Page 2

SAFETY RECOMMENDATIONS

WATCH FOR THIS SYMBOL. IT IDENTIFIES IMPORTANT SAFETY MESSAGES. WHEN YOU SEE THIS SYMBOL, READ THIS SAFETY MESSAGE

CAREFULLY.

GENERAL SAFETY

1. Never allow anyone to ride on the tractor drawbar, or on the disc. The person(s) riding may fall and be seriously or fatally injured.

2. Disc should be operated ONLY by persons responsible and qualified to do so.

3. Never allow anyone to climb or play on the tractor or disc. They may fall and be seriously injured.

4. Follow all safety precautions in your tractor manual.

5. Keep a First Aid Kit in the tractor at all times.

ASSEMBLY SAFETY

1. When assembling disc, use aligning punch to line up holes. Keep fingers out of holes. Any sudden movement of heavy components will severely

injure or sever your fingers.

2. Use adequate manpower or hoist to lift the heavy components into place. Attempting to lift heavy components by yourself could cause serious

injury.

3. Be sure all bolts and hydraulic fittings are tight, and all cotter pins are installed in the slotted nuts and pins.

4. Support the main and wing frames securely before assembling the components. Inadequate support may result in the heavy components falling

and causing serious injury to you or person(s) nearby.

5. Be sure all wheel bolts are checked for tightness during initial transport or when first discing. Loose wheel bolts may result in the wheel falling

off, causing serious damage to the disc and may cause serious injury to the operator or person(s) nearby.

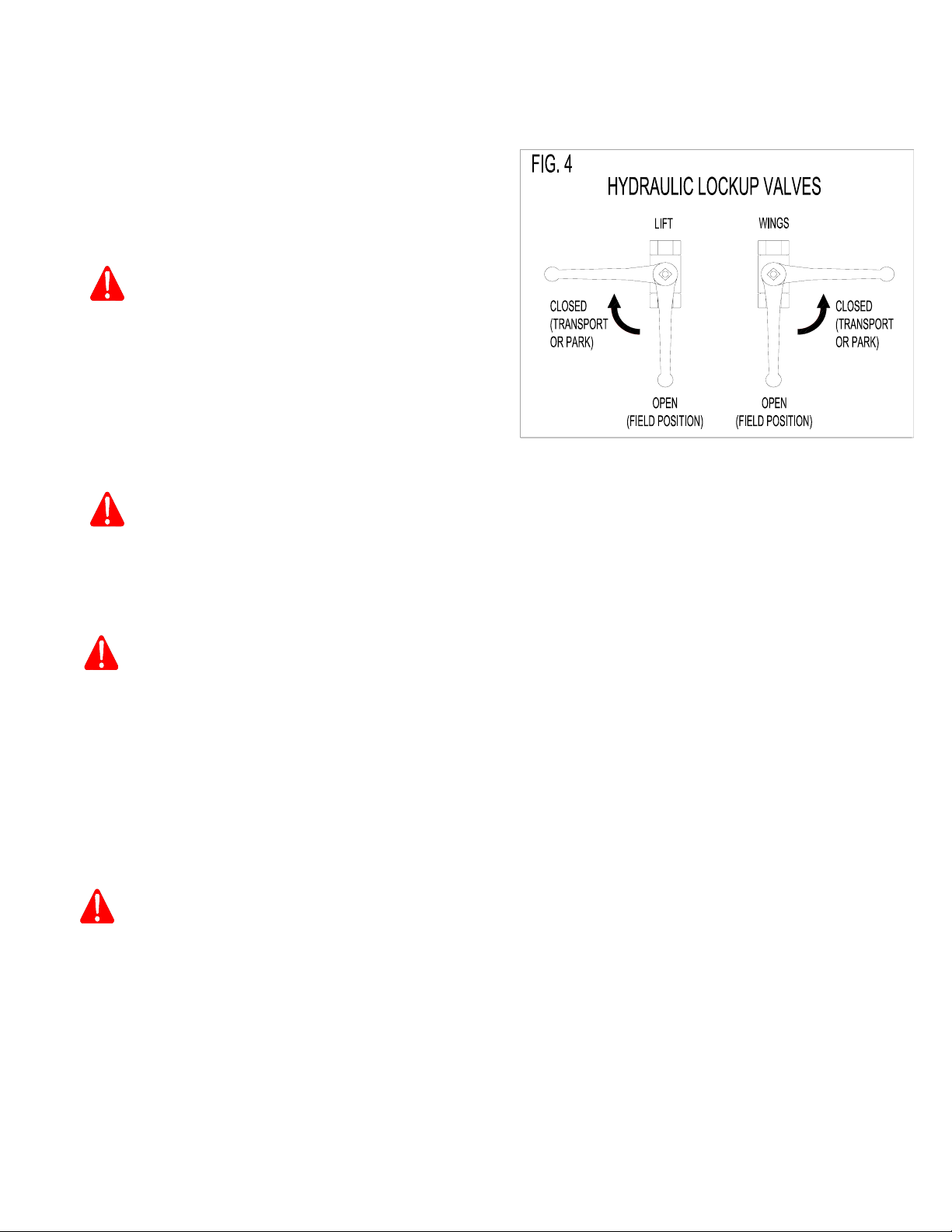

6. To fill the wing lift cylinders with hydraulic fluid, remove the pin from the shaft end of each wing lift cylinder and pump fluid into the cylinders.

Extend and contract the cylinders until they are completely filled with hydraulic fluid. The wings will free-fall if the cylinders are not completely

filled with fluid, resulting in serious damage to machine or serious injury or death to person(s) nearby.

7. Do not raise or lower the main or wing frames until all components are securely tightened. Loose components will cause serious damage to the

disc and serious injury or death to you and person(s) nearby if the main or wing frames fell.

8. Hydraulic oil escaping under pressure has sufficient force to cause serious injury. Relieve pressure in all hydraulic components before

disconnecting any hydraulic components. Before applying pressure to hydraulic system, be sure all connections are tight and components are

not damaged. If injured by escaping hydraulic fluid, see a medical doctor immediately.

9. When attaching gang assemblies, wear protective gloves to prevent injury from cutting edges of blades.

10. Before applying pressure to the hydraulic system, be sure all connections are tight and the components are not damaged.

11. Wings will free fall if wing cylinder is not full of oil causing serious damage to machine or serious injury or death to person(s) nearby.

12. If hydraulic cylinder shafts are unpinned and cycled to fill the cylinders with oil, they can be seriously damaged if clevis of shaft strikes rockshaft

arm or wing cylinder lug.

13. Do not stand under folded wings when working on disc. If hydraulic system failed or if hydraulic lever was accidentally operated, wings may fall

resulting in serious injury or death to person(s) near disc.

14. When assembling gangs besure adequate support is placed under main frame and wing frames. Do not use lock out valves as safety device to

prevent frame from falling. If any hydraulic component failed, disc could drop causing serious injury or death to person(s) nearby.