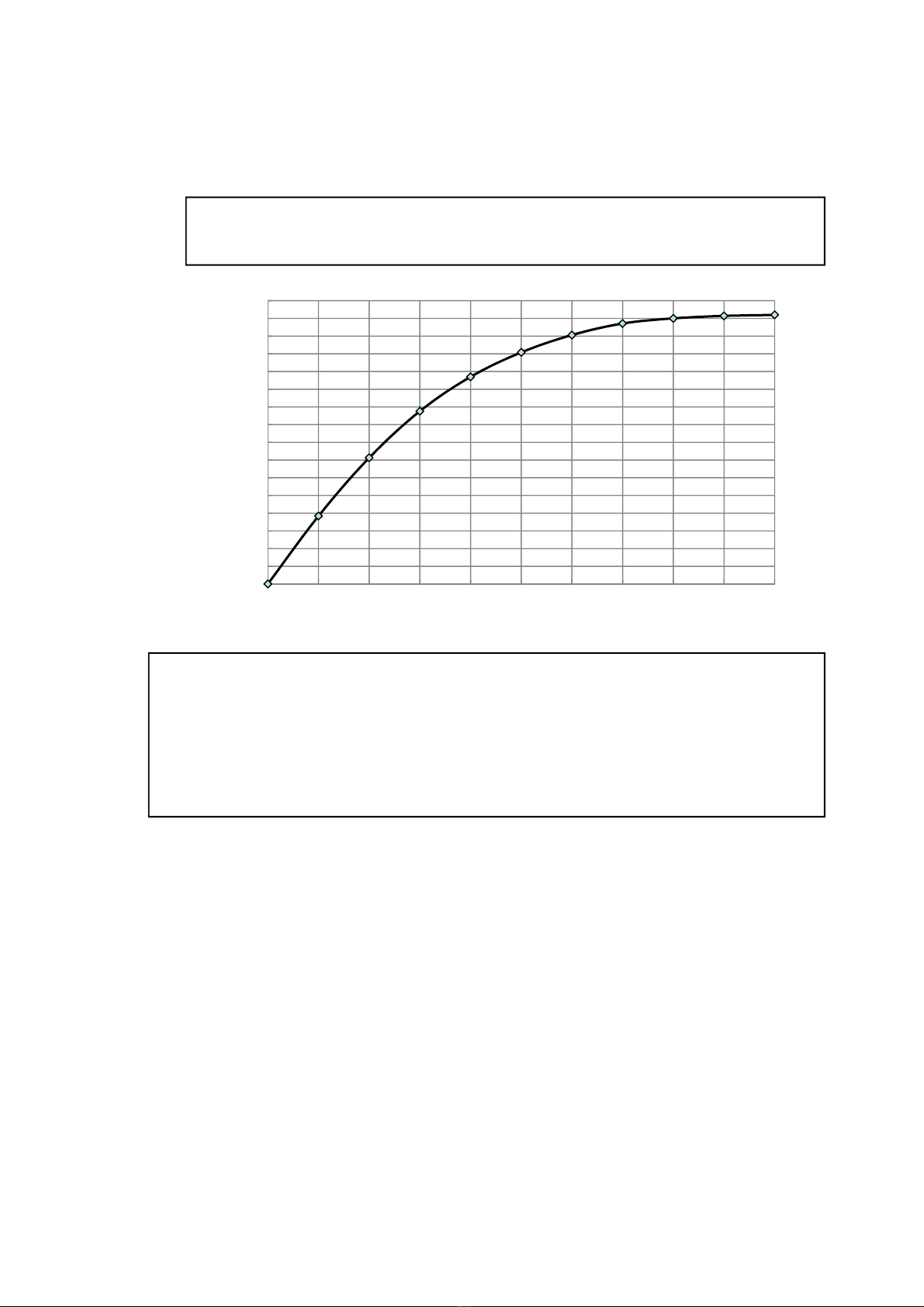

※1.The performance shown is at the ambient temperature of 20℃and at no load.

※2.The power input shown is the value not including the capacity of service outlet.

This product is applicable to drying of the

diluted aqueous solution of protein, enzyme, etc.

or drying of the extracted solution of biologic

sample or biotic sample (urine, blood serum, etc.).

Product name Freeze dryer

Model FDS-1000

Cooling method Can body cooling

Perfor-

mance

Trap cooling temperature ※1 -80℃

Dehumidification rate 150mL/one batch

Function

Setting and display function Sheet key input and digital display

Safety function Leak/overcurrent breaker, circuit protector for socket outlet, refrigerator self-diagnosis

function, control board self-diagnosis function

Vacuum releasing function Automatic vacuum leak valve

Trap deicing function Deicing by the can body heater

Other functions Automatic vacuum pump operation, display of automatic vacuum pump operation

time, stopwatch function, freeze-drying ready display, selection of power recovery,

monitoring of vacuum abnormality, monitoring of trap temperature

Compo-

sition

Temperature sensor Ttype thermocouple sensor

Refrigerator, refrigerant Stirling refrigerator, helium(non-CFC)

Defrosting heater Silicon rubber heater, 60W

Standard

Vacuum pump (required

displacement) Option: 50L/min or more

Vacuum gauge

Pirani vacuum indicator:Digital display(0.0~533Pa)

Display accuracy at 0.4~4.0Pa ±2.0 Pa

at 4.1~10.0Pa ±3.0 Pa

at 10.1~15.0Pa ±4.0 Pa

at 15.1~40.0Pa ±7.0 Pa

Trap size (mm)・material Φ90×145(about 0.85L)・SUS304

Vacuum pump connection port

(mm) Outside diameter 17 (Rear side of main body)

Service socket Max.5A for both vacuum pump and driver chamber

Operating ambient temperature range 5~35℃

Outside dimensions (mm)(excluding

projection))455W×220D×497H

Weight About 19kg

Power input/rated power ※20.9A 200VA・AC230V 50Hz

2Product Outline

2-1 Application

Never attempt to modify the product.

Operate the unit for the specified

purpose only.

An electric shock or a malfunction may result if the

product is modified or used for any purposes other

than that specified.

Warning

2-2 Specification