This product is a dry and clean thermostat

without using water or oil and is suitable for

condensing a hydrophobic sample such as

moisture.

2-1 Usage

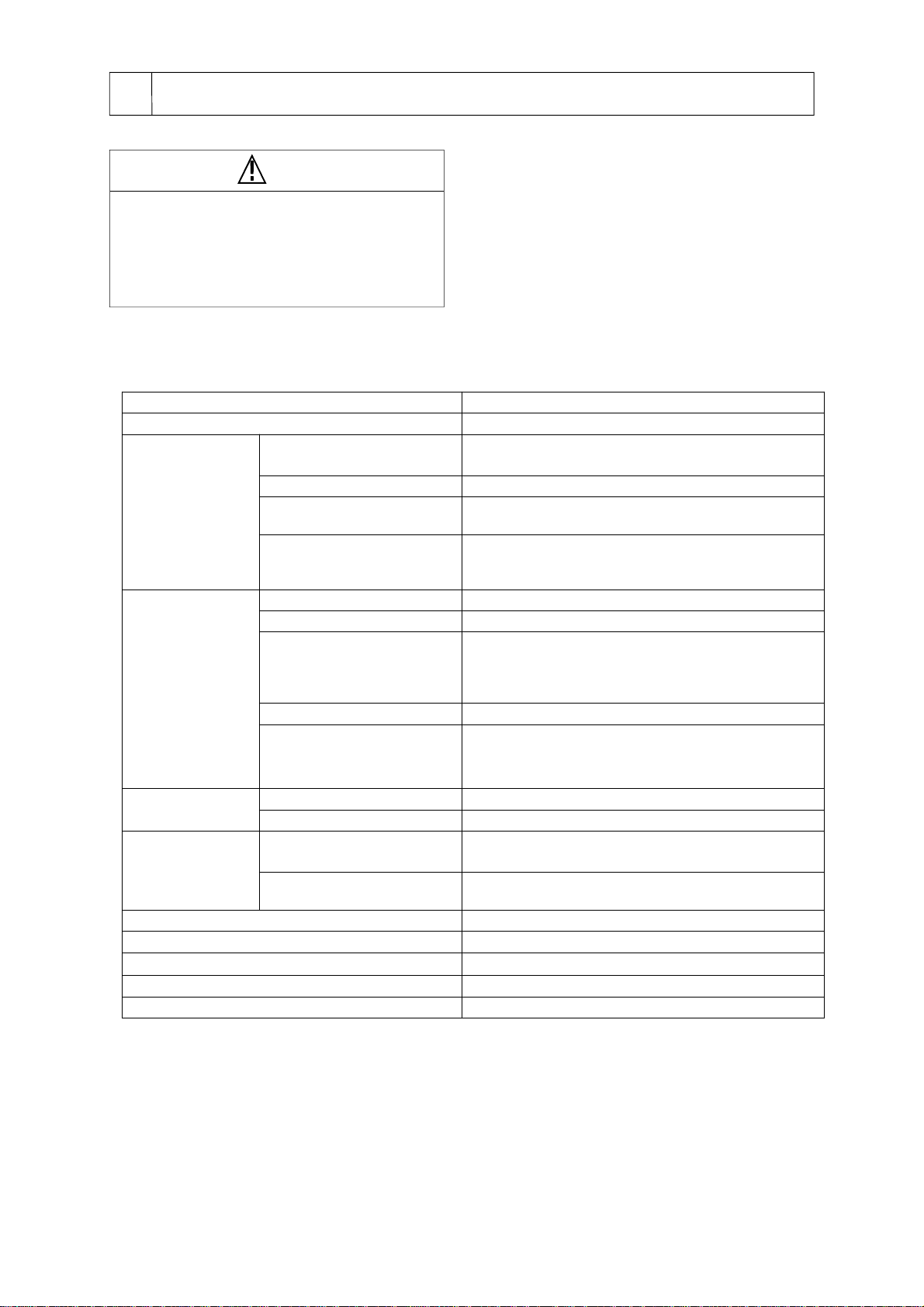

Do not remodel the product.

Make sure that it should not

be used out of intended use.

2-2 仕様

Outline of the product

2

Warning

Product name Aluminum block thermostat

Model MG-3100

Performance

Range of temperature control

(Range of temperature setting) Room temperature +5.0 to 200.0℃

(10.0 to 200.0℃)

Accuracy of temperature control *1 ±0.1℃~

Required time for rising

temperature *1 20→100℃Approx. 15 min.

20→200℃Approx. 40 min.

Range of temperature distribution

*2

5.0℃200℃(When setting up 200℃)

3.0℃(When setting up 120℃)

2.0℃(When setting up 37℃)

Function

Temperature control PIDcontrol with auto-tuning

Setting up temp. • display Sheet key input, digital display

Attached function *3

Auto Stop, Auto Start,

8-step program,

Compensating temperature display, auto tuning, setup for

recovery from power failure, setup for buzzer

Setup time for timer 0 min. to 99 hrs. 59 min.

Safety functions

Self-diagnosis function (

Upper limit temperature limiter, loop abnormality,

Sensor disconnection) Fuse, fixed temperature overheat

prevention device)

Composition Temperature sensor Platinum resistance temperature detectorPt100Ω

Heater Maika heater 235 W

Specification/Standard Block dimensions *4 Model MGBH: 90W x 62.5D x 70H

Model MGB: 90W x 125D x 70H

Number of blocks *4 Model MGBH: 2

Model MGB: 1

Ambient temperature range in use 5 ~ 35℃

Outer dimensions (mm) 200W x 315D x 125H

Mass *5 About3.9kg

Power input 2.5A 250VA

Rated power AC100V 50/60Hz

*1 Room temperature at 20ºC, rated power supply-voltage, regular block model MGB-1524, without

sample/container, without sample temperature sensor.

* 2 Temperature in aluminum block

*3 If sample temperature sensor is used, it may not be controllable under the conditions that the sample thermal

capacity is large, the container thermal conductivity is small, etc.

*4 Aluminum block is one of the optional accessories (sold separately).

As for the types of aluminum block, please refer to “Options” on page 37.

*5 Weight of aluminum block is not included.

-2-

Remodeling and improper use may

cause electric shock or breakdown.