1 Guide for Safe Use・・・・・・・・・・・

2 Product Overview

2-1 Applications・・・・・・・・・・・・

2-2 Specifications ・・・・・・・・・・・

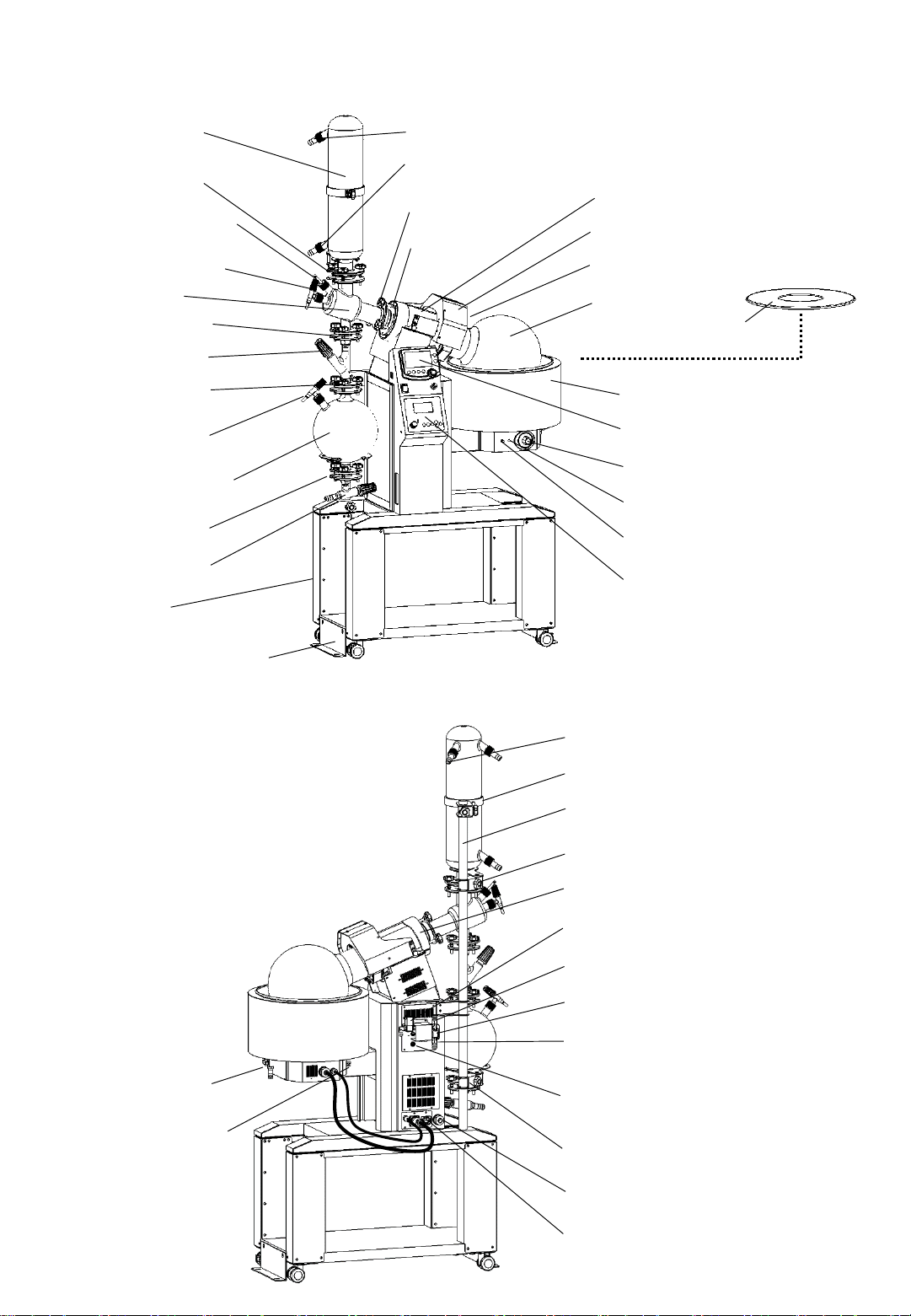

2-3 Descriptions・・・・・・・・・・・・

2-4 Control Modes・・・・・・・・・・・

3 Names and Functions of the Control Panel

3-1 Control Panel ・・・・・・・・・・・

3-2 Vacuum Control Unit Control

Panel ・・ ・・ ・・ ・・ ・・ ・・・

3-3 Main Unit Control Panel・・・・・・・

3-4 Main Unit Safety features and

Alarms ・・・ ・・ ・・ ・・ ・・・

3-5 Alarms and Warning Functions of the

Vacuum Control Unit Control

Panel ・・ ・・ ・・ ・・ ・・ ・・・

4 Installation

4-1 Installation Environment ・・・・・・

4-2 Installation Requirements ・・・・・・

4-3 Peripheral Devices ・・・・・・・・

4-4 Connecting the Utility・・・・・・・・

4-5 Precautions ・・・・・・・・・・・・

4-6 Assembling Glassware ・・・・・・・

5 Operation

5-1 Preparation・・・・・・・・・・・・・・・

5-2 How to Operate the Main Unit・・・・・・・

5-3 Alarm Functions of the Main Unit ・・・・・

