02/05/2020 1

SERVICE MANUAL

CONVEYOR BELT

1. INTRODUCTION.............................................................................................................................................................. 4

2. OPERATING TESTS........................................................................................................................................................ 4

3. SAFETY INSTRUCTIONS ............................................................................................................................................... 4

4. PICTOGRAMS................................................................................................................................................................. 5

5. UPKEEP........................................................................................................................................................................... 6

6. PROLONGED PERIOD OF INACTIVITY.......................................................................................................................... 6

7. MAINTENANCE ................................................................................................................................................................. 6

7.1. DAILY MAINTENANCE....................................................................................................................................................7

7.2. REGULAR CHECKS PERFORMED BY THE USER.....................................................................................................8

7.3. EVERYDAY CLEANING ...............................................................................................................................................8

7.4. SPECIALISED MAINTENANCE ..................................................................................................................................9

8. HYGIENE REGULATIONS ............................................................................................................................................. 10

9. REMOVAL OF PACKAGING.......................................................................................................................................... 10

9.1. RECYCLING................................................................................................................................................................10

10. GENERAL INFORMATION AND WARNINGS.............................................................................................................. 11

11. USE ............................................................................................................................................................................... 12

12. MODELS AND VERSIONS ........................................................................................................................................... 13

13. DIMENSIONS ............................................................................................................................................................... 14

13.1. CCO-120, CCO-160, CCO-120 ECO and CCO-160 ECO.......................................................................................14

13.2. CCO-120 and CCO-160 + CDT-600, CCO-120 ECO and CCO-160 ECO + CDT-600 .........................................14

13.3. CCO-180 and CCO-225 + CDT-600, CCO-270 and CCO-320 + CDT-600, CCO-180 ECO and CCO-225 ECO +

CDT-600, CCO-270 ECO and CCO-320 ECO +CDT-600................................................................................................15

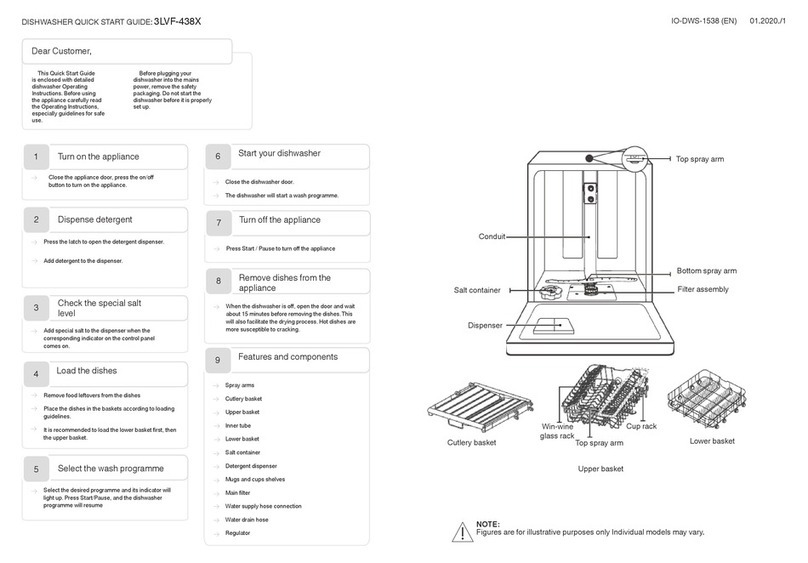

14. COMPOSITION ............................................................................................................................................................ 16

15. TECHNICAL DATA....................................................................................................................................................... 18

16. CONNECTIONS............................................................................................................................................................ 20

16.1. CCO-120 and CCO-160, CCO-120 and CCO-160 + CDT-600, CCO-1.................................................................20

16.2. CCO-120 ECO and CCO-160 ECO, CCO-120 ECO and CCO-160 ECO + CDT-600, CCO-1............................... 21

16.3. CCO-180 and CCO-225 + CDT-600, CCO-270 and CCO-320 + CDT-800, CCO-180 ECO and CCO-225 ECO

+CDT-600, CCO-270 ECO and CCO-320 ECO + CDT-800............................................................................................. 22

17. SAFETY ASPECTS OF THE MACHINE: ...................................................................................................................... 23

18. PRODUCT DETAILS..................................................................................................................................................... 24

19. INSTALLATION INSTRUCTIONS................................................................................................................................ 25

19.1. POSITIONING AND LEVELLING.............................................................................................................................25

19.2. ELECTRICAL CONNECTION................................................................................................................................... 26

19.3. POWERS ...................................................................................................................................................................28

19.4. WATER CONSUMPTION......................................................................................................................................... 32

19.5. CONNECTION OF ECO MODELS ........................................................................................................................... 33

19.6. DRAIN CONNECTION.............................................................................................................................................. 33