5-4 Setting Functions of the Main Unit ・・・・・

5-5 How to Operate the Vacuum Control Unit ・・

5-6 MANUAL Mode Operation ・・・・・・・・

5-7 AUTO Mode ・・・・・・・・・・・・・・

5-8 PROGRAM Mode ・・・・・ ・・・・・・

5-9 STEP PROGRAM Mode ・・・・・・・・・

5-10 Linked Operation with the Operational Part of

the Main Unit ・・・・・・・・・・・・・

5-11 Setting the Parameters ・・・・・・・・・

5-12 Operation After Control ・・・・・・・・・

6 Troubleshooting・・・・・・・・・・・・・・・

7 Maintenance and Inspection

7-1 Cleaning ・・・・・・・・・・・・・・・・

7-2 Replacing the Fuse ・・・・・・・・・・・

7-3 Cleaning the Control Solenoid Valve ・・・・

7-4 Replacing the Vacuum Seal・・・・・・・・

8 Disposal・・・・・・・・・・・・・・・・・・

9 After-sales service ・・・・・・・・・・・・・

10 List of Consumable and Replacement Parts and

Optional Accessories・・・・・・・・・・・・

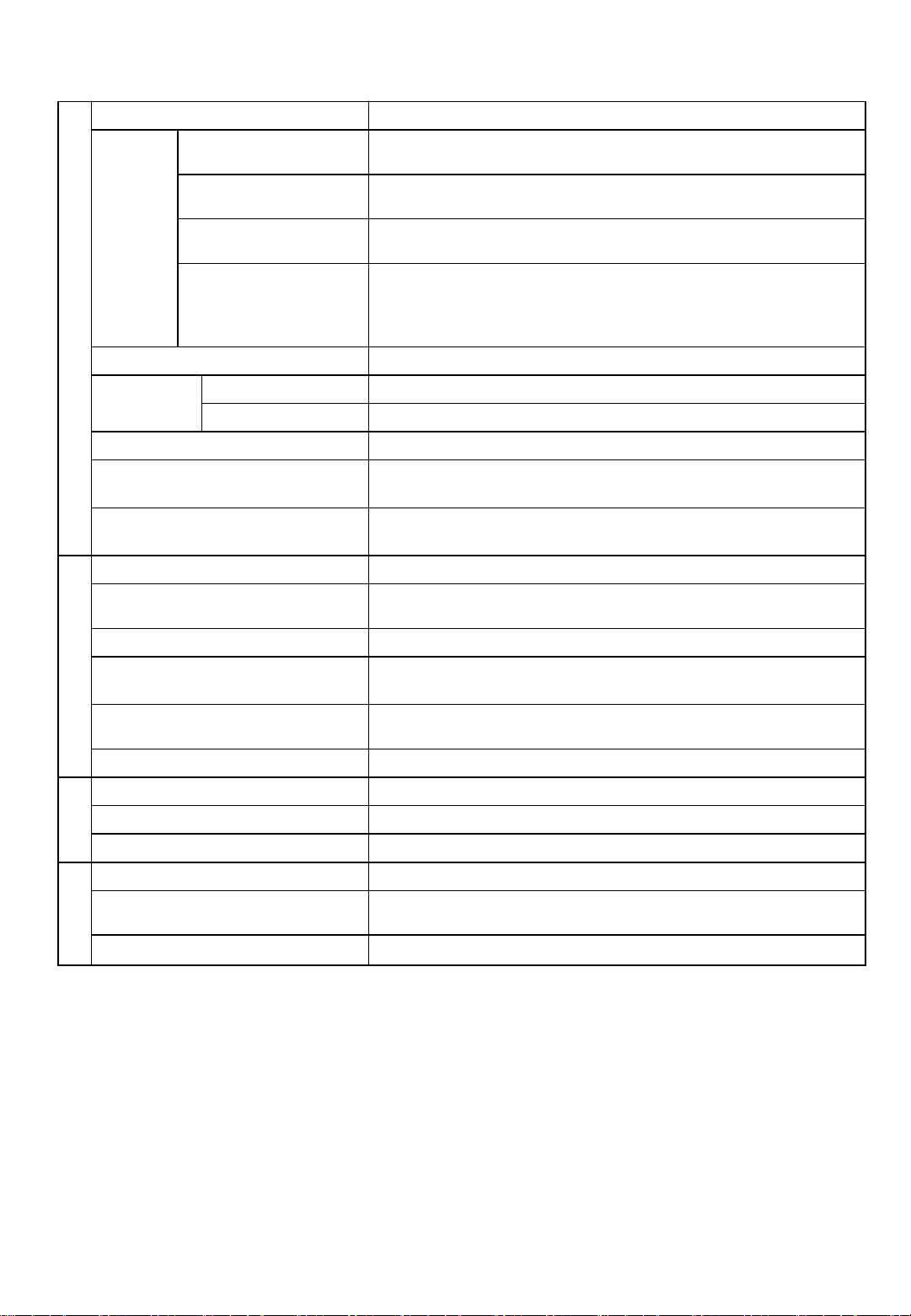

Be sure to check the type and quantity of parts

before installation.

In addition, prepare an appropriate vacuum pump

for depressurization, vacuum hose, cooling water

circulator, piping hose, cold trap, and etc.

Thank you for purchasing.

product.

This manual describes procedures for installation, operation, troubleshooting, maintenance, inspection,

and disposal of the

10L Scale Rotary Evaporator Model N-3100.

Please read this manual carefully and fully understand the contents before using the product.

Introduction

Contents

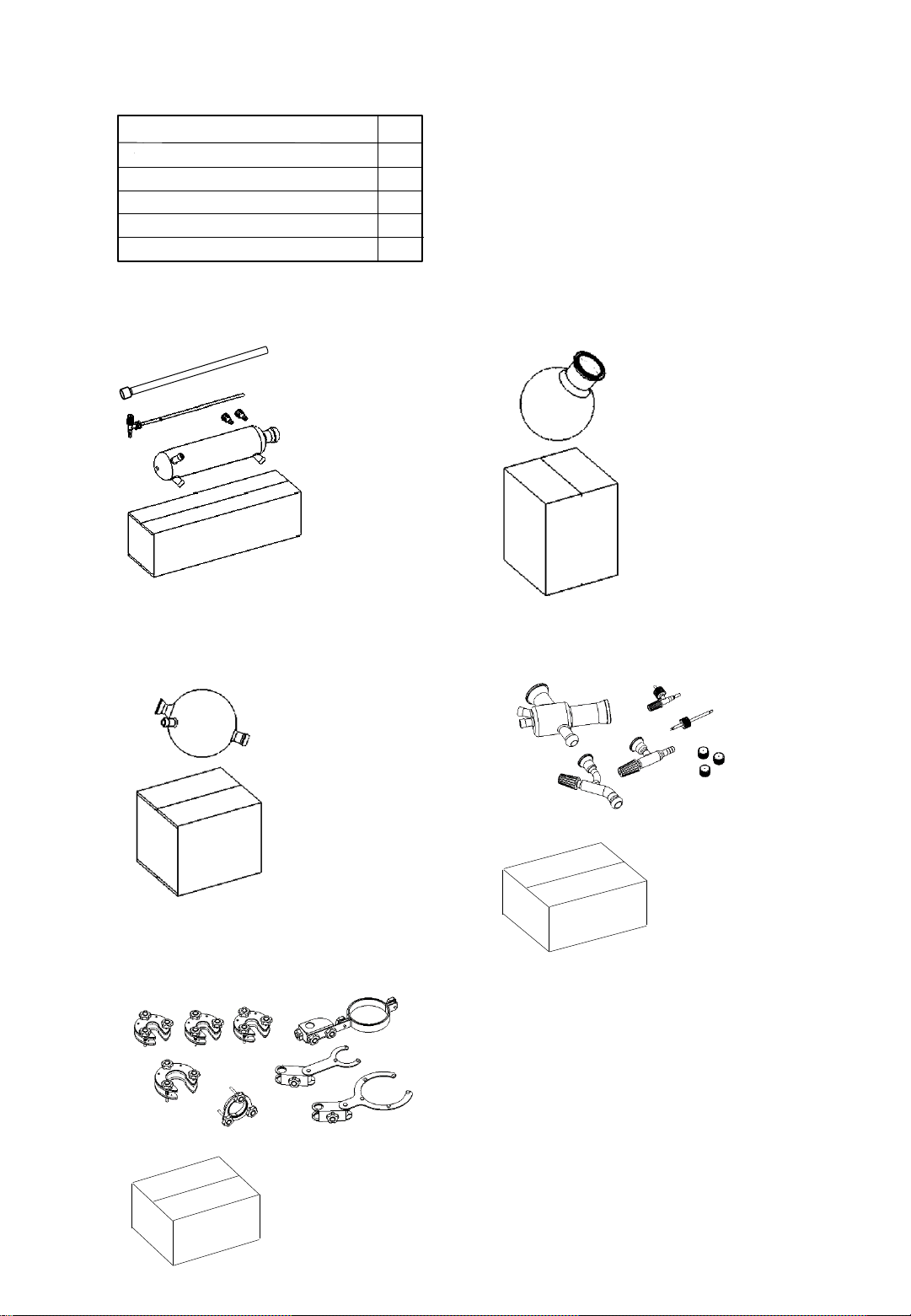

Contents of the package

Qty

Evaporator main unit 1 set

Stand pole 1

1

1

1

1

1) Main unit packing box

Instruction manual

Warranty card

Sample flask receiver 2

Fuse (2 A)

1

2

2

4

6

8

9

10

11

14

17

17

18

19

20

21

24

25

26

27

32

36

38

41

46

51

52

55

56

60

60

61

62

63

64

65

2) Box for glassware

1) Box for main unit

Spanner